Transcription

〈797〉 Pharmaceutical Compounding—Sterile PreparationsRevision BulletinChange to read:〈797〉 PHARMACEUTICALCOMPOUNDING—STERILE PREPARATIONSINTRODUCTIONThe objective of this chapter is to describeconditions and practices to prevent harm,including death, to patients that could result from(1) microbial contamination (nonsterility), (2)excessive bacterial endotoxins, (3) variability inthe intended strength of correct ingredients thatexceeds either monograph limits for officialarticles (see ―official‖ and ―article‖ in the GeneralNotices and Requirements) or 10% for nonofficialarticles, (4) unintended chemical and physicalcontaminants, and (5) ingredients of inappropriatequality in compounded sterile preparations (CSPs).Contaminated CSPs are potentially mosthazardous to patients when administered into bodycavities, central nervous and vascular systems,eyes, and joints, and when used as baths for liveorgans and tissues. When CSPs contain excessivebacterial endotoxins (see Bacterial Endotoxins Test〈85〉), they are potentially most hazardous topatients when administered into the centralnervous system.Despite the extensive attention in this chapter tothe provision, maintenance, and evaluation of airquality, the avoidance of direct or physical contactcontamination is paramount. It is generallyacknowledged that direct or physical contact ofcritical sites of CSPs with contaminants, especiallymicrobial sources, poses the greatest probability ofrisk to patients. Therefore, compounding personnelmust be meticulously conscientious in precludingcontact contamination of CSPs both within andoutside ISO Class 5 (see Table 1) areas.To achieve the above five conditions andpractices, this chapter provides minimum practiceand1quality standards for CSPs of drugs and nutrientsbased on current scientific information and beststerile compounding practices. The use oftechnologies,techniques,materials,andprocedures other than those described in thischapter is not prohibited so long as they have beenproven to be equivalent or superior with statisticalsignificance to those described herein. Thestandards in this chapter do not pertain to theclinical administration of CSPs to patients viaapplication, implantation, infusion, inhalation,injection, insertion, instillation, and irrigation,which are the routes of administration. Fourspecific categories of CSPs are described in thischapter: low-risk level, medium-risk level, andhigh-risk level, and immediate use. Sterilecompounding differs from nonsterile compounding(see Pharmaceutical Compound-ing—NonsterilePreparations 〈795〉 and Good CompoundingPractices 〈1075〉) primarily by requiring themaintenance of sterility when compoundingexclusively with sterile ingredients andcomponents ( i.e., with immediate-use CSPs,low-risk level CSPs, and medium-risk level CSPs)and the achievement of sterility whencompounding with nonsterile ingredients andcomponents (i.e., with high-risk level CSPs). Somedifferences between standards for sterilecompounding in this chapter and those fornonsterile compounding in PharmaceuticalCompounding—Nonsterile Preparations 〈795〉include, but are not limited to, ISO-classified airenvironments (see Table 1); personnel garbing andgloving; personnel training and testing inprinciples and practices of aseptic specifications and monitoring; and disinfection ofgloves and surfaces of ISO Class 5 (see Table 1)sources.Copyright 2008 The United States Pharmacopeial ConventionAll Rights Reserved.

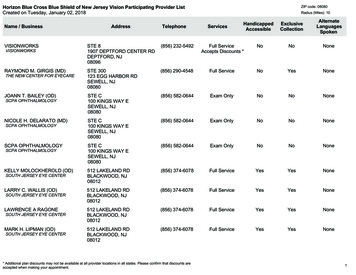

2〈797〉 Pharmaceutical Compounding—Sterile PreparationsTable 1. ISO Classification of ParticulateMatter in Room Air (limits are in particles of0.5 μm and larger per cubic meter [current ISO]and cubic feet [former Federal Standard No.209E,FS 209E])*Class NameISOClass3U.S. FS209EClass 145678Class 10Class 100Class 1,000Class 10,000ClassParticle CountFS209E,ISO, 10,000100,00*Adapted from former Federal Standard No. 209E, General ServicesAdministration, Washington, DC, 20407 (September 11, 1992) andISO 14644-1 : 1999, Cleanrooms and associated controlledenvironments—Part 1: Classification of air cleanliness. For example,3,520 particles of 0.5 mm per m3 or larger (ISO Class 5) isequivalent to 100 particles per ft3 (Class 100) (1 m3 35.2 ft3).The standards in this chapter are intended toapply to all persons who prepare CSPs and allplaces where CSPs are prepared (e.g., hospitals andother healthcare institutions, patient treatmentclinics, pharmacies, physicians‘ practice facilities,and other locations and facilities in which CSPs areprepared, stored, and transported). Persons whoperform sterile compounding include pharmacists,nurses, pharmacy technicians, and physicians.These terms recognize that most sterilecompounding is performed by or under thesupervision of pharmacists in pharmacies and alsothat this chapter applies to all healthcare personnelwho prepare, store, and transport CSPs. For thepurposes of this chapter, CSPs include any of thefollowing:(1) Compounded biologics, diagnostics, drugs,nutrients, and radiopharmaceuticals, including butnot limited to the following dosage forms that mustbe sterile when they are administered to patients:aqueous bronchial and nasal inhalations, baths andsoaks for live organs and tissues, injections (e.g.,colloidal dispersions, emulsions, solutions,suspensions), irrigations for wounds and bodycavities, ophthalmicRevision Bulletindrops and ointments, and tissueimplants.(2) Manufactured sterile products that are eitherprepared strictly according to the instructionsappearing in manufacturers‘ approved labeling(product package inserts) or prepareddifferently than published in such labeling.[NOTE—The FDA states that ―Compoundingdoes not include mixing, reconstituting, orsimilar acts that are performed in accordancewith the directions contained in approvedlabeling providedby ctions consistent with that labeling‖ [(21USC 321 (k) and (m)]. However, theFDA-approved labeling (product packageinsert) rarely describes environmental quality(e.g., ISO Class air designation, exposuredurations to non-ISO classified air, personnelgarbing and gloving, and other asepticprecautions by which sterile products are to beprepared for administration). Beyond-useexposure and storage dates or times (seeGeneral Notices and Requirements ons 〈795〉) for sterile products thathave been either opened or prepared foradministration are not specified in all packageinserts for all sterile products. Furthermore,when such durations are specified, they mayrefer to chemical stability and not necessarilyto microbiological purity or safety.]ORGANIZATION OF THIS CHAPTERThe sections in this chapter are organized tofacilitate the practitioner‘s understanding of thefundamental accuracy and quality practices forpreparing CSPs. They provide a foundation for thedevelopment and implementation of essentialprocedures for the safe preparation of low-risk,medium-risk, and high-risk level CSPs andimmediate-use CSPs, which are classifiedaccording to the potential for microbial, chemical,and physical contamination. The chapter is dividedinto the following main sections:Copyright 2008 The United States Pharmacopeial ConventionAll Rights Reserved.

〈797〉 Pharmaceutical Compounding—Sterile PreparationsRevision Bulletin DefinitionsResponsibility of Compounding PersonnelCSP Microbial Contamination Risk LevelsPersonnel Training and Evaluation in AsepticManipulation Skills Immediate-Use CSPs Single-Dose and Multiple-Dose Containers Hazardous Drugs as CSPs Radiopharmaceuticals as CSPs Allergen Extracts as CSPs Verification of Compounding Accuracy andSterility Environmental Quality and Control Suggested Standard Operating Procedures(SOPs) Elements of Quality Control Verification of Automated CompoundingDevices (ACDs) for Parenteral NutritionCompounding Finished Preparation Release Checks andTests Storage and Beyond-Use Dating Maintaining Sterility, Purity, and Stability ofDispensed and Distributed CSPs Patient or Caregiver Training Patient Monitoring and Adverse EventsReporting Quality Assurance (QA) Program Abbreviations and Acronyms Appendices I–VThe requirements and recommendations in thischapter are summarized in Appendix I. A list ofabbreviations and acronyms is included at the endof the main text, before the Appendices.All personnel who prepare CSPs shall beresponsible for understanding these fundamentalpractices and precautions, for developing andimplementing appropriate procedures, and forcontinually evaluating these procedures and thequality of final CSPs to prevent harm.DEFINITIONSAnte-Area—An ISO Class 8 (see Table 1) orbetter area where personnel hand hygiene andgarbing procedures, staging of components, eneratingactivitiesareperformed. It is also a transition area that (1)provides assurance that pressure relationships areconstantly maintained so that air flows from cleanto dirty areas and (2) reduces the need for theheating, ventilating, and air-conditioning (HVAC)control system to respond tolarge disturbances.1Aseptic Processing (see MicrobiologicalEvaluation of Clean Rooms and Other ControlledEnvironments 〈1116〉)—A mode of processingpharmaceutical and medical products that involvesthe separate sterilization of the product and of thepackage (containers–closures or packagingmaterial for medical devices) and the transfer ofthe product into the container and its closure underat least ISO Class 5 (see Table 1) conditions.Beyond-Use Date (BUD) (see General —NonsterilePreparations〈795〉)—For the purpose of this chapter, the dateor time after which a CSP shall not be stored ortransported. The date is determined from the dateor time the preparation is compounded.Biological Safety Cabinet (BSC)—A ventilatedcabinet for CSPs, personnel, product, andenvironmental protection having an open frontwith inward airflow for personnel EPA)-filtered laminar airflow for productprotection, and HEPA-filtered exhausted air forenvironmental protection.Buffer Area—An area where the primaryengineering control (PEC) is physically located.Activities that occur in this area include thepreparation and staging of components and suppliesused when compounding CSPs.Clean Room (see Microbiological Evaluation ofClean Rooms and Other Controlled Environments〈1116〉 and also the definition of Buffer Area)—Aroom in which the concentration of airborneparticles is controlled to meet a specified airborneparticulate cleanliness class. Microorganisms inthe environment are monitored so that a microbial1See American Society of Heating, Refrigerating andAir-Conditioning Engineers, Inc. (ASHRAE), Laboratory DesignGuide.Copyright 2008 The United States Pharmacopeial Convention All Rights Reserved.

4〈797〉 Pharmaceutical Compounding—Sterile Preparationslevel for air, surface, and personnel gear are notexceeded for a specified cleanliness class.Compounding Aseptic Containment Isolator(CACI)—A compounding aseptic isolator (CAI)designed to provide worker protection fromexposure to undesirable levels of airborne drugthroughout the compounding and material transferprocesses and to provide an aseptic environmentfor compounding sterile preparations. Airexchange with the surrounding environmentshould not occur unless the air is first passedthrough a microbial retentive filter (HEPAminimum) system capable of containing airborneconcentrations of the physical size and state of thedrug being compounded. Where volatile hazardousdrugs are prepared, the exhaust air from theisolator should be appropriately removed byproperly designed building ventilation.Compounding Aseptic Isolator (CAI)—Aform of isolator specifically designed forcompounding pharmaceutical ingredients orpreparations. It is designed to maintain an asepticcompounding environment within the isolatorthroughout the compounding and material transferprocesses. Air exchange into the isolator from thesurrounding environment should not occur unlessthe air has first passed through a microbiallyretentive filter (HEPA minimum).2Critical Area—An ISO Class 5 (see Table 1)environment.Critical Site—A location that includes anycomponent or fluid pathway surfaces (e.g., vialsepta, injection ports, beakers) or openings (e.g.,opened ampuls, needle hubs) exposed and at riskof direct contact with air (e.g., ambient room orHEPA filtered), moisture (e.g., oral and mucosalsecretions), or touch contamination. Risk ofmicrobial particulate contamination of the criticalsite increases with the size of the openings andexposure time.Direct Compounding Area (DCA)—A criticalarea within the ISO Class 5 (see Table 1) primaryengineering control (PEC) where critical sites are2CETA Applications Guide for the Use of Compounding Isolators inCompounding Sterile Preparations in Healthcare Facilities,CAG-001-2005, Controlled Environment Testing Association(CETA), November 8, 2005.Revision Bulletinexposed to unidirectional HEPA-filtered air, alsoknown as first air.Disinfectant—An agent that frees frominfection, usually a chemical agent but sometimesa physical one, and that destroys disease-causingpathogens or other harmful microorganisms butmay not kill bacterial and fungal spores. It refers tosubstances applied to inanimate objects.First Air—The air exiting the HEPA filter in aunidirectional air stream that is essentially particlefree.Hazardous Drugs—Drugs are classified ashazardous if studies in animals or humans indicatethat exposures to them have a potential for causingcancer, developmental or reproductive toxicity, orharm to organs. (See current NIOSH ents and 21 USC 321 (k) and (m)]—Aterm that designates all labels and other written,printed, or graphic matter on an immediatecontainer of an article or preparation or on, or in,any package or wrapper in which it is enclosed,except any outer shipping container. The term―label‖ designates that part of the labeling on theimmediate ion of Clean Rooms and Other ControlledEnvironments 〈1116〉)—A test used to qualifyaseptic technique of compounding personnel orprocesses and to ensure that the processes used areable to produce sterile product without microbialcontamination. During this test, a microbiologicalgrowth medium such as Soybean–Casein DigestMedium is substituted for the actual drug productto simulate admixture compounding.3 The issuesto consider in the development of a media-fill testare media-fill procedures, media selection, fillvolume, incubation, time and temperature,inspection of filled units, documentation,interpretation of results, and possible correctiveactions required.Multiple-Dose Container (see General Noticesand Requirements and Containers for Injectionsunder Injections 〈1〉)—A multiple-unit container3U.S. Food and Drug Administration, Guidance for Industry, SterileDrug Products Produced by Aseptic Processing—Current GoodManufacturing Practice, September 2004.Copyright 2008 The United States Pharmacopeial ConventionAll Rights Reserved.

Revision Bulletin〈797〉 Pharmaceutical Compounding—Sterile Preparationsfor articles or preparations intended for parenteraladministration only and usually containingantimicrobial preservatives. The beyond-use date(BUD) for an opened or entered (e.g.,needle-punctured) multiple-dose container withantimicrobial preservatives is 28 days (seeAntimicrobial Effectiveness Testing 〈51〉), unlessotherwise specified by the manufacturer.Negative Pressure Room—A room that is at alower pressure than the adjacent spaces and,therefore, the net flow of air is into the room.1Pharmacy Bulk Package (see Containers forInjections under Injections 〈1〉)—A container of asterile preparation for parenteral use that containsmany single doses. The contents are intended foruse in a pharmacy admixture program and arerestricted to the preparation of admixtures forinfusion or, through a sterile transfer device, forthe filling of empty sterile syringes. The closureshall be penetrated only one time after constitutionwith a suitable sterile transfer device or dispensingset, which allows measured dispensing of thecontents. The pharmacy bulk package is to be usedonly in a suitable work area such as a laminar flowhood (or an equivalent clean air compoundingarea).Where a container is offered as a pharmacy bulkpackage, the label shall (a) state prominently―Pharmacy Bulk Package—Not for DirectInfusion,‖ (b) contain or refer to information onproper techniques to help ensure safe use of theproduct, and (c) bear a statement limiting the timeframe in which the container may be used once ithas been entered, provided it is held under thelabeled storage conditions.Primary Engineering Control (PEC)—Adevice or room that provides an ISO Class 5 (seeTable 1) environment for the exposure of criticalsites when compounding CSPs. Such devicesinclude, but may not be limited to, laminar airflowworkbenches (LAFWs), biological safety cabinets(BSCs), compounding aseptic isolators (CAIs),and compounding aseptic containment isolators(CACIs).Preparation—A preparation, or a CSP, that is asterile drug or nutrient compounded in a licensedpharmacy or other healthcare-related facilitypursuant5to the order of a licensed prescriber; thearticle may or may not contain sterile products.Product—A commercially manufactured steriledrug or nutrient that has been evaluated for safetyand efficacy by the FDA. Products areaccompanied by full prescribing information,which is commonly known as the FDA-approvedmanufacturer‘s labeling or product package insert.Positive Pressure Room—A room that is at ahigher pressure than the adjacent spaces and,therefore, the net airflow is out of the room.1Single-Dose Container (see General Noticesand Requirements and Containers for Injectionsunder Injections 〈1〉)—A single-dose container is asingle-unit container for articles (see GeneralNotices and Requirements) or preparationsintended for parenteral administration only. It isintended for a single use. A single-dose containeris labeled as such. Examples of single-dosecontainers include prefilled syringes, cartridges,fusion-sealed containers, and closure-sealedcontainers when so labeled.Segregated Compounding Area—A designatedspace, either a demarcated area or room, that isrestricted to preparing low-risk level CSPs with12hour or less BUD. Such area shall contain adevice that provides unidirectional airflow of ISOClass 5 (see Table 1) air quality for preparation ofCSPs and shall be void of activities and materialsthat are extraneous to sterile compounding.Sterilizing Grade Membranes—Membranesthat are documented to retain 100% of a culture of107 microorganisms of a strain of Brevundimonas(Pseudomonas) diminuta per square centimeter ofmembrane surface under a pressure of not less than30 psi (2.0 bar). Such filter membranes arenominally at 0.22-mm or 0.2-mm nominal poresize, depending on the manufacturer‘s practice.Sterilization by Filtration—Passage of a fluidor solution through a sterilizing grade membraneto produce a sterile effluent.Terminal Sterilization—The application of alethal process (e.g., steam under pressure orautoclaving) to sealed containers for the purposeof achieving a predetermined sterility assuranceCopyright 2008 The United States Pharmacopeial ConventionAll Rights Reserved.

6〈797〉 Pharmaceutical Compounding—Sterile Preparationslevel of usually less than 10-6, or a probability ofless than one in one million of a nonsterile unit.3Unidirectional Flow (see footnote 3)—Anairflow moving in a single direction in a robustand uniform manner and at sufficient speed toreproducibily sweep particles away from thecritical processing or testing area.RESPONSIBILITY OF COMPOUNDINGPERSONNELCompounding personnel are responsible forensuring that CSPs are accurately identified,measured, diluted, and mixed and are correctlypurified, sterilized, packaged, sealed, labeled,stored, dispensed, and distributed. Theseperformance responsibilities include maintainingappropriate cleanliness conditions and providinglabeling and supplementary instructions for theproper clinical administration of CSPs.Compounding supervisors shall ensure, througheither direct measurement or appropriateinformation sources, that specific CSPs maintaintheir labeled strength within monograph limits forUSP articles, or within 10% if not specified, untiltheir BUDs. All CSPs are prepared in a mannerthat maintains sterility and minimizes theintroduction of particulate matter.A written quality assurance procedure includesthe following in-process checks that are applied, asappropriate, to specific CSPs: accuracy andprecision of measuring and weighing; therequirement for sterility; methods of sterilizationand purification; safe limits and ranges for strengthof ingredients, bacterial endotoxins, andparticulate matter; pH; labeling accuracy andcompleteness; BUD assignment; and packagingand storage requirements. The dispenser shall,when appropriate and practicable, obtain andevaluate results of testing for identity, strength,purity, and sterility before a CSP is dispensed.Qualified licensed healthcare professionals whosupervise compounding and dispensing of CSPsshall ensure that the following objectives areachieved:1.Compounding personnel areadequately skilled, educated, instructed, andtrained to2.3.4.5.6.7.Revision Bulletincorrectly perform and document the followingactivities in their sterile compounding duties:a. perform antiseptic hand cleansing anddisinfection of nonsterile compoundingsurfaces;b. select and appropriately don protectivegarb;c. maintain or achieve sterility of CSPs inISO Class 5 (see Table 1) PEC devicesand protect personnel and compoundingenvironments from contamination by radioactive, cytotoxic, and chemotoxicdrugs (see Hazardous Drugs as CSPs andRadiopharmaceuticals as CSPs);d. identify, weigh, and measure ingredients;ande. manipulate sterile products aseptically,sterilize high-risk level CSPs, and labeland quality inspect CSPs.Ingredients have their correct identity, quality,and purity.Opened or partially used packages ofingredients for subsequent use in CSPs areproperly stored under restricted accessconditions in the compounding facility. Suchpackages cannot be used when visualinspection detects unauthorized breaks in thecontainer, closure, and seal; when the contentsdo not possess the expected appearance,aroma, and texture; when the contents do notpass identification tests specified by thecompounding facility; and when either theBUD or expiration date has been exceeded.Water-containing CSPs that are nonsterileduring any phase of the compoundingprocedure are sterilized within 6 hours aftercompleting the preparation in order tominimize the generation of bacterialendotoxins.Sterilization methods achieve sterility ofCSPs while maintaining the labeled strengthof active ingredients and the physical integrityof packaging.Measuring, mixing, sterilizing, and purifyingdevices are clean, appropriately accurate, andeffective for their intended use.Potential harm from added substances andCopyright 2008 The United States Pharmacopeial ConventionAll Rights Reserved.

Revision Bulletin〈797〉 Pharmaceutical Compounding—Sterile Preparationsdifferences in rate and extent ofbioavailability of active ingredients for otherthan oral route of administration are carefullyevaluated before such CSPs are dispensed andadministered.8. Packaging selected for CSPs is appropriate topreserve the sterility and strength until theBUD.9. While being used, the compoundingenvironment maintains the sterility or thepresterilizationpurity,whicheverisappropriate, of the CSP.10. Labels on CSPs list the names and amounts orconcentrations of active ingredients, and thelabels or labeling of injections (seePreservation, Packaging, Storage, andLabeling in the General Notices andRequirements) list the names and amounts orconcentrations of all ingredients (seeInjections 〈1〉). Before being dispensed oradministered, the clarity of solutions isvisually confirmed; also, the identity andamounts of ingredients, procedures to prepareand sterilize CSPs, and specific releasecriteria are reviewed to ensure their accuracyand completeness.11. BUDs are assigned on the basis of directtesting or extrapolation from reliable literaturesources and other documentation (seeStability Criteria and Beyond-Use reparations〈795〉).12. Procedures for measuring, mixing, dilution,purification, sterilization, packaging, andlabeling conform to the correct sequence andquality established for the specified CSP.13. Deficiencies in compounding, labeling,packaging, and quality testing and inspectioncan be rapidly identified and corrected.14. When time and personnel availability sopermit, compounding manipulations andproceduresareseparatedfrompostcompounding quality inspection andreview before CSPs are dispensed.This chapter emphasizes the need to maintainhigh standards for the quality and control ofprocesses, components, and environments and for7the skill and knowledge of personnel who prepareCSPs. The rigor of in-process quality-controlchecks and of postcompounding quality inspectionand testing increases with the potential hazard ofthe route of administration. For ntamination, large errors in strength of correctingredients, and incorrect ingredients in CSPs arepotentially more dangerous to patients when theCSPs are administered into the vascular andcentral nervous systems than when administeredby most other routes.CSP MICROBIAL CONTAMINATION RISKLEVELSThe three contamination categories for CSPsdescribed in this section are assigned primarilyaccording to the potential for microbialcontamination during the compounding of low-risklevel CSPs and medium-risk level CSPs or thepotential for not sterilizing high-risk level CSPs,any of which would subject patients to risk ofharm, including death. High-risk level CSPs mustbe sterilized before being administered to patients.The appropriate risk level—low, medium, orhigh—is assigned according to the correspondingprobability of contaminating a CSP with (1)microbialcontamination(e.g.,microbialorganisms, spores, endotoxins) and (2) chemicaland physical contamination (e.g., foreignchemicals, physical matter). Potential sources ofcontamination include, but are not limited to, solidand liquid matter from compounding personnel andobjects; non-sterile components employed priate conditions within the lizationprocedureswithaqueouspreparations; and nonsterile dosage forms used tocompound CSPs.The characteristics described below for low-,medium-, and high-risk level CSPs are intended asa guide to the breadth and depth of care necessaryin compounding, but they are neither exhaustivenor prescriptive. The licensed healthcareprofessionals who supervise compounding areresponsible for determining the procedural andenvironmentalCopyright 2008 The United States Pharmacopeial Convention All Rights Reserved.

8〈797〉 Pharmaceutical Compounding—Sterile Preparationsquality practices and attributes that arenecessary for the risk level they assign to specificCSPs.These risk levels apply to the quality of CSPsimmediately after the final aseptic mixing orfilling or immediately after the final sterilization,unless precluded by the specific characteristics ofthe preparation. Upon subsequent storage andshipping of freshly finished CSPs, an increase inthe risks of chemical degradation of ingredients,contamination from physical damage to packaging,and permeability of plastic and elastomericpackaging is expected. In such cases,compounding personnel are responsible forconsidering the potential additional risks to theintegrity of CSPs when assigning BUDs. Thepre-administrationstoragedurationandtemperature limits specified in the followingsubsections apply in the absence of direct sterilitytesting results that justify different limits forspecific CSPs.Low-Risk Level CSPsCSPs compounded under all the followingconditions are at a low risk of contamination.Low-Risk Conditions—1. The CSPs are compounded with asepticmanipulations entirely within ISO Class 5(see Table 1) or better air quality using onlysterile ingredients, products, components, anddevices.2. The compounding involves only transfer,measuring, and mixing manipulations usingnotmorethanthreecommerciallymanufactured packages of sterile products andnot more than two entries into any one sterilecontainer or package (e.g., bag, vial) of sterileproduct or administration container/device toprepare the CSP.3. Manipulations are limited to asepticallyopening ampuls, penetrating disinfectedstoppers on vials with sterile needles andsyringes, and transferring sterile liquids insterile syringes to sterile administrationdevices, package containers of other sterileproducts, and containers for storage anddispensing.Revision Bulletin4. For a low-risk level preparation, in the absenceof passing a sterility test (see Sterility Tests〈71〉), the storage periods cannot exceed thefollowing time periods: before administration,the CSPs are properly stored and are exposedfor not more than 48 hours at controlled roomtemperature (see General Notices andRequirements), for not more than 14 days at acold temperature (see General Notices andRequirements), and for 45 days in solid frozenstate between 25 and 10 .Examples of Low-Risk Compounding—1. Single-volume transfers of sterile dosageforms from ampuls, bottles, bags, and vialsusing sterile syringes with sterile needles,other administration devices, and other sterilecontainers. The solution content of ampulsshould be passed through a sterile filter toremove

nurses, pharmacy technicians, and physicians. These terms recognize that most sterile compounding is performed by or under the supervision of pharmacists in pharmacies and also that this chapter applies to all healthcare personnel who prepare, store, and transport CSPs. For the pur