Transcription

PneumaticCylindersPNEUMATIC CYLINDERSComposite,round LINEline REPAIRABLErepairableORanddisposable,COMPOSITE, ROUNDDISPOSABLE,ANDNFPASQUAREINTERCHANGEABLEand NFPA square interchangeable

About ARO ARO is a worldwide manufacturer of fluid management products that are skillfully engineered to deliver performance and serviceability, allowing success to flowfreely in our customers’ businesses. That’s why ARO is fluid intelligence—the smartchoice in fluid management products for industrial operations.With over an 85-year legacy of premier product performance and service excellence, ARO provides fluid management equipment for customers and industriesaround the globe; including chemical, manufacturing, energy, pharmaceutical, mining and more.ARO has the right product to meet our customers’ specific needs. We offer airoperated diaphragm pumps, piston pumps and packages, filters, regulators, andlubricators (FRLs), lubrication equipment, and pneumatic valves and cylinders.2AROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.com

Table of ContentsSeries 01 Micro-Air CylindersPremair Series Round Compact Cylinders3/4” and 1-1/8” Bore Sizes1-1/8”, 1-1/2”, 2”, 2-1/2”, 3”, 4”Application Information, Features, Capabilities. 9Ordering Information. 9Mounting Kits. 10Dimensional Information. 11Repair Kits. 46Application Information, Features, Capabilities. 48Ordering Information. 49Accessories. 50Switches. 51Dimensional Information. 52-55Repair Kits. 62Series S Silverair CylindersPremair Series Square Metric Compact Cylinders1/2”, 3/4”, 1-1/16”, 1-1/4”, 1-1/2”, 2” & 2-1/2” Bore SizesApplication Information, Features, Capabilities. 56Ordering Information. 57Mounts, Dimensional Information. 59-61Switches. 62Dimensional Information. 58Repair Kits. 62Application Information, Features, Capabilities. 12Ordering Information. 13Mounting Kits. 14-15Dimensional Information. 16-22Switches. 23Volume Chambers. 24Series 23, 24 and 28 Economair Cylinders1-1/8”, 1-1/2”, 2”, 2-1/2”, 3” and 4” Bore SizesApplication Information, Features, Capabilities. 25Ordering Information. 26Mounting Kits. 27Dimensional Information. 28Switches. 29Repair Kits. 46AccessoriesAir System Components. 65-68Flow Controls. 63-64Warnings and Cautions. 69Warranties. 70Series AN and SN Provenair Cylinders1-1/2”, 2”, 2-1/2”, 3-1/4”, 4”, 6”, 8” & 10” Bore SizesApplication Information, Features, Capabilities. 31-32Series AN (aluminum) Ordering Information. 33Series SN (stainless steel) Ordering Information. 34Mounting Kits. 35Dimensional Information (Series AN, SN). 36-42Switches (Series AN). 43Rod End Accessories (Series AN). 42Repair Kits. 47Tanks and Reservoirs, 1-1/2” thru 4”.43, 45Rod Alignment Couplers. 30Economair and Provenair are registered trademarks of Aro.arotechsupport@irco.com (800) 495-0276 / Pneumatic Cylinders AROzone.com3

Pneumatic CylindersSeries 01 Micro-Air (3/4” and 1-1/8” bore)Micro-Air Cylinders, small bore,repairable, double-acting cylinders,are designed for light dutyapplications. Available in 3/4, and1-1/8 inch bore sizes. Operate onair pressure to 200 PSI, generatingthrusts from 4.9 to 199 pounds. Theyare available in stroke lengths up to 6inches and in several mounting styles.zF or more information,see pages 9 through 11.Series S Silverair (1/2” thru 2-1/2” bore)Silverair Cylinders, small and mediumbore, disposable, single- and doubleacting cylinders are designed for lightduty applications. Available in boresizes from 1/2 inch to 2-1/2 inches.Operate on air pressures to 200 PSI,generating thrusts up to 982 pounds.z For more information,see pages 12 through 24.Series 23, 24 & 28Economair (1-1/8” thru 4” bore)Economair Cylinders, round linerepairable cylinders, are designedfor medium to heavy-duty usein a wide range of applications.Available in 1-1/8 to 4-inch boresizes. Operate on air pressure to 200PSI, generating thrusts from 25 to2,513 pounds. Available as doubleacting, with optional cushions,magnetic pistons or double rod ends.O-ring seals are standard. U-cupor low friction seals are optional. Avariety of mounts are available tomeet a wide range of applicationrequirements.z For more Esee pages 25 through BLEMEDIUMBOREREPAIRABLELARGEBORELIGHT DUTYLIGHT DUTYREPAIRABLEREPAIRABLEMED-HEAVYDUTYAROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.com

Series AN & SN Provenair (1-1/2” thru 10” bore)Provenair Cylinders are NFPAinterchangeable square headcylinders designed for rugged use.Available in 1-1/2 to 10-inch boresizes. They operate on air pressureup to 250 PSI, generating thrustsup to 3,141 pounds. They areavailable as double-acting, withoptional cushions, magnetic pistonsand/or with double rod ends. Abroad selection of NFPA standardmounts makes them dimensionallyinterchangeable with other NFPAcylinders.Premair SeriesRound Compact(1-1/8” thru 4” bore)Premair SeriesSquare Metric Compact(12mm thru 160mm bore)Stainless steel tie bolts and aluminumspacers lock precision machinedheads tightly around a heavy walled,aluminum alloy cylinder barrel. Thebarrel's extremely smooth, self-lubricating interior surface insures highlyreliable performance and extendedseal life.Premair Square Metric CompactCylinders are available in 13 boresizes, from 12mm thru 160mm.All cylinders come with NPT Portsand inch threads on rod end,and magnetic piston as standard.Mounting through holes are tappedand accept a variety of mountingkits. These cylinders interchange withthe leading manufacturers of SquareCompact Cylinders.z For more information,see pages 48 through 55.z For more information,see pages 56 through 62.z For more information,see pages 31 through EHEAVYDUTYLIGHT DUTYREPAIRABLESMALLBOREREPAIRABLEMEDIUMBORELIGHT DUTYarotechsupport@irco.com (800) 495-0276 / Pneumatic Cylinders AROzone.com3

Pneumatic CylindersAccessoriesz Mounts Micro-Air Silverair Premair Economair Provenair (1-1/2 thru 10-inch bore)Provenair Stainless Steel (1-1/2 thru 8-inch bore)zMountsRod End AccessoriesMicro-Air Silverair Premair Economair Provenair (1-1/2 thru 10-inch bore)zAlignment CouplerszSwitches, Cylinder MountedzFlow Control ValveszVolume ChamberszRepair KitsRod End AccessoriesAlignment CouplersElectrical SwitchesRight Angle Flow Controls4AROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.com

Pneumatic CylindersDeveloping Specificationsz Calculating the Proper Bore SizeA cylinder’s bore size determines the force it will produce at a given supplypressure. The weight of the load or the clamping force required will largelydetermine the force requirements of the cylinder, and hence, the boresize required. But before determining the appropriate bore size you mustcompensate for air pressure drop, packing friction and load variations usingthe following computation:A) Compensating for Pressure Drop – Decrease the line pressure valueby 15 p.s.i. This compensates for pressure drop in the system. Operating pressure (psig) Line pressure (psig) less15 (psig) pressure dropAir pressure atsource. 95 psiDownstream pressurebecause of pressureloss in lines: 80 psipressure loss in linesPackingFrictionLoadFrictionThis illustration shows a pressure loss of 15 PSI through the airlines and pointsout friction factors, both of which must be compensated for. Example: If the line pressure is 95 (psig), subtract 15 (psig) toobtain 80 (psig) operating pressure (for sizing purposes)B) Compensating for Packing Friction – Before you begin selecting a cylinder you already know the weight of the loadyou must move or the clamping force you must apply. Multiply this force or load value by 1.25. This compensatesfor packing friction and load variations. (If speed is of concern for your application, multiply the force value by 2.0.)Force required (in pounds) 1.25 x load (or required clamping force) Example: If cylinder must move 100 pound load, multiplying 100 pounds by 1.25 125 pounds forcerequired.Now, at the top of the chart on the next page, find the column with the operating pressure calculated in “A” above (inthis example, 80 psig). Go down that column until you find the force requirement calculated in “B”, above (or the nexthigher value). Note that the force values in bold type represent the extend force while those in standard type representretract force (retract force is lower because the rod reduces the effective piston area). Choose the appropriate value,then go to the Cylinder Bore column to find the bore requirements for your application.Now that you know the cylinder bore size that will produce the force required for your application, go to page 7 todetermine rod size requirements. Air consumption for each cylinder bore size can be found in the chart below.z Cylinder Air ConsumptionTo calculate the air consumption of a cylinder, multiply the total inches of stroke(extend plus retract) by the cycles per minute times the SCFM factor from thechart below. To find the SCFM factor, find your gauge pressure in the left handcolumn. Next, find your cylinder bore size in the chart. Where the two intersect,read down to the SCFM factor at the bottom of the chart.2-inch cylinder251 poundsof force5/8-inch diameter227 pounds of forceGiven equal pressure on both sides of a piston, the surface area onthe extend side will provide greater force.arotechsupport@irco.com (800) 495-0276 / Pneumatic Cylinders AROzone.com5

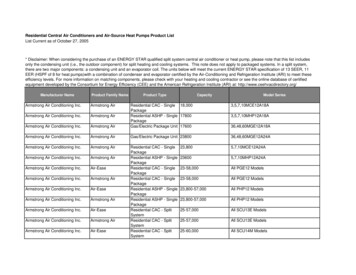

Pneumatic Cylindersz Bore Selection ING BORE -3/48EFFECTIVE PISTON AREA X OPERATING PRESSURE FORCEEFFECTIVEPISTONAREA OPERATING PRESSURE (PSI)(SQ. IN.)204060708090100FORCE OR LOAD 62837539 781 11-3/4VALUES IN BOLD TYPE REPRESENT EXTEND FORCE. Other values represent retract force (piston area, less area of piston rod).Check series order information for available rod diameters in each series.6110AROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.com9754956415228

Pneumatic Cylindersz Rod DiameterA) Use the stroke factor tableto find the proper multiplierbased on the mountingconfiguration and rod endconnection used.B) Multiply your requiredworking stroke length bythe factor you found fromthe stroke factor table inStep A. Note: if you requirea rod or thread extensionin your application (Longerthan standard) add the extralength(s) to your requiredworking stroke length andthen multiply by the strokefactor found in Step A, theresult of this arithmetic is the“L” Value.C) Use the piston rod diameter/stop length chart to completeyour cylinder specification.Find the approximate “L”value (determined in StepsA & B) on the left side ofthe chart. At the bottomof the chart, find the force(thrust) required for yourcylinder. Reference the boreselection sizes table on theprevious page to determinebore size, rod diameter orforce at various PSI. Findthe intersection of the “L”value (Horizontal) line withthe force in pounds (Vertical)line. The intersection shouldbe on, or to-the-left of thediagonal (rod diameter) line.The diagonal (rod diameter)line indicates the correctpiston rod diameter for yourapplication.Note: If your “L” valueforce lines intersect above,or to-the-right of a diagonalline, find a cylinder withthe next larger piston roddiameter to avoid prematurecylinder wear or failure.STROKE FACTORCYLINDER RIGIDLY MOUNTEDROD YGUIDEDL-MOUNTS, SIDEFRONT ORTAPPED SIDEREAR FLANGEEND LUGSMOUNTING NUTSCYLINDER PIVOT EVIS EYE. EDNote: Remember, long ,slim piston rods may buckle when subjected to a heavy push load.Note: When a stop tube is needed, a minimum 2” length is required on all Economaircylinders with Lip packings, and in 4”, 5”, 6” and 8” Provenair cylinders.z Stop Tube RequirementsAvailable in Economair & Provenair OnlyOccasionally, an application will require a stop tube Stop tube length is determinedby “L” value. If your “L” value (from Step B) is 40 or greater, find the correct stoptube length for your cylinder on the right side of the piston rod diameter/stop lengthchart. The recommended stop-tube length is shown above the “L” value line.Note: I f “L” value is 39, no stop tube is required. If “L” value is 40-49,a 1” stop tube is recommended.If “L” value is 50-59, a 2” stop tube is recommended, etc.arotechsupport@irco.com (800) 495-0276 / Pneumatic Cylinders AROzone.com7

Pneumatic Cylindersz OptionsAdditional options required will help determine which cylinder series will be selected: Stainless steel piston rods are beneficial in corrosive environments. Stainless steel rods are standard on Micro-Air andSilverair Series. Stainless Steel rods are options on Economair and Provenair Series. Cylinder cushions are designed to reduce the shock experienced at the end of the stroke by reducing piston speed thelast fraction of an inch of stroke. Cylinder cushions are available in Economair and Provenair Series, only.z Packing shape and material affect cylinder performance: O-Ring packings are good, general purpose packings, but they require more breakaway force than other packingshapes. O -Ring – Low Friction packings provide the effective sealing characteristics of Buna N with the low frictioncharacteristics of PTFE. This design is effective where the cylinder must operate at low pressures. U-Cup packings offer low breakaway friction and better sealing characteristics at low pressure than O-Ring packings.U-cups are wear compensating seals; they offer longer wear life than O-rings. U -Cup – Self Lube (“Slippery Seals”) packings are ideal in applications where air line lubrication cannot be used.This packing design helps reduce cylinder “chatter” in low pressure applications and it offers the same sealingcharacteristics as Buna N.z Packing GO-RINGO-RINGU-CUP-SELF-LUBE(“Slippery ureToleranceAvailabilityPTFE overBuna N O-Ring SealBuna NViton GoodMedium0 to 180 FEconomairGoodGoodHighHigh0 to 180 FUp to 300 FPremair, Micro-Air, EconomairPremair, Micro-Air, EconomairNitrileBuna NVitonVery GoodVery GoodVery GoodLowMediumMedium0 to 180 F0 to 180 FUp to 300 FEconomair, ProvenairEconomair, ProvenairEconomair, ProvenairNote: W hen applying rod cylinders, there must be no side load or bending stress at any point along the rod. Applications which induce side load and/or bending stress will damage packings, bushings, piston barrels,piston rods and cushion bosses. When metal parts are damaged, seal and packing replacement is an inadequate repair. The elastomers will quickly become damaged. Inspect and replace all worn or damagedparts when rebuilding cylinders.8AROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.com

Micro-Airz FeaturesSeries 01Micro-Air Cylinders are ideal for small part positioning, clamping and ejecting. Also they’rethe perfect choice for applications where small bore, medium duty, repairable cylinders arepreferred. Prelubed, they’re suitable for operations without externally applied lubrication. M icro-Air Cylinders are repairable. Service kits are available to extend the useable lifeof the cylinder. Micro-Air Cylinders operate on air pressure to 200 p.s.i. (14 bar). A tough littlecylinder that can handle the pressures! Superior performance over a wide temperature range – 0 to 180 F (-18 to 82 C),even to 300 F (149 C) when Viton seals are used (consult factory). Micro-Air Cylinders have superior wear characteristics, thanks to the hard coatedaluminum tubing I.D. In addition to an internal hardness of 60 Rockwell C, the barrelhas an internal finish of 16 microinches or better. Micro-Air Cylinders are equipped with Series 303 stainless steel piston rods forcorrosion resistance. Also, the ground and polished finish on the rods minimizesfriction, providing longer packing life. Micro-Air Cylinders provide greater durability than disposable cylinders. Double end-mount cylinders can also be used as a pivot mount. Pivot pin includedwith each cylinder.z Performance Specs3/4” and 1-1/8”Bore Sizes:Maximum Output Force: 199 pounds (1-1/8” bore) tandard OperatingSTemperature Range:0 to 180 F (-18 to 82 C)Viton Seals Models:For high heat applications. Consult factory.Range of mounting styles and attachable mounts/ accessories to meet nearly any application requirement.z OrderingPositionExample:101XX2-XX3XX-0XPosition 1Position 2Positon 3Bore SizeCylinder Type and Mounting StyleStroke Length76 - 3/4"18 - 1-1/8"1009 - Double Acting, Double End Mount and Pivot Mount, BUNA-N Seals5029 - Double Acting, Nose Mount, Rear Port, BUNA-N Seals1309 - Double Acting, Double End Mount and Pivot Mount, Viton Seals5329 - Double Acting, Nose Mount, Rear Port, Viton SealsNOTE: Bold selections denote most popular models.Whole Inches0 0"1 1"2 2"3 3"4 4"5 5"6 6"XFraction Inches0 None1 1/8"2 1/4"3 3/8"4 1/2"5 5/8"6 3/4"7 7/8"Maximum stroke length - 6-7/8-inches. Consult factory for the other stroke requirements.arotechsupport@irco.com (800) 495-0276 / Pneumatic Cylinders AROzone.com9

Micro-Airz Dimensional DataSeries 01L-MountRod Clevis & Clevis Bracket.199 Dia. Mounting Hole, 2 Pl.688 Dia. Hole.199 Dia Mounting Hole, 2 Pl.25 Dia. Pin.250 Dia. Hole.501/2” and 3/4” Bore: 1/4-281-1/8” Bore: 5.7501.250Rear FlangeFront Flange1.750 Sq.875.6875.625.25.50.625.8131.1251.0315/8-18 ThreadMounting Nut.25.688 Dia. Hole3/4 Hex.199 Dia. Mounting Hole, 4 Pl1.375 Sq.CTrunnionJ.688 Sq.HHJ.078A.656FBz OrderingGMounting KitL-MOUNTS (2 Qty) *FLANGE MOUNT *Cylinder Bore3/4" 1-1/8"20515 205152051620516MOUNTING NUT (2 Qty) 20514-1 20514-1CLEVIS BRACKET2051920519TRUNNION20523NATRUNNION BRACKETS**20561NAROD CLEVIS20517 20518-1* NOTE: Mounting nuts included.** 20561 Trunnion Bracket Kit (right and left brackets) is used for20523 Trunnion. Reference Clevis bracket dimensions.10A/2ACylinder BoreReference3/4"Trunnion DimensionsA1.50B0.625C Dia.0.953D0.500E0.250F Dia.–G Dia. .0020.250H .0100.250J–AROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.comDE

z Dimensional DataSeries 01ReferenceCylinder Bore (Inches)3/41-1/8Rod DiameterAABBCCCBDDEEFF*GG ( .002)HHJJ (UNF-2A)KKLL (NPTF)MMPPQQ (SLOT) .002RR (PIN)SSTT 130.250.625.950.250.6251.375* Note: FF shows total thread, including run out.** On rear head only of 5029 dimension is 1.291.01XX-1X09 BasicDouble End / Pivot Mount01XX-5X29 BasicRear Portarotechsupport@irco.com (800) 495-0276 / Pneumatic Cylinders AROzone.com11

Silverair z FeaturesSeries SSilverair round cylinders are designed for application in OEM and MRO applicationswhere a disposable, light duty cylinder is preferred. Prelubed, they’re suitable foroperations without externally applied lubrication. Constructed of stainless steel andaluminum, they stand up to the attack of corrosive environments. S ilverair cylinders feature stainless steel (Series 304) barrels. Drawn and polishedinternal diameters have superior lube-holding characteristics for a low frictionsurface that gives smooth performance and outstanding cycle life. P iston rods are centerless ground and polished Series 303 stainless steel, providingsmooth rod movement. L ightweight aluminum heads feature full flow ports for maximum air flow andsmooth response. Piston rod threads are roll formed to provide superior strength and durability. U-cup design on piston seals provides continuous cylinder barrel contact, minimizesblow-by and offers longer seal life than O-ring piston seals. T he oil-permeated bronze rod bushing is precision ball sized for reduced frictionand increased cylinder life. R eturn springs on single-acting cylinders are made from a high tensile alloy forexceptional performance and long service life. S ilverair cylinders are prelubricated, so they’re ideal in applications where externallubrication can’t be supplied.z Performance SpecificationsBore Sizes:Air Pressure:Operating Temperature Range:Maximum Output Force:Viton Seals Models:1/2”, 3/4”, 1-1/16”, 1-1/4”, 1-1/2”, 2” & 2-1/2”to 200 p.s.i. (14 bar)-40 to 160 F (18 to 82 C)982 pounds (2-1/2-inch bore cylinder)For high heat applications, consult factoryRange of mounting styles and attachable mounts/accessories covers wide range of application requirements.Magnetic pistons available for use with Hall Effect or Reed Switches.z OrderingSee following page.12AROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.com

z OrderingInclude dashes. Dashes are significant.Position123Example:SXXX-Position 1Position 2SeriesCylinder TypeS - Stainless Steel4567XXXX8-XXXPositon 3Bore SizeS - S ingle Acting, Spring Return(Not available on 25 bore size)D - Double ActingR - S ingle Acting, Spring Extend(Not available on 25 bore size)H - S ingle Acting, Hex Rod (Non-rotating rod)(Spring return only)Not available on 14,17,20 or 25 bore sizes)05071114151720251/2"3/4"1-1/16"1-1/4" (Not available on type SH)1-1/2"1-3/4" (Not available on type SH)2" (Not available on type SH)2-1/2" (Not available on type SS, SR or SH)Position 4Position 5Positon 6Positon 7Mounting StyleMagnet/Bumpers (Note A)PackingWearsrtip (Note B)B - B lock Mount(Available on 05, 07, 11 and 15 boresize only)(Not available on type SH)D - Double Rod End(Double Acting Only)N-N ose MountP - U niversal Mount (Pivot or Double End)4-N o Bumpers, no magnetB - B umpersM - Magnetic Piston(Not available in 1/2” bore or forsingle-acting cylinders)B-B una NV-V iton4-N one (standard)W-W earstripFor switch information, see page 23.Silverair attachable mounts must be orderedseparately.See page 14Positon 8Stroke LengthWhole Inches00 0"01 1"02 2"03 3"04 4"05 5"06 6"10 10"etc.Fraction Inches0 None1 1/8"2 1/4"3 3/8"4 1/2"5 5/8"6 3/4"7 7/8"Note A: Bumpers Not available with magnetic piston option. Standard on double rod ends. Do not affect external dimensions.Note B: Wearstrip is standard on double-acting nose mount, universal mount and block front mount of 5” or more of stroke. Also onsingle acting, spring extend cylinders with 3” or more of stroke. Not available on 1/2” bore cylinders. Not available on singleacting, hex rod (non-rotating rod)NOTE: Bold selections denote most popular models.For recommended maximum stroke lengths, per type, see pages 16 through 21.arotechsupport@irco.com (800) 495-0276 / Pneumatic Cylinders AROzone.com13

Silverair z OrderingSeries S (Mounting Kits)1/23/41-1/16CYLINDER BORE 555-171-3/422-1/2L-MOUNT (Single Acting)Order Mounting Nut below.118108-5118108-7L-MOUNT (DOUBLE ACTING)Order Mounting Nut below.118108-50118108-11MOUNTING NUT (SINGLE ACTING*)118109-5118109-7118109-11MOUNTING NUT (DOUBLE ACTING)118109-50118109-11118109-11PIVOT BRACKET (PIVOT PIN INCLUDED)117523-5117523-7117523-7ROD CLEVIS (PIVOT PIN INCLUDED)117555-5117555-7117555-11PIVOT PINS (STANDARD INER118592-5OPTIONAL PRESS FIT PIN118121-5118121-7FOR DOUBLE END MOUNTING OF SINGLE-ACTING CYLINDERS, ORDER THE FOLLOWING:1/2-inch bore One 118108-5 L-Mount and one 118109-5 Nut for rear mounting thread. One 118108-50L-Mount and one 118109-50 Nut for front mounting thread.3/4-inch bore Two 118108-7 L-Mounts, one 118109-7 Nut for rear mounting thread and one 118109-11 Nutfor front mounting thread.*NOTE: Silverair accessories are bright zinc plated steel.L-MountPivot Bracket and Rod ClevisMounting Nut14AROzone.com Pneumatic Cylinders / (800) 495-0276 arotechsupport@irco.comBlock Front Mount

z Dimensional DataSeries S (Mounting Kits)DimRef1/2Single DoubleActing ActingCYLINDER BORE (INCHES)3/4 1-1/16 1-1/41-1/2Single DoubleAllAllAllActing Acting Types TypesTypes1-3/4AllTypesL-Mount G56 56 45 45 45 49 49 .50Mounting 3/8-24 7/16-20 1/2-20 5/8-18 5/8-18 3/4-16 1.0452 1.253.001.00.341.622.251.001.3860 1.503.001.00.341.622.881.251.5063 1.753.75GHJL-MountABCMounting Nut1.501.852.06.56.50.501-14 1-1/4-12 1-3/8-12DADimRef1/2AllTypes3/4AllTypesPivot 50 53 H.64.87J.751.19Rod .25G.941.20H.12.16Pivot PinAs supplied with Pivot Bracket:A.69.81B.15.25For press fit into pivot hole:A.50.75B.15.24C.17.26CYLINDER BORE 1.2653 .871.19.32.77.75.94.31.2653 1.061.25.39.961.001.25.38.3852 1.371.63.39.961.001.25.38.3852 1.371.63.451.201.001.43.38.3848 1.681.81.451.201.001.43.38.3848 .371.13.371.44.371.44.37.75.24.26.87.24.261.12.

cylinders designed for rugged use. Available in 1-1/2 to 10-inch bore sizes. They operate on air pressure up to 250 PSI, generating thrusts up to 3,141 pounds. They are available as double-acting, with optional cushions, magnetic pistons and/or with double rod ends. A broad s