Transcription

DIESEL GENERATORSERVICE MANUALOPEN TYPE: DHY6000LE / DHY6000LE-3SOUNDPROOF TYPE: DHY6000SE / DHY6000SE-3Licensed by Hyundai Corporation, Seoul, South Korea

POWER PRODUCTSThis manual contains information how to maintain and how to do troubleshooting.Keep this owner’s manual handy, so you can refer to it at any time.This service manual describes correct method of the maintaining this equipment. As a result ofthis disregard of our rules caused by person casualty and equipment damaged, our companydoes not assume any responsibility.NOTICE:Copyright reserved, and no part of this publication may be reproduced without ourCompany’s written permission.SAFETY MESSAGESYour safety and the safety of others are very important. We have provided important safetymes3ges in this manual and on the generator. Please read these messages carefully.A safety message reminds you to potential hazards that could hurt you or others. Each safetymessage is preceded by a safety alert symbol and one of three words: DANGER,WARNING, or CAUTION. These mean:DANGERYou WILL be KILLED or SERIOUSLY HURTif you don’t follow instructions.WARNINGYou CAN be KILLED or SERIOUSLY HURTif you don’t follow instructions.CAUTIONYou CAN be HURT if you don’t follow instructions.NOTICEYour generator or other property could be damagedif you don’t follow instructions.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

CONTENTS1 PREFACE1-1 Generator Component Identification1-2 Control Panel1-3 Specifications of generator1-4 Specifications of engine1-5 Maintenance Standard2Periodic Maintenance2.1 Service Intervals2.2 Routine Maintenance Procedures3. Engine Disassembly and Reassembly3.1 Disassembly3.2 Reassembly3.3 Recoil Starter Assembly4. Inspection and Service4.1 Cylinder Head4.2 Piston and Piston Pin4.3 Connecting rod4.4 Crankshaft, main bearing and flywheel4.5 Camshaft4.6 Timing Gear4.7 Crankshaft Cover4.8 Cylinder Sleeve and Block4.9 Lubricating System4.10 Fuel System4.11 Governor4.12 Adjustments5. Troubleshooting5.1 No fuel delivery to injection pump5.2 No fuel flow from drain valve5.3 Low compression5.4 Hard starting (fuel delivery and compression normal)5.5 No start or hard start (engine cranks)5.6 Engine over speed5.7 Unsteady engine speed5.8 Unexpected shutdown6Generator6.1 Removal/Installation7 Circuit diagram8 AppendixPOWER 4042424242424243444445455153Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS1. PREFACE1-1 Generator Component IdentificationOpen Type: DHY6000LE, DHY6000LE-3FUEL TANK CAPUP COVERFRAMEFUEL TANKDIESEL ENGINECONTROL PANELINJECTION PUMPRECOIL STARTERSPEED GOVERNORALTERNATORCOCK OF OIL DRANINGRUBBER ABSORBEROIL PUMPBOTTOM FRAMEAIR CLEANERMUFFLERSTART MOTORBATTERY CHARGEROIL DIPSTICKBATTERYPUSH WHEEL KIT1Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTSSoundproof Type: DHY6000SE, DHY6000SE-3FUEL TANK CAPHOOKCONTROL PANELAC OUTPUT SOCKETFRONT DOORPUSH WHEELSFUEL LEVEL INDICATORMUFFLER2Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS1-2 CONTROL PANELELECTRIC START KEYOPEN TYPE: DHY6000LEPCBLED4 DISPLAYLEAKAGE BREAKERPRE-HEATER BUTTON12V DC FUSESOCKETGROUND TERMINALATS SIGNAL SOCKET12V DC SOCKETSUNDPROOF TYPE: DHY6000SEPCBELECTRIC START KEYLEAKAGE BREAKERE-STOP BUTTONLED4 DISPLAYIP66 WATERPROOFCOVER12V DC TERMINALS12V DC FUSEATS SIGNAL SOCKETGROUND TERMINALPRE-HEATER BUTTON3Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

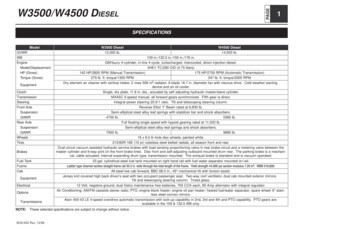

POWER PRODUCTS1-3 Specifications of generatoropen typeGenerator ModelFrequencyRated powerMax. powerVoltageRated currentPhaseStart modeFuel tank capacityFuel consumption 50% loadSound pressure level(7m 75% load)BatteryEngine ModelRated powerStart modeDisplacementOil capacityAlternator ModelRated powerPower factorVoltage regulationDimension and WeightNet weightGross weightProduct dimension (L W H)Box dimension (L W mmunit / containerDHY6000LE50 / 604.5 / 5.04.5 / 5.05.0 / 5.5230 / 24019.6 / 20.81- phaseElectric & Manual145.27912V/36AhD400E10.0Electric & Manual4181.655kVA 190L-138/D50(D60)51Blush type / AVRDHY6000LE-350 / 605.6 / 6.34.5 / 5.06.2 / 6.9230 / 2408.1 / 8.63- phaseElectric & Manual145.27912V/36AhD400E10.0Electric & Manual4181.656.3kVA 190L-138/D50(D60)6.30.8Blush type / AVR140147142149720 480 600740 500 64099/20GP; 207/40GP; 220/40HQElectrical standard and optionsDHY6000LEDHY6000LE-31-phase (2 15A Australian sockets)3-phase (1 15A Australian socket )American;UK;European sockets;etcDisplay LED4Display LED3Prosice overload protectionCommon overload protectionDC output:12V / 8.3AEarth connectionPre-heaterATS sensorRemote controlATS control box(50A) Mechanical standard and optionsFrame tube diameter 32mmBasic color:Pantone black CAlternator:Steel plate Q195Alternator:Silicon steel plate DW800Push wheel kitOption : Standard feature : No available : 4Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTSsoundproof typeGenerator ModelFrequencyRated powerMax. powerVoltageRated currentPhaseStart modeFuel tank capacityFuel consumption 50% loadSound pressure level(7m 75% load)BatteryEngine ModelRated powerStart modeDisplacementOil capacityAlternator ModelRated powerPower factorVoltage regulationDimension and WeightNet weightGross weightProduct dimension (L W H)Box dimension (L W 0SE50 / 604.5 / 5.04.5 / 5.05.0 / 5.5230 / 24019.6 / 181.655kVA 190L-138/D50(D60)51Blush type / AVRDHY6000SE-350 / 605.6 / 6.34.5 / 5.06.2 / 6.9400 / 4208.1 / 81.656.3kVA 190L-138/D50(D60)6.30.8Blush type / AVR170180172182kgkgmmmmunit / container920 520 740960 560 79048/20GP; 96/40GP; 144/40HQElectrical standard and options1-phase (2 16A European sockets)3-phase (1 16A European socket )American;UK;Australian sockets;etcDisplay LED4Display LED3Prosice overload protectionCommon overload protectionE-stop buttonDC output:12V / 8.3AEarth connectionPre-heaterATS sensorRemote controlATS control box(50A)DHY6000SEDHY6000SE-3 Mechanical standard and optionsBasic color: Pantone black CAlternator: Steel plate Q195Alternator: Silicon steel plate DW800Decompression handleOption : Standard feature : No available : 5Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

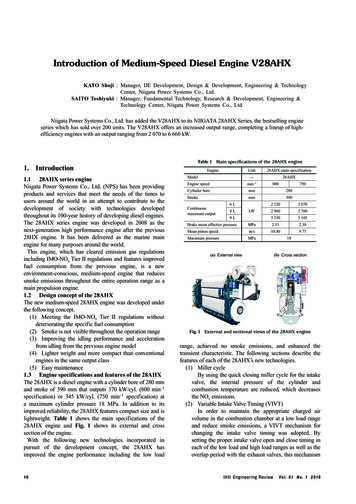

POWER PRODUCTS1-4 Specifications of engineD4007.3kW(10.0hp)Air cooled diesel engineSingle cylinder, vertical, 4-stroke, air-cooled86x72 (3.39x2.83)BoreXstroke [mm(in)]0.418 (418)Displacement [L(cc)]26024022022021020019018017036006.6 (9.0)Max. power [kW(Hp)]6.6 (9.0)7.3 (10.0)1.65 (0.435)ExhaustTemperature 2.15 (0.57)Lube oil capacity [L(US.gal)]Recoil starter / Elec. startercrankshaft / camshaftOutput ShaftFuel trademark0#(summer), -10#(winter) dieselOil trademarkCD grade or SAE10W-30 15W-40Recoil start 48 (105.6);Elec. Start 53 (117)Net Weight [kG(lbs)]417x470x494 (16.42x18.50x19.45)Overall dimension L W H [mm(in)]400:model codeE: electric startSpecification FuelConsumptionFuel consumption [L(US.gal)/hr.Starting 5 (1.45)Fuel tank capacity [L(US.gal)]10987654321000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000Smoke Density30005.9 (8.0)Kmg Nm C600500400300200PS kW1098765432g/kWh g/PSh3002802602402202202102001901801707654321000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000Engine Speed min-1PTO DimensionsKeyway shaftPS kWEngine Speed min-1Rated power [kW(Hp)]Rated speed (rpm)D: diesel engine28019:1Compression ratioKmg Nm C600500400300200g/kWh sel Engine ModelSd6420OutputD400/ESpecification FuelConsumptionExhaustTemperatureSmoke DensityPerformance CurvesPTO FlagersThread shaftTaper shaftCrankshaft PTOEngineDimensions4176Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Camshaft PTO

POWER PRODUCTS1-5 Maintenance StandardDiesel EnginePartsDieselEngineCylinderItemMaximum Speed (No Load)Cylinder CompressionSleeve I.D--Ø23mmPiston Pin Bore I.D. 05mm18.0mm17.954mmPiston Pin-to-Piston Pin Bore Clearance0.002-0.014mm0.06mmRing Side 29.98mm29.92mmIN0.15 0.02mm--EX0.20 mIN0.02-0.044mm0.1mmEX0.06-0.087mm0.12mmSeat Width0.8mm2.0mmSpring Free Length34mm32.5mmSecondRing Enc Gap:SecondRing WidthSecondSmall End I.DBig End I.DBig Oil ClearanceBig End Side ClearanceCrankshaft pin O.DValve ClearanceStem O.DValve 1.17Mpa(1400rpm)0.015-0.05mmPiston Pin O.DCrankshaft--85.94mmPiston-to-Cylinder ClearanceConnectingRod3150 3180rpm--Skirt O.D.Piston RingsService limit86.0mmCylinder HeadWarpageCoverPistonStandardGuide I.DStem Clearance7Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTSCam HeightIN27.7mm27.45mmCam mm#68--13.7 1.5mm--Pilot Screw Opening2-1/8 turns--Spark PlugGap0.7-0.8mm--Spark PlugCapResistance5kΩ--Primary Coil0.8-1.0Ω--Secondary Coil5.9-7.1kΩ--0.4-0.6mm--CamshaftJournal O.DCrankcaseCoverCamshaft Bracket I.DMain JetCarburetorFloat HeightResistanceIgnition CoilAir gapy GeneratorPartsStator WindingRotor ExcitationWindingCarbon BrushItemStandardService limitStator Winding1.8 10%Ω at 20 --Stator Auxiliary Winding3.5 10%Ω at 20 --Excitation Winding51.3 10%Ω at 20 --10mm6mmResistanceResistanceCarbon Brush Length8Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS2. Periodic Maintenance2.1 Service IntervalsGood maintenance is essential for safe, economical, and trouble-free operation. It will also help reduce airpollution.Exhaust gas contains poisonous carbon monoxide. Shut off the engine beforeWARNINGperform any maintenance. If the engine must be run, make sure the area is wellventilated.Periodic maintenance and adjustment is necessary to keep the generator in good operating condition.Perform the service and inspection at the intervals shown in the Maintenance schedule below:(1) Service more frequently when used in dusty areas.(2) These items should be serviced by an authorized generator dealer.(3) When more often use, only servicing according to above correct intervals can insure the generator setlong-term use.9Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS2-2 Routine Maintenance Procedures2.2.1 Oil ChangeDrain the used oil while the engine is warm. Warm oil drains quickly and completely.1. Place a suitable container below the engine to catch the used oil, and then removethe filler cap/dipstick and the drain plug.2. Allow the used oil to drain completely, and then reinstall the drain plug, and tightenit securely.3. With the engine in a level position, fill to the outer edge of the oil filler hole with therecommended oil.DIPSTICKDRAIN BOLT2.2.2 Oil Filter ServiceRemove the bolt that secures the filter and carefully pull the assembly towardyou.The filter may be immersed in solvent then blown dry with compressed air.Replace the filter at the scheduled service interval or anytime the screen isdamaged or all deposits cannot be removed.10Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS2.2.3 Air Filter ServiceRemove the air cleaner cover and inspect the filter. Clean or replace dirty filter elements.Always replace damaged filter elements.2.2.4 Fuel Filter Service1. Drain out the fuel from the fuel tank. Turn the screw in the drain plug counterclockwise until fuel flows. Use a suitable container to catch the fuel.2. Remove the three screws securing the fuel cock assembly and remove the filterfrom the housing.FUEL TANKDRAIN PLUGFUEL COCKFUEL FILTERASSEMBLY11Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS2.2.5 Adjust the valve clearance(1) The clearance must be adjusted when the engine is cold.Standard.15 mmIntake/Exhaust clearanceMaintenance Limit--(2) Valve timingIntakeExhaustOpenCloseOpenClose14 before TDC50 after BDC54 before BDC10 after TDC12Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS3. Engine disassembly and reassembly3.1 Disassembly3.1.1 Fuel tank1. Release the joint between the fuel line and fuel tank.2. Release the hose clamp of the fuel line on the pump side.3. Remove the tank.3.1.2 Exhaust Muffler1. Remove the flange bolt2. Remove the set bolt3. Discard the muffler gasket. Do not reuse.3.1.3 Air cleaner(1). Disassemble the air cleaner cover.(2). Pull out the element.(3). Disassemble the air cleaner bottom case.3.1.4 Recoil starter unit(do not disassemble)3.1.5 Disassemble the fan coverUnbolt and remove the fan cover.4.1.6 Starter pulleyUnbolt and remove13Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS3.1.7 Air inlet pipe3.1.8 Remove electric starter motor3.1.9 Remove cylinder head cover3.1.10 Valve rocker arm seat3.1.11 Push rods3.1.12 Fuel injector(1) Remove the high-pressure fuel line.(2) Remove fuel injector.(3) Be careful not to damage the nozzle washer and spacer.14Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS3.1.7 Air inlet pipe3.1.8 Remove electric starter motor3.1.9 Remove cylinder head cover3.1.10 Valve rocker arm seat3.1.11 Push rods3.1.12 Fuel injector(1) Remove the high-pressure fuel line.(2) Remove fuel injector.(3) Be careful not to damage the nozzle washer and spacer.15Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS3.1.13 Remove the cylinder head3.1.14 Remove the injection pump(1) Remove the pump together with the base.(2) Ensure the hooking part of control lever is at the meshing position beforedisassembling.(3) Pull out the flat tappet remaining inside the housing3.1.15 Crankcase cover(1) Remove the engine oil injection pump cover.(2

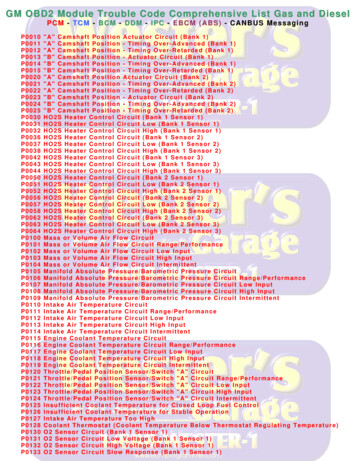

5. Troubleshooting 42 5.1 No fuel delivery to injection pump 42 5.2 No fuel flow from drain valve 42 5.3 Low compression 42 5.4 Hard starting (fuel delivery and compression normal) 42 5.5 No start or hard start (engine cranks) 42