Transcription

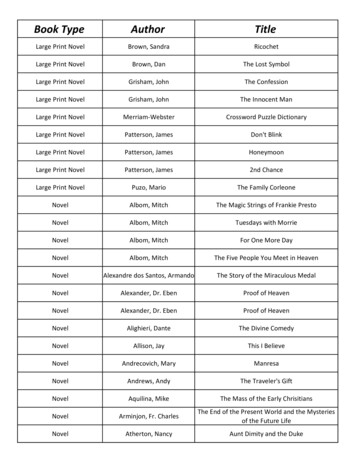

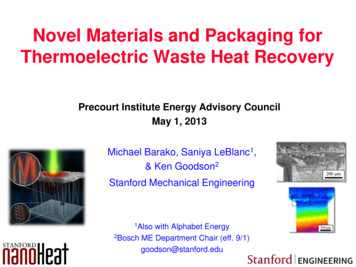

Novel Materials and Packaging forThermoelectric Waste Heat RecoveryPrecourt Institute Energy Advisory CouncilMay 1, 2013Michael Barako, Saniya LeBlanc1,& Ken Goodson2Stanford Mechanical Engineering1Alsowith Alphabet Energy2Bosch ME Department Chair (eff. 9/1)goodson@stanford.edu

Key StudentsMichael Barako, PhD StudentNanostructured Packaging for Energy Conversion NDSEG Fellow Project Leader for NSF-DOE Thermoelectrics Partnership Mentor for energy scavenging sensors project with ADISaniya LeBlanc, PhD Graduate 2012Nanowire Energy Conversion Materials Fellowships: NSF, Sandia Labs, Stanford DARE.Now with Alphabet EnergyAdvisor for LBNL Globally Transformative TechnologiesMentor for our ADI Project on energy scavenging sensors

Current GroupWoosung ParkMichael BarakoShilpi Roy (EE)Joe Katz (EE)Jungwan ChoJena BarnesKen GoodsonElah Bozorg-GrayeliTom DessaultSri LingamneniAditya Sood (MSE)Marc DunhamManeeshika MadduriKen LopezMatt HoffmanDr. Saniya LeBlancDr. Takashi KodamaDr. Yoonjin WonDr. Damena AgonaferConsulting Prof. Mehdi AsheghiSelected AlumniProf. Dan FletcherProf. Evelyn WangProf. Katsuo KurabayashiProf. Sungtaek JuProf. Amy MarconnetProf. Bill KingProf. Eric PopProf. Sanjiv SinhaProf. Xeujiao HuProf. Carlos HidrovoProf. Kaustav BanerjeeProf. Ankur JainProf. Sarah ParikhUC BerkeleyMITU. MichiganUCLAPurdueUIUCStanford (EE)UIUCWuhan Univ.UT AustinUCSB (EE)UT ArlingtonFoothill CollegeDr. Jeremy RowletteDr. Patricia GharagozlooDr. Per SverdrupDr. Chen FangDr. Milnes DavidDr. Saniya LeblancDr. Roger FlynnDr. Julie SteinbrennerDr. John ReifenbergDr. David FoggDr. Matthew PanzerDr. Yuan GaoDr. Joe MilerDaylight SolnsSandia LabsIntelExxon-MobileIBMAlphabet En.IntelXerox ParcAlphabet En.CreareKLA-TencorOracleARPA-E

informationappliancestransportationdefense

Heat & Energy Challengesinformationenergy efficiencynanoscale transportnano e

Heat & Energy se

Heat & Energy se

Wasted Energy as an OpportunityOver 50% of energy isrejected as heat.M. Zebarjadi et al., Energy & Env. Sci. (2012)

Thermoelectrics ApplicationsCurrentIn DevelopmentAppliances:Space exploration:Industrial es.comwww.nasa.govAutomotive heat g, Nature Materials, 2009

Thermoelectric Waste Heat RecoveryAppliances:Industrial furnaces:600 CHeatcontact resistanceshot side / heat exchangerthermalthermalinsulation / e.g. ceramic plateconductor/ e.g. copperelectricalwww.fuelsavessystems.com& thermalnconductor/ e.g. copperpdiffusion barrierwww.boschappliances.comjoining technologyconductor/ e.g. copperinsulation / e.g. ceramic plateelectrical& thermalthermalthermalAutomotive heat recovery:cold side / heat exchangerCooling90 CVining, Nature Materials, 2009

Thermoelectric Waste Heat RecoveryImprovements in the intrinsic ZT of TE materials are proving to be verydifficult to translate into efficient, reliable power recovery systems.600 CHeatcontact resistanceshot side / heat exchangerthermalthermalinsulation / e.g. ceramic plateconductor/ e.g. copperelectrical& thermalnconductor/ e.g. copperpdiffusion barrierjoining technologyconductor/ e.g. copperinsulation / e.g. ceramic platecold side / heat exchangerCooling90 Celectrical& thermalthermalthermalMajor needs include Low resistance interfaces thatare stable under thermal cycling. High-temperature TE materialsthat are stable and promise lowcost scaleup. Characterization methods thatinclude interfaces and correlatebetter with system performance.

Interfacial Failure Modes in ThermoelectricsInterface degradation due to thermalexpansion mismatch & electromigrationReduced conversion efficiency and failureFinite elementsimulation50 μm200 μm500 μmCourtesy Bosch LLCBarako, Park, Goodson, et al., J. Elec. Mat. (2013)

Interfacial Failure Modes in ThermoelectricsAfter 45,000 CyclesMicrocracks50 μm5 μm200 μmVoids500 μm50 μmBarako, Park, Goodson, et al., J. Elec. Mat. (2013)

Interfacial Failure Modes in ThermoelectricsAfter 45,000 Cycles1.250 μmNormalized parameter, y/y 0Thermal Conductivity1Electrical ConductivityFigure of Merit ZT0.8 2ZT T k0.6 0.4kelectrical45,000 CyclesDevice Failurethermal 0.210200 μmZT1001,00010,000Cycles [#]Barako, Park, Goodson, et al., J. Elec. Mat. (2013)500 μm

NSF-DOE Thermoelectrics PartnershipAutomotive Thermoelectric ModulesBoschFaculty & StaffProf. Kenneth Goodson (Stanford), PIProf. George Nolas (USF)Dr. Boris Kozinsky (Bosch)Prof. Mehdi Asheghi, Stanford Mechanical EngineeringDr. Winnie Wong-Ng, NIST Functional Properties GroupDr. Yongkwan Dong, USF Department of PhysicsStudents:Michael Barako, Lewis Hom, Saniya Leblanc, Yuan Gao, Amy MarconnetLeveraged Support:Northrop Grumman, AMD/SRC, NSF Graduate Fellowships, Stanford GraduateFellowship, Stanford DARE Fellowship, Sandia National Labs Fellowship

Prototype TEG’s In Ford Fusion, BMW X6and Chevy Suburban- DOE Programs-BMW X-6Vehicle Technologies ProgramCourtesy John Fairbanks, DOEeere.energy.gov

Overview of NSF-DOE ProgramNanostructuredthermal interfacesMetal NanowiresThermal/mechanicalcharacterization2 μmCarbon Nanotubes150 μmTh 300-700 KCeramic plateHigh-temperaturethermoelectric materialsConnecting metaln-typePelletp-typePelletCourtesy G. Nolas and Y. Dong(University of South Florida)Heat SinkHigh-temperature in-situthermal metrology500 μm

Nanostructured Thermal Interface MaterialsElastic Modulus (MPa)Thermal interface materials require:1) Low thermal resistivityPerformance2) Low elastic modulusReliability104Solders, metals103MetalNanowiresCarbonNanotubes1022 μmxGNPCompositesGreases, gels,polymers101GOAL0.010.1Thermal Resistivity (m K / W)1.0

Nanostructured Thermal Interface MaterialsLow melting temperaturealloy binderUS Patent 7504453Panzer, Goodson et al., Nano Letters (2010)Hu, Goodson et al., J. Heat Transfer (2006)Adhesion layerNanofibersmechanicalbacker 100 nm is thetypical variation inCNT height.Upon heating, the low melting binderconforms to CNT and substratetopography.Heat to meltbinderSubstrateSubstrate

Rig ComplexityNano Thermal & Mechanical MetrologyRestrict theconductionlengthscale usinghigh speed opticsRestrict the conductionlengthscale usingnanofabricationSample Complexity

Rig ComplexityNano Thermal & Mechanical MetrologyKodama, Jain, Goodson,Nano Letters 9 (2009)CarbonNanotube (SW)Students: Eric PopStudents: Yoneoka, LeePhys. Review Letters (2005) Nano Letters (2012)Sample Complexity

Nano Thermal & Mechanical Metrologydelayed probe12 ps pumpRig ComplexityGaNSiC / DiamondStudents: Cho, Bozorg-Grayeli, ReifenbergElectron Device Letters (2010,2011,2012)Student: MarconnetACS Nano (2011)CarbonNanotube (SW)Students: Eric PopStudents: Yoneoka, Li, KodamaPhys. Review Letters (2005) Nano Letters (2012b)Sample Complexity

Mechanical Characterization ToolsExperimental MeasurementsComputational ModelingLaser Doppler Velicometry using microfabricated cantileversCoarse-grained molecular simulationsResonator lengthand shape variationCNT on a CantileverSimulation CellWon, Gao, Goodson et al., Carbon (2012)Courtesy of Dr. Yoonjin Won

Energy Scavenging with Analog DevicesMicro-thermoelectrics to powersmall distributed sensors in thepresence of a “free” (lowmagnitude) temperature gradientsCourtesy of Analog Devices, Inc. Current analysis looks at standard vertical thermoelectric configurationand parameters required to meet design specificationsn-typep-typen-typehot sourcecold sink Novel Lateral Geometry for CMOScompatibilityMarc Dunham

Major Reviews“Thermal Phenomena in Carbon Nanotubesand Related Nanostructured Materials”Marconnet, Panzer, GoodsonReviews of Modern Physics (invited & in press)SaniyaLeblancAmyMarconnet“Material and Manufacturing CostConsiderations for Thermoelectrics”Leblanc, Yee, Scullin, Dames, & Goodson(under review)“A /W Metric for Thermoelectric PowerGeneration: Beyond ZT”Yee, Leblanc, Goodson, & Dames(under review)Reviews ofModern Physics(2013)

Manufacturing Costs 0.30 /cm2 0.25 0.20 0.15 0.10Molecular beam epitaxyShuntCeramic PlateMicrofabricationDicingMetalizationHeat Exchanger 0.05 alMaterials“Material and Manufacturing CostConsiderations for Thermoelectrics”Leblanc, Yee, Scullin, Dames, & Goodson(under review)ModuleHeatExchangerSystemcomponents

Materials CostsTh 500 COxidesClathratesSilicides“Material and Manufacturing Cost Considerations for Thermoelectrics”Leblanc, Yee, Scullin, Dames, & Goodson (under review)BulkSkutteruditesNanobulkHalf HeuslerChalcogenides SiGe

Thermoelectrics Cost-PerformanceTh 500 COxidesClathratesSilicidesSystem Cost, G ( /W)1,000.00SkutteruditesHalf HeuslerOtherChalcogenides100.00F 110.001.000.100.01Material Cost2319241326188299111728222012215277Material Identification Number0.040.100.25Approx. ZTm“Material and Manufacturing Cost Considerations for Thermoelectrics”Leblanc, Yee, Scullin, Dames, & Goodson (under review)0.500.751.33

Thermoelectrics Cost-PerformanceTh 500 COxidesClathratesSilicidesSystem Cost, G ( /W)1,000.00SkutteruditesHalf HeuslerOtherChalcogenides100.00F 110.00Organic Rankine1.00Optimum FCurrent PhotovoltaicsNatural GasProjected Photovoltaics0.100.01Material Cost2319241326188299111728222012215277Material Identification Number0.040.100.25Approx. ZTm“Material and Manufacturing Cost Considerations for Thermoelectrics”Leblanc, Yee, Scullin, Dames, & Goodson (under review)0.500.751.33

Outreach to K-12 and UndergraduatesUndergraduates:K-12 students & teachers:Jena BarnesMaterials Science & Engineering ‘13Synthesis and Characterization ofZnO Nanowire Films Presented at national materialsscience conference Accepted fellowship to pursuePhD in materials science at DukeUniversityManeeshika MadduriElectrical Engineering ‘13Thermal Characterization of ZnONanowire Films Accepted into Sandia NationalLaboratory Master’s FellowshipProgramPartnering with publichighschool to provide materialsand mentors for design lab.

Undergraduate Thermoelectrics MentorshipUndergraduate Thermoelectrics Research – Summers 2012 & 2013Thermoelectric materials and interfaces characterization as undergraduate researchHigh temperature infrared microscopy experiment designed andfabricated to measure thermoelectric properties up to 600oC600500Fused silicaTE material400300200Fused silicaTemperature [oC]Heat source100Heat sinkInstructional YouTube Videos on Thermoelectric MetrologyMovies were produced to describe heat transfer metrology andwere made publicly available via Stanford’s YouTube channel Videos describe infrared thermometry, thermocouplethermometry, heat sink analysis, and thermal boundary resistanceProduced through the mentorship of a novice engineering studentunder the guidance of a more experienced senior graduate student31

Key StudentsMichael Barako, PhD StudentNanostructured Packaging for Energy Conversion NDSEG Fellow Project Leader for NSF-DOE Thermoelectrics Partnership Mentor for energy scavenging sensors project with ADISaniya LeBlanc, PhD Graduate 2012Nanowire Energy Conversion Materials Fellowships: NSF, Sandia Labs, Stanford DARE.Now with Alphabet EnergyAdvisor for LBNL Globally Transformative TechnologiesMentor for our ADI Project on energy scavenging sensors

A Few Extra Slides

Technical Accomplishments:High-Temperature In-Situ Thermal ImagingIR ImageChilledWater LoopPressuresensorSampleNichrome HeatersLinear StageHigh Temp IR Rig Temperature vs Applied Voltage600700500500Fused silica400TE material300Infrared300200Fused silica200100Heat sink100010400Thermocouple203040Volts (V)506070FY13 goalFor large temperature gradients, the IR signal intensity spansseveral orders of magnitude. It is difficult to accurately measurethe signal at each pixel simultaneously under these conditions. T 4I rad qradTemperature [oC]Hot side (TC)Hot side (IR)Cold side (TC)Cold side (IR)600Temp (C)Heat sourceOutreach FY12: Designed and builtby two summer undergraduateresearch assistants as part of theStanford outreach activitiesTechnical Accomplishment FY12:Target maximum temperatureachievedTwo generations have been constructed by the end of FY121st Generation: 2nd Generation:FY11FY12oMax T [ C]400 600Time constant [min]20015Mass [kg]20534

Thermal Properties of CNT ArraysFrequency domain thermoreflectancemeasurement of CNT thermal resistanceIn-situ bonding and infrared microscopymeasurement of CNT interface resistance100CNToC]TemperatureTemperature [[C]90Fused Silica80706050InterfaceRegion403000.51Distance [mm]Distance[mm]1.5Barako, Goodson et. al, Proc. ITHERM (2012)Gao, Goodson et. al, IEEE Trans. Comp. Pckg. (2013)

Transitioning from Lab to .arredemo.org Waste-heat exhaust sources are a 90 billion worldwide opportunity inequipment sales. Project costs ( 4,500/kW) associated with sub-MW generators areprohibitive since the only solutions are engine-based (ORC, steam) andrequire several complex systems including working fluids and cooling towers.

Stanford Mechanical Engineering 1Also with Alphabet Energy 2Bosch ME Department Chair (eff. 9/1) goodson@stanford.edu Novel Materials and Packaging for Thermoelectric Waste Heat Recove