Transcription

PROJECTLittle (Precast) House36ASCENT, SPRING 2006

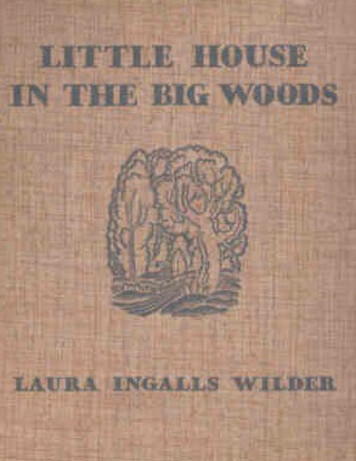

Precast concrete loghomes offer key benefitscompared to typicalwood logsAnew technique for making loghomes replicates the look ofwood logs so well that it mightfool termites — at least until they tried tobite into one. The homes feature precastcomponents that are cast and stained toresemble wood logs, creating a designthat offers great potential for homesaround the country, its makers say.“We see a lot of people who don’twant to deal with the problems created bywood logs,” says Tom Beaudette, principalin Beaudette Consulting Engineers, whichhelped create the connection designs andschematics.The concept has been developed byCultured Log Systems in Missoula, Mont.,which worked with Missoula ConcreteConstruction to create the system andproducts. The precast homes were thebrainstorm of Missoula Concrete’s formerowner, Dick Morgenstern, explains DougBauer, president. Morgenstern sawimpending problems with finding largeenough logs to continue building loghomes in the region, where they werequite popular. In addition, wood logs hadsignificant drawbacks that he thoughtcould be overcome with precast concretedesigns.On The Prairie— Craig A. ShuttTree Provides TemplateTo create a template, Morgenstern cutdown a tree in his own front yard (“I don’tthink his wife has forgiven him,” Bauersays) and used it to create a rubber mold.ASCENT, SPRING 200637

From that, reverse impressions weremade to create a form liner for theprecast logs.The panels created from thedesign are 16 inches high, 8 incheswide and a maximum of 28 feet long.That height can be formed into two8-inch logs or other configurationsas well, Bauer notes. Three styles oflog currently are offered as standarddesigns: a 16-inch-tall panel witha hand-hewed, squared-off look; apanel with two 8-inch-tall D-logs; anda 16-inch-tall panel with a squared-offstyle Bauer calls the “back East look.”Each log also includes an insulatedcore to improve energy efficiency.Rebar connects the logs vertically,explains Stewart Hansen, presidentof Cultured Log Systems. “The heightthat can be created is unlimited,” hesays. Most homes to date have beentwo stories, but four or five storiesis possible by simply using a widerfoundation and slightly thicker logs atthe base, he notes.A wide range of roof styles can beattached to the logs, Beaudette says.“We can adapt the system to almostany type of roofing the homeownerdesires.” Standard connections areused throughout, making it an easysystem to replicate, he adds. “Thehomes use typical structural detailsthat are normal for any residentialsituation,” he says. “And the logswon’t move around.”Benefits Compared To WoodIndeed, one key advantage thestructures offer is that they won’tshrink, settle or shift as log homesoften do, Beaudette says. There areSeveral styles of logs are available, and whilethey resemble hand-hewn wood, they actuallyconsist of precast concrete.The panels are16 inches high,8 inches wideand a maximum of28 feet long.38ASCENT, WINTER 2006other benefits to the precast design,too: The precast components arriveat the site ready to erect, unlikewood-log packages that canrequire modifications at the jobsite. The precast logs are castto architectural specifications inadvance, and the factory castingof the pieces ensures openingsare precise to window and doormanufacturers’ specifications, saysHansen. There is no need to restain orseal the logs annually, as thereoften is with wood logs. This cansave more than 750 per year inmaintenance costs. Precast concrete’s compositionmakes the logs fire resistant,providing a three-hour firerating. That durability produces aminimum of a 20-percent reductionin insurance costs compared tocomparable log or frame homes,Hansen says. The homes are resistant to insectsand decay, as well as mold andfungus, due to their inorganicmaterial. That saves further byalleviating the need to preventthese problems. The precast mix can includerecycled materials such as fly ash.The thermal mass of the concretehelps to retain heated or coolair, which is aided by the interiorinsulation. That can producesavings of between 30 and 40percent on heating and coolingcosts, Hansen says.In general, the precast log homeshave lower material costs and also

‘We see a lot ofpeople who don’twant to deal with theproblems created bywood logs.’save on erection labor. Typical labor on a log home costs 25- 35 per square foot,Hansen estimates, which will cost a homeowner between 50,000 and 70,000less for a 2,000-square-foot home. “This is a substantial savings in anyone’sbudget.”The system has been well received in Montana, Hansen notes, and theprocess is poised for expansion. “It’s a patented system, and we’ve beenwaiting for that to be completed,” he explains. “So we’ve been intentionallyquiet until early last year.” Currently, the homes are being shipped only toMontana and Idaho locations, Bauer notes. “But we’ve had interest from downin Virginia, so there’s real potential for expansion.”The construction method and appearance continue to be refined, he adds.“This is our laboratory out here. We’re still in the process of determining howbest to market the homes before we try to expand nationwide.” The companyhopes to license other precasters to sell the homes and cast the logs. “It’staking off so quickly that it’s apparent we won’t be able to keep up with demandfrom one facility, and the shipping costs from Montana would be prohibitive insome cases.”“The full potential remains to be seen,” says Beaudette. “But we do a lotof log and timber construction out here, and this new approach is proving verypopular. More and more, these precast designs will take off as word of mouthspreads and more structures are constructed. The homeowners are tellingothers that these are thermally well insulated homes that are a structurally superefficient design. You can’t tell the difference between this and wood unless youget right up to it and pound on it. The texture and color are very good.” For more information on this or other projects visit www.pci.org/ascent.The logs save money on maintenance, energy,insurance and other long-term costs.ASCENT, SPRING 200639

PROJECTSeveral styles of logs are available, and whilethey resemble hand-hewn wood, they actuallyconsist of precast concrete.ASCENT, SPRING 2006

PROJECTASCENT, SPRING 2006

PROJECTThe logs save moneyon maintenance,energy, insuranceand other long-term costs.ASCENT, SPRING 2006

Little (Precast) House On The Prairie — Craig A. Shutt Precast concrete log homes offer key benefits compared to typical wood logs A new technique for making log homes replicates the look of wood logs so well that it might fool termites — at least until they tried to bite into one. The homes feature precast