Transcription

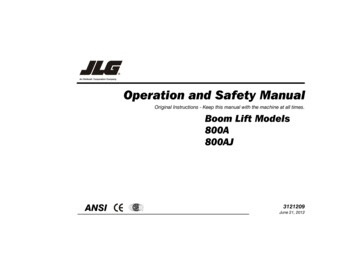

Operation and Safety ManualOriginal Instructions - Keep this manual with the machine at all times.Boom Lift Models800A800AJANSI3121209 June 21, 2012

FOREWORDFOREWORDThis manual is a very important tool! Keep it with the machine at all times.The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions andoperating procedures essential for the safe and proper machine operation for its intended purpose.Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changeswithout prior notification. Contact JLG Industries, Inc. for updated information.3121209– JLG Lift –a

FOREWORDSAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDSThis is the Safety Alert Symbol. It is used to alert you to the potential personalinjury hazards. Obey all safety messages that follow this symbol to avoid possibleinjury or deathINDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOTAVOIDED, WILL RESULT IN SERIOUS INJURY OR DEATH. THIS DECALWILL HAVE A RED BACKGROUND.INDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOTAVOIDED, COULD RESULT IN SERIOUS INJURY OR DEATH. THISDECAL WILL HAVE AN ORANGE BACKGROUND.bINDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOTAVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAYALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE AYELLOW BACKGROUND.INDICATES INFORMATION OR A COMPANY POLICY THAT RELATESDIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.– JLG Lift –3121209

FOREWORDFor:THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZEDJLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETYRELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THISPRODUCT. Accident Reporting Product Safety Publications Current Owner Updates Questions RegardingProduct SafetyJLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THEOWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES,INC. TO ENSURE THAT THE CURRENT OWNER RECORDS AREUPDATED AND ACCURATE.JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALLINSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN ANACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL ORWHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRODUCT. Standards and RegulationsCompliance Information Questions Regarding Special Product Applications Questions Regarding Product ModificationsContact:Product Safety and Reliability DepartmentJLG Industries, Inc.13224 Fountainhead PlazaHagerstown, MD 21742USAor Your Local JLG Office(See addresses on inside of manual cover)In USA:Toll Free:877-JLG-SAFE (877-554-7233)Outside USA:Phone:Fax:E-mail:3121209– JLG Lift –240-420-2661301-745-3713ProductSafety@JLG.comc

FOREWORDREVISION LOGdOriginal Issue- May 4, 2005Revised- September 1, 2005Revised- March 7, 2006Revised- July 17, 2006Revised- March 12, 2007Revised- March 30, 2007Revised- January 6, 2009Revised- November 6, 2009Revised- December 12, 2009Revised- July 26, 2010Revised- June 21, 2012– JLG Lift –3121209

TABLE OF CONTENTSSECTION - PARAGRAPH, SUBJECTPAGESECTION - PARAGRAPH, SUBJECTSECTION - 1 - SAFETY PRECAUTIONS1.11.21.31.41.52.3GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1Operator Training and Knowledge . . . . . . . . . . . 1-1Workplace Inspection . . . . . . . . . . . . . . . . . . . . . 1-2Machine Inspection . . . . . . . . . . . . . . . . . . . . . . 1-2OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3Trip and Fall Hazards . . . . . . . . . . . . . . . . . . . . . 1-3Electrocution Hazards . . . . . . . . . . . . . . . . . . . . 1-4Tipping Hazards . . . . . . . . . . . . . . . . . . . . . . . . . 1-6Crushing and Collision Hazards. . . . . . . . . . . . . 1-7TOWING, LIFTING, AND HAULING . . . . . . . . . . . . .1-8ADDITIONAL HAZARDS / SAFETY . . . . . . . . . . . . .1-9SECTION - 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION2.12.231212092.4PAGEFUNCTION CHECK. . . . . . . . . . . . . . . . . . . . . . . . 2-11From the Ground Control Station with No Load in thePlatform:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11From the Platform Control Station: . . . . . . . . . . 2-15OSCILLATING AXLE LOCKOUT TEST(IF EQUIPPED) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18SECTION - 3 - MACHINE CONTROLS AND INDICATORS3.13.2GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1CONTROLS AND INDICATORS . . . . . . . . . . . . . . . 3-1Ground Control Station . . . . . . . . . . . . . . . . . . . . 3-1Ground Control Indicator Panel . . . . . . . . . . . . . 3-6Platform Station . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9Platform Control Indicator Panel . . . . . . . . . . . . 3-16SECTION - 4 - MACHINE OPERATIONPERSONNEL TRAINING . . . . . . . . . . . . . . . . . . . . .2-1Operator Training . . . . . . . . . . . . . . . . . . . . . . . . 2-1Training Supervision. . . . . . . . . . . . . . . . . . . . . . 2-1Operator Responsibility . . . . . . . . . . . . . . . . . . . 2-1PREPARATION, INSPECTION, ANDMAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . 2-4GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8– JLG Lift –4.14.24.3DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . .OPERATING CHARACTERISTICS ANDLIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ENGINE OPERATION . . . . . . . . . . . . . . . . . . . . . . .Starting Procedure . . . . . . . . . . . . . . . . . . . . . . .Shutdown Procedure . . . . . . . . . . . . . . . . . . . . .4-14-14-14-14-24-24-6i

TABLE OF CONTENTSSECTION - PARAGRAPH, iPAGETRAVELING (DRIVING) . . . . . . . . . . . . . . . . . . . . . . 4-6Traveling Forward and Reverse. . . . . . . . . . . . . 4-7STEERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7PARKING AND STOWING . . . . . . . . . . . . . . . . . . . . 4-7PLATFORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8Loading From Ground Level . . . . . . . . . . . . . . . 4-8Loading From Positions Above Ground Level . 4-8Platform Level Adjustment . . . . . . . . . . . . . . . . . 4-8Platform Rotation . . . . . . . . . . . . . . . . . . . . . . . . 4-8BOOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10Swinging the Boom . . . . . . . . . . . . . . . . . . . . . 4-10Raising and Lowering the Tower Boom . . . . . 4-11Raising and Lowering the Main Boom . . . . . . 4-11Telescoping the Main Boom . . . . . . . . . . . . . . 4-11Function of Tower Boom . . . . . . . . . . . . . . . . . 4-12SHUT DOWN AND PARK . . . . . . . . . . . . . . . . . . . 4-13LIFTING AND TIE DOWN. . . . . . . . . . . . . . . . . . . . 4-13OSCILLATING AXLE LOCKOUT TEST(IF EQUIPPED) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16TOWING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16TOW BAR (IF EQUIPPED) . . . . . . . . . . . . . . . . . . . 4-17WELDING LEAD (IF EQUIPPED). . . . . . . . . . . . . . 4-17DUAL FUEL SYSTEM (GAS ENGINE ONLY) . . . . 4-19Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19Changing From Gasoline to LP Gas . . . . . . . . 4-19Changing From LP Gas to Gasoline . . . . . . . . 4-19SECTION - PARAGRAPH, SUBJECTPAGE4.16 RE-SYNCHRONIZE UPRIGHT . . . . . . . . . . . . . . . .4-20Releveling Valve . . . . . . . . . . . . . . . . . . . . . . . . 4-20SECTION - 5 - EMERGENCY PROCEDURES5.15.25.35.45.5GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . .5-1EMERGENCY TOWING PROCEDURES . . . . . . . . .5-1EMERGENCY CONTROLS AND THEIRLOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2Power/Emergency Stop Switches . . . . . . . . . . . 5-2Ground Control Station . . . . . . . . . . . . . . . . . . . 5-2Auxiliary Power . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . .5-3Use of Ground Controls . . . . . . . . . . . . . . . . . . . 5-3Operator Unable to Control Machine . . . . . . . . . 5-4Platform or Boom Caught Overhead . . . . . . . . . 5-4SECTION - 6 - GENERAL SPECIFICATIONS & OPERATORMAINTENANCE– JLG Lift –6.16.2INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1OPERATING SPECIFICATIONS . . . . . . . . . . . . . . . .6-1Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3Engine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-63121209

TABLE OF CONTENTSSECTION - PARAGRAPH, SUBJECT6.36.46.56.66.76.8PAGESECTION - PARAGRAPH, SUBJECTCritical Stability Weights . . . . . . . . . . . . . . . . . . 6-10OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . .6-21TIRES & WHEELS . . . . . . . . . . . . . . . . . . . . . . . . .6-29Tire Inflation . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29Tire Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29Tire Replacement . . . . . . . . . . . . . . . . . . . . . . . 6-30Wheel Replacement . . . . . . . . . . . . . . . . . . . . . 6-30Wheel Installation . . . . . . . . . . . . . . . . . . . . . . . 6-31DRAINING OIL BUILD UP FROM THE PROPANE REGULATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32PROPANE FUEL FILTER REPLACEMENT. . . . . . .6-34Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34PROPANE FUEL SYSTEM PRESSURE RELIEF . .6-36SUPPLEMENTAL INFORMATION . . . . . . . . . . . . .6-36SECTION - 7 - INSPECTION AND REPAIR LOGLIST OF FIGURES2-1.2-2.2-3.2-4.2-5.2-6.3121209Machine Nomenclature - 800A (Sheet 1 of 2) . . . . .2-5Machine Nomenclature - 800AJ (Sheet 2 of 2) . . . .2-6Daily Walk-Around Inspection (Sheet 1 of 4). . . . . .2-7Daily Walk-Around Inspection (Sheet 2 of 4). . . . . .2-8Daily Walk-Around Inspection (Sheet 3 of 4). . . . . .2-9Daily Walk-Around Inspection (Sheet 4 of 4). . . . .2-10– JLG Lift 6-1.PAGETower Boom Vertical Limit Switch . . . . . . . . . . . . 2-11Tower Boom Horizontal Limit Switch . . . . . . . . . . 2-12Boom Upright Positioning - Correct . . . . . . . . . . . 2-13Boom Upright Positioning - Incorrect . . . . . . . . . . 2-14Ground Control Station. . . . . . . . . . . . . . . . . . . . . . 3-2Ground Control Indicator Panel . . . . . . . . . . . . . . . 3-6Platform Control Console . . . . . . . . . . . . . . . . . . . 3-10Platform Control Console - w/Drive Orientation . . 3-11Platform Light Panel . . . . . . . . . . . . . . . . . . . . . . . 3-18Platform Light Panel w/Drive Orientation . . . . . . . 3-19Position of Least Forward Stability . . . . . . . . . . . . . 4-3Positions of Least Backward Stability(Sheet 1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4Positions of Least Backward Stability(Sheet 2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5Grade and Sideslopes . . . . . . . . . . . . . . . . . . . . . . 4-9Machine Tie Down . . . . . . . . . . . . . . . . . . . . . . . . 4-14Lifting Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15Tow Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18Releveling Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20Decal Installation - Sheet 1 of 5 . . . . . . . . . . . . . . 4-21Decal Installation - Sheet 2 of 5 . . . . . . . . . . . . . . 4-22Decal Installation - Sheet 3 of 5 . . . . . . . . . . . . . . 4-23Decal Installation - Sheet 4 of 5 . . . . . . . . . . . . . . 4-24Decal Installation - Sheet 5 of 5 . . . . . . . . . . . . . . 4-25Engine Operating Temperature Specifications - Deutziii

TABLE OF CONTENTSSECTION - PARAGRAPH, SUBJECTPAGE- Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12Engine Operating Temperature Specifications - Deutz- Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-136-3. Engine Operating Temperature Specifications - Ford Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-146-4. Engine Operating Temperature Specifications - Ford Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-156-5. Engine Operating Temperature Specifications Caterpillar - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . 6-166-6. Engine Operating Temperature Specifications Caterpillar - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . 6-176-7. Engine Operating Temperature Specifications - GM Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-186-8. Engine Operating Temperature Specifications - GM Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-196-9. Operator Maintenance and Lubrication Diagram . 6-206-10. Filter Lock Assembly . . . . . . . . . . . . . . . . . . . . . . . 6-356-2.LIST OF TABLES1-11-22-14-14-26-1ivMinimum Approach Distances (M.A.D.) . . . . . . . . . 1-5Beaufort Scale (For Reference Only) . . . . . . . . . . 1-10Inspection and Maintenance Table . . . . . . . . . . . . . 2-3Decal Legend - 800A . . . . . . . . . . . . . . . . . . . . . . . 4-26Decal Legend - 800AJ . . . . . . . . . . . . . . . . . . . . . . 4-30Operating Specifications . . . . . . . . . . . . . . . . . . . . . 6-1SECTION - PARAGRAPH, 46-156-166-176-186-196-207-1– JLG Lift –PAGETire Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 6-2Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3Ford LRG-425 Specifications . . . . . . . . . . . . . . . . . 6-3Deutz F4M2011F Specifications . . . . . . . . . . . . . . 6-4Deutz D2011L04 Specifications . . . . . . . . . . . . . . . 6-4Caterpillar 3044C/3.4 . . . . . . . . . . . . . . . . . . . . . . . 6-5Isuzu 4JB1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5GM 3.0L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6Mobilfluid 424 Specs . . . . . . . . . . . . . . . . . . . . . . . 6-7Mobil DTE 13M Specs . . . . . . . . . . . . . . . . . . . . . . 6-7Mobil EAL 224H Specs. . . . . . . . . . . . . . . . . . . . . . 6-8UCon Hydrolube HP-5046 . . . . . . . . . . . . . . . . . . . 6-8Exxon Univis HVI 26 Specs . . . . . . . . . . . . . . . . . . 6-9Quintolubric 888-46 . . . . . . . . . . . . . . . . . . . . . . . . 6-9Critical Stability Weights - 800A . . . . . . . . . . . . . . 6-10Critical Stability Weights - 800AJ . . . . . . . . . . . . . 6-11Lubrication Specifications . . . . . . . . . . . . . . . . . . 6-21Wheel Torque Chart . . . . . . . . . . . . . . . . . . . . . . . 6-32Inspection and Repair Log . . . . . . . . . . . . . . . . . . . 7-13121209

SECTION 1 - SAFETY PRECAUTIONSSECTION 1. SAFETY PRECAUTIONS1.1GENERAL1.2This section outlines the necessary precautions for properand safe machine operation and maintenance. For propermachine use, it is mandatory that a daily routine is established based on the content of this manual. A maintenanceprogram, using the information provided in this manual andthe Service and Maintenance Manual, must also be established by a qualified person and followed to ensure themachine is safe to operate.PRE-OPERATIONOperator Training and Knowledge Read and understand this manual before operating themachine.The owner/user/operator/lessor/lessee of the machineshould not operate the machine until this manual has beenread, training is accomplished, and operation of the machinehas been completed under the supervision of an experienced and qualified operator.If there are any questions with regard to safety, training,inspection, maintenance, application, and operation, pleasecontact JLG Industries, Inc. (“JLG”).FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED INTHIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.3121209– JLG Lift – Do not operate this machine until complete training is performed by authorized persons. Only authorized and qualified personnel can operate themachine.1-1

SECTION 1 - SAFETY PRECAUTIONS Read, understand, and obey all DANGERS, WARNINGS,CAUTIONS, and operating instructions on the machineand in this manual. Use the machine in a manner which is within the scope ofits intended application set by JLG. All operating personnel must be familiar with the emergency controls and emergency operation of the machineas specified in this manual. Read, understand, and obey all applicable employer,local, and governmental regulations as they pertain tooperation of the machine.Machine Inspection Before machine operation, perform inspections and functional checks. Refer to Section 2 of this manual fordetailed instructions. Do not operate this machine until it has been serviced andmaintained according to requirements specified in theService and Maintenance Manual. Be sure the footswitch and all other safety devices areoperating properly. Modification of these devices is asafety violation.Workplace Inspection The operator is to take safety measures to avoid all hazards in the work area prior to machine operation. Do not operate or raise the platform while on trucks, trailers, railway cars, floating vessels, scaffolds or other equipment unless approved in writing by JLG. Do not operate the machine in hazardous environmentsunless approved for that purpose by JLG. Be sure that the ground conditions are able to support themaximum load shown on the decals located on themachine.1-2MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORMSHALL BE MADE ONLY WITH WRITTEN PERMISSION FROM THE MANUFACTURER Do not operate any machine on which safety or instructionplacards or decals are missing or illegible. Avoid any buildup of debris on the platform floor. Keepmud, oil, grease, and other slippery substances from footwear and platform floor.– JLG Lift –3121209

SECTION 1 - SAFETY PRECAUTIONS1.3OPERATION Supplies or tools which extend outside the platform areprohibited unless approved by JLG.General When driving, always position boom over rear axle in linewith the direction of travel. Remember, if boom is over thefront axle, steer and drive functions will be reversed. Do not use the machine for any purpose other than positioning personnel, their tools, and equipment. Do not assist a stuck or disabled machine by pushing,pulling, or by using boom functions. Only pull the unitfrom the tie-down lugs on the chassis. Never operate a machine that is not working properly. If amalfunctions occurs, shut down the machine. Never slam a control switch or lever through neutral to anopposite direction. Always return switch to neutral andstop before moving the switch to the next function. Operate controls with slow and even pressure. Hydraulic cylinders should never be left fully extended orfully retracted before shutdown or for long periods of time. Do not place boom or platform against any structure tosteady the platform or to support the structure. Stow boom and shut off all power before leaving machine.Trip and Fall Hazards Do not allow personnel to tamper with or operate themachine from the ground with personnel in the platform,except in an emergency. Do not carry materials directly on platform railing. ContactJLG for approved material handling accessories.During operation, occupants in the platform must wear a fullbody harness with a lanyard attached to an authorized lanyard anchorage point. Attach only one (1) lanyard per lanyard anchorage point. When two or more persons are in the platform, the operator shall be responsible for all machine operations. Always ensure that power tools are properly stowed andnever left hanging by their cord from the platform workarea.3121209– JLG Lift –1-3

SECTION 1 - SAFETY PRECAUTIONS Before operating the machine, make sure all gates areclosed and fastened in their proper position. Use extreme caution when entering or leaving platform.Be sure that the boom is fully lowered. It may be necessary to telescope out to position the platform closer to theground for entry/exit. Face the machine, maintain “threepoint contact” with the machine, using two hands and onefoot or two feet and one hand during entry and exit.Electrocution Hazards This machine is not insulated and does not provide protection from contact or proximity to electrical current. Keep both feet firmly positioned on the platform floor at alltimes. Never use ladders, boxes, steps, planks, or similaritems on platform to provide additional reach. Never use the boom assembly to enter or leave the platform.1-4– JLG Lift –3121209

SECTION 1 - SAFETY PRECAUTIONSTable 1-1. Minimum Approach Distances (M.A.D.)Voltage Range(Phase to Phase)0 to 50 KV10 (3)Over 50KV to 200 KV15 (5)Over 200 KV to 350 KV20 (6)Over 350 KV to 500 KV25 (8)Over 500 KV to 750 KV35 (11)Over 750 KV to 1000 KV45 (14)NOTE: Maintain distance from electrical lines, apparatus, or anyenergized (exposed or insulated) parts according to theMinimum Approach Distance (MAD) as shown in Table 11. Allow for machine movement and electrical line swaying.3121209– JLG Lift –MINIMUM APPROACH DISTANCEin Feet (Meters)This requirement shall apply except whereemployer, local or governmental regulationsare more stringent. Maintain a clearance of at least 10 ft. (3m) between any partof the machine and its occupants, their tools, and theirequipment from any electrical line or apparatus carrying upto 50,000 volts. One foot additional clearance is required forevery additional 30,000 volts or less.1-5

SECTION 1 - SAFETY PRECAUTIONS The minimum approach distance may be reduced if insulating barriers are installed to prevent contact, and the barriersare rated for the voltage of the line being guarded. Thesebarriers shall not be part of (or attached to) the machine. Theminimum approach distance shall be reduced to a distancewithin the designed working dimensions of the insulatingbarrier. This determination shall be made by a qualified person in accordance with the employer, local, or governmentalrequirements for work practices near energized equipmentTipping Hazards The user should be familiar with the surface before driving. Do not exceed the allowable sideslope and gradewhile driving.DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITEDZONE (MAD). ASSUME ALL ELECTRICAL PARTS AND WIRING AREENERGIZED UNLESS KNOWN OTHERWISE.1-6– JLG Lift –3121209

SECTION 1 - SAFETY PRECAUTIONS Do not elevate platform or drive with platform elevatedwhile on a sloping, uneven, or soft surface. If boom assembly or platform is in a position that one ormore wheels are off the ground, all persons must beremoved before attempting to stabilize the machine. Usecranes, forklift trucks, or other appropriate equipment tostabilize machine. Before driving on floors, bridges, trucks, and other surfaces, check allowable capacity of the surfaces. Never exceed the maximum platform capacity. Distributeloads evenly on platform floor.Crushing and Collision Hazards Do not raise the platform or drive from an elevated position unless the machine is on firm, level and smooth surfaces. Keep the chassis of the machine at least 2 ft. (0.6m) fromholes, bumps, drop-offs, obstructions, debris, concealedholes, and other potential hazards on the floor/surface. Approved head gear must be worn by all operating andground personnel. Check work area for clearances overhead, on sides, andbottom of platform when lifting or lowering platform, anddriving. Do not push or pull any object with the boom. Never attempt to use the machine as a crane. Do not tieoff machine to any adjacent structure. Do not operate the machine when wind conditions exceed28 mph (12.5 m/s). Refer to Table 1-2, Beaufort Scale (ForReference Only). Do not increase the surface area of the platform or theload. Increase of the area exposed to the wind willdecrease stability. Do not increase the platform size with unauthorized deckextensions or attachments.3121209– JLG Lift – During operation, keep all body parts inside platform railing.1-7

SECTION 1 - SAFETY PRECAUTIONS Use the boom functions, not the drive function, to positionthe platform close to obstacles. Always post a lookout when driving in areas where visionis obstructed. Keep non-operating personnel at least 6 ft. (1.8m) awayfrom machine during all driving and swing operations. Limit travel speed according to conditions of ground surface, congestion, visibility, slope, location of personnel,and other factors which may cause collision or injury topersonnel. Be aware of stopping distances in all drive speeds. Whendriving in high speed, switch to low speed before stopping. Travel grades in low speed only. Do not use high speed drive in restricted or close quartersor when driving in reverse. Exercise extreme caution at all times to prevent obstaclesfrom striking or interfering with operating controls and persons in the platform.1.4TOWING, LIFTING, AND HAULING Never allow personnel in platform while towing, lifting, orhauling. This machine should not be towed, except in the event ofemergency, malfunction, power failure, or loading/unloading. Refer to the Emergency Procedures section of thismanual for emergency towing procedures. Ensure boom is in the stowed position and the turntablelocked prior to towing, lifting or hauling. The platform mustbe completely empty of tools. When lifting machine, lift only at designated areas of themachine. Lift the unit with equipment of adequate capacity. Refer to the Machine Operation section of this manual forlifting information. Be sure that operators of other overhead and floor levelmachines are aware of the aerial work platform’s presence. Disconnect power to overhead cranes. Warn personnel not to work, stand, or walk under a raisedboom or platform. Position barricades on floor if necessary.1-8– JLG Lift –3121209

SECTION 1 - SAFETY PRECAUTIONS1.5ADDITIONAL HAZARDS / SAFETY Do not refuel the machine with the engine running. Battery fluid is highly corrosive. Avoid contact with skinand clothing at all times. Do not use machine as a ground for welding. When performing welding or metal cutting operations,precautions must be taken to protect the chassis fromdirect exposure to weld and metal cutting spatter.3121209– JLG Lift – Charge batteries only in a well ventilated area.1-9

SECTION 1 - SAFETY PRECAUTIONSDO NOT OPERATE THE MACHINE WHEN WIND CONDITIONS EXCEED 28MPH (12.5 M/S).Table 1-2. Beaufort Scale (For Reference Only)1-10Wind SpeedBeaufortNumbermphm/s000-0.211-30.3-1.5Light airWind motion visible in smoke.24-71.6-3.3Light breezeWind felt on exposed skin. Leaves rustle.38-123.4-5.4Gentle breezeLeaves and smaller twigs in constant motion.413-185.5-7.9Moderate breezeDust and loose paper raised. Small branches begin to move.DescriptionLand ConditionsCalmCalm. Smoke rises vertically.519-248.0-10.7Fresh breezeSmaller trees sway.625-3110.8-13.8Strong breezeLarge branches in motion. Whistling heard in overhead wires.Umbrella use becomes difficult.732-3813.9-17.1Near Gale/Moderate GaleWhole trees in motion. Effort needed to walk against the wind.839-4617.2-20.7Fresh GaleTwigs broken from trees. Cars veer on road.947-5420.8-24.4Strong GaleLight structure damage.– JLG Lift –3121209

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTIONSECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION2.1 PERSONNEL TRAINING6. The safest means to operate the machine where overhead obstructions, other moving equipment, and obstacles, depressions, holes, drop-offs.The aerial platform is a personnel handling device; so it isnecessary that it be operated and maintained only by trainedpersonnel.Persons under the influence of drugs or alcohol or who aresubject to seizures, dizziness or loss of physical control mustnot operate this machine.7. Means to avoid the hazards of unprotected electricalconductors.8. Specific job requirements or machine application.Training SupervisionOperator TrainingTraining must be done under the supervision of a qualifiedperson in an open area free of obstructions until the traineehas developed the ability to safely control and operate themachine.Operator training must cover:1. Use and limitations of the controls in the platform and atthe ground, emergency controls and safety systems.2. Control labels, instructions, and warnings on themachine.Operator Responsibility3. Rules of the employer and government regulations.4. Use of approved fall protection device.The operator must be instructed that he/she has the responsibility and authority to shut down the machine in case of amalfunction or other unsafe condition of either the machineor the job site.5. Enough knowledge of the mechanical operation of themachine to recognize a malfunction or potential malfunction.3121209– JLG Lift –2-1

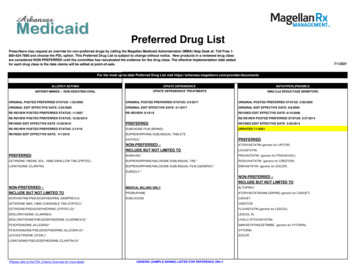

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION2.2PREPARATION, INSPECTION, ANDMAINTENANCEThe following table covers the periodic machine inspectionsand maintenance required by JLG Industries, Inc. Consultlocal regulations for further requirements for aerial work platforms. The frequency of inspections and maintenance mustbe increased as necessary when the machine is used in aharsh or hostile environment, if the machine is

FOREWORD 3121209 – JLG Lift – a FOREWORD This manual is a very important tool! Keep it with the machine at all times. The purpose of this manual is to provide owners, users,