Transcription

excellenccelebringeEconomy through AutomationatSAREY03SADPRAUPGROPlastic Auxiliary Equipments from World LeadersTHI

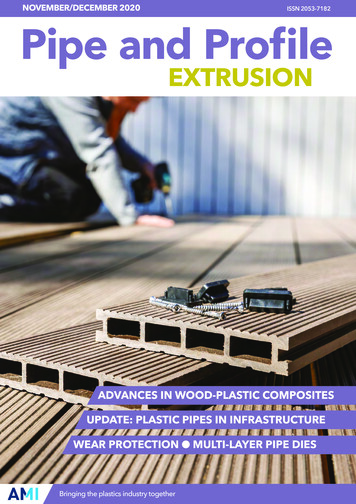

Economy through AutomationTotal SolutionRaw Material to Finish ProductSolutions for Diverse ApplicationsPrasad Group of companies - started operations in 1984 for manufacturing post extrusionequipment for plastics industry. Now, Prasad has India's largest and most sophisticatedinfrastructure for manufacturing Plastic Auxiliary Equipments.Automation, sophistication and upgradation of technology is the need of the hour and thecompany keeps itself fully updated to provide the same. Responding to the ever growing demandof automation solutions, the people at Prasad are always focused on customer satisfaction,operational excellence and above all design innovation.PET Preforms lingSilo andFeedingSystemPowderBatching andConveyingDehumidifiedAir enderCompactChillerPET RecyclingTCaps & ClosuresHouse Hold &White GoodsEngineeringComponentsWires & CablesAutomobilesElectricals &ElectronicsHDPE Pipes &DuctsPVC Pipes &ProfilesWoven nlineGranulatorGranulatorShredders

Prasad Koch-Technik Pvt. Ltd.THIA joint venture with Werner Koch Maschinentechnik GmbH - GermanyHopper Loader & Ratio LoaderDehumidified Air Dryer For conveying wide varietyof polymers. Output from 8 kg/hrto 2500 kg/hr. Most energy efficient design gives dewpoint up to -50o C. Special line for PET & PET flakesintegrated with inline crystalizer forthroughput upto 700 kg/hr. Capacity from 25 m3/hr to 3000 m3/hr.Volumetric FeederAll Metal Separator This modular feeding systemgives accurate dosing and mixingof master batch online withmicroprocessor control. Supplied with optional agitator forhomogenous mixing. Protects plastic processing machinescrew, barrel and die from ferrous andnon-ferrous metal debris. Patented control eject unwanted partsout of the system online withoutdisturbing main process.Gravimetric BlenderCentral Conveying System Weighing, Metering, Controllingand Correcting in one operation,new GRAVIKO series giveshighest accuracy in industry. Upto 8 component dosing andthroughput for 1800 kg/hr. Prasad Group has successfullycommissioned many central conveyingsystems in India. Computerised sophisticated materialmanagement system caters from 4machines to 40 machines with 16different materials.Hot Air DryerSilo and Silo Feeding System Stainless steel dryers with insulationare designed for easy cleaning andquick material change. Capacity from 15 ltrs. to 5000 ltrs. Aluminium, stainless steel and carbonsteel with coating from 5 m3 to 100 m3storage capacity. Silo Feeding System unloads materialfrom 25 kg. bags and jumbo bags.Extrusion Process ControlDebagging Surge Bin Control extruder output under 0.5%and saves expensive material bybetter GSM control. Ideal for multi layer film plant, pipeplant and calendering line. Different size of debagging bins toempty 25 kg., 250 kg., 500 kg. and1 ton jumbo bags quickly and easily. Capacity from 100 ltrs. to 2500 ltrs.www.koch-technik.com

Prasad GWK Cooltech Pvt. Ltd.A joint venture with Gesellschaft Warme Kaltetechnik mbH - GermanyCompact Chiller Energy efficient air/water cooled compact chillers,suitable for working in high ambient conditions. User friendly Microprocessor/PLC based controller withdigital indication, function and fault details. Cooling capacity from 7 KW (2 TR) to 790 KW (225 TR).Screw Chiller Air/Water cooled type Cooling capacity from 140 KW (40 TR) to 900 KW (260 TR) Step less capacity control (25 to 100%)Air Chiller Direct cooling air chillers for blown film plants. Precise temperature control ensures uniformair temperature throughout the day. Lower air temperature at reduced power cost. Capacity from 1500 m3/hr to 10000 m3/hr.Mould Temperature ControllerMould Temperature Controller (Water or Oil based) with precisemicroprocessor control with simultaneous display of set and actual values. Mould draining facility Leak stop operation Automatic re-feeding Fault indication Mimic diagramWater based Mould Temperature Controller up to 1500 C.Mould Sweat Protector Prevents sweating on the surface of the mould and thus allows torun mould at a lower cycle time that leads to high productivity.www.gwk.com

Prasad Wemo Robot Systems Pvt. Ltd.A joint venture with Wemo Automation AB - SwedenWemo Automation AB, Sweden provides Indian plastic industry a competitive edge inmodern automation.All models in Wemo Robot systems are equipped with maintenance free ACservomotors. These servomotors facilitate lower energy costs, longer lifetime, higherperformance and greater flexibility.Servo RobotsHigh speed servo & eco servodrive with all 3 axis fullcontrol system for injectionmoulding machine ranging 25tons to 2500 tons.Intelligent ControlMost advanced control inindustry. Interactive dialoguemode with configurablesymbols and text gives rapidand easy programming tool.New Servo Swing Arm RobotThis servo sprue picker isfuturistic innovation fromWemo. A unique automationsystem with high speedrotating axis is ideal for sprueas well as parts picker forsmaller injection mouldingmachines.eDesign RoboteDesign stands for : economy efficiency energy savingOptimizes for costefficientinvestmentAll three linear axes aredesigned with high efficient ACservo motors for simultaneousmovement (3D)Quick Gripper SystemPatented WGS : Quick - LockGrip Exchange System can beadapted to new as well as toexisting robots. Reduce setting &gripper changing time drasticallyin case of rapid product mouldchanging.Gripper Kit GBL1GBL 1 is an easy starter kit,made out to facilitate the startfor the inexperienced fitter.The starter kit contains morethan 300 components makingit possible to build up to 9different grippers.www.wemo.se

Prasad Crilec Automation Pvt. Ltd.A joint venture with Costruzioni Meccaniche Crizaf S.p.A. - ItalyPrasad offers Polymer conveyor belts from world renowned Crizaf, S.p.A, ITALY.This intelligent part conveyor integrated with other ancillary equipmentcan greatly increase quality and efficiency of the processing unit.Horizontal Conveyer Belt (with robots)Plastic Conveyer BeltsSprue Separator and ConveyingDrum SeparatorParts Counting - WeighingStacking SystemAdvantages of Crizaf Conveyor Belts Saving of labour & parts damage.Clean room condition - untouched by human.Integrated with Robots - assembly line.Automatic counting of parts & filling into box. Separation of sprue & parts automatically.Go under the mould - connected to online granulator.Can be integrated with any existing line.High quality and consistency in production.www.crizaf.com

Prasad Machinery Pvt. Ltd.Technical collaboration with Moditec s.r.l. - FranceModitec, France offers this patented technology which is very different thanconventional grinder. It does not have any screen, knife or blades. When you usesuch Slow Speed Technology it works with no noise, no material distortion and nodust.The Power of Slow SpeedThis technology works on 28RPM and produces excellentquality of regrind withoutdegrading polymerproperties. PLC Base controland ABS – Anti BlockingSystem ensures full safety.Goliath GranulatorIt is ideal solution for onlineprocess and by the machinerecovery of plastic waste. Itgives highest return oninvestment with technicalpolymers like PA, PC, Acrylicand glass filled material.Auger Feed DeviceThe Granulator with augerfeed designed to be useddirectly under the mould,ideal for processing spruesand runners when robots orthree platen moulds areused. Augur feed is withoptional metal detectionsystem to prevent undesiredobject to go inside cuttingchamber.Goliath TwinFor higher output and biggerarticles, Moditec offers GoliathTwin. This modular systememploy same goliath cutter insegmented parts and eachcutter is reversible so ifrequired, cutter can bereversed and used withoutre-sharpening.Masher SystemPatented masher system isspecially designed forGoliath Twin or BiggerGranulator. It is the 3rd cutterfitted inside hopper. It grabslonger parts and pushesinside cutting chamber.Bigger GranulatorDesigned for big & bulkyobjects like automobilebumpers, dash boards & pinchoffs, sanitary, TV cabinets,washing machine buckets,refrigerator trays etc.It works on low speed, thusconsumes much lesser energy.nly11 KW Owww.mo-di-tec.fr

Prasad Machinery Pvt. Ltd.Technical collaboration with Rapid Granulator AB, SwedenRecycling plastic waste directly offers several advantages like material savings,improved flow management, increased competitiveness and environment-friendlymanufacturing. Rapid manufactures individual granulators and complete integratedrecycling system for the plastics industry. The company now offers its expertise andservices in India under technical collaboration with Prasad Group.Rapid’s 40 years of experience gives solutions for individual demands. Every Rapidgranulator is built to ensure that you get cost-effective granulation and high-qualityregrind month after month, year after year.Open hearted conceptfor easy accessConveyor beltwithmetal detectionAirMilled plasticMilledplasticAirAir &dustDustparticlesGranulateAir &dustGranulateComplete Integrated Dust Separating SystemCompact Serieswww.rapidgranulator.se

Prasad Pneucon Solution Pvt. Ltd.Silo and Silo Feeding SystemManufacturing silo from 50 tons to20,000 tons with carbon steel,stainless steel, aluminum denseand dilute phase with feedingsystem.PVC Powder Conveying SystemConveying of PVC dry blend, filleror any kind of difficult powderwas never been so easy. Ariosteapowder loader with carbon filtercartridge and Jet pulse cleaningcan give you output from 150kg/hr to 2500 kg/hr.PVC Dry Blend Batching SystemTo load PVC & CaCo3 gravimetricallyon high speed mixer can greatlyincrease the efficiency of mixer.Sophisticated control which canintegrate with any existing systemmakes your operation errorless.Additives and LiquidDosing additives and liquidgravimetrically on mixer improvesquality of dry blend. This can beintegrated with loading PVC andfiller to automate whole process.Total projects like . PVC pipes & profiles PVC Fittings Masterbatch Compounding Cable Compounding Plant Polymer Compounding Wood Plastic Compositewww.prasadgroup.com

ExpositionsMilestones1984 - 93 Began operations with manufacturing plastic auxiliary and post extrusionequipments for Klockner Windsor India Ltd. Manufactured mono layer film plant PP500 and PP750 (Polypropylene andHM) for Klockner Windsor India Ltd. Manufactured Nitride screws for extrusion and injection moulding machines1994 - 98K - GermanyK - GermanyChina Plast - Shanghai Technical collaboration (in 1995) with Koch-Technik, Germany for manufacturingplastic auxiliary equipments - Dosing, mixing, conveying and drying systems Joint Venture (in 1996) with Koch-Technik, Germany Joint Venture (in 1998) with GWK, Germany to manufacture chiller andmould temperature controller Technical collaboration (in 1998) with Moditec, France to manufacture lowspeed, high torque granulator, 'Goliath’ 1st plastic auxiliary equipments manufacturer in India, to obtain ISO 9001:2000quality certification1999 - 03Plastindia - New Delhi Supplied 1st central conveying system to Essel Packaging Ltd., Wada Shifted to new facility with an area of 15,840 sq. mts. Supplied 1st high-tech 'Goliath' twin granulator toBalmer Lawrie-Vann Leer Ltd., Mumbai Set-up new facility for GWK with modern insulated factory andpre-fabricated structurePlexpo - AhmedabadPlastivision - MumbaiOur Global Presence2004 - 08RUSSIA Technical collaboration (in 2005) with Crizaf, Italy Joint Venture (in 2006) with Wemo Automation AB, Sweden to manufacturerobots for plastic industry Technical collaboration (in 2007) withRapid Granulator AB, Sweden 1st Robot installed on Injection moulding machine, Havells India Ltd., Baddi Technical collaboration (in 2008) with Ariostea, Italyto manufacture bulk material handling systems,PVC and all powder E d’IVORY NIGERIASAUDI ARABIASUDANOMANVIETNAM2013 - 2014ETHIOPIAGHANA CONGO UGANDAKENYADR ASCARSOUTH AFRICAAUSTRALIA Extension for manufacturing higher capacity screw type chilling plants Inauguration of new manufacturing facility for powder material handlingsystem - Prasad Pneucon Solution Pvt. Ltd. New green office building for sales, marketing and financeand the journey continues.

excellenccelebringeatInfrastructureThe lush green environment,insulated factory premisesand work friendly atmosphereto support creation ofworld class products.Spread across 72,000 m2, the company is equipped with modern infrastructure.SAR30 YESADPRAUPGRO

Corporate Social ResponsibilityOur GroupThe Group is equally committed to its Corporate Social Responsibility and is actively involved inupliftment of needy communities in several districts of Gujarat and Bihar through its close linkagewith various NGOs and charitable trusts.The activities include providing primary education and free health services, operating grain banks,deployment of water conservation projects and building homes for homeless.PLASTIC AUXILIARY EQUIPMENTS DIVISIONTHIPRASAD KOCH-TECHNIK PVT. LTD.A joint venture with Koch Technik-GERMANYfor manufacturing Plastic Auxiliary EquipmentsPRASAD GWK COOLTECH PVT. LTD.A joint venture with GWK-GERMANYfor manufacturing Chillers and Mould Temp. ControllersPRASAD WEMO ROBOT SYSTEMS PVT. LTD.A joint venture with Wemo-SWEDENfor Servo Robot System and Automation in Injection MouldingPRASAD CRILEC AUTOMATION PVT. LTD.A joint venture with Crizaf-ITALYfor Conveyor Belts and Part Handling SystemPRASAD MACHINERY PVT. LTD.Rain

modern automation. All models in Wemo Robot systems are equipped with maintenance free AC servomotors. These servomotors facilitate lower energy costs, longer lifetime, higher performance and greater flexibility. Intelligent Control Most advanced control in industry. Interactive dialogue mode with configurable symbols and text gives rapid and easy programming tool. New Servo Swing Arm Robot .