Transcription

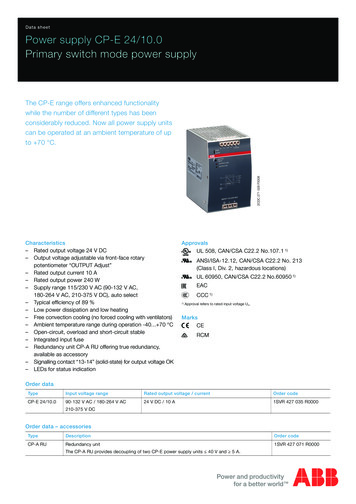

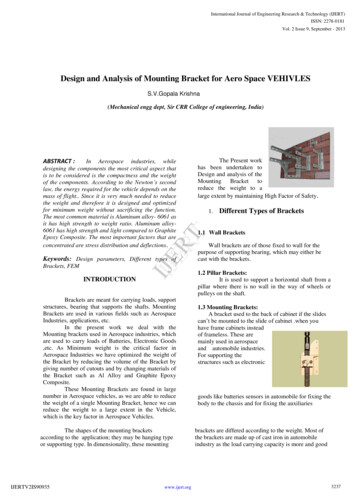

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013Design and Analysis of Mounting Bracket for Aero Space VEHIVLESS.V.Gopala Krishna(Mechanical engg dept, Sir CRR College of engineering, India)ABSTRACT :Keywords: Design parameters, Different types ofBrackets, FEMINTRODUCTION1.Different Types of Brackets1.1 Wall BracketsWall brackets are of those fixed to wall for thepurpose of supporting bearing, which may either becast with the brackets.1.2 Pillar Brackets:It is used to support a horizontal shaft from apillar where there is no wall in the way of wheels orpulleys on the shaft.Brackets are meant for carrying loads, supportstructures, bearing that supports the shafts. MountingBrackets are used in various fields such as AerospaceIndustries, applications, etc.In the present work we deal with theMounting brackets used in Aerospace industries, whichare used to carry loads of Batteries, Electronic Goods,etc. As Minimum weight is the critical factor inAerospace Industries we have optimized the weight ofthe Bracket by reducing the volume of the Bracket bygiving number of cutouts and by changing materials ofthe Bracket such as Al Alloy and Graphite EpoxyComposite.These Mounting Brackets are found in largenumber in Aerospace vehicles, as we are able to reducethe weight of a single Mounting Bracket, hence we canreduce the weight to a large extent in the Vehicle,which is the key factor in Aerospace Vehicles.The shapes of the mounting bracketsaccording to the application; they may be hanging typeor supporting type. In dimensionality, these mountingIJERTV2IS90935The Present workhas been undertaken toDesign and analysis of theMounting Bracket toreduce the weight to alarge extent by maintaining High Factor of Safety.IJERTIn Aerospace industries, whiledesigning the components the most critical aspect thatis to be considered is the compactness and the weightof the components. According to the Newton’s secondlaw, the energy required for the vehicle depends on themass of flight. Since it is very much needed to reducethe weight and therefore it is designed and optimizedfor minimum weight without sacrificing the function.The most common material is Aluminum alloy- 6061 asit has high strength to weight ratio. Aluminum alloy6061 has high strength and light compared to GraphiteEpoxy Composite. The most important factors that areconcentrated are stress distribution and deflections.www.ijert.org1.3 Mounting Brackets:A bracket used to the back of cabinet if the slidescan’t be mounted to the slide of cabinet .when youhave frame cabinets insteadof frameless. These aremainly used in aerospaceand automobile industries.For supporting thestructures such as electronicgoods like batteries sensors in automobile for fixing thebody to the chassis and for fixing the auxiliariesbrackets are differed according to the weight. Most ofthe brackets are made up of cast iron in automobileindustry as the load carrying capacity is more and good3237

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013electronic goods like batteries sensors in automobilefor fixing the body to the chassis and for fixing theaxiliariesThe criterion for design of the mountingbracket it depends on the loading also. If any eccentricloading acts on the brackets the design criteria basedon the shear and flexural moment. If the loads acttransverse, the design is based on shear and bendingstress. These mounting brackets are fixed to thestructure bolts are pins.IJERTin compression and absorbs the disturbances intravelling1.4Drive bay Mounting Bracket:These are mainly used in aerospace and automobileindustries. For supporting the structures such asThe shapes of the mounting brackets aredifferent and are particularly varied according to theapplication; they may be hanging type or supportingtype. In dimensionality, these mounting brackets arediffered according to the weight i.e. to be carried or ofthe size object to be carried.The material selections for the bracket are alsodepending on the application point of view. Most of thebrackets are made up of cast iron in automobileindustry as the load carrying capacity is more and goodin compression and absorbs the disturbances intravelling. In aerospace industry these are made up ofaluminum as the weight is considered as critical factorand at the same time the strength to weight ratio isneeded to be more.Fig : Automobile Mounting BracketIDENTIFICAION OF PROBLEMIn any design problem, output of the designdepends on the input given i.e., the design parameters,which affects the design adversely and some of thedefinitions are to be mentioned clearly. Some of thegeneral inputs are mentioned What is the importance of the part? What are the design parameters? What are the loads that are acting on the designedcomponent?Some of the inputs of mounting brackets areThe unambiguous definition of the problemmakes the designers work easy. Probably the mostcritical step in the design process is the definition ofthe problem. The true problem is not always what isseems to be at first glance because this first steprequires such a small part of the total time to create thefinal design, its important is often overlooked. Thisproject deals with the optimize of the mountingbrackets, which are mostly used in many areas likeaerospace, automotive etc.The mounting bracket, which is optimizedand analyzed, is being used in aerospace launchingIJERTV2IS90935vehicles, for mounting batteries of different weightsand size. The problem is to optimize the minimumweight, as the aerospace vehicle is needed to design forminimum weight. In the launching vehicles mountingbrackets are mostly used for supporting parts andstructures.www.ijert.orgThe dimensions of battery i.e. to be mounted on thebrackets are:Length of battery 350mmWidth of battery 280mmHeight of the battery 100mmWeight of the battery 20kgThe initial dimensions of the mounting bracket atfirst step are:3238

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013Length of bracket 400mmLoading conditions:Width of the bracket 300mmThe static load of the battery 20kgInitial thickness 6mm (based on shear and bendingstress)Accelerated load 20 9.81 mm𝑠𝑒𝑐 2380636835IJERT610All dimensions in mm.Fig: Model of Mounting BracketTaking the above bracket is consider 5 sections.that is having 20 cylinder volumes subtracted.That’s in 1st volume 5th volume; 2nd volume 4th volume; &3rd volume.Density mass/volumeMass density*volumeWeight of bracket without cut:Volume of bracket without cuts [1st &2nd & 3rd &4th &5th volumes ]-[20 cylinder volumes]Cube volume l*b*h; cylinder volume π *r2 *h;Volume of Bracket without cuts [(l1*b1*h1) (l2*b2*h2) (l3*b3*h3) (l4*b4*h4) (l5*b5*h5)]-[20* π *r2 *h][(.01*.3*.006) (.006*.3*.035) (.38*.3*.006) (.006*.3*.035) (.01*.3*.006)]-[20*π*.003*0.003*.006][.000018 .000063 .000684 .000063 3239

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013.00084260582 m3Mass of bracket for aluminium material density*volume 2800*.00084260582 2.35929 kgMass of bracket for graphite epoxy material density *volume 1600*.00084260582 1.34816915 kgWeight of bracket with single cut:Volume of bracket with single cut volume of bracket without cuts –single cut of volume .00084260582-(.2*.15*.006) 00084260582-.00018 .00066260582 m3IJERTMass of bracket for aluminum material density*volume 2800*.00066260582 1.8552960 kgMass of bracket for graphite epoxy material density *volume 1600*.00066260582 1.06016915 kgWeight of bracket with double cuts:Volume of bracket with double cut volume of bracket without cuts-double cut of volume .00084260582-(2*.2*.1*.006) .00084260582-.00024 .00060260582m3Mass of bracket for aluminum material density*volume 5www.ijert.org3240

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013 1.6882960 kgMass of bracket for graphite epoxy material density *volume 1600*.00060260582 .96416915 kgWeight of bracket with four cuts:Volume of bracket with four cuts volume of bracket without cuts-four cuts of volume .00084260582-(4*.11*.085*.006) .00084260582-.000198 .00064460582 m3Mass of bracket for aluminium material density*volume 2800*.00064460582 1.8048960 kgIJERTMass of bracket for graphite epoxy material density *volume 1600*.00064460582 1.03136915 kg2.Introduction to Finite Element AnalysisEngineers today face increasing difficultchallenges to contend in rapidly changing globalmarket-to-market products in better quality at lowestcost possible, so that product have good market incompetition. To achieve these goals, one of thepowerful tools available for the designer is computeraided finite element analysis.Finite element analysis is a powerfulnumerical technique for analysis. FEA is used forstress analysis in that area of solid mechanics. Thebasic concept of finite element method is that aIJERTV2IS90935www.ijert.orgbody/structure may be divided in to smaller elementscalled finite elements. The properties of the elementsare formulated and combined to obtain the solution forthe entire body/structure. For a given practical designproblem, the engineers has to idealize the physicalsystem into a FE model with proper boundaryconditions and loads that are acting on the system.Then the descritiztion of a body or structure into cellsof finite elements is performed and the mathematicalmodel is analyzed for every elements and the forcomplete structure. The various unknown parametersare computed by using known parameters3241

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013materialCutUy in metersUz in metersoutsSUM inVon MisesmetersStresses 0815490.0000429280.000004384391.85898Cut outsUy in metersUz in metersSUM in meters0.000022980.0093882.00941118Von MisesStresses 029404.0029815541.88380IJERTAL0Table:Results summary of various outputs stressesIJERTV2IS90935www.ijert.org3242

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 20133.1 DEFORMED SHAPE AND VON MISES STRESSES OF MOUNTING BRACKET BY USINGAL ALLOY-6061Fig:3.1.b Von mises stresses of mounting bracket with out cuts(6mm)IJERTFig:3.1.a Deformed shape of mounting bracket with out cuts(6mm)Fig:3.1.c Deformed shape of mounting bracket with single cut(6mm)Fig:3.1.d Von mises stresses of mounting bracket with single cut(6mm)Fig:3.1.e Deformed shape of mounting bracket with double cut (6mm)Fig:3.1.f Von mises stresses of m,ounting bracket with double cut (6mm)Fig:3.1.g Deformed shape of mounting bracket with four cut (6mm)IJERTV2IS90935Fig:3.1.h Von mises stresses of mounting bracket with four cut (6mm)www.ijert.org3243

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013DEFORMED SHAPE AND VON MISES STRESSES OF MOUNTING BRACKET BY USINGGRAPHITE EPOXY COMPOSITEIJERTFig:3.1.i Deformed shape of mounting bracket with out cuts(6mm) Fig:3.1.j Vonmises stresses of mounting bracket with out cuts(6mm)Fig:3.1.k Deformed shape of mounting bracket with single cut(6mm) Fig:3.1.l Vonmises stresses of mounting bracket with single cut(6mm)Fig:3.1.m Deformed shape of mounting bracket with double cut (6mm)Fig:3.1.n Vonmises stresses of mounting bracket with double cut (6mm)Fig:3.1.o Deformed shape of mounting bracket with four cut (6mm)IJERTV2IS90935www.ijert.orgFig:3.1.p Von mises stresses of mounting bracket with four cut (6mm)3244

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 20133.2 Graphs Representing Various Outputs4deformation3.5Weight 50GECAl0.50cut0cut1cut2cut4number of cutsIJERTnumber of cutsGraph 3.2.a: compare b/w weights of Al alloy-6061& GEC350000vonmises stresses (pa)300000Graph 3.2.b: compare b/w deformations of Al alloy-6061 & GEC250000200000Al150000GEC100000500000without cutsingle cutdouble cutfour cutnumber of cutsGraph 3.2.c: compare b/w vonmises stresses of Al alloy-6061& GECIJERTV2IS90935www.ijert.org3245

International Journal of Engineering Research & Technology (IJERT)ISSN: 2278-0181Vol. 2 Issue 9, September - 2013CONCLUSIONSThe conclusions that are drawn from the present workareComparing the mass of 6mm mountingbracket, 6mm without cuts is weighing 2.362kgBy reducing the thickness of bracket to 6mmdouble cut is weighs to 1.688 kg, thepercentage reduction of weight is 28.5% ascompared to without cut to double cut bracket. For the mounting bracket Deflections arecoming far less that 1mm.The stresses inducedare coming well below the Allowable stressesmaintaining High factor of safety. As all the results i.e. Deflections and Stressesare within range. 6mm with double cut Al alloymounting bracket is considered as Optimumsize for minimum weight (1.688kg)consideration. Mass of 6mm double cut Composite bracket isweighing about 0.966kg, which is very lesscompared to 6mm without cut (1.34kg).IJERT Mass of 6mm thick Graphite Epoxy Composite bracketwith 6mm 2 cuts is 0.966kg which is about 42.5% lessthan the 6mm 2 cuts Al alloy bracketREFERENCES[1].Comparative fatigue assessment of soft toeand nested bracket welded aluminium structures whoseauthors are S. Irving *, F. Ferguson-Smith, X.Z. Hu, Y.Liu, Available 5 March 2005[2].A literature review of automotive vehicleengine mounting Systems whose authors are Yunhe Yua, Nagi G. Naganathan a, Rao V. Dukkipati ,accepted 6December 1999[3].Dynamic interaction of rotating momentumwheels with spacecraft elements whose authors are S.Shankar Narayana, , P.S. Naira, Ashitava Ghosalb aIJERTV2IS90935ISRO Satellite Centre, Vimanapura Post, Air PortRoad, Bangalore 560 017, India .28 July 2007[4]Vibrations of a Body supported by shearMountings of incompressible material with a,Italy, accepted 4 august 2000[5]Suppression of brake squeal noise applyingfinite element brake and pad model enhanced byspectral-based assurance criteria whose authors are YiDai a, Teik C. Lim b,a Haldex Brake Products Inc., Research andDevelopment Center, 103 Echlin Blvd., Prattville, AL36067, USA accepted 28 September 2006[6]SHAPE DESIGN OF AN ENGINE MOUNTBY A METHOD OF PARAMETER OPTIMIZATIONwhose authors are Joong Jae Kim? and Heon YoungKim , S Department of Mechanical (Received I1 May 1994)[7]Stable mounting of beam splitters for aninterferometer Whose authors are A.A. van Veggel andH. Nijmeijer ,Department of Mechanical Engineering,Eindhoven University of Technology, Den Dolech 2,5612 AZ Eindhoven, The Netherlands Received 23April 2007www.ijert.org[8]Auxiliary headrest mounting bracket forhandicapped patients whose authors are J.O. KilfoilD.D.S and P.P. Popovitch D.D.S.Harry S. TrumanMemorial Veterans Hospital, Columbia, Mo. USAAvailable online 10 October 2006[9]Bond strength of orthodontic direct-bondingcement-bracket systems as studied in vitro whoseauthors are V. A. James Buzzitta D.D.S., M.S.*, StevenE. Hallgren D.D.S., M.S. and John M. Powers Ph.D.From the School of Dentistry, The University ofMichigan, Ann Arbor, Mich., USA Available online 9June 2004.[10]Bond strengths of three resin systems usedwith bracket and embedded wire attachments whoseauthors are Robert P. Schulz D.D.S., Robert B.Mayhew D.M.D., Ph.D., Larry J. Oesterle D.D.S.,M.S. and Wayne P. Pierson Ph.D., San Antonio,Texas, USA Available online 10 June 2004.3246

1.6882960 kg Mass of bracket for graphite epoxy material density *volume 1600*.00060260582 .96416915 kg Weight of bracket with four cuts: Volume of bracket with four cuts volume of bracket without cuts-four cuts of volume