Transcription

A Guide toScaffold Use in theConstruction IndustrySmall Business Safety Management SeriesOSHA 31502002 (Revised)

This informational booklet is intended to providea generic, non-exhaustive overview of a particularstandards-related topic. This publication does notitself alter or determine compliance responsibilities,which are set forth in OSHA standards themselvesand the Occupational Safety and Health Act of1970.Moreover, because interpretations and enforcementpolicy may change over time, for additional guidance on OSHA compliance requirements, the readershould consult current administrative interpretationsand decisions by the Occupational Safety andHealth Review Commission and the courts.Material contained in this publication is in thepublic domain and may be reproduced, fully orpartially, without permission of the FederalGovernment. Source credit is requested but notrequired.This information will be made available to sensoryimpaired individuals upon request.Voice phone: (202) 219-8615;Teletypewriter (TTY): (887) 889-5627

A Guide to Scaffold Usein the Construction IndustrySmall Business Safety Management SeriesU.S. Department of LaborOccupational Safety and Health AdministrationOSHA 31502002 (Revised)

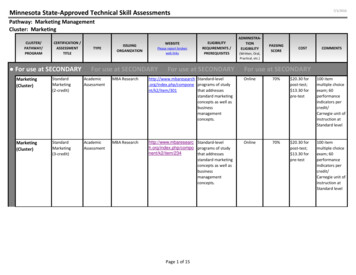

ContentsiiiHow to Use This Booklet . vSummary . 1General Requirements for Scaffolds §1926.451 . 3Capacity . 3Scaffold Platform Construction . 3Criteria for Supported Scaffolds . 4Criteria for Suspended Scaffolds . 4Access Requirements . 7Use Requirements . 7Fall Protection Requirements . 7Falling Object Protection. 8Specific Scaffold §1926.452 and Aerial Lift Requirements §1926.453 . 9Training Requirements §1926.454 . 10Non-Mandatory Appendices to the Standard . 11OSHA Assistance, Services, and Programs . 12Safety and Health Program Management Assistance . 12State Plans . 12Consultation Assistance . 12Voluntary Protection Programs . 13OSHA’s Strategic Partnership Program . 14Training and Education . 15Other Assistance Materials . 15OSHA Regional and Area Offices . 16OSHA-Approved Safety and Health Plans . 21OSHA Onsite Consultation Offices . 23Construction Focused Inspection Guidelines . 28Regulatory Text . 29Contents

How to Use This BookletThe Occupational Safety and Health Act of 1970charges the Occupational Safety and Health Administration (OSHA) with protecting all working menand women across the United States. To do so, theagency sets federal standards1 for general industry,construction, and shipyard employment. OSHA alsopromotes a variety of voluntary programs that striveto form partnerships with businesses, labor, andother groups to help employers provide safer andmore healthful workplaces for employees. Some ofthe agency’s voluntary initiatives include safety andhealth management programs, the Voluntary Protection Programs, consultation assistance, and trainingand education programs and grants. For moreinformation on these outreach efforts, see page 12 ofthis booklet.The agency’s recent rule, Safety Standards forScaffolds Use in the Construction Industry rule aimsto protect workers using scaffolding in constructionwork. Scaffolding hazards continue to rank high onthe list of the most frequently cited standards in theconstruction industry. Scaffold-related fatalitiesaccount for a significant number of fatalities in thevconstruction workplace. This booklet addressessome of the most common questions about OSHA’sscaffold standard. It is all part of the agency’s effortto provide guidance to employers who need help incomplying with OSHA’s standards to protect theworking men and women across the nation.This booklet is organized in a question andanswer format to highlight pertinent informationthat employers and employees need to know. Thesubjects addressed in each question follow the basicorganization of the standard. In addition, eachanswer references the regulatory text where thatparticular information can be located. These references appear at the end of each answer in boldfacetype.An appendix also includes an alphabetical indexto the standard for quick reference.It is important to note that the question andanswer section of this booklet simply provides anoverview of the standard. For compliance with allof the regulation’s requirements, refer to the regulatory text or Title 29 of the Code Federal Regulations(CFR) Part 1926, Subpart L.1Section 18(b) of The Occupational Safety and Health Actof 1970, P.L. 91-596, encourages states to develop andoperate, under OSHA guidance, their own job safety andhealth plans. An OSHA-approved state plan must havesafety and health requirements at least as effective as thoseof Federal OSHA and must adopt comparable statestandards within 6 months of promulgation of federalstandards.How to Use This Booklet

Summary and Explanation of the Final RuleWhat are the highlights of the scaffoldingstandard?OSHA’s scaffolding standard has several keyprovisions: Fall protection or fall arrest systems—Each employee more than 10 feet above a lower level shallbe protected from falls by guardrails or a fall arrestsystem, except those on single-point and two-pointadjustable suspension scaffolds. Each employee ona single-point and two-point adjustable suspendedscaffold shall be protected by both a personal fallarrest system and a guardrail. 1926.451(g)(1) Guardrail height—The height of the toprail forscaffolds manufactured and placed in service afterJanuary 1, 2000 must be between 38 inches (0.9meters) and 45 inches (1.2 meters). The height ofthe toprail for scaffolds manufactured and placed inservice before January 1, 2000 can be between 36inches (0.9 meters) and 45 inches (1.2 meters).1926.451(g)(4)(ii) Crossbracing—When the crosspoint ofcrossbracing is used as a toprail, it must bebetween 38 inches (0.97 m) and 48 inches (1.3meters) above the work platform.1926.451(g)(4)(xv) Midrails— Midrails must be installed approximately halfway between the toprail and the platformsurface. When a crosspoint of crossbracing is usedas a midrail, it must be between 20 inches (0.5meters) and 30 inches (0.8 m) above the workplatform. 1926.451(g)(4) Footings—Support scaffold footings shall be leveland capable of supporting the loaded scaffold. Thelegs, poles, frames, and uprights shall bear on baseplates and mud sills. 1926.451(c)(2) Platforms—Supported scaffold platforms shall befully planked or decked. 1926.451(b) Guying ties, and braces—Supported scaffolds witha height-to-base of more than 4:1 shall be restainedfrom tipping by guying, tying, bracing, or theequivalent. 1926.451(c)(1) Capacity—Scaffolds and scaffold compponentsmust support at least 4 times the maximum intendedload. Suspension scaffold rigging must at least 6times the intended load. 1926.451(a)(1) and (3)1 Training—Employers must train each employeewho works on a scaffold on the hazards and theprocedures to control the hazards. 1926.454 Inspections—Before each work shift and after anyoccurrence that could affect the structural integrity,a competent person must inspect the scaffold andscaffold components for visible defects.1926.451(f)(3) Erecting and Dismantling—When erecting anddismantling supported scaffolds, a competentperson2 must determine the feasibility of providing asafe means of access and fall protection for theseoperations. 1926.451(e)(9) & (g)(2)When is a competent person required forscaffolding?OSHA’s scaffolding standard defines a competentperson as “one who is capable of identifying existingand predictable hazards in the surroundings or workingconditions, which are unsanitary, hazardous to employees, and who has authorization to take prompt corrective measures to eliminate them.”The standard requires a competent person to performthe following duties under thesecircumstances: In General:- To select and direct employees who erect, dismantle, move, or alter scaffolds. 1926.451(f)(7)- To determine if it is safe for employees to work onor from a scaffold during storms or high windsand to ensure that a personal fall arrest system orwind screens protect these employees. (Note:Windscreens should not be used unless thescaffold is secured against the anticipated windforces imposed.) 1926.451(f)(12) For Training:- To train employees involved in erecting, disassembling, moving, operating, repairing, maintaining, or inspecting scaffolds to recognize associated work hazards. 1926.454(b) For Inspections:- To inspect scaffolds and scaffold components forvisible defects before each work shift and afterany occurrence which could affect the structuralintegrity and to authorize prompt correctiveactions. 1926.451(f)(3)2See the standard’s requirements for and definition of acompetent person in the next question.Summary

2- To inspect ropes on suspended scaffolds priorto each workshift and after every occurrencewhich could affect the structural integrity andto authorize prompt corrective actions.1926.451(d)(10)- To inspect manila or plastic (or other synthetic) rope being used for toprails or midrails.1926.451(g)(4)(xiv) For Suspension Scaffolds:- To evaluate direct connections to support theload. 1926.451 (d)(3)(i)- To evaluate the need to secure two-point andmulti-point scaffolds to prevent swaying.1926.451(d)(18) For Erectors and Dismantlers:- To determine the feasibility and safety ofproviding fall protection and access.1926.451(e)(9) and 1926.451(g)(2)- To train erectors and dismantlers (effectiveSeptember 2, 1997) to recognize associatedwork hazards. 1926.454(b) For Scaffold Components:- To determine if a scaffold will be structurallysound when intermixing components fromdifferent manufacturers. 1926.451(b)(10)- To determine if galvanic action has affectedthe capacity when using components ofdissimilar metals. 1926.451(b)(11)When is a qualified person required forscaffolding?The standard defines a qualified person as “onewho—by possession of a recognized degree,certificate, or professional standing, or who byextensive knowledge, training, and experience—hassuccessfully demonstrated his/her ability to solve orresolve problems related to the subject matter, thework, or the project.”The qualified person must perform the followingduties in these circumstances: In General:- To design and load scaffolds in accordancewith that design. 1926.451(a)(6) For Training:- To train employees working on the scaffoldsto recognize the associated hazards andunderstand procedures to control or minimizethose hazards. 1926.454(a) For Suspension Scaffolds:- To design the rigging for single-point adjustable suspension scaffolds. 1926.452(o)(2)(i)- To design platforms on two-point adjustablesuspension types that are less than 36 inches(0.9 m) wide to prevent instability.1926.452(p)(1)- To make swaged attachments or spliced eyeson wire suspension ropes. 1926.451(d)(11) For Components and Design:- To design scaffold components construction inaccordance with the design. 1926.451(a)(6)When is an engineer required?The standard requires a registered professionalengineer to perform the following duties in thesecircumstances:

Specific Scaffold §1926.452 and Aerial Lift Requirements §1926.453 . 9 Training Requirements §1926.454 . OSHA Onsite Consultation Offices . 23 Construction Focused Inspection Guidelines . 28 Regulatory Text .