Transcription

inner portion of graphic band- keep color bars, transparency, partitions, and photo’s to the grid- preferred is one or two photo’s, with a maximum of three photo’s- maximum of three partitionsPower Supply Measurementand Analysisgridshowing columnsand subdivisionsPrimerA4 cropUS cropnd

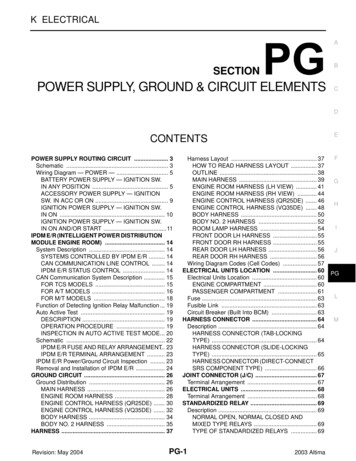

PrimerTable of ContentsIntroduction. urment.Needs. y of Power Loss in Switch-Mode Devices . 4Turn-Off Loss . 4Turn-On Loss . 5Power Loss . 5Safe Operating Area . 6Dynamic On Resistance . 6Making Active Component Measurements . 6Choosing the Right Measurement Solution . 7Performance Considerations For the Oscilloscope. 7Rise Time . 7Sample Rate . 7Record Length . 7Power Measurement and Analysis Software . 7Eliminating Skew Between Voltageand Current Probes . 9Eliminating Probe Offset and Noise .11Automated Offset Removal . 11Manual Offset Removal . ements:.Magnetics.12.-.17Induction Basics .Making Induction Measurements with an Oscilloscope.Magnetic Power Loss Basics .Core Loss .Copper Loss .Making Magnetic Power Loss Measurementswith an Oscilloscope .Magnetic Properties Basics .B-H Plot .Magnetic Property Measurements .Measuring Magnetic Properties with an Oscilloscope 19Power Quality Measurements .18Making Power Quality Measurementswith an Oscilloscope .19Conclusion. .20Product.Comparison.Chart. .21

Power Supply Measurement and AnalysisIntroductionA power supply is a component, subsystem, or system thatconverts electrical power from one form to another; commonlyfrom alternating current (AC) utility power to direct current (DC)power. The proper operation of electronic devices rangingfrom personal computers to military equipment and industrialmachinery depends on the performance and reliability of DCpower supplies.Power Supply Design QuestionsPoint Toward Measurement NeedsIdeally every power supply would behave like the mathematicalmodels used to design it. But in the real world, componentsare imperfect; loads vary; line power may be distorted;environmental changes alter performance. Moreover, changingperformance and cost demands complicate power supplydesign. Consider these questions:There are many different kinds and sizes of power suppliesfrom traditional analog types to high-efficiency switch-modepower supplies. All face a complex, dynamic operatingenvironment. Device loads and demands can changedramatically from one instant to the next. Even a commodityswitch-mode power supply must be able to survive suddenpeaks that far exceed its average operating levels. Engineersdesigning power supplies or the systems that use them needto understand their supplies behavior under conditions rangingfrom quiescent to worst-case.How many watts beyond rated output capacity can thepower supply sustain, and for how long?Historically, characterizing the behavior of a power supply hasmeant taking static current and voltage measurements witha digital multimeter and performing painstaking calculationson a calculator or PC. Today most engineers turn to theoscilloscope as their preferred power measurement platform.What happens when the supply’s input voltage changes(line regulation)?Modern oscilloscopes can be equipped withintegrated power measurement and analysissoftware which simplifies setup and makes iteasier to conduct measurements over time.Users can customize critical parameters,automate calculations, and see results not justraw numbers in seconds.This primer will focus on switch-mode power supply designmeasurements with an oscilloscope and application-specificsoftware.How much heat does the supply dissipate, what happenswhen it overheats, and how much cooling airflow does itrequire?What happens when the load current increasessubstantially? Can the device maintain its rated outputvoltage (load regulation)? How does the supply react to adead short on its output?The designer is asked to create a power supply that takes upless space, is more efficient, reduces heat, cuts manufacturingcosts, and meets tougher EMI/EMC standards. Only arigorous regime of measurements can guide the engineertoward these goals.Switch-Mode Power Supply BasicsThe prevailing DC power supply architecture in most modernsystems is the Switch-Mode Power Supply (SMPS), whichis known for its ability to handle changing loads efficiently.The power signal path of a typical SMPS includes passive,active, and magnetic components. The SMPS minimizes theuse of lossy components such as resistors and linear-modetransistors, and emphasizes components that are (ideally)lossless: switch-mode transistors, capacitors, and magnetics.www.tektronix.com/power3

PrimerActive Component Measurements:Switching ElementsTheory of Power Loss in Switch-Mode DevicesGateDrainSourceClockPassive ComponentsActive ComponentsMagneticsFigure.1.Switch-mode power supply simplified schematic.SMPS devices also include a control section containingelements such as pulse-width-modulated regulators, pulserate-modulated regulators, and feedback loops.1 Controlsections may have their own power supplies. Figure 1illustrates a simplified SMPS schematic showing the powerconversion section with active, passive, and magneticelements.SMPS technology rests on power semiconductor switchingdevices such as Metal Oxide Semiconductor Field EffectTransistors (MOSFET) and Insulated Gate Bipolar Transistors(IGBT). These devices offer fast switching times and areable to withstand erratic voltage spikes. Equally important,they dissipate very little power in either the On or Off states,achieving high efficiency with low heat dissipation. For themost part, the switching device determines the overallperformance of an SMPS. Key measurements for switchingdevices include: switching loss, average power loss, safeoperating area, and more.14This primer deals with measurements that pertain to the power path, includingtests on internal elements that contribute to the output. Control sectionmeasurements are more conventional waveform- and logic-based observationsand will not be covered in this document.www.tektronix.com/powerTransistor switch circuits often dissipate the most energyduring transitions because circuit parasitics prevent thedevices from switching instantaneously. “Turn-off Loss”describes the loss when the device transitions from ON toOFF. “Turn-on Loss” describes the energy lost when theswitching device transitions from OFF to ON.Turn-Off LossFigure 2 diagrams the calculation of Turn-off loss. After t1,the switch current falls while the diode current rises. The time(t2-t1) depends on the how fast the driver can charge thegate-drain capacitance Cgd of the MOSFET.Energy loss during the transition can be estimated by thefollowing equation:Where:is the average energy loss in the switch during thetransition.is the voltage at the gate.is the current through the inductor.is when the transition is complete.is when the transition begins.This formula assumes the linear rise of voltage across Cds(capacitance from drain to source) and Cgd. Cds and Cgd are theparasitic capacitances.In real-world devices, the capacitances Cgd and Cds are highlynon-linear, tending to vary with drain-source voltage. To someextent, this compromises the theoretical calculations justpresented. In case of an IGBT, the fall time of current would behigher due to the tail current phenomenon. These differencesmake it essential to capture the actual profile of the voltagevariation. An oscilloscope with dedicated power measurementsoftware can greatly simplify these measurements.

Power Supply Measurement and AnalysisTransistorWaveformsiliA (t)vgvA (t)TransistorWaveformsiA (t)vgilvA (t)iliB (t)qrtiB (t)DiodeWaveformstv B (t)-v gDiodeWaveformsAreavB (t)-q r-vgtt-v g ilAreat0Areat1t2tont0 t1 t2Figure.2.Calculation of Turn-off Loss.Figure.3.Turn-on Loss in a MOSFET with clamped inductive load.2Turn-On LossWhere:t1va energyloss in the switch during the transition.iaFigure 3 shows the turn-on loss in a MOSFET with a clampedon is thettinductive load and with the diode recovery charge. When theva isia the instantaneous gate voltage.ontMOSFET is turned on with a clamped inductive load, the diode tvaiaonis the instantaneous current through the switch.voltage cannot build up until the stored charge is recovered.tt1Therefore the diode continues to conduct current in thet1 is when the transition is complete.vaiaonnegative direction until it can block voltage. This leads to hugeia transition begins.t0 vonisawhen theloss in the switch. The reverse recovery current depends ont0the external circuit in the diode path. The charge in the diodePower Lossdepends on the forward current and the di/dt of the fall currentThe total loss is the average power loss in the switch.during the off transition of the diode.This includes the switching losses and conduction losses. TheEnergy loss during the transition is estimated by the followingtotal loss is given by the formulaequation:01100t1on2t0vaiaSimplified and adapted from a presentation titled Fundamentals of Power Electronics,Robert A. Erickson,University of Colorado.Where:is the average power loss in the switch.is the instantaneous voltage across the switch.is the instantaneous current through the switch.is the switching period.www.tektronix.com/power5

PrimerSafe Operating AreaThe Safe Operating Area (SOA) measurement on a switchingdevice plots voltage vs. current to characterize the operatingregion of the device. It is often useful to create an SOA plot forthe diverse operating conditions the power supply is expectedto encounter.The switching device manufacturer’s data sheet summarizescertain constraints on the switching device. The object is toensure that the switching device will tolerate the operationalboundaries that the power supply must deal with in itsend-user environment. SOA test variables may includevarious load scenarios, operating temperature variations,high and low line input voltages, and more. Figure 4 is anexample of an SOA plot.SOA tests usually calculate the Power using the followingequation:Figure.4.This example from Tektronix’ DPOPWR illustrates an SOA plot for anSMPS. The plot can be compared with the data published by the switching devicemanufacturer.Dynamic On Resistanceis the voltage.The resistance of a switching device in the “on” state canbe approximated by using the RDSON value found in thecomponent’s data sheet. However, the actual resistance (andtherefore the switch conduction loss) is not constant and mayvary significantly with changes in switch voltage or current.is the current.di/dt and dv/dtis the sample number.A di/dt measurement represents the rate at which the currentchanges during switching, while a dv/dt measurementrepresents the rate at which the voltage changes duringswitching.Where:is the instantaneous power.The following equation computes the Average Power:Making Active Component MeasurementsWhere:is the number of samples in a switching period.To those accustomed to making high-bandwidthmeasurements with an oscilloscope, power measurements,with their relatively low frequencies, might appear simple. Inreality, power measurements present a host of challenges thatthe high-speed circuit designer never has to confront.The voltage across a switching device can be very large, andis often “floating,” that is, not referenced to ground. Thereare variations in the pulse width, period, frequency, and dutycycle of the signal. Waveforms must be faithfully captured andanalyzed for imperfections.6www.tektronix.com/power

Power Supply Measurement and AnalysisChoosing.the.Right.Measurement.SolutionFor switch-mode power supply measurements, it is importantto choose the tools that can do the job. To turn the SMPSon and off during test, a pulse stimulus from a signal sourcemay be required. To accurately simulate the gate drive signalunder normal operating conditions, the stimulus must haveadjustable duty cycle, edge transition times, and frequency.To drive IGBT devices, the stimulus must also be able togenerate the required voltage of typically 12 V to 15 V.The oscilloscope must, of course, have the basic bandwidthand sample rate to handle the switching frequencies within anSMPS. And, it must have deep memory to provide the recordle

This primer will focus on switch-mode power supply design measurements with an oscilloscope and application-specific software. Power Supply Design Questions Point Toward Measurement Needs Ideally every power supply would behave like the mathematical models used to design it. But in the real world, components are imperfect; loads vary; line power may be distorted; environmental changes