Transcription

Geometric DesignTolerancing:Theories, Standardsand Applications

Geometric DesignTolerancing:Theories, Standardsand ApplicationsEdited byHoda A. EIMaraghy, Ph.D., P.Eng.Professor, Faculty of EngineeringUniversity ofWindsorCanadaluniSPRINGER-SCIENCE BUSINESS MEDIA. RV.

First edition 19981998 Springer Science Business Media DordrechtOrigina1ly published by Chapman & Hali in 1998Softcover reprint ofthe hardcover 1st edition 1998@ISBN 978-1-4613-7656-9ISBN 978-1-4615-5797-5 (eBook)DOI 10.1007/978-1-4615-5797-5Ali rights reserved. No part of tbis publication may be reproduced, stored in aretrieval system or transmitted in any form or by any means, electronic, mechanical,photocopying, recording or otherwise, without the prior written permission of thepublishers. Applications for permis sion should be addressed to the rights manager atthe London address of the publisher.The publisher makes IlO representation, express or implied, with regard to theaccuracy of the information contained in tbis book and cannot accept any legalresponsibility or liability for any errors or omissions that may be made.A catalogue record for tbis book is available from the British Library

CONTENTSPrefaceixHoda A. ElMaraghyView Points on Future Directions in CAT ResearchxiiiHerbert Voelcker, Leonard Farmer and Roland WeillModeling Representation and Processing of Tolerances,Tolerance Inspection:A Survey of Current HypothesisLuc Mathieu, Andre Clement and Pierre BourdetPART I Tolerance Theory and Standards1 International Standards for Design Tolerancing Review and Future PerspectivePer Bennich2 Research In Statistical Tolerancing: Examples of Intrinsic Non-Normalitiesand their effectsPeter R. Braun, Edward P. Morse and Herbert B. Voelker3537523 Composing Distribution Function Zones for Statistical Tolerance AnalysisMichael A. 0 'Connor and Vijay Srinivasan644 ISO Deliberates Statistical TolerancingVijay Srinivasan775 Relations Between ISO 1101 and Geometric Tolerances and VectorialTolerances - Conversion ProblemsZbigniew Humienny, S. Bialas and K. Kiszka6 The Tools & Rules for Computer Automated Datum ReferenceFrame ConstructionWilliam TandlerPART II Tolerance Representation in CAD7 Remarks on the Essential Element of Tolerancing Schemes Short CommunicationHerbert B. Voelcker881001171198 The TTRS: 13 Constraints for Dimensioning and TolerancingAndre Clement, Alain Riviere, Philippe Serre and Catherine Valade1229 Variational Method for Assessment of Toleranced FeaturesVladimir T. Portman, Roland D. Weill and Victoria Shuster132

viContents10 The Application of FAST Diagrams to Dimensioning andTolerancingLeonard E. Farmer14711 Identifying and Quantifying Functional Element DispersionsDuring Functional AnalysisLuc Laperriere15712 Three Dimensional Functional Tolerancing with Proportioned AssembliesClearance Volume (U.P.E.L.: Unions Ponderees d'Espaces de Liberte):application to setup planningDenis Teissandier; lVes Couetard & Alain Gerard171PART ill Modeling of Geometric Errors18313 Determination of Part Position Uncertainty Within MechanicalAssembly Using Screw ParametersAlain Desrochers and Olivier Delbart18514 A Computation Method for the Consequences of Geometric Errorsin MechanismsEric Ballot and Pierre BourdetI 9715 A Unified Model for Variation Simulation of Sheet Metal AssembliesYufeng Joshua Long and S. Jack Hu20816 Practical Applications for Intersections of Mechanical Primitives forGeometric TolerancingS. Valluri, Waguih H. ElMaraghy and Mohammed A.E. Gadalla22017 Functional Dimensioning and Toierancing of Manufactured Partsfor Fluid Leakage ControlChuck Zhang, David Zhang and Ben Wang23218 Geometric Tolerancing for Assembly with Maximum Material PartsDean M. Robinson24219 More on the Effects of Non-Normal Statistics in Geometric Tolerancing Short CommunicationEdward P. Morse254PART IV263Tolerance Analysis and Synthesis20 A New Algorithm for Combinatorial Optimization: Application to ToleranceSynthesis with Optimum Process SelectionMohamed H. Gadallah and Hoda A. EIMaraghy26521 Automated Cost Modeling for Tolerance Synthesis Using ManufacturingProcess Data, Knowledge Reasoning and OptimizationZuomin Dong and Gary G. Wang28222 A Comprehensive System for Computer Aided Tolerance Analysis of2-D and 3-D Mechanical AssembliesKenneth W. Chase, Spencer P. Magleby and Charles G. Glancy294

Contents23 Parametric Kinematic Tolerance Analysis of Planar Pairswith Multiple Contractsvii308Elisha Sacks and Leo Joskowicz24 Advanced Methodology and Software for Tolerancing andStochastic OptimizationJean M. Parks and Chung Li25 Towards a Designed Experiments Approach to Tolerance DesignRichard J. Gerth and Ziau Islam325337PART V Evaluation of Geometric Deviations34726 An Iterative Approach to Profile Evaluation Using Interpolationof Measured Positions and Surface Normals349Robert Edgeworth and Robert G. Wilhelm27 Virtual Gage with Internal Mobilities for the Verification ofFunctional Specifications360Luc Mathieu and Alex Ballu28 On the Accurate Evaluation of Geometric Deviations from CMM Data37229 Tolerancing of Free Form Surfaces387Ashraf o. Nasset. Anis Limaiem and Hoda A. EIMaraghyMohamed A.E. Gadalla and Waguih H. EIMaraghy30 Minimum Zone Evaluation of Cylindricity Using Non-LinearOptimization MethodElsayed A. Orady, Songnian Li and Yubao ChenPART VI398Industrial Applications and CAT Systems41131 Geometrical Evaluation Models in Sheet Metal Forming:A Classification Method for Shape Errors of Free-Form Surfaces413Kiwamu Kase, Norio Matsuki, Hiromasa Suzuki, Fumihiko Kimura andAkitake Makinouchi32 Tolerancing Problems for Aircraft IndustriesBenoit Marguet and Luc Mathieu33 Teaching Tolerances: A Comparison Between The Conventional andReverse Engineering ApproachesJoseph Pegna, Clement Fortin and Rene Mayer34 Current Status of CAT SystemsO. W. Salomons, Fred J.A.M. van Houten and Hubert J.J. Kals35 Tolerance Analysis Using VSA-3D for Engine ApplicationsDonald M. Wisniewski and Praveen Gomer419428438453Authors' index465Keyword index467

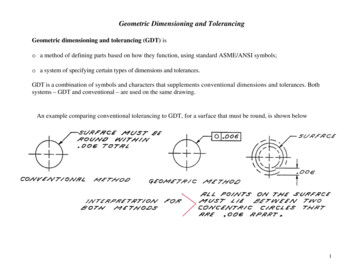

PREFACEThe importance of proper geometric dimensioning and tolerancing as a means of expressing the designer'sfunctional intent and controlling the inevitable geometric and dimensional variations of mechanical parts andassemblies, is becoming well recognized. The research efforts and innovations in the field of tolerancing design,the development of supporting tools, techniques and algorithms, and the significant advances in computingsoftware and hardware all have contributed to its recognition as a viable area of serious scholarly contributions.The field of tolerancing design is successfully making the transition to maturity where deeper insights andsound theories are being developed to offer explanations, and reliable implementations are introduced toprovide solutions.Machine designers realized very early that manufacturing processes do not produce the nominal dimensions ofdesigned parts. The notion of associating a lower and an upper limit, referred to as tolerances, with each dimension was introduced. Tolerances were specified to ensure the proper function of mating features. Fits of matingfeatures included clearances, location fits, and interference fits, with various sub-grades in each categoryassigned a tolerance value depending on the nominal size of the mating features. During the inspection process,a part is rejected if a dimension fell outside the specified range. As the accuracy requirements in assembliesbecame tighter, designers had to consider other critical dimensions and allocate tolerances to them in order toensure the assembly's functionality. Tolerance charts were used to analyse the effect of various dimensions on acritical clearance or on a pair of mating parts. Critical dimensions were also analysed not only for individualcomponents but also for assemblies. Tolerance charts were limited to linearly related tolerances. However,many applications had dimensions that are nonlinearily related, hence, tolerance chains with nonlinear relationships were introduced. The allocation of tight tolerances led to higher manufacturing costs. Tolerancingresearchers recognized that the variability by which machines produce dimensions can be modelled statistically.The probability that an assembly will satisfy the functional requirements, given a set of dimensional tolerancesimposed on the assembly's features, was determined. The probabilistic analysis of tolerances led to the conceptof allowing a small percentage of assembly rejection in order to allocate wider tolerances and control cost. Theresearch done in tolerance analysis was extended to tolerances allocation or synthesis. Manufacturing cost wasfound to decrease exponentially with the increase of tolerance magnitudes. At the same time, however, widertolerances led to higher rejection rates. Traditionally the tradeoff between cost and rejection rate has beensolved by allocating tolerances ti minimize the production cost while constraining the rejection rate to a certainvalue. Dimensional tolerances alone were found to be insufficient for controlling manufacturing variations.Geometric tolerances were introduced as limitations for controlling variations in features geometries likestraightness, perpendicularity, circularity, cylindricity, size, etc. Geometric dimensioning and tolerancing(GD&n standards which specify the types of tolerances to be used to control certain geometric variations weredeveloped (e.g., the ANSI Y14.5M 1982 and 1994 standards) and continue to evolve. Several schemes forcontrolling the geometric variability have emerged such as the worst case parametric and geometric tolerancing,kinematic/vectorial tolerancing and total quality control methodologies (e.g., using Taguchi methods). Sincereliable cost-tolerance data for various manufacturing processes and machines is scarce, many extrapolationsand assumptions were made. Very recently, a new criterion for allocating geometric tolerances (both magnitudes and types) to maximize the compliance with the functional requirements was introduced. this mathematically formulated criterion does not require cost-tolerance data for individual features but embodies implicitlythe cost of rejects, loss of quality and market share.

xPrefaceThe above historical perspective clearly indicates that tolerancing design has evolved over the decades as ascience dealing with the specification, accumulation, analysis, selection and evaluation of the allowable rangesof dimensions or geometries, within which a surface is manufactured in order to ensure the proper assembly andfunctioning of manufactured parts and products.Currently available books in the area of tolerancing focus primarily on the interpretation of the standards and aremostly limited to dimensional (not geometric) tolerances. Furthermore, various approaches to tolerance analysisand synthesis are often studied in isolation. This book aims at positioning and relating the developments andavailable knowledge in the various sub-fields of tolerancing and to bridge existing gaps. Several contributionsin the book identify the commonalities and complementarities of various approaches and define important areaswhere more knowledge and research are needed.This book covers the main Engineering Tolerance related research areas and implementations with a special focuson design issues. It includes contributions by recognized researchers and experienced practitioners in tolerancingdesign. It contains comprehensive assessment of approaches for modelling, representation and inspection oftolerances as well as extensive reviews of relevant evolving international standards and future directions. Thecontributions deal with topics such as tolerance analysis, synthesis, modelling and evaluation of geometricdeviations, inspection, theories, standards and education issues. Emphasis has been placed on including, inaddition to theories and analysis, actual implementations, case studies and industrial applications. The bookstrives to present a blend of cutting edge research, working implementations and practical applications.Many contributions are based on presentations made at the Fifth CIRP Seminar on Computer-AidedTolerancing held in Toronto, Ontario Canada in April 27-29, 1997. The International Institution forProduction Engineering Research, CIRP (College International pour recherche en production) in Paris, Francesponsors this technical seminar every two years.This book is intended for a wide audience including:a)b)c)d)e)Researchers in the field of product design, geometric and dimensional tolerancing (professors andgraduate students) and individuals interested in the evolving ISO standards for tolerancing in mechanicaldesign (including designers and engineers).Practitioners; designers, design engineers, manufacturing engineers, staff in R&D and productiondepartments of manufacturers (e.g., automotive, aerospace, machines . )Instructors and students of graduate (masters and Ph.D.), professional development and undergraduatecourses in design.Software developers for CAD/CAM and computer-aided tolerancing (CAT) application packages.Individuals interested in Design, Manufacture, precision machining, assembly, and CAD/CAM/CIM.The book is organized into six parts following the Editor's Preface, some invited viewpoints on future directions in Computer-Aided Tolerancing (CAT) research and a comprehensive review paper. The chosen organization and grouping of contributions into parts reflect the natural development of this field. Part I discussesTolerance Theory and Standards which constitute the guidelines used by tolerancing practitioners. Part II isconcerned with Tolerance Representation in CAD which is required to include tolerance definitions andstandards in computerized design systems. Part III presents the Modelling of Geometric Errors which areparticularly important for evaluating critical assembly dimensions and geometrics. Part IV deals with the nextlogical step of Tolerance Analysis and Synthesis in which tolerances are specified, assessed and optimized tomeet functional requirements and ensure proper control of variability in manufactured parts and assemblies.Part V focuses on the Evaluation of Geometric Deviations which takes place during the inspection of producedparts and assemblies to ensure compliance with the designer's intent expressed in the GD&T specifications.Part VI presents Industrial Applications and CAT Systems where approaches such as those presented in earlierparts are used and implemented.

PrefacexiProfessor Hoda EIMaraghy is a professor of Industrial and Manufacturing Systems Engineering at Universityof Windsor. She held various academic positions at McMaster University and University of windsor in Canadaand Cairo University in Egypt. She is the first woman Dean of Engineering in Canada. Her research expertiseincludes design, flexible manufacturing and robotics. She is the founding Director of the IntelligentManufacturing Systems (lMS) Centre which is funded by Ontario and Canadian research organizations as wellas industry. She is an author/co-author of 220 journal and conference publications. Dr. EIMaraghy serves onseveral boards of directors, and acts as a consultant to industry in canada and internationally. She isHamilton's 1990 Woman of the Year in the Workplace, recipient of the Professional Engineers of OntarioMedal for Research and Development and a Fellow of the Canadian Society for Mechanical Engineering.

VIEW POINTS ONFUTURE DIRECTIONS IN CAT RESEARCHSome years hence, we may look back on the decade now ending as a watershed marking the end of a 200-yearera in which control mechanisms for 'form variability' in mechanical products (first gages, then accurate shopfloor measurement, followed by tolerances and CMMs) evolved from shop and drafting-room practice, and thebeginning of a new era of 'science-based' variation control. Consider: the decade opened with a 'MetrologyCrisis' traceable to the proliferation of CMMs in the 1970 and '80s; this triggered the American efforts to'mathematize' tolerancing standards at mid-decade, and the decade is ending with major reorganization of the ISOstandards community and the launching of ambitious projects aimed at rationalizing and formalizing tolerancingand conformance technologies. I see at present four streams of acitivity:I)2)3)4)maintenance and mathematization of current standards;fixing problems (e.g. with the notion of 'size') and filling gaps (e.g. getting 'statisticaltolerance'defined);comprehensive rationalization -- what ISO/TC 213 is gearing-up to do; andresearch on the 'physics' and modelling of applications.Progress -- at least evolutionary progress -- in the first two streams is almost certain. The third stream is lesspredictable, because it seems to require clumps of knowledge we don't have at present. The fourth stream iswhere the big prizes lie. Ifwe (researchers, practitioners, . all players are welcome) can produce models thatreflect a much deeper understanding of the interplay between spatial variability, assembleability, andfunctionalism, then we may finally devise really appropriate specification and control technologies for variabilityto replace today's inherited ad-hocery.Dr. Herbert VoelckerProfessor. Dept. ofMechanical EngineeringCornell University. USAThe basic purpose of dimensions and tolerances is to enable designers to specify manufacturing and assemblyrequirements of product components and assemblies that, when satisfied, will ensure the finished product willmeet its customer's requirements. Factors which also influence the presentation and interpretation of productspecifications are the current technologies that are in use for preparing designs and manufacturing, assemblingand inspecting products. Much attention has been focused on these technologies in recent times with appropriateadjustments in the dimensioning and tolerancing standards. Whilst these changes may suit the current state ofthesetechnologies there are instances where they do little to help, or in some cases even hinder the attempts of designersto clearly and concisely represent the customer or functional requirements of product designs. To address thisimbalance efforts will have to be made to better understand the process of identifying and describing productfunctional requirements. From this point a new level of compatibility will be found between functionalrequirement needs, dimension and tolerance specifications and the new manufacturing, assembly and inspectiontechnologies.Dr. Leonard E. FarmerProfessor. School ofMechanical & ManufacturingThe University ofNew South Wales. Australia

xivView Points on Future Directions in CAT ResearchThe international standardization organizations, such as ISO (International Standards Organization) and ANSI(American National Standard Institute) are devoting intensive efforts to introduce the concept of CAT in the newstandards. e.g. the ANSI Y 14.5 M -1995 on "Mathematical Definition of Dimensioning and TolerancingPrinciples" is essentially intended to develop computerized tolerancing. In ISO, a new development was initiatedby the introduction of the conceptofGPS (Geometrical Product Specification). The intention is to harmonize theactual system of standards so that no ambiguities or contradictions appear in their application. A newmethodology, called "Chain of Standards", includes all the standards pertaining to the design and manufacturingof a new product, including also techniques for measurement and estimation of their uncertainties.The recent developments in the field of a comprehensive definition of functional tolerancing should, of course,be implemented in computerized CAD/CAM systems. Unfortunately, this integration is not today verysatisfactory. An interaction between the teams active in the development of the GPS concept and the teams in thestandardization of Product Model Data, such as STEP (Standard for the Exchange of Product Model Data) orPDES (product Data Exchange) is now urgently required.In the future, the forum offered by the CAT seminars, should probably be devoted more systematically to theanalysis of the new concepts introduced by the GPS approach of ISO and the mathematization of toleranceprinciples by ANSI. The concept of "Functional Product Analysis", seems to provide an excellent guide forefficient developments in computerized tolerancing implemented in CAD/CAM systems.Dr. Roltuld D. WeillProfessor, Faculty ofMechanical EngineeringTechnion, Israel

The importance of proper geometric dimensioning and tolerancing as a means of expressing the designer's functional intent and controlling the inevitable geometric and dimensional variations of mechanical parts and assemblies, is becoming well recognized. The research efforts and innovat