Transcription

Refrigerated Compressed Air Dryers5-6,000 scfm.14-170 m3/min䡲 Refrigerated Non-Cycling䡲 Refrigerated Cycling䡲 Refrigerated High Temperature

Sullair Capabilitiesproducts are known around the worldfor their universally applicable design,outstanding craftsmanship andsuperior quality.Sullair LeadershipSince 1965, Sullair has beenrecognized around the world as aninnovator anda leader inrotary screwcompressionand vacuumtechnology.For more than40 years, Sullairhas designed and manufactured itsown rotors and air end assemblies atthe corporate headquarters inMichigan City, Indiana.The award-winning rotary screw designsets the industry standards anddelivers the quality and reliability oneexpects from a leader.Sullair’s Statistical Process ControlSullair’s Statistical Process Control(SPC) system monitors rotor qualitystandards to assure consistentcompressor and vacuum performance.Sullair’s Commitment to InnovationSullair TechnologyUtilizing the most moderntechnologies, equipment andadvanced manufacturing techniques,Sullair designs, manufactures,assembles, and tests the mostinnovative compressed air and vacuumproducts in the industry. SullairThe Sullair Stationary Air Power SystemOWS - 210This System includes: rotary screw compressor wet storage refrigerated dryer filters to meet your requirement dry storage flow controller drains oil/water separator ethernet-based eConnect to monitor and control the entire system2Underlying Sullair’s leadership is adedication to excellence and acommitment to innovation. Sullair isconstantly exploring new ideas andseeking new ways to meet industry’sneed for increasingly energy efficientcompressed air and vacuum solutions.

The Importance of Clean, Dry Compressed AirHow much water is too much?Any amount of water is too much.Water jeopardizes everything you want your compressed airsystem to do. It ruins product and fouls processes. Relative humidity is the amount of water vapor in airrelative to what it could hold at a given temperature Moisture in compressed air remains in a vapor statethrough the compression cycle, so it is not aproblem until it leaves the compressorLiquid remaining after the aftercooler: 14.7 gallons (32%) Air discharged from a compressor is approximately150 F to 450 F At 75 F and 75% relative humidity, a 75 hp compressortakes in 46 gallons of water vapor in 24 hours. When thisair is cooled to approximately 35 F at 100 psig, the watervapor condenses into 46 gallons of liquid!Liquid remaining after a refrigerated dryer: 1.8 gallons (4%)Refrigerated DryersSullair offers these configurations ofrefrigerant dryers RN – Refrigerated Non-Cycling5 to 325 scfm RD – Refrigerated Digital Cycling400 to 6,000 scfm RC – Refrigerated Cycling150 to 3,000 scfm RH – Refrigerated High Temperature15 to 100 scfmAll Sullair refrigerated dryers have these advantagesand features: Energy saving – true green product- 3-in-1 heat exchanger- High efficiency compressors Globally marketable refrigerant R-134a Standard electronic timer drains for 35 scfm and above Refrigerant analyzer indicator Fan cycle switch Easy removable side panels and parts Consistent dew point performance Low power consumption Low pressure drop Insulated heat exchanger Evaporator with multi-stage separator stainless steeldemister High quality fan motors Oversized condenserMax Inlet Temperature: 150 F(240 F High Temperature)Max Inlet Pressure: 230 psigMax Ambient Temperature 120 F3

Features of the Sullair Refrigerated DryersRefrigerated Non-Cycling DryersRN Series: 5-325 scfmRefrigerated Digital Cycling DryersRD Series: 400-6,000 scfm Optimum dew point levels for the highest systemperformance Cycling control for increased energy savings Energy efficient scroll compressor Low operating cost Optional communication package Consistent dew pointNo dew point swingsCompact footprintVariable flow capacity from 10% to 100%High inlet temperature (up to 150 F)Counter-current, variable flow heat exchangerNon-velocity sensitive demister/separatorConsistent dew pointRefrigerated Cycling DryersRC Series: 150-3,000 scfmHigh Temperature DryersRH Series: 15-100 scfm 4Stainless steel pump and cold storage tankThermal expansion valveProgrammable temperature controllerEnergy savings at low loadsIntermittent compressor operationSimple refrigerant circuitThermal mass storage mediumAccurate dew point controlInlet temperature up to 240 FIndependent air cooled after-coolerMoisture separatorTwo independent timer drainsEasy removable panels and maintenanceRated at 50 F dew point

How the Energy Saving 3-in-1 Heat Exchanger Works Warm air enters the Air to Air HeatAir to RefrigerantHeat ExchangerExchanger and exchanges heatwith the cooler air leaving.Air-to-Air HeatExchangerSeparator The air proceeds to the DryerSection and is cooled using eithermechanical refrigeration or liquid toa designated dew point.RefrigerantOutlet The mixture of cold air and moistureenters the separation chamber. Themoisture condenses into liquid andis isolated from the air stream and isdispensed with a timer drain.Air OutletRefrigerantInletAir Inlet The dry air then proceeds backthrough the Recuperation Sectionwhere it is heated by the incomingwarm air.How Refrigerated Cycling Dryers WorkHot saturated air from the after-coolerenters the air-to-air heat exchanger,where the air is pre-cooled by the cold,dry air leaving the heat exchanger. Thepre-cooled air then enters the air/glycolheat exchanger where it is cooled to itsfinal dew point by chilled water/glycol,flowing in the counter-current directionthrough the shell. The chilled airpasses through the moisture separator,which has a high efficiency ofseparation at different flow rates.Condensate is removed from thesystem using a timed drain valve.Finally, the cold, dry air is reheated inthe air-to-air heat exchanger by theincoming hot air for maximumvolumetric efficiency before exiting thedryer.The water/glycol is chilled by a cyclingrefrigeration system and continuouslypumped through the shell side of theair/glycol heat exchanger. The glycolflow rate remains constant, regardlessof compressed air load. Therefrigeration compressor unloadsand/or cycles OFF when presettemperature is reached for water/glycol, thus minimizing electricalpower consumption.Refrigerant Hot Refrigerant Cooled RefrigerantWater/Glycol Chilled Mixture Warm MixtureHot AirCool Air Hot Air Cooled Air Pre-cooled/Reheated Air Cooled Dry Air5

Comprehensive ControlsAdvanced, User-Friendly Microprocessor ControlsModels RC-400, RD-400 and larger dryers include: Digital multi-functional display Digital dew point temperature read-out for an accurateindication of actual working conditions Multiple alarm safety with easy-to-understand codedmessages Extensive programmability allows system to bepersonalized to individual user needs Status reports for quick reference to dryer operation Indicator to optimize preventive maintenance Volt-free alarm contact offers a remote status signal The controller has 8 temperature sensor inputsModels RN and RH dryers usesimple analog indicators and controls. Off switch with light Dew point indicatorThe Thermal Mass RC dryers use aElectro-Mechanical controller. Remote Stop/Start Remote Alarm Contact - Normally OpenRemote Monitoring Capabilities (Optional)The Sullair controller has a communications interface thatcan be used for remotely monitoring. Modbus RTUprotocol is used for communication. The user can remotelystart the dryer, stop the dryer, reset any alarm and monitor: Evaporator temperature Inlet air temperature Ambient temperature Refrigerant gas high and low temperature Fan, compressor and condenser working conditions Dew point Drain function Working hoursOperator InterfaceCloseup of panel shows its many features.Drain OutletControlEconomy ModeAlarm ResetPower ONOperator ConfiguratorButtonsPower OFFThe front panel view of the controller contains a four line 20character LCD display, 9 buttons and one alarm indicator LED.6

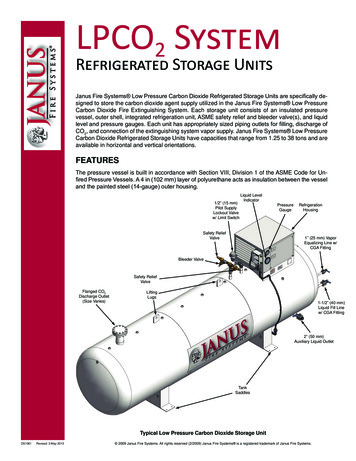

Intelligent Integral Zero-Loss DrainThe condensate drain is one ofthe most important componentsAll refrigerated dryers comestandard with a high quality timerdrain. A truly unique zero loss drainis offered as an option. With thezero loss drain, condensate iscollected in a chamber, segregatedfrom the air flow. As condensatebuilds, it activates a drain levelsensor built into the chamber. Thisopens an external solenoid valve toevacuate the condensate, closingthe valve again before any airescapes. The drain cycle continuallyadjusts itself to working conditions.R-134a Refrigerant:EnvironmentallyConsiderate and EfficientAll Sullair refrigerant dryers use R-134a refrigerantWhy R-134a?Features of R-134a: Does not deplete ozone Thermodynamic properties similar to R-12(dichlorodifluoromethane) 100% chlorine free Environmentally considerate Completely inert High and low temperature refrigerant Operates at nearly half the pressure of other refrigerants,so the compressor life span will increase. R-134a makes the refrigerated dryer much more tolerantto adverse conditions such as high ambient temperature.Optional zero loss drainSelf-diagnostic software avoidsfault situations. And should an erroroccur, an alarm will be signaledand the drain will continue tooperate on a pre-programmedtimed drain cycle. The controls forthe drain are part of themicroprocessor’s fully integratedcontrol and alarm system. Sullairoffers a drain alcove on all itsstandard dryers. This simplesolution is a major benefit to theuser. The drain is one of the mostimportant components within thedryer. If it doesn’t work properly thedryer’s whole operation iscompromised.The Sullair WarrantyAll Inclusive “Peace of Mind”WarrantySullair backs our commitment to quality with anunparalleled, non-prorated 5-year warranty (parts and labor)on the major components. No other manufacturer offers awarranty that is as all inclusive. (Note: a Sullair pre-filter mustbe installed upstream of the dryer as a prerequisite for thiswarranty.)Quality is Third Party Certified and Guaranteed.Dryers are manufactured in an ISO 9001 environment.7

Specifications: RN Non-Cycling Models60Hz Motor FrequencyModelElectricalAC / ACACAC50Hz Motor FrequencyModelElectricalAC / CACACACCapacityscfm nmmHeightin mmWeightlbs 12.82.83.53.54.24.24.95.67.07.07.07.09.29.29.21/2" NPT1/2" NPT1/2" NPT1/2" NPT1/2" NPT1/2" NPT1/2" NPT3/4" NPT3/4" NPT3/4" NPT3/4" NPT3/4" NPT3/4" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT2" NPT2" NPT2" 197215215243243465465465465494494494Capacityscfm 52002503251/2" NPT1/2" NPT1/2" NPT3/4" NPT3/4" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT2" 9Widthin 70127012701270Heightin 0210224224224Weightlbskg246102461023.2 59223.2 59228.7 72931.6 80534.2 87134.2 87149.8 126549.8 40Correction Factors for Models RN and RDInlet PressurepsigbarFactor Pressure: .51.10150101.16175121.25200141.30Ambient Temperature F CFactor Ambient: F3*Inlet Temperature F CFactor Inlet: F2*859029321.20 0600.45150650.35Performance Data Based On:Ambient temperatureInlet temperatureInlet 110430.90100 F100 F100 psig115460.80120490.6525 C35 C7 barFor flow rates at other conditions, please contact Sullair for correct sizing.*Flow Correction FactorsCapacity correction to be used when operating conditions differ from those shown above. To obtain dryercapacity at new conditions, multiply nominal capacity x F1 x F2 x F3.8Performance data obtained and presented in accordance with CAGI Standard No. ADF 100, “Refrigerated Compressed Air Dryers –Methods for Testing and Rating.”

Specifications: RD Digital Cycling Models60Hz Motor FrequencyModelElectricalAC / ACAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WC50Hz Motor FrequencyModelElectricalAC / -50400-3-50400-3-50400-3-50400-3-50400-3-50ACACAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCCapacityscfm fm 41.6169.9Inlet–OutletConnectionDrain2" NPT2" NPT2" NPT2" NPT2" NPT2" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT4" FLG4" FLG4" FLG4" FLG6" FLG6" FLG6" FLG6" FLG6" FLG6" FLG8" FLG8" FLG8" FLG8" -1/4"Inlet–OutletConnectionDrain2" NPT2" NPT3" NPT3" NPT3" NPT3" NPT4" FLG4" FLG6" FLG6" FLG6" FLG8" FLG8" /4"1-1/4"1-1/4"1-1/4"Widthin 19021902190276027602540254025402540Widthin 04805005105107607758759801095110012509

Specifications: RC Cycling Models60Hz Motor -60575-3-60460-3-60575-3-6050Hz Motor 3-50Correction Factors for RC Models10AC / WCCapacityscfm CACACACACACACACACAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / 200024002400300030001-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT2" NPT2" NPT2" NPT2" NPT2" NPT2" NPT2" NPT2" NPT2" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT3" NPT4" FLG4" FLG4" FLG4" FLG6" FLG6" FLG6" FLG6" "1-1/4"1-1/4"AC / WCCapacityscfm 3254005007008501000120016002000240030001-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT1-1/2" NPT2" NPT2" NPT2" NPT3" NPT3" NPT3" NPT3" NPT4" FLG4" FLG6" FLG6" /4"1-1/4"1-1/4"1-1/4"1-1/4"ACACACACACACAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / WCAC / 06Heightin 68096096011151280Inlet Pressurepsig50 60 75 100 115 125 150 175 200bar3.5 4.15

compressor and vacuum performance. Sullair’sCommitmenttoInnovation Underlying Sullair’s leadership is a dedication to excellence and a commitment to innovation. Sullair is constantly exploring new ideas and seeking new ways to meet industry’s need for increasingly energy efficient compressed air and