Transcription

Build Your Own Robot ArmPart of the IEEE Teacher In-Service Program - www.ieee.org/organizations/eab/precollegeLesson FocusDevelop a robot arm using common materials. Students will explore design, construction,teamwork, and materials selection and use.Lesson SynopsisParticipating teams of three or four students are provided with a bag including thematerials listed below. Each team must use the materials to design and build a workingrobot arm. The robot arm must be at least 18 inches in length and be able to pick up anempty Styrofoam cup. Teams of students must agree on a design for the robot arm andidentify what materials will be used. Students will draw a sketch of their agreed upondesign prior to construction. Resulting robot arms are then tested and checked for rangeof motion and satisfaction of the given criteria.Age Levels10-18.Objectives LearnLearnLearnLearndesign concepts.teamwork.problem solving techniques.about simple machines.Anticipated Learner OutcomesAs a result of this activity, students should develop an understanding of: design concepts teamwork needed in the design process impact of technology in manufacturingLesson ActivitiesStudents design and build a working robotic arm from a set of everyday items with a goalof having the arm be able to pick up a Styrofoam cup. Working in teams of three or fourstudents, the students explore effective teamwork skills while learning simple robotmechanics.Alignment to Curriculum FrameworksSee attached curriculum alignment sheet.Robot ArmDeveloped by IEEE as part of the IEEE Teacher In-Service ge 1 of 6

Resources/Materials 3" wide and approx. 22" long strips of cardboard-- 5 or soBinder clips (different sizes)-- 8 or moreBrads-- @10Clothespins-- 6Craft sticks--10-15Fishing line-- 3-4 feetHangers-- 1 or 2Paper clips (diff. Sizes)-- 10-15Pencils-- 3-4Rubber bands (different sizes)--15Tape-- clear and masking (partial rolls should be fine)Twine-- 3-4 feetVarious size scraps of cardboard--10 assortedInternet Connections Design Your Own Robot (www.mos.org/exhibits/robot) FIRST Robotics Competition (www.usfirst.org) IEEE Teacher In-Service tispt) IEEE Virtual Museum (www.ieee-virtual-museum.org) McREL Compendium of Standards and Benchmarks(www.mcrel.org/standards-benchmarks) A compilation of content standards for K12 curriculum in both searchable and browsable formats. National Council of Teachers of Mathematics Principals and Standards for SchoolMathematics (www.nctm.org/standards) National Science Education Standards (www.nsta.org/standards) Robot Books (www.robotbooks.com)Recommended Reading Artificial Intelligence: Robotics and Machine Evolution by David Jefferis (ISBN:0778700461) Robotics, Mechatronics, and Artificial Intelligence: Experimental Circuit Blocks forDesigners by Newton C. Braga (ISBN: 0750673893) Robot Builder's Sourcebook : Over 2,500 Sources for Robot Parts by GordonMcComb (ISBN: 0071406859) Robots (Fast Forward) by Mark Bergin (ISBN: 0531146162)Optional Writing Activity Write an essay (or paragraph depending on age) about how the invention of robotsand robotics has impacted manufacturing.ReferencesRalph D. Painter and other volunteers - Florida West Coast USA Section of IEEEURL: http://ewh.ieee.org/r3/floridawcRobot ArmDeveloped by IEEE as part of the IEEE Teacher In-Service ge 2 of 6

Build Your Own Robot ArmFor Teachers:Alignment to Curriculum FrameworksNote: All Lesson Plans in this series are aligned to the National Science EducationStandards which were produced by the National Research Council and endorsed by theNational Science Teachers Association, and if applicable, also to the InternationalTechnology Education Association's Standards for Technological Literacy or the NationalCouncil of Teachers of Mathematics' Principals and Standards for School Mathematics. National Science Education Standards Grades 5-8 (ages 10 - 14)CONTENT STANDARD B: Physical ScienceAs a result of their activities, all students should develop an understanding of Motions and forces Transfer of energy National Science Education Standards Grades 9-12 (ages 14 - 18)CONTENT STANDARD B: Physical ScienceAs a result of their activities, all students should develop understanding of Motions and forces Interactions of energy and matterCONTENT STANDARD E: Science and TechnologyAs a result of activities, all students should develop Abilities of technological design Understandings about science and technology Standards for Technological Literacy - All AgesThe Nature of Technology Standard 3: Students will develop an understanding of the relationshipsamong technologies and the connections between technology and other fieldsof study.Technology and Society Standard 7: Students will develop an understanding of the influence oftechnology on history.Design Standard 9: Students will develop an understanding of engineering design. Standard 10: Students will develop an understanding of the role oftroubleshooting, research and development, invention and innovation, andexperimentation in problem solving.Abilities for a Technological World Standard 11: Students will develop abilities to apply the design process.The Designed World Standard 19: Students will develop an understanding of and be able to selectand use manufacturing technologies.Robot ArmDeveloped by IEEE as part of the IEEE Teacher In-Service ge 3 of 6

Build Your Own Robot ArmFor Teachers:Teacher ResourcesDivide your class into teams of three or four students, and provide student handout(attached). Students are then instructed to examine the materials provided (see listbelow) and to work as a team to design and build a robot arm out of the materials. Therobot arm must be at least 18 inches in length and be able to pick up an empty Styrofoamcup. Teams of students must agree on a design for the robot arm and identify whatmaterials will be used. Students should draw a sketch of their agreed upon design priorto construction.Explain that teamwork, trial, and error are part of the design process. There is no "right"answer to the problem - each team's creativity will likely generate an arm that is uniquefrom the others designed in your class.Resources/Materials 3" wide and approx. 22" long strips of cardboard-- 5 or soBinder clips (different sizes)-- 8 or moreBrads-- @10Clothespins-- 6Craft sticks--10-15Fishing line-- 3-4 feetHangers-- 1 or 2Paper clips (diff. Sizes)-- 10-15Pencils-- 3-4Rubber bands (different sizes)--15Tape-- clear and masking (partial rolls should be fine)Twine-- 3-4 feetVarious size scraps of cardboard--10 assortedExtension Ideas"Humans and Robots," a NASA educational brief which isattached, describes the robotics features on the InternationalSpace Station. The brief's classroom activity is about makingand using an ISS grapple fixture known as an end effector. ThePDF file is also available at http://spacelink.nasa.gov.Robot ArmDeveloped by IEEE as part of the IEEE Teacher In-Service ge 4 of 6

Build Your Own Robot ArmStudent Handout:How To Build Your Own Robot ArmYou are a member of a team of three or four students, all working together to design andbuild a robot arm out of the following materials which are provided to you. The robot armmust be at least 18 inches in length and be able to pick up an empty Styrofoam cup. Yourteam must agree on a design for the robot arm and identify what materials will be used.Your team should draw a sketch of their agreed upon design prior to construction.Part of the teamwork process is sharing ideas and determining which design your teamwill go with. Trial and error are part of the design process. There is no "right" answer tothe problem - your team's creativity will likely generate an arm that is unique from theothers designed in your class.Resources/Materials 3" wide and approx. 22" long strips of cardboard-- 5 or soBinder clips (different sizes)-- 8 or moreBrads-- @10Clothespins-- 6Craft sticks--10-15Fishing line-- 3-4 feetHangers-- 1 or 2Paper clips (diff. Sizes)-- 10-15Pencils-- 3-4Rubber bands (different sizes)--15Tape-- clear and masking (partial rolls should be fine)Twine-- 3-4 feetVarious size scraps of cardboard--10 assortedRobot ArmDeveloped by IEEE as part of the IEEE Teacher In-Service ge 5 of 6

Build Your Own Robot ArmStudent Handout:Robot Arm Exercise Questions Did you use all the materials provided to you? Why, or why not? Which item was most critical to your robot arm design? How did working as a team of four help in the design process? Were there any drawbacks to designing as a team? What did you learn from the designs developed by other teams? Name three industries that make use of robots in manufacturing:Robot ArmDeveloped by IEEE as part of the IEEE Teacher In-Service ge 6 of 6

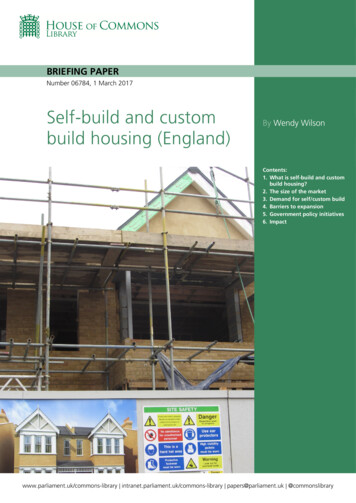

Educational ProductNational Aeronautics andSpace AdministrationEducators Grades 5-12EB-2001-04-004-JSCEducational BriefHumans and RobotsFollowing the remarkable successes of the ApolloMoon landings and the Skylab space station program,many space experts began reconsidering the role ofhumans in space exploration. In a healthy debate onexploration strategies, some experts concluded the goalsof the future would be best served by robotic spacecraft.Human space travelers require extensive life supportsystems. With current propulsive technologies, it wouldjust take too long to reach any destination beyond theMoon. Robots could survive long space voyages andaccomplish exploration goals just as well as humans.Other space experts disagreed. Humans have animportant place in space exploration, they contended.Robots and humans are not interchangeable. Humansare far more adaptable than robots and can react better tothe unexpected. When things go wrong, humans canmake repairs. This, they pointed out, was demonstratedconclusively during Skylab, when spacewalkers maderepairs that saved the mission.Today, new exploration strategies are at work. Thegoal is no longer humans or robots. It is humans androbots working together. Each bring importantcomplimentary capabilities to the exploration of space.This has been demonstrated time and again with theSpace Shuttle Remote Manipulator System (RMS) robotarm. The arm, also called Canadarm because it wasdesigned and constructed by Canada, has beeninstrumental to the success of numerous space missions.The 15-meter-long arm is mounted near the forward endof the port side of the orbiter’s payload bay. It has sevendegrees of freedom (DOF). In robot terms, this meansthat the arm can bend and rotate in seven differentdirections to accomplish its tasks. Like a human arm, ithas a shoulder joint that can move in two directions (2DOF); an elbow joint (1 DOF); a wrist joint that can roll,pitch, and yaw (3 DOF); and a gripping device (1 DOF).The gripping device is called an end effector. Thatmeans it is located at the end of the arm and it has aneffect (such as grasping) on objects within its reach. TheRMS’s end effector is a snare device that closes aroundspecial posts, called grapple fixtures. The grapplefixtures are attached to the objects the RMS is trying tograsp.On several occasions, the RMS was used to graspthe Hubble Space Telescope and bring the spacecraft intothe orbiter’s payload bay. After the spacecraft waslocked into position, the RMS helped spacewalkingastronauts repair the telescope and replace some of itsinstruments. During operations, the RMS is controlledby an astronaut inside the orbiter. The RMS actuallybecomes an extension of the operator’s own arm.Television cameras spaced along the RMS permit theoperator to see what the arm is doing and precisely targetits end effector. At times, during the Hubble servicing,one of the spacewalkers hitched a ride on the endeffector to gain access to parts of the telescope that weredifficult to reach. The arm became a space version ofthe terrestrial cherry picker.International Space StationMobile Servicing System(MSS)Special PurposeDexterous Manipulator(SPDM)Space StationRemote ManipulatorSystem (SSRMS)Truss BeamMobile RemoteServicer BaseSystem (MSB)MobileTransporter (MT)

Arm InterfaceRobots on the International Space StationThe International Space Station (ISS), currentlyunder construction in Earth orbit, will have severalrobots to help astronauts complete their tasks in space.Five of the ISS international partner nations aredeveloping robotic systems for the station. Japan isdeveloping the JEM Remote Manipulator System. TheEuropean Space Agency and the Russian Space Agencyare developing the European Robotic Arm. Canada andthe United States are developing the Mobile ServicingSystem (MSS). Detailed information on each of thesesystems can be obtained at the website listed below.Latch/UmbilicalMechanism (4)Electronic UnitsMobile Servicing SystemThe most complex robotic system on the ISS is theMSS. It consists of the Space Station RemoteManipulator System (SSRMS), the Mobile RemoteServicer Base System (MBS), the Special PurposeDexterous Manipulator (SPDM), and the MobileTransporter (MT). The MSS will be controlled by anastronaut working at one of two Robotics Work Stationsinside the ISS.The primary functions of the MSS robotic system onthe ISS are to: assist in the assembly of the main elements of thestation (e.g. aligning newly delivered modules to thestructure) handle large payloads replace orbital replacement units (plug-in equipmentLatching End Effectordesigned to be periodically replaced with newer units) support astronauts during extravehicular activities assist in station maintenance provide transportation around the stationThe main component of the MSS is the 17-meterlong SSRMS robot arm. It is similar to the Shuttle RMSbut will ride from one end of the station to the other onthe mobile transporter, which will glide along the gianttruss beam. After arriving at a worksite, the arm willgrasp payloads, modules, or other structures with its wiresnare end effector. If a work location is too distant forthe arm to reach while still attached to the transporter,the arm can connect to an intermediate grapple fixture.Electrical power will be rerouted through that fixture.The SSRMS will then release its other end and“inchworm” itself through successive fixtures until itreaches the desired site. The SSRMS is also able to pickup and connect to the SPDM. This unit consists of a pairof 3.5-meter, 7-joint arms connected to a single jointbase. The SPDM can pick up small tools for repair orservicing activities or effect delicate manipulations ofsmaller objects than the SSRMS can handle.Camera Light,Pan/Tilt UnitLatching EndEffector "A"Elbow(pitch)Backup DriveCamera Light,Pan/Tilt UnitArm ComputerUnitSpace Station RemoteManipulator SystemWrist Joint(roll, pitch, yaw)Grapple FixtureInterfaceB End IndicatorStripeJoint Electronics UnitCamera, Light AssemblyLatching EndEffector "B”Power and DataGrapple FixtureHumans and Robots2EB-2001-04-004-JSC

The FutureForce MomentSensorORU/Tool ChangeOut MechanismAdvanced robotic systemsare under development for useon the ISS. The ISS providesan exceptional laboratoryfor testing newrobots such asRobotic WorkNASA’sStationRobonaut.Robonaut will feature endeffectors based on the human hand andwill be capable of handling detailed andcomplex tasks. It will interface with the MSS and serveas a spacewalker’s assistant or surrogate for tasks toodangerous for humans.When astronauts return to Earth’s Moon and set footon Mars, they will not be alone. Robots will be there asassistants and partners in the exploration of space.Robotic research and application on the ISS will lead theway for the advanced intelligent robotic systems of thefuture.Wrist Joints (3)(roll, pitch, yaw)Power/DataGrappleFixtureElbow Joint(pitch)Shoulder Joints (3)(roll, pitch, yaw)Arm ComputerUnit (2)JointElectronicsUnitCamera, Light andPan/Tilt Unit (2)ToolHolsters (4)Latching EndEffectorBody JointBody JointElectronic UnitSpecial PurposeDexterous ManipulatorResources: For more information about robots on the International Space Station,refer to the reference section of this web site. http://spaceflight.nasa.gov/stationClassroom Activity – Making and Using an ISS End EffectorObjectives:easier to cut through the outer cupfirst and then the inner cup.Theimportant part about cuttingelosthe two cups is that theirCcut-off ends lie flushwith each other whenthe cups are nested.Use the knives as scrapersto smooth the cut edges.Upon completing the endeffector, have your students design agrapple fixture. The idea here is todesign something that the end effector can grab ontowithout slipping off. After grapple fixtures arecompleted, tell students to compare their fixture to thosecreated by two other students or groups. Ask them tocreate a table or a chart comparing the strong and weakpoints of the fixtures they evaluated. They shouldsummarize theirresults with aMaterials and Toolsstatement aboutStyrofoam coffee cups (2 each)how they canString - 12-cm pieces (3 each)improve theCellophane tapefixture theyPlastic picnic knives (serrated)designed.Open Students will learn how the end effectors for therobotic arms used on the Space Shuttle and theInternational Space Station work. Students will design and construct a grapple fixture thatwill enable the end effector to pick up an object.National Standards:Science Content Abilities of technological designTechnology Education Content8. Students will develop an understanding of theattributes of design9. Students will develop an understanding of engineering design10. Students will develop an understanding of the role oftroubleshooting, research and development, invention and innovation, and experimentation in problemsolving11. Students will develop abilities to apply the designprocessTeaching Plan:In this activity, students can worksingly or in small groups of two orthree. Have students use a sawingmotion to cut through the cups. It isHumans and Robots3EB-2001-04-004-JSC

5. While holding the rim of the inner cup, rotate theouter cup until the three strings cross each other. Thestrings will have some slack. Pull the end of thestrings on the outside until they are straight andintersect exactly in the middle of the opening. Pressthe tape on the outside to hold the strings.Making the End Effector:1. Nest the two cups together and cut through both cupswhere indicated in the diagram by the dashed line.Smooth the cut edges by scraping them with thepicnic knife edge.Using the End Effector:1. Use the end effector to pick up an object such as apencil. Have someone hold a pencil upright. Openyour end effector so that the strings are not crossingeach other. Slip the end effector over the pencil sothat the pencil extends down the center and notthrough any of the loops. Rotate the outer cup untilthe strings grasp the pencil. Pick up the pencil.2. You may find that the pencil is too slippery to be heldsecurely. How might you modify the pencil so that itcan be held? Design a standard grapple fixture thatcan be mounted to other objects so that they can bepicked up.3. Compare your grapple fixture to two other grapplefixtures designed by your classmates. Which oneworks the best? Why? Create a chart or a table thatevaluates the strong and weak points of each grapplefixture you compared. How can you improve yourdesign?Saw throughboth cups2. Cut three pieces of string 12 centimeters long each.3. Tape the end of the first string to the inside of theinner coffee cup just below the cut edge. Tape theother end of the string to the outside of the cup but donot press this piece of tape tightly yet.Tape string loopfrom outside tothe insideAssessment:Review the tables or charts created by your students.Pay special attention to the ideas students have forimproving their grapple fixtures.Extensions:4. Repeat step 3 twice more, but place the strings about1/3 of the way (120 degrees) around the cup from thefirst string.Open PositionSearch robot sites on the Internet and reviewdifferent end effector designs. How does the design ofan end effector enable it to pick up and manipulatevarious objects?Rotate Outer CupContinue Rotating toClose SnaresPlease take a moment to evaluate this product athttp://ehb2.gsfc.nasa.gov/edcats/educational briefYour evaluation and suggestions are vital tocontinually improving NASA educational materi als.Thank you.Humans and Robots4EB-2001-04-004-JSC

Build Your Own Robot Arm For Teachers: Teacher Resources Divide your class into teams of three or four students, and provide student handout (attached). Students are then instructed to examine the materials provided (see list below) and to work as a team