Transcription

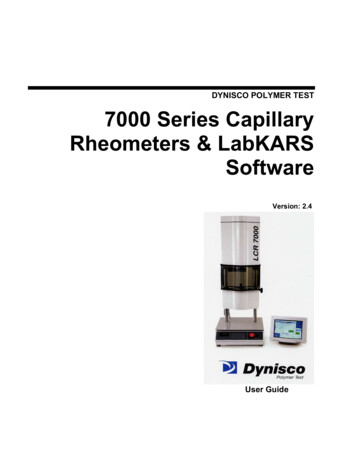

DYNISCO POLYMER TEST7000 Series CapillaryRheometers & LabKARSSoftwareVersion: 2.4User Guide

This manual was produced using Doc-To-Help , by WexTech Systems, Inc.WexTech Systems, Inc.310 Madison Avenue, Suite 905New York, NY 100171-800-WEXTECHNoticeThis manual contains descriptions, drawings and specifications for a Dynisco Polymer Test Systems Product.Equipment or products made prior to or subsequent to the publication date of this manual may have parts, features,options or configurations that are not covered in this manual.Specifications contained herein are subject to change by Dynisco Polymer Test Systems without prior notice.Dynisco Polymer Test Systems is not responsible for errors or omissions that may be contained herein or for incidentalor consequential damages in connection with the furnishing or use of this information. The information contained inthis manual is the property of Dynisco Polymer Test Systems, unless otherwise stated.Thank you to all Dynisco Polymer Test Systems employees for their input into this manual.Comments or suggestions for possible improvement to the manual are appreciated and may be sent to the followinglocation:Dynisco Polymer Test SystemsAttention: Technical Publications Department38 Forge ParkwayFranklin, MA 02038-3134orEmail: www.Dynisco.com

ContentsINTRODUCTION . 71. How to use this manual . 72. Typographic Conventions. 73. How to Contact DYNISCO POLYMER TEST . 8GETTING STARTED. 91. Uncrating and Setup. 92. Bench Requirements and Placement . 93. Unpacking the Rheometer . 94. Power connection . 105. Computer Connection. 106. Laser Micrometer connection (optional). 107. Model 7000. 108. Model 7001. 109. Model 7002. 1010. Load Cell assembly (models 7000 & 7001). 1111. Connecting the Barrel Pressure Transducer plug (models 7001 & 7002) 1112. Powering up the Rheometer . 1213. Software installation. 1214. E-mail Software Upgrades . 1316. Rheometer Firmware and Firmware Upgrades . 1417. Die Swell Laser Installation . 15SAFETY . 171. Use Gloves - Its Hot! . 172. Electrical Hazard . 173. Calibration Thermometers use Mercury (Models 7000, 7001 & 7002) . 174. Pinch Points. 185. Fumes from Materials . 186. Before Testing Safety Check . 187. Purging the rheometer. 198. Putting the Die(s) in the Barrel . 199. Loading the Sample . 1910. Starting the Purge. 2011. Cleaning Up . 20TEST DRIVE. 221. Time Sweep Test . 222. Starting Lab KARS and setting up the rheometer. 223. Performing the test . 224. The Second Test: A Rate Sweep. 235. Cleaning Up a really Big Mess. 23LAB KARS. 25DYNISCO POLYMER TEST LCR 7000 Series Capillary RheometersIntroduction 3

LABKARS 7000 and 7001 . 25LABKARS 7002 . 25LABKARS OPERATIONS . 25PC Requirements & Port Settings . 26Starting LabKARS or LabKARS Set-Up . 28Creating a LabKARS Icon . 28Security/Pasword Protection. 29LabKARS Security Access Levels . 29Database Record Manipulation Keys. 30Before The Start of any Run . 30Moving around LabKARS. 31SET UP TEST PAGE . 31Setting up a new test . 32Data Point Setup. 33Data Acquisition Mode. 35Start Position . 35Die Selection. 36Generic Prerun Check List . 36Test Setup Example. 37HAMA LASER MICROMETER . 38Starting up and testing the laser. 38HAMA Laser Calibration . 40RHEOMETER CONTROL SCREEN . 40Control Buttons . 41Real-time Data during the Test . 42Test Automation Server . 43PLOTTING AND ANALYZING YOUR DATA . 44Plotting . 44Merging . 44Single Run Analyze / Database. 45Plotting . 46From Database/ Filters Option . 46From Single Run/Modify Screen. 46Modifying Plots using the Plot Toolbar . 46Appending and Overlaying Plots. 48Copying Plots . 48Saving Plots . 48Global Preferences (SQC, NNI, I.V. and Bagley) . 48SQC Plots . 48NNI . 49I.V. Preferences . 50Misc. . 50Bagley Correction . 50Plot RMS Error. 51LABKARS REPORTS . 51EXPORTING DATA TO EXCEL . 53C. Selecting Load Cell or Pressure Transducer. 54D. Time Sweep . 54E. Shear Rate Sweep. 55F. Shear Stress Sweep. 56G. Combining Time and Rate Runs . 56H. Accuracy and Reproducibility . 57Precision . 57Accuracy. 57FORMULAS USED IN DATA ANALYSIS. 584 IntroductionDYNISCO POLYMER TEST LCR 7000 Series Capillary Rheometers

Apparent Shear Rate Calculation: . 58Apparent Shear Stress Calculation: . 58Apparent Shear Viscosity Calculation: . 59Volumetric Flow Rate Calculation:. 59Mass Flow Rate Calculation: . 60INTRODUCTION TO RHEOLOGY. 61A. Geometries of Deformation. 61B. Newton's Law . 63C. Effect of Shear Rate on Viscosity . 66D. Effect of Time on Viscosity . 66E. Effect of Temperature on Viscosity . 66F. Effect of Fillers on Viscosity . 67G. Effect of Moisture on Viscosity . 67H. Equations and Corrections . 67I. Pressure Profile . 68J. Why use a Pressure Transducer? . 69K. Common Assumptions. 69L. Weissenberg-Rabinowitsch Correction . 69M. Corrected Shear Stress. 70N. Extrudate Swell . 71O. PVC. 711. System Configuration . 72MAINT

this manual is the property of Dynisco Polymer Test Systems, unless otherwise stated. Thank you to all Dynisco Polymer Test Systems employees for their input into this manual. Comments or suggestions for possible improvement to the manual are appreciated and may be sent to the following location: Dynisco Polymer Test Systems Attention: Technical Publications Department 38 Forge Parkway Franklin, MA