Transcription

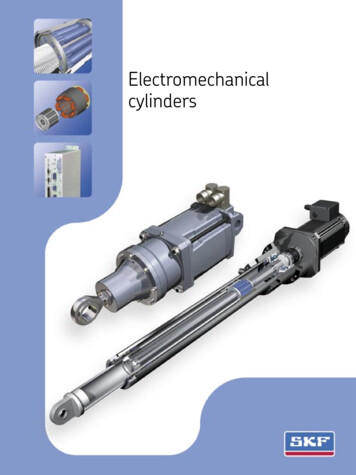

Electromechanicalcylinders

Spot weldingServo-pressThermoformingMedicalSteel industry2

Electromechanical cylindersElectromechanical cylinders:roller screw combined with brushless motor1SKF electromechanical cylinder benefits compared to other technologies ------------------------- 05Quick selection of product range ------------------------- 06Three ranges to meet your requirements -------------- 07Modular electromechanical cylindersDescription of the mechanism ---------------------------Main benefits ilor-made solutions with very flexible choice ------Product range ck size selection ----------------------------------------Quick motor selection -------------------------------------Life time selection SRSA -----------------------------Designation erformance and dimensional specifications ---------Option: high resolution cylinders SVSA ----------------Life time selection SVSA -----------------------------Performance and dimensional specifications ---------Option: high speed cylinders SLSA ---------------------Life time selection SLSA -----------------------------Performance and dimensional specifications ---------Front attachment 10111213161830313238394044Compact electromechanical cylindersThe new standard for high performance motion ----Main benefits formance ignation erformances compact range and ultra compact range sional data -------------------------------------------Option: integrated load sensor --------------------------Option: integrated water-cooling system ---------------4747474849515859Motion controllers for electromechanical cylindersMain specifications -----------------------------------------Detailed specifications -------------------------------------Compliance with “CE” standards ------------------------Functions --Motion explorer software --------------------------------Accessories 626363646566Screw jacksExperience About the screw jack actuator --------------------------Performance and dimensional specifications ---------Main benefits lications 6969707272Technical requirements for SKF electromechanical cylinders74-----32345

At last, an all electric SKF cylinderperforming with the power of hydraulicsand the velocity of pneumatics.SKF cylinders using SKF planetary roller screws are expandingthe limits of linear cylinders.They are designed for long life, high acceleration and highforce applications.The cylinders use brushless servomotor technology, with an inline or parallel drive as standard.4

Electromechanical cylindersSKF electromechanical cylinder benefits compared toother technologiesSKF ersLoad capacityVery highVery highHighLifetimeVery longCan be long withproper maintenanceCan be long withproper maintenanceSpeedVery highHighVery highAccelerationVery highVery highVery highStiffnessVery highHighVery lowShock resistanceVery highVery highHigh 50 %Efficiency 80 % 50 %MaintenanceVery lowVery highHighInstallationVery easyComplexVery complexPosition controlVery easyComplexVery complexPosition accuracyVery highAverageLowEnvironmentalconcernsLowFrequent leaksHigh noise levelRoller screwThe thread design of the rollersand nut eliminate rolling elementrecirculation and permit a planetary motion of the rollers; thisunique feature supresses thepotential risk of recirculationfailure.The diameters of the 3 basicelements (screw, rollers and nut)are selected in such a mannerthat the rollers, when they freelyroll inside the nut, follow a planetary path and do not move axially.The profile of the screw shaft andthe nut thread has a 90 degreeangle, for optimised shear resistance.1If hydraulic cylinders remain theonly solution for high loads andlong strokes, electromechanicalcylinders are a cost effectivealternative for all other cases.There is one energy conversionversus two in hydraulic system.Installation time is reduced.Set up is easy: the motioncontroller can be connected toall industrial electrical powersupplies and customer interfacesmake mounting easy.Brushless motorThe profile of the thread flankson the roller is shaped to give anequivalent large ball diameterwith much higher contact pointsthan a conventional ball screw.The shape and the number ofcontact points provide a high loadcarrying capacity. Roller screwshave a load carrying capacityabout 3 times higher than theaverage ball screw capacity.Angular acceleration greater than12 000 rad/s2 is possible.The motor winding is wound intothe stator and permanentmagnets fixed onto the rotor.No brush means minimummaintenance. Designed for highperformance, it provides very high acceleration high and constant torqueover a wide range of speed high nominal speed precise speed and/orposition control.5

Recommendations for selection 6

Recommendations for selectionThree ranges to meet your requirements1 RSJA SRSACEMC 7

Modular cylinderslongrdnrod ecrewball capachgihsiontrunn8

Modular cylindersDescription of the mechanismThe high performance electromechanical cylinder consists of anSKF planetary roller screw directly driven through a coupling by abrushless motor. A planetarygear box is associated in someconfigurations. The roller screwconverts rotary motion into linearmovement.As the screw rotates, the nutextends and retracts the forcetube, which is attached to theload.The screw is held by a combination of SKF angular contact ballbearings which allow for highspeed, high rigidity and highdurability; for long strokes thefree end of the shaft is supportedand guided inside the force tubeto prevent any vibration.The force tube and rollerscrew nut are guided inside theexternal tube which gives anaxially and radially stiff system.The cylinder is sealed betweenthe force tube and external tube.The unit is designed and finishedto suit industrial requirements.The integrated anti-rotation(option) is designed with theprofile rail guides. This preloadeddesign provides a very hightorsional stiffness and durability.Two internal bumpers securethe mechanism during theadjustment phase.2Main benefits Easy use and set up Permit faster operation andlonger travel under high load High acceleration capability Long service life is achievedwith a simple power train ofmotor, coupling and roller screw High durability High rigidity Less maintenance required dueto fewer components Programmable controller Integrated anti-rotation.Tailor-made solutionswith very flexible choiceFrom the basic product rangeconsisting of different cylindertypes, you can build your owncylinder.Starting from the mechanicalperformances (dynamic loadcapacity, speed), you can choosethe motor that will bring theperformances suitable for yourapplication (nominal force, linearspeed, peak force, etc ) you arenot limited to one configuration.9

Modular cylindersProduct range 10

Modular cylindersQuick size selection - Life time selection 2 11

Modular cylindersMotor selection Performance 3905- -X82RBSRSA3905- -X84QBSRSA3905- -X82R3BSRSA3905- **175,0108,365,00 . 8000 . 8000 . 8000 . 8005 ( 2)5 ( 2)5 ( 2)5 ( - -X84QBSRSA3910- -X82R3BSRSA3910- -X84Q3BSRSA3910- 50,0216,7116,770,00 . 8000 . 8000 . 8000 . 8005 ( 2)5 ( 2)5 ( 2)5 ( - -X86JBSRSA3915- -X84K3BSRSA3915- -X86J3BSRSA3915- 50,0291,7216,7130,00 . 8000 . 8000 . 8000 . 8005 ( 2)5 ( 2)5 ( 2)5 ( 2)138,5138,5138,5138,57,56,87,57,532323232(1) This calculation is approximate, just to help for quick selection.An exact calculation should integrate acceleration/deceleration loads, mean speed To get an optimized cylinder definition, please contact SKF.(2) If you don’t find any cylinder that meets your requirement, please contact SKF.12

Modular cylindersLife time selectionSRSA 25Mean load (N)2Basic life rating (10 6 mm)Mean load (N)SRSA 30Basic life rating (10 6 mm)13

Modular cylindersMean load (N)SRSA 39Basic life rating (10 6 mm)Mean load (N)SRSA 48Basic life rating (10 6 mm)14

Modular cylindersSRSA 60Mean load (N)2Basic life rating (10 6 mm)Mean load (N)SRSA 75Basic life rating (10 6 mm)15

Modular cylindersDesignationSRSA4815-0400Cylinder typeSRSA planetary roller screwSVSA recirculating roller screwSLSA long lead ball screwScrew diameter mm25 diameter 2530 diameter 3039 diameter 39 diameter Screw lead mm05 lead 510 lead 1015 lead 15xx lead xxStroke mm0050 stroke 500150 stroke 1501100 stroke 1100xxxx stroke xxxxCylinder design (frame)S standard designZ custom designCylinder design (motor assembly)L design with in line motorP design with parallel motorCylinder design (function)0 without anti-rotation on the force tube1 with anti-rotation on the force tubeFixe attachment (linked to the frame)T1 trunnion (standard), same dynamic capacity as the front attachmentT2 high capacity trunnionZ custom attachment16-SL0-T1

Modular cylindersDesignation- R2 - 1 1 1- X63N7 B -05 - MC 08 PFront attachment (linked to the force tube)R2 rod end with 2 degres of freedomR3 rod end with 3 degres of freedomZ custom attachmentN without attachment2Limit switches - home sensor0 no limit switch in retracted position1 limit switch in

The thread design of the rollers and nut eliminate rolling element recirculation and permit a plane-tary motion of the rollers; this unique feature supresses the potential risk of recirculation failure. The diameters of the 3 basic elements (screw, rollers and nut) are selected in such a manner that the rollers, when they freely roll inside the nut, follow a plane-tary path and do not move .