Transcription

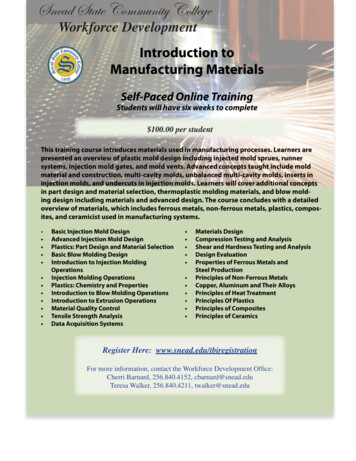

Snead State Community CollegeWorkforce DevelopmentIntroduction toManufacturing MaterialsSelf-Paced Online TrainingStudents will have six weeks to complete 100.00 per studentThis training course introduces materials used in manufacturing processes. Learners arepresented an overview of plastic mold design including injected mold sprues, runnersystems, injection mold gates, and mold vents. Advanced concepts taught include moldmaterial and construction, multi-cavity molds, unbalanced multi-cavity molds, inserts ininjection molds, and undercuts in injection molds. Learners will cover additional conceptsin part design and material selection, thermoplastic molding materials, and blow molding design including materials and advanced design. The course concludes with a detailedoverview of materials, which includes ferrous metals, non-ferrous metals, plastics, composites, and ceramicist used in manufacturing systems. Basic Injection Mold DesignAdvanced Injection Mold DesignPlastics: Part Design and Material SelectionBasic Blow Molding DesignIntroduction to Injection MoldingOperationsInjection Molding OperationsPlastics: Chemistry and PropertiesIntroduction to Blow Molding OperationsIntroduction to Extrusion OperationsMaterial Quality ControlTensile Strength AnalysisData Acquisition Systems Materials DesignCompression Testing and AnalysisShear and Hardness Testing and AnalysisDesign EvaluationProperties of Ferrous Metals andSteel ProductionPrinciples of Non-Ferrous MetalsCopper, Aluminum and Their AlloysPrinciples of Heat TreatmentPrinciples Of PlasticsPrinciples of CompositesPrinciples of CeramicsRegister Here: www.snead.edu/tbiregistrationgFor more information, contact the Workforce Development Office:Cherri Barnard, 256.840.4152, cbarnard@snead.eduTeresa Walker, 256.840.4211, twalker@snead.edu

Introduction to Manufacturing MaterialsThis training course introduces materials used in manufacturing processes. Learners arepresented an overview of plastic mold design, including injected mold sprues, runner systems,injection mold gates and mold vents. Advanced concepts taught include mold material andconstruction, multi-cavity molds, unbalanced multi-cavity molds, inserts in injection molds andundercuts in injection molds. Learners will cover additional concepts in part design and materialselection, thermoplastic molding materials, and blow molding design, including materials andadvanced design. The course concludes with a detailed overview of materials, which includesferrous metals, non-ferrous metals, plastics, composites and ceramicist used in manufacturingsystems.Outline1. Basic Injection Mold DesignSegment 1 - Introduction to Injection MoldsObjective 1 - Describe the Function and Operation of an Injection Molding ProcessObjective 2 - Describe the Functions of Seven Basic Components of an Injection MoldObjective 3 - Describe the Function of Three Additional Components of an Injection MoldActivity 1 - Identify Seven Components of an Injection MoldSelf Review 1Segment 2 - Injection Mold Sprues and Runner SystemsObjective 4 - Describe the Operation of a Sprue Bushing in an Injection MoldObjective 5 - Describe the Operation of a Runner in an Injection MoldObjective 6 - Describe the Operation of a Cold-Slug Well in a Runner SystemObjective 7 - Describe the Operation of Three Types of Runner ShapesObjective 8 - Describe Two Methods of Determining the Size of a RunnerSkill 1 - Determine the Runner and Sprue Diameter Given a Specific Plastics MoldSelf Review 2Segment 3 - Injection Mold GatesObjective 9 - Describe the Operation of Three Types of Gates in an Injection Mold and Give an Application ofEachObjective 10 - Describe How Gate Size Is Determined for a MoldSkill 2 - Determine the Gate Size and Location for an Injection MoldSelf Review 3Segment 4 - Injection Mold VentsObjective 11 - Describe the Operation of Two Types of Vents and Give an Application of EachObjective 12 - Describe How a Vent Size Is Determined for an Injection MoldObjective 13 - Describe How to Draw CAD/CAM Geometry for Runners, Gates, and VentsSelf Review 42. Advanced Injection Mold DesignSegment 1 - Mold Material and ConstructionObjective 1 - Describe Three Methods of Creating a MoldObjective 2 - Describe Six Common Materials Used to Create MoldsIntroduction to Manufacturing Materials1 Page

Skill 1 - Select a Mold Material Given a Mold Usage ScenarioObjective 3 - Describe How to Determine the Size of a MoldSkill 2 - Determine the Size of a Mold Given a Mold DesignSelf Review 1Segment 2 - Multi-Cavity MoldsObjective 4 - Describe the Function of a Multi-Cavity Mold and Give an ApplicationObjective 5 - Describe the Functions of Primary Runners, Secondary Runners, and Tertiary RunnersObjective 6 - Describe How to Size Runners for a Multi-Cavity MoldSelf Review 2Segment 3 - Unbalanced Multi-Cavity MoldsObjective 7 - Describe the Function of Balanced and Unbalanced Multi-Cavity Molds and Give an Applicationof EachObjective 8 - Describe How to Size a Runner System for an Unbalanced Multi-Cavity MoldSkill 3 - Determine Runner Sizes for an Unbalanced Multi-Cavity MoldSelf Review 3Segment 4 - Inserts in Injection MoldsObjective 9 - Describe the Function of Mold InsertsObjective 10 - Describe Three Methods Used to Add Inserts into a Plastics PartSelf Review 4Segment 5 - Undercuts in Injection MoldsObjective 11 - Describe How to Design Undercuts into a MoldSelf Review 53. Plastics: Part Design and Material SelectionSegment 1 - Product DesignObjective 1 - Describe the Difference between a Product and a PartObjective 2 - Describe Four Product Design Rules That Must Be Considered When Designing a New ProductSelf Review 1Segment 2 - Part Design-Shrinkage and WarpageObjective 3 - Describe Four Part Design Rules That Must Be Considered When Designing a New Part or MoldObjective 4 - Describe Material Shrinkage and How It Influences Mold DesignSelf Review 2Segment 3 - Thermoplastic Molding MaterialsObjective 5 - Describe the Properties of Nine Commonly Used Thermoplastics and Give an Application ofEachObjective 6 - Define the Terms Crystalline and Amorphous Polymers and Give Four Examples of EachObjective 7 - Describe the General Properties of Crystalline and Amorphous PolymersSkill 1 - Select a Plastics Material for an Application Given an ExampleSelf Review 34. Basic Blow Molding DesignSegment 1 - Introduction to Blow MoldsObjective 1 - Describe the Function and Operation of a Blow Molding OperationObjective 2 - Describe the Six Components of a Blow MoldSelf Review 1Segment 2 - Blow Mold DesignObjective 3 - Describe Five Applications for a Blow Molding OperationObjective 4 - Describe Four Guidelines of Blow Mold DesignSelf Review 2Segment 3 - Blow Molding: Materials and Advanced DesignObjective 5 - Describe Five Common Materials Used in the Blow Molding ProcessObjective 6 - Describe the Function of Regrind in a Blow Molding ApplicationObjective 7 - Describe How Material Shrinkage Affects Mold DesignObjective 8 - Describe Three Advanced Design Features for a Blow MoldSelf Review 3Introduction to Manufacturing Materials2 Page

5. Introduction to Injection Molding OperationsSegment 1 - Injection Molding ProcessObjective 1 - Define the Terms Plastics and PlasticObjective 2 - Describe the Importance of PlasticsObjective 3 - Describe the Operation of Two Types of Plastics Injection Molding ProcessesObjective 4 - Describe the Six Main Parts of an Injection Molding MachineSelf Review 1Segment 2 - Molding: Material and Machine SafetyObjective 5 - Describe the Function of a Safety Data Sheet (SDS)Skill 1 - Read and Interpret a Safety Data SheetObjective 6 - Describe How to Request a Safety Data SheetSkill 2 - Write a Request for a Safety Data SheetObjective 7 - Describe Eight Safety Rules to Follow When Working around Plastics Molding MachinesSelf Review 2Segment 3 - Molding OperationsObjective 8 - Describe the Functions of Seven Basic Components of an Injection MoldObjective 9 - Describe the Function of Three Additional Components of an Injection MoldObjective 10 - Describe the Importance of Correct Alignment between the Nozzle and the MoldSelf Review 3Segment 4 - Molding Problems and SolutionsObjective 11 - Describe Five Causes of Non-Fill during an Injection Molding ProcessObjective 12 - Describe Three Causes of Weld Lines during an Injection Molding ProcessObjective 13 - Describe Three Causes of Burn Marks during an Injection Molding ProcessObjective 14 - Describe Four Causes of Flash during an Injection Molding ProcessSelf Review 46. Injection Molding OperationsSegment 1 - InsertsObjective 1 - Describe the Function of Three Types of Inserts Used in Plastics Parts and Give an Applicationof EachSelf Review 1Segment 2 - Threads and Multiple Part MoldsObjective 2 - Describe Three Methods Used to Create Internal Threaded Features in a Plastics PartObjective 3 - Describe Two Methods Used to Create External Threaded Features on a Plastics PartObjective 4 - Describe the Function and Operation of a Multi-Cavity MoldObjective 5 - Describe the Function of a Runner SystemObjective 6 - Describe the Function of a Gate in an Injection Molding OperationSelf Review 2Segment 3 - Integral HingeObjective 7 - Describe the Function and Operation of a Hinge on a Plastics PartSelf Review 3Segment 4 - System PurgingObjective 8 - Describe Two Methods Used to Purge a Plastics MachineSelf Review 47. Plastics: Chemistry and PropertiesSegment 1 - Basic ChemistryObjective 1 - Define an AtomObjective 2 - Describe the Arrangement of Electrons around the NucleusObjective 3 - Describe the Operation of Valence ElectronsObjective 4 - Define Elements, Compounds, and MoleculesObjective 5 - Describe Two Types of Primary Bonds and Give an Example of EachObjective 6 - Describe Three Types of Secondary BondsObjective 7 - Describe Two Types of Hydrocarbons: Aliphatic and CyclicSelf Review 1Introduction to Manufacturing Materials3 Page

Segment 2 - PolymersObjective 8 - Define a Polymer and PolymerizationObjective 9 - Describe Two Types of Polymers, Elastomers and Plastics, and Give an Example of EachSelf Review 2Segment 3 - Properties of PlasticsObjective 10 - Describe Six Types of Plastics PropertiesObjective 11 - Describe the Properties of Two Types of Plastics, Thermoplastics and ThermosetsObjective 12 - Describe the Characteristics of Four Common Thermoplastics and Give an Application of EachObjective 13 - Describe the Characteristics of Four Common Thermosets and Give an Application of EachSkill 1 - Select a Plastics for an Application Based on Its PropertiesSelf Review 3Segment 4 - Manufacturing Characteristics of PlasticsObjective 14 - Describe the Effect of Shrinkage on Plastics and Explain How It Is MeasuredObjective 15 - Describe the Effect of Warpage on PlasticsSelf Review 48. Introduction to Blow Molding OperationsSegment 1 - Blow Molding ProcessObjective 1 - Describe Two Types of Blow Molding ProcessesObjective 2 - Describe Six Components of a Blow Molding MachineSelf Review 1Segment 2 - Blow Molding Safety and OperationObjective 3 - Describe Eight Safety Rules to Follow around a Blow Molding MachineObjective 4 - Describe the Function and Operation of a Blow MoldSelf Review 2Segment 3 - Blow Molding TroubleshootingObjective 5 - Describe Seven Causes of an Incomplete Blow Molding OperationObjective 6 - Describe the Importance of Wall Thickness in a Blow Molded PartObjective 7 - Describe the Effect of Weld Strength on a Blow Molded PartSelf Review 39. Introduction to Extrusion OperationsSegment 1 - Extrusion ProcessObjective 1 - Describe Four Types of Extruded ProductsObjective 2 - Describe Seven Components of an Extrusion MachineSelf Review 1Segment 2 - Extrusion Safety and OperationObjective 3 - Describe Eight Safety Rules to Follow around an Extrusion MachineObjective 4 - Describe the Function and Operation of an Extrusion DieSelf Review 2Segment 3 - Extrusion TroubleshootingObjective 5 - Describe Three Causes of Uneven Surface Finish on an Extruded PartObjective 6 - Describe Three Causes of Burns on an Extruded PartObjective 7 - Describe Three Causes of Thin Part Diameter on an Extruded PartSelf Review 310. Material Quality ControlSegment 1 - Material Quality ConceptsObjective 1 - Explain How Material Characteristics Are Maintained in a ProcessObjective 2 - List and Describe Three Types of Component FailureObjective 3 - Describe the Function of Component Failure Analysis and PreventionObjective 4 - List and Describe the Four Steps Used to Analyze a Component FailureSelf Review 1Segment 2 - The Cause and Effect DiagramObjective 5 - Describe the Function and Construction of a Cause and Effect DiagramObjective 6 - Describe How to Construct a C&E DiagramIntroduction to Manufacturing Materials4 Page

Activity 1 - Create a Cause and Effect Diagram as Part of a Brainstorming ProcessSelf Review 2Segment 3 - Non-Destructive TestingObjective 7 - List and Describe the Application of Six Types of Non-Destructive TestingSelf Review 3Segment 4 - Destructive TestingObjective 8 - List and Describe the Application of Seven Types of Destructive TestingSkill 1 - Select One or More Testing Methods Given a Description of Component FailureSelf Review 411. Tensile Strength AnalysisSegment 1 - Tensile CharacteristicsObjective 1 - Define Stress and Explain Its ImportanceSkill 1 - Calculate Stress Given a Set of DataObjective 2 - Define Strain and Explain Its ImportanceSkill 2 - Calculate Strain Given a Set of DataObjective 3 - List and Describe the Five Components of a Stress/Strain Diagram for a Part under TensionSelf Review 1Segment 2 - Tensile TestingObjective 4 - List and Describe Two Types of Tensile Testing MachinesObjective 5 - List and Describe Two Methods of Collecting Data from a Tensile TestSelf Review 2Segment 3 - Tensile AnalysisObjective 6 - Define Modulus of Elasticity and Explain Its ImportanceSkill 3 - Use the Modulus of Elasticity to Calculate Stress, Strain, and ElongationSelf Review 312. Data Acquisition SystemsSegment 1 - Introduction to Data Acquisition SoftwareObjective 1 - Describe the Function of a Data Acquisition System and Give Two AdvantagesObjective 2 - Describe the Function of Four Components of a Data Acquisition SystemSelf Review 1Segment 2 - TransducersObjective 3 - Define Sensitivity and Explain Its ImportanceSkill 1 - Calculate Transducer Sensitivity Given Measurement DataObjective 4 - Describe the Operation of a Linear PotentiometerObjective 5 - Describe the Operation of a Pressure TransducerSelf Review 2Segment 3 - Data Acquisition OperationObjective 6 - List and Describe Two Types of Sampling MethodsSelf Review 3Segment 4 - Data Acquisition AnalysisObjective 7 - Describe the Function of a Data Acquisition FormulaSelf Review 413. Materials DesignSegment 1 - Material Science ConceptsObjective 1 - Define a Metal and List Five PropertiesObjective 2 - Define an Alloy and Explain Its ImportanceObjective 3 - Describe the Properties of Four Common Alloys and Give an Application of EachSelf Review 1Segment 2 - Identification SystemsObjective 4 - Describe an Identification System Used to Identify SteelObjective 5 - Describe the AA Identification System Used to Identify Aluminum AlloysObjective 6 - Describe the CDA Identification System Used to Identify CopperObjective 7 - Describe the Unified Numbering System for Material Identification and Explain Its PurposeIntroduction to Manufacturing Materials5 Page

Skill 1 - Identify the Composition of an Alloy Given Its UNS NumberSelf Review 2Segment 3 - Alloy DesignObjective 8 - List and Describe Three Mechanical Properties of a MaterialObjective 9 - List and Describe Four Physical Properties of a MaterialObjective 10 - List and Describe Seven Steel Alloying Elements and Give an Application of EachObjective 11 - List and Describe Four Aluminum Alloying Elements and Give an Application of EachObjective 12 - Describe the Function of Alloying Elements in CopperSelf Review 3Segment 4 - Heat TreatingObjective 13 - Define Heat Treating and Explain Its ImportanceObjective 14 - List and Describe Four Types of Heat Treating and Give an ApplicationSelf Review 4Segment 5 - Material Field IdentificationObjective 15 - List Three Methods Used to Identify MaterialsObjective 16 - List and Describe Four Types of Field Tests Used to Identify MaterialsSelf Review 514. Compression Testing and AnalysisSegment 1 - Compression StrengthObjective 1 - Define Compression Strength and Explain Its ImportanceObjective 2 - Describe How Stress Is Determined for a Part under a Compression LoadObjective 3 - Describe How Strain Is Determined for a Part under a Compression LoadSkill 1 - Calculate the Compression Stress and Strain Given a Set of DataSelf Review 1Segment 2 - Compression TestingObjective 4 - List and Describe the Five Areas of a Stress/Strain Diagram for a Part under a CompressionLoadSelf Review 2Segment 3 - Compression AnalysisSkill 2 - Use the Modulus of Elasticity to Calculate Stress, Strain, and CompressionSelf Review 315. Shear and Hardness Testing and AnalysisSegment 1 - Shear TestingObjective 1 - Define Shear Strength and Explain Its ImportanceObjective 2 - Describe Two Applications of Shear StressSelf Review 1Segment 2 - Shear AnalysisObjective 3 - List Two Types of Shear Stresses and Give an Example of EachObjective 4 - Describe How to Calculate Shear StressSkill 1 - Calculate Shear Stress Given a Set of DataSelf Review 2Segment 3 - Hardness TestingObjective 5 - Define Material Hardness and Explain Its ImportanceObjective 6 - List and Describe Three Methods of Hardness TestingObjective 7 - Describe Three Types of Indention Hardness Tests and Give an Advantage of EachSelf Review 3Segment 4 - Hardness AnalysisObjective 8 - Describe How the Brinell Hardness Number Is Used to Determine Ultimate Tensile StrengthSkill 2 - Calculate Tensile Strength Given a Brinell Hardness NumberSelf Review 416. Design EvaluationSegment 1 - Design ConsiderationsObjective 1 - List and Describe Three Ways to Reduce Stress in the Design of a PartIntroduction to Manufacturing Materials6 Page

Objective 2 - Define Safety FactorSkill 1 - Calculate a Safety Factor for a DesignSelf Review 1Segment 2 - Models and PrototypesObjective 3 - Describe the Function of a ModelObjective 4 - Describe the Function of a PrototypeObjective 5 - Describe How to Determine Testing Conditions for a ModelSkill 2 - Calculate the Force to Be Applied to a Model in Order to Test a DesignSelf Review 2Segment 3 - Introduction to the PolariscopeObjective 6 - Describe the Function and Operation of a PolariscopeObjective 7 - Explain Why Photoelastic Materials Are Used with a PolariscopeObjective 8 - Describe How to Obtain the Isoclinic and Isochromatic Patterns Used to Interpret StressObjective 9 - Define the Isochromatic Fringe OrderSelf Review 3Segment 4 - Polariscope AnalysisObjective 10 - Describe How to Calibrate a Model Material for a PolariscopeSkill 3 - Calibrate a Photoelastic MaterialObjective 11 - Describe How to Calculate Stresses in a ModelSkill 4 - Calculate the Stress in the Photoelastic Tensile SpecimenSelf Review 417. Properties of Ferrous Metals and Steel ProductionSegment 1 - Introduction to Ferrous MetalsObjective 1 - Define Ferrous Metal and Describe Two TypesObjective 2 - Describe the Properties of MetalsSegment 2 - Steelmaking ProcessObjective 3 - Define Iron Ore and Describe How It Is Mined and ProcessedObjective 4 - Define Pig Iron and Describe How It Is MadeObjective 5 - Describe How Pig Iron Is Processed into SteelObjective 6 - Describe Four Methods for Shaping SteelSegment 3 - Properties of Ferrous MetalsObjective 7 - Identify Five Mechanical Properties of MetalObjective 8 - Describe Metal Strength and Explain How It Is TestedObjective 9 - Describe Metal Ductility and Explain How It Is TestedObjective 10 - Describe Metal Machinability and Explain How It Is TestedObjective 11 - Describe Metal Hardenability and Explain How It Is TestedObjective 12 - Describe Corrosion Resistance and Explain How It Is TestedObjective 13 - Describe How Steel Forming Processes Can Affect Its PropertiesSegment 4 - Elements Used in Steel ProductionObjective 14 - Describe the Alloying Elements Commonly Used in Steel ProductionObjective 15 - Describe the Effects of 10 Elements on Steel ProductionSegment 5 - Classes of Ferrous MetalsObjective 16 - Describe the Four Classes of Ferrous MetalsObjective 17 - Describe Four Groups of Carbon SteelObjective 18 - Describe Four Groups of Alloy SteelObjective 19 - Describe Four Common Grades of Tool SteelObjective 20 - Describe Four Groups of Stainless SteelObjective 21 - List the Five Groups of Cast Iron and Discuss Two Major TypesSegment 6 - Ferrous Metal SpecificationsObjective 22 - Describe Steel Nomenclature and Specification Systems and List Five TypesObjective 23 - Describe the AISI/SAE Nomenclature SystemObjective 24 - Describe the UNS Nomenclature SystemObjective 25 - Describe How Ferrous Metals Are SpecifiedIntroduction to Manufacturing Materials7 Page

18. Principles of Non-ferrous MetalsSegment 1 - The Forming Processes of Non-Ferrous MetalsObjective 1 - Describe the Importance of Non-Ferrous Metals in ManufacturingObjective 2 - Describe the Steps Necessary to Prepare Non-Ferrous Metals for Commercial PurposesObjective 3 - Describe the Processes for Extracting Aluminum and CopperObjective 4 - Describe Alloying and the Forming ProcessObjective 5 - Describe Four Common Casting ProcessesObjective 6 - Describe Four Common Wrought Treatment ProcessesObjective 7 - Describe Four Methods of TemperingSegment 2 - Physical Properties of Non-Ferrous MetalsObjective 8 - Describe the Physical Properties of Non-Ferrous MetalsObjective 9 - Describe How to Test the Mechanical Properties of Non-Ferrous MetalObjective 10 - Describe How Forming Processes Can Affect Non-Ferrous Metals' Physical Properties19. Copper, Aluminum and Their AlloysSegment 1 - Elements of Aluminum and Aluminum AlloysObjective 1 - Describe How Alloys Effect the Physical Properties of Non-Ferrous MetalObjective 2 - Describe How Alloys Are Used to Change the Physical Properties of AluminumObjective 3 - Describe Two Classes of AluminumSegment 2 - Elements of Copper and Copper AlloysObjective 4 - Describe How Alloys Are Used to Change the Physical Properties of CopperObjective 5 - Describe Two Classes of CopperObjective 6 - Describe the Unified Numbering System for Non-Ferrous MetalSegment 3 - Copper and Aluminum SpecificationsObjective 7 - Describe the Aluminum Association (AA) NomenclatureObjective 8 - Describe Non-Ferrous Metal Specifications20. Principles of Heat TreatmentSegment 1 - Introduction to Heat TreatingObjective 1 - Define Heat Treating and Explain Its ImportanceObjective 2 - Describe Six Types of Heat Treating ProcessesObjective 3 - Describe the Hardening Heat Treating ProcessesObjective 4 - Describe the Quenching ProcessesObjective 5 - Describe the Annealing ProcessObjective 6 - Describe TemperingObjective 7 - Describe NormalizingObjective 8 - Describe Stress RelievingObjective 9 - Describe Characteristics Used to Select a Heat Treatment for an ApplicationObjective 10 - Describe the History of the Heat Treating ProcessSelf Review 1Segment 2 - The Heat Treating ProcessObjective 11 - Describe the Chemical Changes of Ferrous Metal During Heat TreatmentObjective 12 - Describe the Chemical Changes of Non-Ferrous Metal During Heat TreatmentSelf Review 2Segment 3 - Manufacturing Heat Treating ProcessesObjective 13 - Describe Batch Production Heat TreatingObjective 14 - Describe Continuous Production Heat TreatingSelf Review 3Segment 4 - Heat Treat Hardness ClassificationObjective 15 - Describe Heat Treated Metal TestingObjective 16 - Describe the Types of Organizations that Govern Heat Treating StandardsObjective 17 - Describe the Nomenclature System for Heat Treating StandardsSelf Review 421. Principles of PlasticsSegment 1 - Introduction to PlasticsIntroduction to Manufacturing Materials8 Page

Objective 1 - Define Plastics and Explain Their ImportanceObjective 2 - Describe the Properties of Two Types of Plastics: Thermoplastics and ThermosetsObjective 3 - Describe the Characteristics of Four Common ThermoplasticsObjective 4 - Describe the Characteristics of Four Common ThermosetsObjective 5 - Describe the History of PlasticsSelf Review 1Segment 2 - Plastics Making ProcessObjective 6 - Define a Polymer and PolymerizationObjective 7 - Describe How Ethylene and Propylene Are ObtainedObjective 8 - Describe the Basic Plastics-Making ProcessSelf Review 2Segment 3 - Properties of PlasticsObjective 9 - Describe the Mechanical Properties of PlasticsObjective 10 - Describe the Physical Properties of PlasticsObjective 11 - Describe the Thermal Properties of PlasticsObjective 12 - Describe the Optical Properties of PlasticsObjective 13 - Describe the Electrical Properties of PlasticsObjective 14 - Describe the Environmental Properties of PlasticsSelf Review 3Segment 4 - Plastics Manufacturing ProcessesObjective 15 - Describe the Injection Molding ProcessObjective 16 - Describe the Blow Molding ProcessObjective 17 - Describe the Extrusion ProcessObjective 18 - Describe the Manufacturing Characteristics of PlasticsObjective 19 - Describe Post-Manufacturing ProcessesSelf Review 4Segment 5 - Plastics NomenclatureObjective 20 - Describe the ASTM Nomenclature System for PlasticsObjective 21 - Describe the ISO Nomenclature System for PlasticsSelf Review 5Segment 6 - Environmental ConsiderationsObjective 22 - Describe the Impact of Plastics on the EnvironmentObjective 23 - Describe How Recycling Reduces Environmental ImpactObjective 24 - Describe How the Plastics Industry Is Reducing Its Environmental ImpactSelf Review 622. Principles of CompositesSegment 1 - Introduction to CompositesObjective 1 - Define Composites and Explain Their ImportanceObjective 2 - Describe Types of Constituent Materials That Make up a CompositeObjective 3 - Describe Two Categories of Fiber-Reinforced MaterialsObjective 4 - Describe the History of CompositesSelf Review 1Segment 2 - Properties of CompositesObjective 5 - Describe the Mechanical Properties of CompositesObjective 6 - Describe the Thermal Properties of CompositesObjective 7 - Describe the Electrical Properties of CompositesObjective 8 - Describe the Environmental Properties of CompositesSelf Review 2Segment 3 - Composite Manufacturing ProcessObjective 9 - Describe the Two Main Manufacturing Steps of a Composite ProductObjective 10 - Describe the Hand Lay-up ProcessObjective 11 - Describe the Spray-up ProcessObjective 12 - Describe the Filament Winding ProcessObjective 13 - Describe the Resin Transfer Molding ProcessIntroduction to Manufacturing Materials9 Page

Objective 14 - Describe Three Types of Curing Processes for Composite MaterialsObjective 15 - Describe Post-Curing Manufacturing Processes for CompositesSelf Review 3Segment 4 - Environmental Considerations for CompositesObjective 16 - Describe the Impact of Composites on the EnvironmentObjective 17 - Describe How the Composite Industry Is Reducing Its Environmental ImpactSelf Review 423. Principles of CeramicsSegment 1 - Introduction to CeramicsObjective 1 - Define Ceramics and Explain Its ImportanceObjective 2 - Describe the Characteristics of Four Types of CeramicsObjective 3 - Describe the Characteristics of Two Types of GlassObjective 4 - Describe the Characteristics of Four Common Categories of Clay ProductsObjective 5 - Describe the Characteristics of Three Classes of RefractoriesObjective 6 - Describe the Characteristics of Five Types of Advanced CeramicsObjective 7 - Describe the History of CeramicsSelf Review 1Segment 2 - Properties of CeramicsObjective 8 - Describe the Mechanical Properties of CeramicsObjective 9 - Describe the Physical Properties of CeramicsObjective 10 - Describe the Thermal Properties of CeramicsObjective 11 - Describe the Electrical Properties of CeramicsObjective 12 - Describe the Environmental Properties of CeramicsSelf Review 2Segment 3 - Ceramic Making ProcessObjective 13 - Describe the Basic Ceramics Material Making ProcessObjective 14 - Describe the Basic Operation of MillingObjective 15 - Describe the Basic Operation of BatchingObjective 16 - Describe the Basic Operation of MixingObjective 17 - Describe the Basic Operation of FormingObjective 18 - Describe the Basic Operation of DryingObjective 19 - Describe the Basic Operation of FiringObjective 20 - Describe the Advanced Ceramics Making ProcessSelf Review 3Segment 4 - Ceramics Manufacturing ProcessesObjective 21 - Describe Ceramic Forming ProcessesObjective 22 - Describe the Pressing ProcessObjective 23 - Describe the Extrusion ProcessObjective 24 - Describe the Injection Molding ProcessObjective 25 - Describe the Drain and Solid Casting ProcessesObjective 26 - Describe the Manufacturing Characteristics of CeramicsObjective 27 - Describe Post-Manufacturing ProcessesSelf Review 4Introduction to Manufacturing Materials10 P a g e

Objective 1 - Describe the Function and Operation of an Injection Molding Process Objective 2 - Describe the Functions of Seven Basic Components of an Injection Mold . Objective 4 - Describe Four Guidelines of Blow Mold Design Self Review 2 Segment 3 - Blow Molding