Transcription

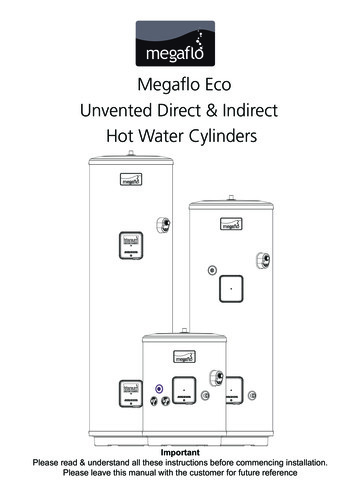

Megaflo EcoUnvented Direct & IndirectHot Water CylindersImportantPlease read & understand all these instructions before commencing installation.Please leave this manual with the customer for future reference

Contents11. Decommissioning 2811.1 Decommissioning procedure281. Introduction 31.1 General 31.2 Symbols used 31.3 Abbreviations 31.4 Liabilities 32. Safety 42.1 General safety warnings42.2 Recommendations 42.3 Specific safety instructions43. Technical specifications54. Description of the product4.1 General description4.2 Operation principle4.3 Main components4.4 Standard delivery4.5 Storage and Handling1010101010105. Before installation5.1 Installation regulations5.2 Installation requirements5.3 Choice of location1212121212. Spare parts 2912.1 Spare parts list29Benchmark checklist34Commissioning & service records35Warranty 366. Installation 136.1 General 136.2 Water connections136.3 Electrical connections196.4 Filling the installation227. Commissioning 237.1 General 237.2 Checklist before commissioning237.3 Commissioning procedure237.4 Benchmark 238. Operation 248.1 General 249. Maintenance259.1 General 259.2 Standard inspection & maintenanceoperations 2510. Troubleshooting 2710.1 Fault finding27Benchmarktm places responsibilities on both manufacturers and installers. The purpose is to ensure thatcustomers are provided with the correct equipment for their needs, that it is installed, commissioned andserviced in accordance with the manufacturer’s instructions by competent persons and that it meets therequirements of the appropriate Building Regulations and relevant electrical qualifications. The BenchmarktmChecklist can be used to demonstrate compliance with Building Regulations and should be provided to thecustomer for future reference. Installers are required to carry out installation, commissioning and servicingwork in accordance with the Benchmarktm Code of Practice which is available from the Heating and HotwaterIndustry Council who manage and promote the Scheme. Visit www.centralheating.co.uk for more information.IMPORTANT NOTE TO USER: PLEASE REFER TO THE COMMISSIONING SECTION, PAGE 23 FORIMPORTANT INFORMATION WITH RESPECT TO THE BENCHMARK SCHEME2

1. Introduction1.1 GeneralIn the interest of UK customers, we are continuouslyendeavouring to make improvements in productquality. All the specifications stated in this documentare therefore subject to change without notice.The following instructions are offered as a guide to theuser and installer.Our liability as the manufacturer may not be invoked inthe following cases:The installation must be carried out by a competentplumbing and electrical installer in accordance withBuilding Regulation G3 (England and Wales), TechnicalStandard P3 (Scotland) or Building Regulation P5(Northern Ireland) and the Water Fitting Regulations(England and Wales) or Water Byelaws (Scotland). Failure to abide by the instructions on using theappliance. Faulty or insufficient maintenance of theappliance. Failure to abide by the instructions on installing theproduct.1.2 Symbols usedIn these instructions, various risk levels are employedto draw the user’s attention to particular information. Indoing so we wish to safeguard the user, avoid hazardsand guarantee the correct operation of the appliance.The installer is responsible for the installation and thecommissioning of the appliance. The installer mustrespect the following instructions:Risk of dangerous situation causing slightphysical injury. Read and follow the instructions given in themanuals provided with the appliance. Carry out installation in compliance with theprevailing legislation and standards. Perform the initial start up and carry out any checksnecessary. Complete the commissioning checklist. Explain the installation to the user. If maintenance is necessary, warn the user of theobligation to check the appliance and maintain it ingood working order. Give all the instruction manuals to the user.CAUTIONUsers liabilityRisk of material damage.To guarantee optimum operation of the appliance, theuser must respect the following instructions:DANGERRisk of a dangerous situation causing seriousphysical injury.WARNING Installer's liabilitySignals important information.1.3 Abbreviations T&P - Temperature & Pressure relief valve PRV - Pressure Reducing Valve Prv - Pressure relief valve1.4 LiabilitiesManufacturers liabilityOur products are manufactured in compliance withthe requirements of the various applicable EuropeanDirectives.This appliance complies with the requirements of theCE marking directive. Read and follow the instructions given in themanuals provided with the appliance. Call on qualified professionals to carry outinstallation and initial start up. Get your fitter to explain your installation to you. Have your required checks and services done. Keep the instruction manuals in good condition andclose to the appliance.This appliance can be used by children agedfrom 8 years and above and persons withreduced physical sensory or mental capabilitiesor lack of experience and knowledge if theyhave been given supervision or instructionconcerning use of the appliance in a safeway and understand the hazards involved.Children shall not play with the appliance.Cleaning and user maintenance shall not bemade by children without supervision. Children must be supervised to ensure theydo not play with the appliance.3

- Water may drip from the discharge pipe ofthe pressure-relief device and this pipe mustbe left open to the atmosphere; (see page 18for more details)-the pressure-relief device is to be operatedregularly to remove lime deposits and to verifythat it is not blocked; (see page 18 for moredetails)- How hot water can be drained. (see page 26for more details)- The type or characteristics of the pressurerelief device and how to connect it; (seeFigure 1 for details and Figure 18, page 30 forexploded view)- A discharge pipe connected to the pressurerelief device is to be installed in a continuouslydownward direction and in frost freeenvironment; (see page 18 for details)Details on how to set the temperaturecontrols for both immersion heaters and boilercontrols can be found in section “InstallationInstructions, page 20.2. Safety2.1 General safety warningDANGERThis cylinder is unvented and as suchbecomes pressurised when in operation. Thecombination of pressurisation and hot watercould lead to serious physical injury if the safetyinstructions in this manual are not adhered to.WARNING If water discharges from thetemperature/pressure relief valveon the cylinder shut down the boiler.Do not turn off any water supply.Contact a competent installer forunvented water heaters to checkthe system. The Pressure Reducing Valve andPressure Relief Valve MUST befitted to the mains water supply(either seperately or combined)to the cylinder. See Section 6Installation for further details). Where the inlet supply to thePressure Reducing Valve is routedthrough a heated space and isfitted with a check valve or otherfitting that would prevent backflow,high pressures can be experiencedin the inlet pipe due to warmingthat can cause damage to thePRV or other fittings on the inletsupply. In these circumstances,the installation of a means toaccomodate expansion and thuslimit the pressure rise in the inletpipe is recommendedCAUTIONWARNING Only competent personshavingreceivedadequatetrainingarepermitted to work on the appliance andthe installation. Do not tamper with any of the safetyvalves or controls supplied with thecylinder. Before any work, switch off the mainssupply to the appliance. Do not switch on if there is a possibilitythat the water in the cylinder is frozen.CAUTIONDo not operate immersion heaters until thecylinder has been filled with water.4Annual maintenance is recommended by acompetent person.WARNING TO USER If this unvented water heater developsa fault, such as a flow of water from thedischarge pipe, switch the heater offand contact the installer. Do not remove or adjust any componentor part of this unvented water heater ;contact installer DO NOT bypass the thermal cut-out(s)in any circumstances.

70i125i145i170i210i210i250i250i300i300i3. Technical specificationsMax direct kW rating3333363636Immersion heat up times(Btm immersion, 3kW)75139167179208208252252294294Immersion heat up times(Top immersion, 3 kW)N/AN/AN/AN/AN/A86N/A92N/A94Immersion heat up times(Both immersions, 6kW)N/AN/AN/AN/AN/A90N/A100N/A104Coil surface area 826.826.828.928.928.328.3Coil heat up timesCoil rating (kW) ²Pressure drop throughcoil15l/min0.005 MPa (0.05 bar)30l/min0.018 MPa (0.18 bar)45l/min0.030 MPa (0.30 bar)Heat loss 9Hot water capacity (volume to 40 C)87.4139159197200200240240284284Weight empty (kg)25313539434450515859Weight full (kg) ¹117168190217238238283283341341Volume (Litres) ¹92137155178195194233232283282Max mains pressure1.6MPa (16 bar)Max design pressure0.8MPa (8 bar)Operating pressure/PRV set pressure0.3MPa (3 bar)Max primary pressure ³1.0MPa (10 bar)Expansion relief valve setting0.8MPa (8 bar)T&P valve setting1.0MPa (10 bar)/90 CT&P Part number95 605 810Immersion heater electrical rating3.0kW@240V/2.8kW@230V Table 1: Technical data - Indirect CylindersNotes:1: at 3 bar water inlet pressure2: at 80 C - /- 2 C3: Although the primary coil pressure rating is 1.0MPa (10bar) the 2 port zone valve and coil compression nuts supplied withthe cylinder is only rated 0.86MPa (8.6 bar). If the cylinder is to be plumbed into a system delivering 1.0MPa (10 bar) asuitable 2 port zone valve and the coil compression nuts supplied will have to be sourced.4:Tested to EN 12897:20065

70D125DD145DD170DD210DD250DD300DDMax direct kW rating3666666Immersion heat up times(Btm immersion, 3kW)75139175193205267309Immersion heat up times(Top immersion, 3 kW)N/A658387899692Immersion heat up times(Both immersions, 6kW)N/A627988909893Heat loss (kWh/24hrs)0.911.051.181.201.421.611.69Hot water capacity (volume to 40 C)83126152178191238286Weight empty (kg)23253134384656Weight full (kg) ¹115165183216237282339Volume (Litres) ¹921401521821992362830.8MPa (8 bar)T&P valve setting1.0MPa (10 bar)/90 CT&P Part number95 605 810Immersion heater electrical rating3.0kW@240V/2.8kW@230V 300DDDD0.3MPa (3 bar)Expansion relief valve setting300DDDOperating pressure/PRV set pressure250DDDD0.8MPa (8 bar)250DDDMax design pressure210DDDD1.6MPa (16 bar)210DDDMax mains pressureMax direct kW rating912912912Immersion heat up times (9kW)686881819797Immersion heat up times (12kW)N/A51N/A60N/A73Heat loss (kWh/24hrs)1.421.421.611.611.691.69Hot water capacity (volume to 40 C)191191238238286286Weight empty (kg)394047485758Weight full (kg) ¹237237282283339339Volume (Litres) ¹198197235235282281Max mains pressure1.6MPa (16 bar)Max design pressure0.8MPa (8 bar)Operating pressure/PRV set pressure0.3MPa (3 bar)Expansion relief valve setting0.8MPa (8 bar)T&P valve setting1.0MPa (10 bar)/90 CT&P Part number95 605 810Immersion heater electrical rating3.0kW@240V/2.8kW@230V Notes:1: at 3 bar water inlet pressure2:Tested to EN 60379:2004Table 2: Technical data - Direct Cylinders6

300iC70.0283.0See page 3 to 2960 CMegaflo 312.67020.480Table: Technical parameters in accordance with European Commission regulations 814/2013 and 812/2013IndirectModel(s)Energy efficiency classStanding loss in WStorage volume V in litresDirectSupplier’s name or trade markSupplier’s model identifierStorage volume V in litresMixed water at 40 C V40 in litresThe declared load profileThe water heating energy efficiency class of the modelThe water heating energy efficiency in %The annual electricity consumption in kWhDaily fuel consumption Q fuel in kWhThe thermostat temperature settings of the water heater,as placed on the market by the supplierSpecific precautions that shall be taken when the waterheater is assembled, installed or maintained and disposedof at end of D 020.580Outer casingWhite pre-coated corrosion protected steel body shell.Polypropylene top and base mouldings. ABS electricalcontrols housings and enclosures.Water containerDuplex stainless steel. 100% pressure tested to 1.6MPa(16 bar)ConnectionsStainless steel grade 1.4404 (316 L)Pipe connections accept 22mm outside diameter pipe(compression nuts and olives supplied). Thread rate is3/4" BSP parallel to accept standard 3/4" BSP femalefittings if requiredThermal insulationCFC/HCFC free fire retardant expanded polyurethanefoam with zero ozone depletion potential. It has a GlobalWarming Potential (GWP) of 3.1Safety FeaturesDirect models: Manually re-settable thermal cut-out oneach immersion heater. Factory fitted T&P Relief ValveIndirect models: Manually re-settable thermal cut-out onimmersion heater. Manually re-settable thermal cut-out forprimary heating - must be wired in conjunction with 2 portmotorised valve supplied. Factory fitted T&P Relief Valve7

Ø 57929T&P VALVE7430 475*B375425*ECD45 * ONLY ON DDD AND DDDD MODELSFigure 1: General dimensions - Direct modelsSizeDIMENSIONS /A649125i3163557941

If this unvented water heater develops a fault, such as a flow of water from the discharge pipe, switch the heater off and contact the installer. Do not remove or adjust any component or part of this unvented water heater ; contact installer DO NOT bypass the thermal cut-out(s) in any circumstances. WARNING Only competent persons having