Transcription

Fuel Cell Based AuxiliaryPower Unit for RefrigeratedTrucksKriston BrooksPacific Northwest National LaboratoryJune 19, 2014Project ID# MT014This presentation does not contain any proprietary, confidential, or otherwise restricted information1

OverviewTimelineProject Start: April 2013Project End: Dec. 2015Percent complete: 37%BudgetFY13 DOE Funding: 800kPlanned FY14 DOEFunding: 0kTotal DOE Project Value: 1.6M Total (PNNL)ProgramIncludes 1.3M forsubcontractsContractor cost share 1.6MBarriersE. Inadequate private fundsavailable for new projectsF. Inadequate user experience forfuel cell applicationsH. Lack of awareness ofapplicationsPartnersProject LeadSystem IntegratorsTransport Refrigeration UnitDevelopersThermoKingCarrier TransicoldSystem DemonstratorsHEB and SyscoH2 Provider:Air Products

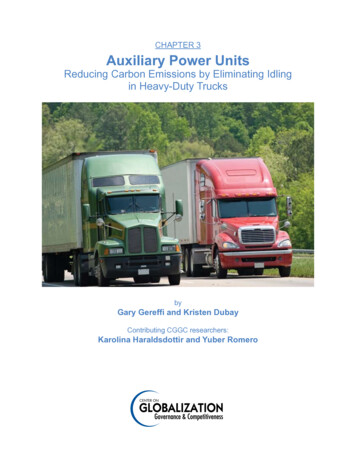

RelevanceOverall Objective: To demonstrate the viability of fuel cellbased Transport Refrigeration Units (TRUs) for refrigeratedClass 8 trucks.Barriers Addressed This Reporting PeriodE. A lack of financing mechanisms: Inadequate private fundsavailable for new projectsProvide DOE funding to support the demonstrationsDeveloped system design and performed prototype testingF. Inadequate user experienceDeveloped safety plan to address operations and refuelingDeveloped business case to determine commercial feasibilityH. Industry stakeholder lack of awareness of applicationsProject involves the two primary TRU companies—ThermoKing andCarrier TransicoldTRU manufacturers involved in business case development3

RelevanceValue Proposition for a Fuel Cell BasedAuxiliary Power Unit for Refrigerated TruckFuel cells system replaces diesel engine in providingpower to the Transport Refrigeration Unit (TRU) resultingin a system that:Is an environmentally-friendly technology system thataddresses recent environmental mandatesHas quiet operation that addresses noise restrictions inurban areas and may allow night-time operationsIs cost-competitive and more energy-efficient compared tothe incumbent internal combustion engine-powered vehiclesAddresses the uncertainty of diesel prices and theincreasing availability of low cost natural gas and hydrogenUltimately shows decreased energy expenditures whencompared to diesel-powered TRUs4

ApproachTwo year program to develop and demonstrate fuel cell system incommercial operationsAssess the system performanceAnalyze its market viability2012-2013Compete &PlaceSubcontractsAcquire Fuel-Cellbased system fordemonstration:Acquisitionsthrough opencompetitionUnited StatescompaniessolicitedTeam ofmanufacturersand elop abusiness case:Voice of sSizetheSystem2014-2015Design& TestAPU2015400 hrDemoMultipleSitesDesign the system:Define the powerrating of the system:Must becomparable tocurrent dieselModel expecteddoor openingsand ambienttemperaturesCollect actualexperimentalpower profilesDevelop fuel cellsystem with ratedpowerProvide powerconversionAddress safetyand compliantissues with TRUMake roadworthy2015AnalyzeDemoResults &ReportPerform testing anddemonstration:Site H2infrastructurepreparationPerformintermediate tests:vibration, etc.Install system andcommission APUPerform multiple400 hour tests withactual deliveriesand varying routes

ApproachDeploy Fuel Cell TRUTRU is a high-powered air conditioner used for transporting cold goodsDevelop Business CaseCompete SubcontractsSource: NuveraSource: PlugPowerDevelop Fuel Cell “Reefer”Source: PlugPowerDemonstrate 400 hrs at 3-4 SitesSource: NuveraApril 29, 2014Source: Plug Power

ApproachPlanned DemonstrationsNuveraDeveloping one systemDeveloping APU for Single Temperature TrailerPerforming two 400-hour demonstrations with HEBSysco is still interested, but do not use single temp trailersPlug PowerDeveloping three systemsDeveloping APU for Multi-Temperature TrailerPerforming four 400 hour demonstrations with Sysco7

ApproachMilestones and DeliverablesMilestone DescriptionOwnerMilestoneType% CompleteNotesDevelop Business CaseNuveraGo/No-Go100%(Sept 2013)DOE gave a “Go”decisionDevelop Safety PlanNuveraPlug PowerStandardOn-GoingImprovementsSafety Plan reviewedby Hydrogen SafetyPanelSubsystem TestingNuveraStandard100%(April 2014)Lab Scale Prototype TestingPlug PowerSuccessful Test of AlphaPrototype8Standard100%(April 2014)Plug PowerGo/No-GoUnderwayDue Date May 2014System Design andVerificationNuveraStandardUnderwayDue Date June 2014DemonstrationNuveraGo/No-GoNot startedNov-Mar 2015DemonstrationPlug PowerGo/No-GoNot startedMay-Sept 2015

Summary of Accomplishments This YearSet up subcontractsDeveloped business caseDefined power requirementsAddressed interfacesRefueling and electrical connectionsPrepared initial design documentsPrepared safety plan included such things as ISV, PrHA,DFMEAPerformed initial system testingDeveloped preliminary design9

AccomplishmentsDeveloped Business CaseApproachIdentify key value driversVoice of the CustomerInterviews with maintenance, engineers, warehouse,managersIdentified customer’s needsValue Proposition AnalysisCost of hydrogen vs. cost of diesel vs. cost of TRUPositive vs. negative net present valuePayback periodResultsMost of the results are considered proprietaryPositive NPV and 2 years payback possibleLarge fleet required to bring down H2 price10

AccomplishmentsNuvera/ThermoKing Business CaseSample Voice of the CustomerCustomer NeedComments and Insights from InterviewsEnsure and AcceptableROI“ROI is the biggest driver after safety.” Commercial Product must ultimately becost-effective on a life-cycle cost basis.Achieve SustainabilityGoalsBeing a sustainability leader in the industry is critical to corporate image, due toexpectations of consumers. “It’s important to restaurants to run green trucks.” “Ourcorporate definition of sustainability is to reduce fossil fuel use.” Waterconsumption is also an issue. Sustainability generally includes long-termeconomic feasibility of proposed solutions.Reduce Noise PollutionNoise from diesel engines is unacceptable in an increasing number of settingswhere food is delivered, including densely residential areas, underground parking,hotels, hospitals, and nursing homes. In some cases noise is specially regulatedby local ordinances. “We have been shut out of places because of noise.”Market AssessmentSample Value Proposition AnalysisWith ITCHydrogen11TRU IncrementalCostDiesel 4.00Diesel 6.00Diesel 8.00Hydrogen 2.50 21,000 21,888 57,399 92,980Hydrogen 4.00 21,000 9,297 44,878 80,459Hydrogen 6.00 21,000 (21,990) 13,592 49,173Hydrogen 8.00 21,000 (53,276) (17,695) 17,887Hydrogen 10.00 21,000 (84,563) (48,981) (13,400)Hydrogen 12.00 21,000 (115,849) (80,268) (44,686)

AccomplishmentsDefined Power RequirementsPlug Power: Data logging at Long Island compared toprevious testing at Sysco Houston

AccomplishmentsAddressed InterfacesHydrogen SupplyInterconnect Strategy 10 kg dispensed to TRU at 350 barPlug Power: Additionof an outdoor dispenserNuvera: PowerTap OnSite GenerationPower leads can berun to the electricinput that alreadyexists.The DG actsas a backup.If there is anissue with thefuel cell, theTRU controlsautomaticallyswitch thepower inputto the DG.Instead of trying tofit a fuel cell intothe TRU envelopefor the demo, itmakes more senseto use the electricstandby option onthe TRU.13

AccomplishmentsPlug Power: Completed Alpha PrototypeTestingLoad Bank20 kW output35 kW thermal rejectionCold temp testing - freeze protectionHigh temp testing - stack cooling marginPerforms well against application loadprofileLoadingDeliveriesPower TRU PrototypeTransport

AccomplishmentsNuvera: Completed Level 1 PrototypeTesting 15Developed PI1 Test StandTested SmartStackTM controls logic20 kW outputPerformed polarization curve

AccomplishmentsDeveloped Preliminary DesignFC System will be packaged in SGCM3000 frame(ThermoKing’s generator)16

Responses to Previous Year Reviewer’sCommentsNot Applicable: First Year Presentation17

CollaborationsNuvera TeamNuveraFuel Cell SupplierSystem IntegratorThermoKing/Ingersoll RandBusiness Case DevelopmentIntegration of APU with TRUHEB and SyscoDemonstration PartnersPlug Power TeamPlug PowerSystem IntegratorCarrier/TransicoldIntegration of APU with TRUSyscoDemonstration PartnerAir ProductsHydrogen Refueling StationSpecial ThanksPete Devlin, DOE-EERE Fuel Cells Technology Office18

Remaining Challenges and BarriersDevelop a robust fuel cell based APU forcommercial TRUs that:Is capable of on-road operationMeets the cost targets that make it economically viableCan be integrated into existing TRU design19

Future Work for Upcoming YearPNNL Manage SubcontractsEnsure high quality work performed to meet milestonesIdentify other value propositionsNuvera and Plug Power TeamDevelop and test full prototype systemFinalize infrastructure changesCertify for On-Road Application20

Project SummaryRelevanceDemonstrate the viability of fuel cell-based TransportRefrigeration Units (TRUs) for refrigerated Class 8trailers.Approach Demonstrate fuel cell system in commercialapplications Assess the system performance Analyze its market viability Developed business cases and safety plansTechnicalAccomplishments Developed system designs and addressed interfacesand H2 infrastructure issuesand Progress Successfully demonstration subsystem performanceCollaborations Nuvera and its team: ThermoKing, Sysco, and HEB Plug Power and its team: Carrier Transicold, Syscoand Air ProductsProposed FutureResearch Continue to oversee project Complete system design and testing Perform multiple 400 hour demonstrationsKriston BrooksProject ID# MT01421(509) 372-4343kriston.brooks@pnnl.gov

Technical Backup Slides22

Timeline of ApproachTaskNuveraContract SignedDevelop Business CaseDevelop Preliminary Safety PlanGo/No-Go #1Complete PrHA and ISVPreliminary DesignDetailed DesignStack Core TestingSubsystem TestingFuel Cell System TestingFuel Cell /TRU IntegrationGo/No-Go #2DemonstrationsFinal Report23Plug PowerContract SignedSystem Requirements DocumentDevelop Preliminary Safety PlanDevelop Load ProfilePrototype Build and TestingGo/No-Go #1Complete Build of 3 SystemsFactory Acceptance TestingOEM TestingGo/No-Go #2Commisioning on TruckDemonstrationFinal ReportQ2Q3Q4Q1FY14Q2 Q3Q4Q1FY15Q2 Q3Q4Q1FY16Q2 Q3Q4

Jun 19, 2014 · Fuel Cell Supplier System Integrator . ThermoKing/Ingersoll Rand . Business Case Development Integration of APU with TRU . HEB and Sysco . Demonstration Partners . 18 . Plug Power Team . Plug Power . System Integrator . Carrier/Transicold . Integration of APU with TRU . Sysco . Demonstratio