Transcription

Dynisco ViscoSensorOnline RheometerExperience the benefits of online rheology measurement

Polymer manufacturers need to create new materials and deliverhigh quality to meet ever changing end-use requirements.Precise testing and analysis is mandatory to ensure quality and to stay competitive.Rely on Dynisco’s solutions to gain a window into your process and speed up thedevelopment, production, quality testing and analysis of polymers.Material AnalysisDynisco analyzers, including melt flow indexers, andrheometers, are recognized for testing the physical, mechanical,and thermal properties of polymers. Offering worldwide supportand innovative instruments that span the complete life cycle ofa polymer, Dynisco’s material analysis solutions range from theanalysis of a polymer in the laboratory, to online quality controlin production, to processing small quantities of special polymersor composites.Scrap ReductionNo matter what stage of the polymer’s life cycle, eliminatingwaste and keeping production levels at peak capacity are crucialto ensuring profitability in today’s highly competitive environment.Our goal is to provide objective measurements and high qualitytesting to improve and speed the development and productionof polymers.SustainabilitySustainability is more than just protecting the environment.We want to lead the way to the future and empower you withsensors, controls, and analytical instruments that offer maximumcontrol, reduce downtime, minimize scrap, and promoteenvironmental consciousness.The ability to feed used plastic into the supply chain tomanufacture new materials, with less costs and withoutcompromises in material specifications, is the goal and has tobe realized through objective measurements and analysis.Return on Investment (ROI)Many polymer production processes go through numeroustransitions as product grade changes are required. TheViscoSensor’s rapid response time shows when a process isin transition and when a new grade has achieved stability –meaning the diversion of material can be reduced as processstability can be measured versus predicted. Traditional methodsof quality assurance and process control ( i.e. obtain melt flowindex data by taking pellet samples and having them analyzed ina lab) may have a leadtime of over an hour!

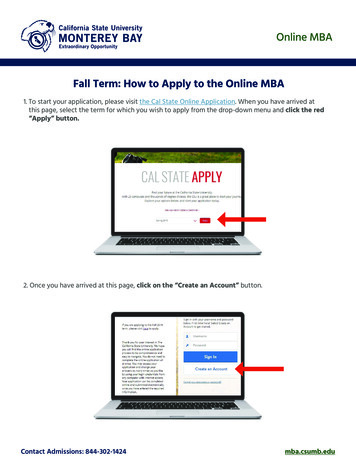

Here's what you get when you go ViscoCapillary RheologyA capillary viscometer forces material through a small diameter capillary die creating apressure drop across the die. By controlling the material’s shear rate through the dieor shear stress across the die, apparent viscosity or melt flow index is obtained. TheViscoSensor uses differential pressure across the capillary die for either a control point formelt flow index measurement or as a measurement point for apparent viscosity calculations.A wide range of capillary dies are available along with several metering pump choicesto fit specific material measurement needs. For example, large lengthto diameter ratio capillaries can be used to minimize entranceand exit effects of flow.ViscoSensor HeadMinimum Detection LevelResolution or minimum detection level of a change in materialor contamination is an important criteria. The ViscoSensor willdetect very small changes in viscocity or melt flow rateof your material. A change of 1 Pa-s or .02 MFR can be seenin measurement data. These changes in measurement canbe used to quickly adapt the parameters of your process.MFR Normal Process–20 Minutes Sample Time 1 MinuteThe above graph shows process readings taken by the ViscoSensorduring relatively consistent material processing. With consistent MeltFlow Ratio (MFR), one knows the material as well as molecular weightis homogeneous.MFR–Process During Material Properties ChangesThe above graph shows process readings taken by the ViscoSensorduring material processing that is in flux. The stock material hasfundamentally changed or a contaminant has entered the process.For example, the flux could be a result of a change in molecularweight/branching or a different material grade being mixed in. Theprocess metric was recovered by addressing the cause of the changemeasured by the ViscoSensor.

Two modes to meet your application needsThe ViscoSensor can be operated in either a shear stress control mode to monitor meltflow or in a constant shear rate mode to continuously measure apparent viscosity.Principals of Operation ViscoSensor system consists of two parts:1. ViscoSensor Head2. V iscoSensor e-RCU and RCU Control Units Connects directly to the process and samples,conditions, and measures the properties of the resin Remotely manages test parameters and providesmeasured and computed material properties Can be mounted on extruders, reactors, or moltenpolymer transfer lines in vertical or horizontal orientations.Dynisco’s e-RCUPerformanceSimplifiedProvides simplifiedrheological data forprocessors CapabilityANALOG OUTPUTS:4-20mADCSelectable SoftwareRCU WIRED/AVAILABLEOPTIONSCOMMUNICATIONSDynisco’s RCUUltimate PerformanceCombines rheologicalproperties of aLaboratory CapillaryRheometer with MFIreadings delivered by aMelt Flow Indexerore-RCURCUMelt flow Ratio Intrinsic Viscosity Relative Viscosity Apparent Viscosity Melt Viscosity Motor Speed (RPM)– Vertex Mercury Free Pressure Sensor (2) Differential Pressure– Shear Rate– Shear Stress– Capillary Temperature– Valve Block Temperature– Auxiliary Temperature– Melt Average Temperature(Capillary Valve Block)– Capillary Diameter– Carbon Steel –Stainless Steel– Hazardous Location– Non Hazardous Location Custom Configurations– ProfiBus– Ethernet Open TCP Ethernet Siemens S7 ModBus Ethernet ModBus RTU / 485– Now comes standardwith our Vertex Mercury FreePressure Sensor

Continuous Monitoring of Material PropertiesEnsures Consistent ResultsWhat are the benefits of online rheology measurement?Maximize Extrusion EfficiencyAdjust your parameters to adapt to changing conditionswhile processing.Decrease Scrap RateProcess improvement begins with understanding materialcharacteristics and adjusting accordingly.Increase Regrind & Wide-SpecRaw Materials UsageUse regrind and wide-spec materials with confidenceknowing that the finished product is to specfication.Gain a “live” look into your process whether compounding,mixing or producing resin and obtain continuousmeasurements of melt flow rate or apparent viscosity orintrinsic viscosity directly from the manufacturing process.Instantly know if material is within specification: Continuous “Real-Time” dataShear stress and shear rateSimple “In The Field” calibrationOperational temperatures up to 350 CWith the ViscoSensor, melt properties can be measured asa function of stress, strain, time and temperature.Applications include:Successfully monitor the viscosity or melt index of a wide variety of molten polymers including:LDPE LLDPE HDPE PC PS TPE PET PA6 PA66 PP EVA and siliconesAdditionally, IV (Intrinsic Viscosty) of PET in a process can be continuously monitored.

Advanced Solutions for Plastic Extrusion and Injection SENSORS ANALYZERS INSTRUMENTATIONwww.dynisco.comDyniscoHotline 1-800-Dynisco38 Forge Parkway Phone 1 508 541 9400Franklin, MA 02038 Fax 1 508 541 6206USAEmail infoinst@dynisco.comDynisco Europe, GmbHDynisco ChinaPfaffenstr. 21Phone 49 7131 297074078 Heilbronn Fax 49 7131 297 166GermanyEmail dyniscoeurope@dynisco.comBuilding 7A,Phone 86 21 34074072819No. 568, Longpan Rd Fax 86 21 34074025Malu, JiadingEmail dynisco.sh@dynisco.com201801 ChinaFrom lab to production, providing a window into the process

polymer transfer lines in vertical or horizontal orientations. 2. ViscoSensor e-RCU and RCU Control Units Remotely manages test parameters and provides measured and computed material properties Dynisco’s RCU Ultimate Performance Combines rheological properties of a Laboratory Capillary Rheometer with MFI readings delivered by a Melt Flow .