Transcription

Replacement Coils for Every Industry Replacemenet Engineering Made EasyWhat We OfferPRODUCTOVERVIEWReplacement CoilsFan Coil UnitsBelt Drive UnitsModular Air HandlersFluid CoolersRemote Condensers

USA COIL & AIRAT A GLANCEabout us: Satisfied CUSTOMERS APPLICATIONS services FOUNDED IN1984NOTABLE PROJECTS:

COMMERCIAL HVAC COILSCUSTOM AND OEM REPLACEMENTWhether you need replacement coils for an existing HVAC/Heat exchange system or a totally new design, wehave the expertise and the equipment to meet your needs. Standard and custom designs available. Our cuttingedge coil sizing/selection program is the most intuitive and “easy to use” sizing software in the industry. Oursoftware quickly generates performance charts and drawings to match your specification needs!EXISTING COIL REPLACEMENTUSA Coil & Air can help with replacement of all major OEM manufactured coils, including,but not limited to: Carrier, Trane, McQuay, York, Heatcraft, Aerofin, American - Standard,Bohn, Colmac, Marlo, and more.QUICK SHIPMENTWe have decades of design and manufacturing experience in the coil & air handlingbusiness. We can get you the products you need fast. The USA Coil & Air Quick Ship Programwill guarantee you can meet deadlines. Most coils can be built on our 5 or 10 working dayExpedited Schedule. In emergencies, some coils can be built in as little as 1 day.PROTECTIVE COATINGWe use “Fin-KOTE”, an 8th generation E-Coat designed for extreme environments. Thiscoating has a high-edge build for improved life, high flexibility for bending and improvedhandling, and corrosion protection. Immersion E-Coat provides a complete, uniformcoating, even in corners, on edges, and in hard to reach spaces. The applied coatingcontains very little water, so there are no runs or sags and parts can be handled almostimmediately.Have any questions or need any additional information? Feel free to contact us - We are here to help!USA Coil & Air Visit us Online at www.usacoil.com Contact us today at 800.872.2645

FLUID COILSCUSTOM AND OEM REPLACEMENTCOIL TUBESPRESSURE TESTINGTubes and return bends shall be constructed from seamlessUNS C12200 copper conforming to ASTM B75 and ASTM B743.Properties shall be O50 light annealed, with a maximum grainsize of 0.040mm. Tubes are to be mechanically expanded intoplate fins for maximum heat transfer.Coils shall be tested at 550 PSIG using dry nitrogen, submergedunder water. Dual-operator verification shall determine thatall coils are leak free. Coils shall be certified to withstand 750PSIG working pressure and guaranteed up to 200 F workingtemperature. Coils shall be shipped with nitrogen charge toverify leak-free integrity and to prevent moisture migration intothe coil.COIL FINSSecondary surface (fins) are of the plate-fin design usingaluminum or copper, with die-formed collars. The fin designfor 5/8” & 1/2” O.D. tubes is to be flat, waffle, or sinewave in astaggered tube pattern to meet performance requirements. Thefin design for 3/8” O.D. tubes is to be flat, louvered, or sinewavein a staggered tube pattern to meet performance requirements.Collars will hold fin spacing at specified density and cover theentire tube surface. Aluminum properties are to be Alloy 1100per ASTM B209, with O (soft) temper; copper is to be Alloy 11000per ASTM B152-06 with soft (anneal) temper. Fins are to be freeof oils and oxidations.COIL HEADERSStandard headers are constructed of seamless UNS C12200,Type L copper material sized to match specified connection size.Headers are to have finished integral spin-closed ends designedto withstand test pressure. 1/4” vents and drains are provided forall fluid coils unless specified otherwise.ARI CERTIFICATIONCOIL CASINGAll water coils designed with 1/2” or 5/8” tubes are to beAHRI performance certified and bear the AHRI symbol. Coilsoutside the scope of the AHRI’s standard rating conditions orthe manufacturer’s certification program will be acceptablesince the manufacturer is a current member of the AHRI coilcertification program, and coils will be rated in accordance withAHRI Standard 410.Coil casing material shall be of G90 galvanized steel, 16 gaugeminimum. Heavier gauge and optional material casings areavailable as required. Intermediate tube supports are to beprovided on all coils 50” and longer fin length. Coil casings ontop and bottom of coils are to have double-flange construction,allowing for vertical stacking of coils.FLUID COILSFLUID , Stainless SteelCasing16 Ga. Galv.Steel12,14 and 18 Ga. Galv. Steel12, 14 and 16 Ga. 304 & 316 Stainless Steel14 Ga. AluminumConnectionCopperSteel, Red BrassTubeCopperStainless Steel, Cupro Nickel, Carbon SteelHeaderCopperStainless Steel, Cupro Nickel, Carbon SteelO.D.STANDARDOPTIONALWALL THICKNESSSTANDARDOPTIONALFIN s and specifications are subject to change without notice

STEAM COILSCUSTOM AND OEM REPLACEMENTCOIL TUBESPRESSURE TESTINGTubes and return bends are to be constructed from seamlessUNS C12200 copper conforming to ASTM B75 and ASTM B743.Properties shall be O50 light annealed, with a maximum grainsize of 0.040mm. Tubes are to be mechanically expanded intoplate fins for maximum heat transfer. Minimum wall thickness:.025 for performance longevity.Coils shall be tested at 550 PSIG using dry nitrogen, submergedunder water. Dual-operator verification shall determine thatall coils are leak free. Coils shall be designed to withstand 150PSIG saturated steam supply pressures with appropriate wallthickness and guaranteed up to 400 F working temperature.COIL FINSCOIL HEADERSSecondary surface (fins) are of the plate-fin design usingaluminum or copper, with die-formed collars. The fin design isto be flat, waffle, or sine-wave in a staggered tube pattern tomeet performance requirements. Fins are to be free of oils andoxidations. Collars will hold fin spacing at specified density andcover the entire tube surface. Aluminum properties are to beAlloy 1100 per ASTM B209, O (soft) temper. Copper is to be Alloy11000 per ASTM B152-06 with soft (anneal) temper.Standard headers are constructed of seamless UNS C12200,Type L copper material sized to match specified connectionsize. All end closures are designed to withstand test pressure.Headers for steam distributing coils shall have die-formed endcaps brazed on the inside of the headers. Headers for standardsteam coils shall have finished integral spin-closed ends.ARI CERTIFICATIONAll steam coils are to be AHRI performance certified and bear theAHRI symbol. Coils outside the scope of AHRI’s standard ratingconditions or the manufacturer’s certification program will beacceptable since the manufacturer is a current member of theAHRI coil certification program, and all coils will be rated inaccordance with AHRI Standard 410.Coil casing material shall be of G90 galvanized steel, 16 gaugeminimum. Heavier gauge and optional material casings areavailable as required. All tube sheet holes are to be oversized toallow for free thermal expansion and contraction of tubes duringoperation. Intermediate tube supports are to be provided on allcoils 50” and longer in fin length. Coil casings on top and bottomof coils are to have double-flanged construction, allowing forvertical stacking of coils.STEAM COILSSTEAM COILSCOIL CASINGMATERIALSTANDARDOPTIONALFinAluminumCopper, Stainless SteelCasing16 Ga. Galv.Steel12,14 and 18 Ga. Galv. Steel12, 14 and 16 Ga. 304 & 316 Stainless Steel14 Ga. AluminumConnectionCopperSteel, Red BrassTubeCopperStainless Steel, Cupro Nickel, Carbon SteelHeaderCopperStainless Steel, Cupro Nickel, Carbon SteelTUBEO.D.STANDARDOPTIONALWALL THICKNESSSTANDARDFIN THICKNESS5/8".025.035.049.006.0075.0101”(SD ONLY).035.049.010N/A*Products and specifications are subject to change without notice.*

CONDENSER COILSCUSTOM AND OEM REPLACEMENTCOIL TUBESPRESSURE TESTINGTubes and return bends shall be constructed from seamlessUNS C12200 copper conforming to ASTM B75 and ASTM B743.Properties shall be O50 light annealed, with a maximum grainsize of 0.040mm. Tubes are to be mechanically expanded intoplate fins for maximum heat transfer.Coils shall be tested at 550 PSIG using dry nitrogen, submergedunder water. Dual-operator verification shall determine thatall coils are leak free. Coils shall be certified to withstand 750PSIG working pressure and guaranteed up to 200 F workingtemperature. Coils shall be shipped with nitrogen charge toverify leak-free integrity and to prevent moisture migration intothe coil.COIL FINSSecondary surface (fins) are of the plate-fin design usingaluminum or copper, with die-formed collars. The fin design is tobe flat, waffle, or sine-wave in a staggered tube pattern to meetperformance requirements. The fin design for 3/8 O.D. tubes isto be flat, louvered, or sinewave in a staggered tube pattern tomeet performance requirements. Fins are to be free of oils andoxidations.ARI CERTIFICATIONCOIL HEADERSStandard headers are to be constructed of seamless UNS C12200,Type L copper material sized to match specified connection size.Headers are to have finished integral spin-closed ends designedto withstand test pressure.COIL CASINGCoils shall be UL recognized as Refrigerant ContainingComponent. Coils that are to be used with refrigerant R-410Ashall have undergone cycle testing and shall be safely listed with750 PSIG rating.Coil casing material shall be of G90 galvanized steel, 16 gaugeminimum. Heavier gauge and optional material casings areavailable as required. Intermediate tube supports are to beprovided on all coils 50” and longer fin length. Coil casings ontop and bottom of coils are to have double-flange construction,allowing for vertical stacking of coils.CONDENSER COILSCONDENSER , Stainless SteelO.D.Casing16 Ga. Galv.Steel12,14 and 18 Ga. Galv. Steel12, 14 and 16 Ga. 304 & 316 Stainless Steel14 Ga. erN/ASTANDARDOPTIONALWALL THICKNESSSTANDARDOPTIONALFIN s and specifications are subject to change without notice*

EVAPORATOR COILSCUSTOM AND OEM REPLACEMENTCOIL TUBESPRESSURE TESTINGTubes and return bends shall be constructed from seamlessUNS C12200 copper conforming to ASTM B75 and ASTM B743.Properties shall be O50 light annealed, with a maximum grainsize of 0.040mm. Tubes are to be mechanically expanded intoplate fins for maximum heat transfer.Coils shall be tested at 550 PSIG using dry nitrogen, submergedunder water. Dual-operator verification shall determine thatall coils are leak free. Coils shall be certified to withstand 750PSIG working pressure and guaranteed up to 200 F workingtemperature. Coils shall be shipped with nitrogen charge toverify leak-free integrity and to prevent moisture migration intothe coil.COIL FINSCOIL HEADERSSecondary surface (fins) are of the plate-fin design usingaluminum or copper, with die-formed collars. The fin designfor 5/8” & 1/2” O.D. tubes is to be flat, waffle, or sinewave in astaggered tube pattern to meet performance requirements. Thefin design for 3/8” O.D. tubes is to be flat, louvered, or sinewavein a staggered tube pattern to meet performance requirements.Collars will hold fin spacing at specified density and cover theentire tube surface. Aluminum properties are to be Alloy 1100per ASTM B209, with O (soft) temper; copper is to be Alloy 11000per ASTM B152-06 with soft (anneal) temper. Fins are to be freeof oils and oxidations.Standard headers are to be constructed of seamless UNS C12200,Type L copper material sized to match specified connection size.Headers are to have finished integral spin-closed ends designedto withstand test pressure.COIL CASINGOur coils are UL recognized as Refrigerant ContainingComponent. Coils to be used with refrigerant R-410A will haveundergone cycle testing and will be safety listed with a 750 PSIGrating.Coil casing material shall be of G90 galvanized steel, 16 gaugeminimum. Heavier gauge and optional material casings areavailable as required. Intermediate tube supports are to beprovided on all coils 50” and longer fin length. Coil casings ontop and bottom of coils are to have double-flange construction,allowing for vertical stacking of coils.EVAPORATOR COILSEVAPORATOR COILSARI umCopperO.D.Casing16 Ga. Galv.Steel12,14 and 18 Ga. Galv. Steel12, 14 and 16 Ga. 304 & 316 Stainless Steel14 Ga. erN/ASTANDARDOPTIONALWALL THICKNESSSTANDARDOPTIONALFIN s and specifications are subject to change without notice*

SENTRYGUARDSENTRYGUARDEliminate the stress of system downtime and unnecessary replacementcosts with the innovative SentryGuard freeze protection system.Remove the possibility of completesystem failure due to freeze damagewith the most effective solutionavailable on the market today.Innovative Solutions That Protect Your Systems

SENTRY GUARD BURST PROOF RELIEF CAPSAPPLICATIONS:Preheat CoilsSteam/Hot Water- 100% outside air, where air is 40 degrees Fahrenheit or lower. The system may have built-incontrols, freezstats, etc. to prevent freezing. Often, systems stop working due to the failure of these controls.The Sentry Guard becomes the “Last Line of Defense” against freeze damage.Chilled Water CoilsCoils that operate during the winter may experience freezing air temperatures. The coil may see 60-degreeFahrenheit air one day and 25-degree Fahrenheit air the next day. Chilled water coils can be 5 to 10 times asexpensive to replace as heating coils due to the increased number of rows.Make-up Air SystemsMany applications such as kitchens, health facilities, and industrial applications require 100% exhaust. Thesesystems work 365 days a year and any mechanical malfunction can cause heating or cooling coils to freeze.Idle Chilled Water CoilsDuring the winter, chilled water coils that are not in operation need to be completely drained and/or filledwith a mixture of glycol/water. This process is costly and corrosive. Sentry Guard coils reduce the need forglycol additives. During a freeze event, the Sentry Guard caps will rupture to release pressure and preventtube bursting. Upon startup in the spring, easy replacement of the caps is all that is needed to get the coilsback in service.USA Coil & Air developed this patented product over a period of four years. Extensive testing wasconducted in International Falls, Minnesota with ambient temperatures as low as -30 degrees Fahrenheit.Based on this testing, USA offers a 30-month burst protection warranty on all Sentry Guard Coils.BenefitsAvoid whole coil replacementDecreases downtime from freeze damageWorks well with steam coil systemsEliminates or lowers cost of repairsNo changing row or circuitry arrangementGuaranteed burst resistantHave any questions or need any additional information? Feel free to contact us - We are here to help!USA Coil & Air Visit us Online at www.usacoil.com Contact us today at 800.872.2645

Premium Solution for Corrosion ProtectionCOIL COATINGFinKote2 is the premium coating system for the HVAC industry. Years of ineffectual coatings in the HVACmarket prompted the development of FinKote as a way to address those shortcomings. Finkote is a high edgebuild e-coating system that effectively coats both microchannel and tube and fin coils in AC units. Aluminum,copper, and steel coils can now be protected from corrosion, particularly in cases of high UV exposure, coastalinstallations, and offshore projects — anywhere with a highly abrasive environment that will cause prematurewear on coils. FinKote2 is the most advanced currently available e-coat system in the HVAC industry.FinKote2 now includes a standard 6 Year Warranty!PRETREATMENTParts are cleaned and pretreated with a conversion coating to prepare the part for electrocoating. This process guarentees a perfect final coat that is able to withstand corrosiveenvironments where conventional coils would break down and fail.ELECTRO-COATDirect current is applied between the parts and an electrode. Paint is attracted by theelectric field to the part where the current is deposited. This process allows for a durable andlonger lasting bond that is optimal for areas that are unable to be painted conventionally. RECOVERYEvery coil and all its parts are rinsed to reclaim deposited paint solids, ensuring a perfectcoating with no leftover residue or product waist. Any debris or foreign material couldeffect performance and result in possible system failure. Perfection and complete customersatisfaction is our number one priority.CUREPaint is thermally cross-linked and cured to the surface. Our curing process allows for atotal dry and hardened exterior in a short period of time. With the heat application andcuring process you can rest assured that your coating will provide adequate protectionand increase longevity.Have any questions or need any additional information? Feel free to contact us - We are here to help!USA Coil & Air Visit us Online at www.usacoil.com Contact us today at 800.872.2645

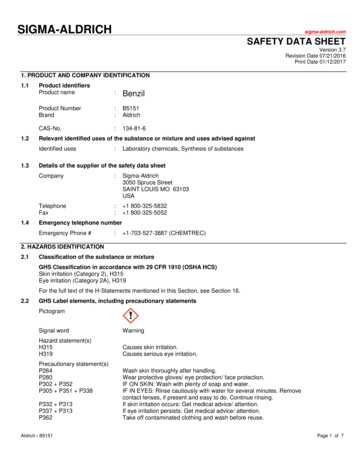

COIL COATINGPremium Solution for Corrosion ProtectionFinKOTE2 PERFORMANCE TESTINGTESTSPECIFICATIONRESULTSSWAAT run to failASTM G85 A3289 Days (6936 hrs)30 Day SWAAT AdhesionASTM G85 A3, ASTM D3359Pass, 4B2400 hr Cyclic corrosion BurstASTM G85 A2Pass, 2100 psiWater resistanceASTM D870-09Chipping resistanceASTM D3170Pass, 7ASteam resistanceASTM D714Pass, 48 hr, #6 or betterHumidity resistanceASTM D2247UV & QUV resistanceASTM G53-88, D4587, D523Pass, 600 hrs, no blistering or gloss loss1000 hrs, no lossChemical resistance48 hr immersion resistant to over 200 chemicalsHeat transfer 3%ThickenssASTM 376.8 - 1.2 mil (E-COAT) 1.8 - 4 mil (total)FlexibilityATSM D4145, ATSM 5222T, 5/8” mandrelImpact resistanceASTM D2794-93120 in. lbs, no cracking or chippingAdhesionASTM 33595BADDITIONAL TOP - COATS AVAILABLE :Extreme Environment Coating SystemsAdvanced Anti-Microbial Protection

DIRE

Coils shall be tested at 550 PSIG using dry nitrogen, submerged . under water. Dual-operator verification shall determine that . all coils are leak free. Coils shall be certified to withstand 750 PSIG working pressure and guaranteed up to 200 F working temperature.