Transcription

Materials DesignFrom violins tosuperconducting magnetsDr Susie SpellerDepartment of Materials, University of Oxford

Overview What is Materials Science? Case studies– the violin– superconducting magnets Curriculum links Outreach activities

Case Study 1: the violin

The Violin Purpose of the box is totransmit vibrations ofthe strings into soundwaves we can hear. Why is it this complexshape? Is wood the bestmaterial to use for thebox?“The violin explained”, J. Beament

Static Forces10KgString tension producesa downwards force ofabout 10Kg onto thefront of the violin. So we need the front plate to be stiff along the length of the violin so that it doesnot bend inwards under the weight of the strings.Can achieve this by:1) Choice of material𝑠𝑡𝑟𝑒𝑠𝑠 𝜎 Using an intrinsically stiff material with high Young’s Modulus 𝐸 𝑠𝑡𝑟𝑎𝑖𝑛 𝜀 .2) Engineering design Using a thicker cross section of material – but this increases mass. Shaping the front plate into an arched shape – same principle as a bridge.“The violin explained”, J. Beament

How is violin sound produced?When a string is plucked, standingwaves are set up with frequenciesdetermined by the string lengthand tension.Fundamentalfrequency1 𝑇𝑓 2𝐿 𝜇String lengthStringtensionMass perunit lengthIn fact, the actual wave in thestring is a sum of the fundamentalfrequency with a series of higherharmonics. but the string itself makes verylittle sound!

How is violin sound produced?String vibration from side to side makes bridge rock.Sets up vibrations in the front plate of the violin bodyproducing sound (pressure) waves.To make a violin sound loud, we want to maximise energytransfer from strings to body.Some resonant vibrationmodes of a model(symmetric) violin body.Woodhouse Rep. Prog. Phys. 77(2014) 115901

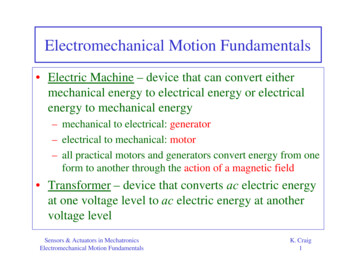

Impedance matchingEvery oscillator has an impedance – essentiallyhow much force is required to make the systemvibrate with a given amplitude. Make strings heavier Make body lighterTo maximise energy transfer from one vibratingobject to another need impedance matching.The speed of sound in a material is very important for determining how sound will betransmitted through the body.Speed of sound in a material:𝑐 𝐸𝜌Young’s Modulus(stiffness)DensitySound radiation parameter:R 𝑐𝜌 1𝐸 23𝜌 2 maximisethis quantity tomaximiseloudness

IncreasingRMaterials SelectionLines ofconstantsoundradiation ratio𝑅 𝐸123𝜌 231log 𝑅 log 𝐸 2 log 𝜌 21 log 𝐸 3 log 𝜌2log 𝐸 3 log 𝜌 2 log 𝑅𝑦 𝑚𝑥 𝑐Woodhouse Rep. Prog. Phys. 77 (2014) 115901

Materials SelectionAverage propertiesEngineers – use thesematerials charts tochoose best fit for a givenapplicationMaterials scientists –interested in whydifferent materials havedifferent properties andhow to design newmaterials with betterproperties.

Spruce microstructureScanning electron micrographs (taken 1993 with A. Heaver, Eng. Dept., Cambridge)Mechanical properties governed by:1) Cell wall mechanical properties2) Microstructure – tubular arrangement of cells with air gaps like foamstructures.500mm

Cell wall propertiesCell walls have high Young’s Modulus because theyconsist of long cellulose fibres wound helically.The stiff cellulose fibres are embedded in softerhemi-cellulose and lignin, increasing toughness carbon fibre reinforced composites are based onthe same principle.MaterialmonomerPolymer 000CrystallineStrongStiffHemi-celluloseGlucose, xyloseetc500-3,000AmorphousWeakSoft

AnisotropyThe Young’s Modulus of spruce is very different along the grain compared to acrossthe grain this directional behaviour is known as anisotropy.Along the grainAcross the grainDeformation along the grain is difficultbecause it involves stretching the strongcovalent bonds in the cellulose ntification/chem922/chem922net.htmlAcross the grain, structure candeform by bending cell walls ratherthan stretching the carbon backboneof the cellulose molecules.Ashby and Jones, Emgineering Materials vol 2

Man-made alternative? Responds over a wide range of audiblefrequencies. All have similar overall shape, particularlylow frequency resonances. The fine scale wiggles are different. Rich tone achieved because somefrequencies (harmonics) sound strongerthan others, but need to avoid any verysharp resonances as these are difficult forthe player to control.Response curves of 5 violinsMaterials selection criterionFormulaSound radiation parameter1𝑅 𝐸Stiffness anisotropy ratioFundamental frequency forgiven shape of plateValue for spruce𝐸𝑎𝑛𝑖𝑠𝑜𝑡𝑟𝑜𝑝𝑦 𝑓 𝐴Woodhouse Rep. Prog. Phys. 77 (2014) 6Thickness t 3mm𝑓 𝐴 0.52

Carbon-fibre reinforced composite1. CFRP has next highest sound radiationcoefficient after wood (excluding foams asthey are unsuitable for processingreasons).

Carbon-fibre reinforced composite1. CFRP has next highest sound radiationcoefficient after wood (excluding foams asthey are unsuitable for processingreasons).2. To achieve the same anisotropy ratio asspruce in CFRP, we need to load thepolymer with the right amount of carbonfibres (Volume fraction Vf 0.13).Spruce

Carbon-fibre reinforced composite1. CFRP has next highest sound radiationcoefficient after wood (excluding foams asthey are unsuitable for processingreasons).2. To achieve the same anisotropy ratio asspruce in CFRP, we need to load thepolymer with the right amount of carbonfibres (Volume fraction Vf 0.13).3. With 𝑉𝑓 0.13, to match the resonantfrequencies the mass of the front platewill be 2.7 times the mass of the spruceequivalent too heavy.Rule of mixtures for Vf 0.13𝐸𝐶𝐹𝑅𝑃 53𝐺𝑃𝑎𝜌𝐶𝐹𝑅𝑃 1.25𝑀𝑔𝑚𝑓𝐶𝐹𝑅𝑃 𝐴𝐸𝑎𝑙𝑜𝑚𝑔 312𝑡𝐶𝐹𝑅𝑃𝜌 A 206 𝑡𝐶𝐹𝑅𝑃 A 0.52 𝑓𝑠𝑝𝑟𝑢𝑐𝑒𝑡𝐶𝐹𝑅𝑃 2.5𝑚𝑚𝑚𝑎𝑠𝑠𝐶𝐹𝑅𝑃 2.7 𝑚𝑎𝑠𝑠𝑠𝑝𝑟𝑢𝑐𝑒

Carbon-fibre reinforced composite1. CFRP has next highest sound radiationcoefficient after wood (excluding foams asthey are unsuitable for processingreasons).2. To achieve the same anisotropy ratio asspruce in CFRP, we need to load thepolymer with the right amount of carbonfibres (Volume fraction Vf 0.13).CFRPCardboardCFRP3. With 𝑉𝑓 0.13, to match the resonantfrequencies the mass of the front platewill be 2.7 times the mass of the spruceequivalent too heavy.To make a material with the required mechanical properties need to sandwich a low density material (cardboard) between CFRP sheets.

ArchingLong fibres- Good stiffness of theplate along length ofviolin to withstandstring tensionShort fibres- Greater flexibility toimprove resonantpropertiesJ.Barker, Violin making: a practical guide

CracksThe microstructureof wood such asspruce means thatcracks can easilypropagate along thegrain.F-holesPurflingcrackgrain

Case study 2:superconducting magnets

Superconducting Magnets Electrical currents create magnetic fieldsSuperconductors offer: Zero resistance Larger currents Higher magnetic fields Cheaper operation A uniform field is produced inside along coil of wireB Imagneticfieldcurrent To generate large magnetic fields weneed large onductingmagnet

Superconducting MaterialsBSCCO2223NbTiBSCCO-2212YBCO BSCCO2212L N2MgB2Nb3SnNb3SnBSCCO-2223NbTiYearMgB2Only six different compounds are commerciallyavailable in wire formYBCO

NbTi: the workhorse superconductor3.5T MRI magnetCritical Field /TNb-47wt%TiCritical Temperature /K Nb is a ductilemetal – easy todraw into wires. Reasonablecritical temperature. Alloying with Tienhances maximummagnetic field toover 10T.NbTiPROBLEM:Perfect NbTiLow current

High CurrentsFlux orNormalconductorcore Magnetic field penetrates asuperconductor in a lattice of “flux lines”. The core of the flux line becomes anormal conductor. Each flux line contains a specific amountof magnetic flux (a flux quantum). The spacing of flux lines decreases withapplied magnetic field.Lorentz forceTop view micrographshowing flux lattice[DOE report of the basic energy sciencesworkshop on superconductivity, 2006] Electrical currents produce a forces on flux lines. Movement of flux lines dissipates energy. To get large currents in high magnetic fields weneed to “pin” the flux lines strongly.Optimum pinning from “normal” defects about thesame size and spacing as the flux lines

Chemical uniformity Minimise chemical variations in NbTi matrixto control size and distribution of nonsuperconducting particles.High gradeNbTi( 1%Ti)Heat treatment Wide range of b compositions naturally formduring solidification[Lee]Chemical etching used to revealvariations in Ti content in opticalmicrograph.High grade (expensive) NbTiproduced by : Repeated arc melting Heat treatment in b phaseregion Using high purity startingmaterials

Thermo-mechanical processFabricationstepsLee and Larbalestier http://fs.magnet.fsu.edu/ lee/pubs/pub691s.pdf Multistage mechanicaldeformation followedby heat treatment toproduce fine scale twophase microstructure The deformation straininfluences the finalscale of themicrostructure

Optimised microstructurea-TiTypicalspacingof fluxlinesb-NbTi Thermo-mechanical process designed to optimise thematerial for a specific application (i.e. a particular magneticfield)[Lee]

Wire processingCast high quality NbTi billetWrap in Nb foil to prevent Tireacting with Cu sheath[Courtesy of Oxford Instruments]Insert inside Cu stabiliserRamExtrude to form wire

Multifilamentary Wire fabricationMulti-stage process for fabricatingLHC strand with: Diameter 1mm Current 500 Amps (@2K, 10T)LHC strandOther strandmorphologies

Making Cables Multifilament strands are twistedtogether as ropes or braids or as“Rutherford cables” Twisting is crucial to control eddycurrents and ac lossesRutherford cableLHC magnets: Each Rutherford cable (15x1.5mm)contains 36 strands Each strand contains 6300 filaments(0.006mm diameter) 7600 km of cable in total 250,000 km of strand[Rogalla & Kes]

Beyond NbTi[Courtesy of NHMFL, Florida]

Coated conductors 1% thickness of tape is superconductor Flexible metal substrate used to provide mechanical stability Grain alignment achieved in substrate or buffer layers Act as template for HTS growth Buffers prevent chemical reactions with substrate Silver layer protects HTS from environmental damageCourtesy of Superpower(http://www.superpower-inc.com)

Links to the National CurriculumChemistry Properties of Materials Bonding Extraction of metals Reactivity series Electrochemistry PolymersPhysics Forces Light Energy Electricity Mechanics Superconductors ThermodynamicsOther Subjects: Maths, D&T, Biology

Course requirements - summaryA-level requirements:MaterialsScienceThree relevant lsubjectsMaths andPhysicsChemistryFurtherMaths, Design& TechnologyTypical offer: A-levels: A*AA IB: 40 including core points (with at least 7,6,6 atHL) Welsh Baccalaureate: Advanced Diploma with A*Agrades at A-level and Core Certificate at Level 3 or any other equivalent (see Admissions website)

Physics Aptitude Test This test is normally held on the first Wednesday in November andis ordinarily taken at your own school or college A single two hour test, covering both Physics and Mathematics. Calculators will not be permitted for this two hour test Concentrates on core knowledge common to all A-levelsyllabuses Sample papers available from admissions office or ons/undergraduate/apptests.htm

Success rates for MaterialsApplicantsSelected forInterviewOffereda 5 Yr Average100927716381 Applicants to Physics who also indicate an interest in being considered forMaterials (PHYS2)2The number in brackets shows how many of these interviewees were PHYS2applicants

How to find out more Ask questions today! jayne.shaw@materials.ox.ac.uk http://www.materials.ox.ac.uk University Undergraduate Prospectus Subject Undergraduate Prospectuses College Prospectuseswww.ox.ac.uk/teacherseguide University website www.oxford.ac.uk www.admissions.ox.ac.uk Department Events Masterclasses Workshops Residential Courses Taster Days Work Experience University Open Days - book a place for a college visit.Many colleges offer an overnight stay if you have to travel a long way. www.admissions.ox.ac.uk/opendays/open2.shtml

– the violin – superconducting magnets Curriculum links Outreach activities . Case Study 1: the violin . The Violin Purpose of the box is to transmit vibrations of the strings into sound waves we can