Transcription

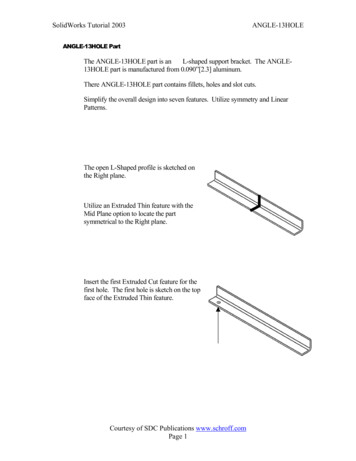

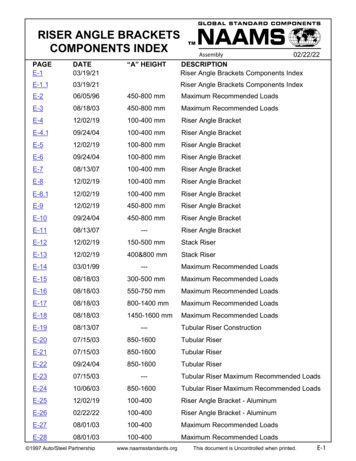

RISER ANGLE BRACKETSCOMPONENTS /21E-206/05/96450-800 mmMaximum Recommended LoadsE-308/18/03450-800 mmMaximum Recommended LoadsE-412/02/19100-400 mmRiser Angle BracketE-4.109/24/04100-400 mmRiser Angle BracketE-512/02/19100-800 mmRiser Angle BracketE-609/24/04100-800 mmRiser Angle BracketE-708/13/07100-400 mmRiser Angle BracketE-812/02/19100-400 mmRiser Angle BracketE-8.112/02/19100-400 mmRiser Angle BracketE-912/02/19450-800 mmRiser Angle BracketE-1009/24/04450-800 mmRiser Angle BracketE-1108/13/07---E-1212/02/19150-500 mmStack RiserE-1312/02/19400&800 mmStack RiserE-1403/01/99E-1508/18/03300-500 mmMaximum Recommended LoadsE-1608/18/03550-750 mmMaximum Recommended LoadsE-1708/18/03800-1400 mmMaximum Recommended LoadsE-1808/18/031450-1600 mmMaximum Recommended LoadsE-1908/13/07E-2007/15/03850-1600Tubular RiserE-2107/15/03850-1600Tubular RiserE-2209/24/04850-1600Tubular RiserE-2307/15/03E-2410/06/03850-1600Tubular Riser Maximum Recommended LoadsE-2512/02/19100-400Riser Angle Bracket - AluminumE-2602/22/22100-400Riser Angle Bracket - AluminumE-2708/01/03100-400Maximum Recommended LoadsE-2808/01/03100-400Maximum Recommended Loads 1997 Auto/Steel Partnership“A” HEIGHTTMDESCRIPTIONRiser Angle Brackets Components IndexRiser Angle Brackets Components Index---------www.naamsstandards.orgRiser Angle BracketMaximum Recommended LoadsTubular Riser ConstructionTubular Riser Maximum Recommended LoadsThis document is Uncontrolled when printed.E-1

RISER ANGLE BRACKETSCOMPONENTS /0703/19/2103/19/21 1997 Auto/Steel PartnershipTMAssembly“A” HEIGHT60-60060-600300-1200mmDESCRIPTIONRiser for Pass TablesRiser for Pass TablesDrop Away Leaf Riser600-1500mm0Drop Away Leaf Riserwww.naamsstandards.org02/22/22This document is Uncontrolled when printed.E-1.1

MAXIMUMRECOMMENDEDLOADSG L O B A L S TA N D A R D C O M P O N E N T STMAssembly06/05/96PA150(6.0)OFFSET BXXXRISERDIM “A”SEE TABLE OF RECOMMENDED LOADS ON FOLLOWING PAGE 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E–2

G L O B A L S TA N D A R D C O M P O N E N T SRISER ANGLEBRACKETTMAssemblyGTolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.0.03 A S12/02/19MATERIAL: STEEL ASTM A-36SEE PAGE B-1.1 FOR GLOBALMATERIALS CHARTCB85.0016.0AØ 13.5(4) HOLESØ 10F7(2) HOLESIDF35.00140.0REF.OL55.035.00AJ20.0OL0.0 TO 25.0 MAX. TYP.15.070.000.0 TO 10.0 MAX. TYP. 5.0110.0 -1.5H47.5B (4) HOLESTYPICAL CONFIGURATION. WILLVARY ACCORDING TO METHODOF FABRICATIONOLØ 8F7(2) HOLESWHERE WELDED, FILLET WELDFULL LENGTH TO AWS D1.1BOTH SIDES OF JOINTA 55.0A 35.00“A”EA -35.00XXX100mm MINFINISH REQ'D-A-15.0OLTABULATED INFORMATION ON FOLLOWING PAGE 1997 Auto/Steel PartnershipThis document is Uncontrolled when printed.E–4

RISER ANGLEBRACKETNAMMS CODE“A” DIMTMAssembly“B”09/24/04WT. 1AAB401M400.0011.013.61ABSEE DRAWING ON PRECEDING PAGE 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-4.1

G L O B A L S TA N D A R D C O M P O N E N T SRISER ANGLEBRACKETTMAssembly12/02/19Tolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.0.03 A SGFMATERIAL: STEEL ASTM A-36SEE PAGE B-1.1 FOR GLOBALMATERIALS CHARTDC100.0030.0030.0MAXIMUM RECOMMENDEDLOADS ON PAGE E-2B110.0020.0Ø 13.5(4) HOLES65.00Ø 10 F7(2) HOLES195.0REF.OL85.00.0 TO 10.0 MAX. TYP.20.00.0 TO 25.0 MAX. TYP.15.0OL130.0065.00H77.5170.0110.0B (4) HOLESTYPICAL CONFIGURATION. WILLVARY ACCORDING TO METHODOF FABRICATIONØ 8F7(2) HOLESWHERE WELDED, FILLET WELDFULL LENGTH TO AWS D1.1BOTH SIDES OF JOINTA 55.0A 35.00E110.0“A”XXXA - 35.00A100mm MINFINISH REQ'DTABULATED INFORMATION ON FOLLOWING PAGE 1997 Auto/Steel Partnership-A-This document is Uncontrolled when printed.20.0OLE–5

RISER ANGLEBRACKETNAMMS CODE“A” DIMTMAssembly09/24/04WT. M10x1.544.4ARA801M800.0011.044.4ABCSEE DRAWING ON PRECEDING PAGE 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-6

G L O B A L S TA N D A R D C O M P O N E N T SRISER ANGLEBRACKETTMAssembly08/13/07Tolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVESURFACES TO BE FLAT, PARALLEL & PERPENDICULAR TO WITHIN 0.015 T.I.R.NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.C“A” DIMWT. kgAHB001M11.02.5AHB002MM10 x 1.52.5NAMMS CODEDMATERIAL: STEEL ASTM A-36SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHARTFAOLE11.0 STARTØ 8H6(2) HOLESA (4) HOLES5" x 5" x 1/2" x 110 mmSTL ANGLE11.0 STARTOL40.01/4" X 3/4" X 110 mm75.00B45 TYP70.00110.0OL20.0 START52.0 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E–7

RISER ANGLEBRACKETG L O B A L S TA N D A R D C O M P O N E N T STMAssemblyTolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.12/02/19EMATERIAL: STEEL ASTM A-36SEE PAGE B-1.1 FOR GLOBALMATERIALS CHARTHCB0.03 A S85.00A16.09/16(4) HOLES35.00SF FOR 3/8 DOWEL(2) HOLES140.0REF.OLD55.00.0 TO 10.0 MAX. TYP.20.0OL0.0 TO 25.0 MAX. TYP.15.0 5.070.0035.00G110.0 -1.547.5B (4) HOLESIOLA 55.0A 35.00S.F FOR 5/16 DOWEL(2) HOLESTYPICAL CONFIGURATION. WILLVARY ACCORDING TO METHODOF FABRICATIONWHERE WELDED, FILLET WELDFULL LENGTH TO AWS D1.1BOTH SIDES OF JOINT“A”A -35.00XXX100mm MINFINISH REQ'D-A- 1997 Auto/Steel PartnershipFThis document is Uncontrolled when printed.15.0OLE–8

G L O B A L S TA N D A R D C O M P O N E N T SRISER ANGLEBRACKETTMAssemblyNAAMS“A” B401E 1997 Auto/Steel 16 tap13/323/8-16 tap13/323/8-16 tap13/323/8-16 tap13/323/8-16 tap13/323/8-16 tap13/323/8-16 tap13/3212/02/19WT. 2.2413.6113.61This document is Uncontrolled when printed.E – 8.1

G L O B A L S TA N D A R D C O M P O N E N T SRISER ANGLEBRACKETTMAssembly0.03 A SMATERIAL: STEEL ASTM A-36SEE PAGE B-1.1 FOR GLOBALMATERIALS CHARTGHEC100.0030.0DMAXIMUM RECOMMENDEDLOADS ON PAGE E-230.00Tolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.12/02/19110.00B20.09/16(4) HOLES65.00SF FOR 3/8 DOWEL(2) HOLES195.0REF.OL85.00.0 TO 10.0 MAX. TYP.20.00.0 TO 25.0 MAX. TYP.15.0OL130.0065.0077.5170.0I110.0B (4) HOLESSF FOR 5/16 DOWEL(2) HOLESA 55.0A 35.00110.0TYPICAL CONFIGURATION. WILLVARY ACCORDING TO METHODOF FABRICATIONXXXWHERE WELDED, FILLET WELDFULL LENGTH TO AWS D1.1BOTH SIDES OF JOINT“A”FA - 35.00100mm MINFINISH REQ'DAC20.0-A-OLTABULATED INFORMATION ON FOLLOWING PAGE 1997 Auto/Steel PartnershipThis document is Uncontrolled when printed.E–9

RISER ANGLEBRACKETTMAssembly“A” DIM“B”WT. kgARA450E450.003/8-16 tap24.5ARA451E450.0013/3224.5ARA500E500.003/8-16 tap28.1ARA501ENAMMS CODE500.0013/3228.1ARA550E550.003/8-16 tap29.5ARA551E550.0013/3229.5ARA600E600.003/8-16 tap31.7ARA601E600.0013/3231.7ARA650E650.003/8-16 tap34.5ARA651E650.0013/3234.5ARA700E700.003/8-16 tap37.2ARA701E700.0013/3237.2ARA750E750.003/8-16 tap39.0ARA751E750.0013/3239.0ARA800E800.003/8-16 tap44.4ARA801E800.0013/3244.409/24/04ABCSEE DRAWING ON PRECEDING PAGE 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-10

RISER ANGLEBRACKETG L O B A L S TA N D A R D C O M P O N E N T STMAssembly08/13/07Tolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACEMATERIAL: STEEL ASTM A-36 0.03 BETWEEN DOWELS IN THE SAME PLANESEE PAGE B-1.1 FOR GLOBAL 0.10 BETWEEN DOWELS IN DIFFERENT PLANESMATERIALS CHART 0.13 TO SCREW HOLES, NON ACCUMULATIVESURFACES TO BE FLAT, PARALLEL & PERPENDICULAR TO WITHIN 0.015 T.I.R.NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.NAAMS “A” DIMCODEAHB001E13/32AHB002E 3/8-16 TAPWT. kgDFE2.52.5CAOL11.0 STARTPF FOR 5/16 DWL(2) HOLESA (4) HOLES5" x 5" x 1/2" x 110 mmSTL ANGLE11.0 STARTOL40.01/4" X 3/4" X 110 mmB75.00110.070.0045 TYPOL20.0 START52.0 1997 Auto/Steel PartnershipThis document is Uncontrolled when printed.E – 11

G L O B A L S TA N D A R D C O M P O N E N T SSTACK RISERTMAssembly12/02/19MATERIAL: STEEL ASTM A-3610.0030.00WHERE WELDED, FILLET WELD FULLLENGTH TO AWS D1.1 BOTH SIDES OF JOINT60.00TYPICAL CONFIGURATION WILL VARYACCORDING TO DESIGN AND METHODOF FABRICATION25.00Tolerances:SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART1 PLACE MACHINING 0.31 PLACE FABRICATION 1.5140.02 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND85.0 REFA HEEL SURFACE 0.03 BETWEEN DOWELSØ10 H6IN THE SAME PLANE(2) HOLES 0.10 BETWEEN DOWELSIN DIFFERENT PLANES100.00 0.13 TO SCREW HOLES,NON ACCUMULATIVE110.015.0NOTES: ALL DIMENSIONS METRICUNLESS OTHERWISENOTED. IDENTIFY WITH77.530.00NAAMS CODE NUMBER ASOLSHOWN XXX.M12X1.75(4) HOLESEFABHC20.015.0XXXDGA20.0195.0OL20.0170.0Ø 65.00PART 0110.0Ø10 F7 (2) HOLES 1997 Auto/Steel PartnershipThis document is Uncontrolled when printed.E – 12

G L O B A L S TA N D A R D C O M P O N E N T SSTACK RISERTMAssemblyTolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLEDOWEL ANDA HEEL SURFACE 0.03 BETWEEN DOWELSIN THE SAME PLANE 0.10 BETWEEN DOWELS140.00IN DIFFERENT PLANES 0.13 TO SCREW HOLES,NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC170.0UNLESS OTHERWISENOTED. IDENTIFY WITHNAAMS CODE NUMBER ASSHOWN XXX.10.00OLD195.0110.0REFH6Ø10(2) HOLESBA15.0H55.0010.0WHERE WELDED, FILLET WELD FULLLENGTH TO AWS D1.1 BOTH SIDES OF JOINTOL75.0087.510.00TYPICAL CONFIGURATION WILL VARYACCORDING TO DESIGN AND METHODOF FABRICATION12/02/19M12 X 1.75(4) HOLES20.015.0MATERIAL: STEEL ASTM A-36SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHARTCXXXFAG20.0215.0120.0OLPART NO.ASR 240ASR 280A40080020.0190.0Ø 13.5(4)HOLES 1997 Auto/Steel PartnershipOLThis document is Uncontrolled when printed.75.0075.00150.00Ø10F7(2) HOLESE – 13

MAXIMUMRECOMMENDEDLOADSG L O B A L S TA N D A R D C O M P O N E N T STMAssembly03/01/99P150 (6.0)OFFSET BXXXRISER DIM "A"HEIGHT "A"STACK RISER DIM "A"SEE TABLE OF RECOMMENDED LOADS ON FOLLOWING PAGE 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E – 14

TUBULAR 085M AND ARB085E880.0440.0NAMMS CODE1 PLACE FABRICATIONTOLERANCES 1.508/13/07ARB090M AND ARB090E930.0465.0ARB095M AND ARB095E980.0490.0ARB100M AND ARB100E1030.0515.0ARB105M AND ARB105E1080.0540.0ARB110M AND ARB110E1130.0565.0ARB115M AND ARB115E1180.0590.0ARB120M AND ARB120E1230.0615.0ARB125M AND ARB125E1280.0640.0ARB130M AND ARB130E1330.0665.0ARB135M AND ARB135E1380.0690.0ARB140M AND ARB140E1430.0715.0ARB145M AND ARB145E1480.0740.0ARB150M AND ARB150E1530.0765.0ARB155M AND ARB155E1580.0790.0ARB160M AND ARB160E1630.0815.0ARISER BRACKETWELDED CONST. STRESS RELIEVE11-STEEL ASTM A-36 7/8” x 8” x 260.0mm LG.22-STEEL ASTM A-36 3/8” x 3” x “C” LG.31-STEEL TUBING 4” x 4” x 3/8 W/T x “B” LG.ASTM A500 GRADE BARB1554 1-STEEL ASTM A-36 1/4” x 4 1/2” x 645.0mm LG.ARB16051-STEEL ASTM A-36 1/4” x 4 1/2” x 670.0mm LG.61-STEEL ASTM A-36 3/4” x 4 1/2” x 160.0mm LG.7 1-STEEL ASTM A-36 3/8” x 3 5/8” x 97.0mm LG.MATERIAL: STEEL ASTM A-36SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART1 1997 Auto/Steel Partnership www.naamsstandards.orgNOTES: ALL DIMENSIONS ARE METRICUNLESS OTHERWISE NOTEDIDENTIFY WITH NAAMS CODENUMBER AS SHOWN XXXThis document is Uncontrolled when printed.E-19B

TUBULAR RISERARB085M THRU ARB160MTMAssembly07/15/03Tolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX."A""B""C" 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-20

TUBULAR RISERARB085E THRU ARB160ETMAssembly07/15/03Tolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX."A""B""C" 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-21

TUBULAR RISERARB085M THRU ARB160M& ARB085E THRU ARB160ETMAssembly09/24/04“A” DIM“B”“C”WT. kgARB085M AND ARB085E850.00880.0440.043.1ARB090M AND ARB090E900.00930.0465.044.9ARB095M AND ARB095E950.00980.0490.046.7ARB100M AND ARB100E1000.001030.0515.048.5ARB105M AND ARB105E1050.001080.0540.050.3ARB110M AND ARB110ENAMMS CODE1100.001130.0565.052.2ARB115M AND ARB115E1150.001180.0590.054.0ARB120M AND ARB120E1200.001230.0615.055.8ARB125M AND ARB125E1250.001280.0640.057.6ARB130M AND ARB130E1300.001330.0665.059.4ARB135M AND ARB135E1350.001380.0690.061.2ARB140M AND ARB140E1400.001430.0715.063.0ARB145M AND ARB145E1450.001480.0740.064.9ARB150M AND ARB150E1500.001530.0765.066.7ARB155M AND ARB155E1550.001580.0790.072.6ARB160M AND ARB160E1600.001630.0815.074.4 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.AE-22

TUBULAR RISERMAXIMUM RECOMMENDEDLOADSTMAssembly07/15/03PLA 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-23

TUBULAR RISERMAXIMUM RECOMMENDEDLOADSOFFSET LIn.mm3001225010200815061004LOAD B110ETMAssembly10/06/03OFFSET LIn.mm3001225010200815061004LOAD 4209NAAMSCODEARB085MandARB085E 1997 Auto/Steel ndARB125EThis document is Uncontrolled when printed.AE-24

G L O B A L S TA N D A R D C O M P O N E N T SRISER ANGLEBRACKET-ALUMINUMTMAssemblyTolerances:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON ACCUMULATIVENOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.0.03 A S12/02/19MATERIAL:ASTM 713 CAST ALUMINUMASEE PAGE B-1.1 FOR GLOBALMATERIALS CHART85.0016.0Ø 13.5(4) HOLESØ 10F7(2) HOLES35.00140.0REF.OL55.035.00A15.020.0OL0.0 TO 25.0 MAX. TYP.70.000.0 TO 10.0 MAX. TYP.110.0B47.5Ø 11(4) HOLESTYPICAL CONFIGURATION. WILLVARY ACCORDING TO METHODOF FABRICATIONOLØ 8F7(2) HOLESWHERE WELDED, FILLET WELDFULL LENGTH TO AWS D1.1BOTH SIDES OF JOINTA 55.0A 35.00“A”A -35.00XXX100mm MINFINISH REQ'D-A-15.0OLTABULATED INFORMATION ON FOLLOWING PAGE 1997 Auto/Steel PartnershipThis document is Uncontrolled when printed.E – 25

RISER � 400.004.369.61SEE DRAWING ON PRECEDING PAGENOTE: IT IS RECOMMENDED TO USE HARDENED FLAT WASHERSON FASTENERS ON ALUMINUM RISERS. 1997 Auto/Steel Partnership www.naamsstandards.orgThis document is Uncontrolled when printed.AE-26

MAXIMUMRECOMMENDEDLOADSTMAssembly08/01/03SEE TABLE OF RECOMMENDED LOADS ON FOLLOWING PAGE 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-27

MAXIMUMRECOMMENDEDLOADSTMAssembly08/01/03MAXIMUM RECOMMENDED LOAD FOR 0.13 mm (0.005 in.) DEFLECTIONOFFSET VALUES (L) AND POINTS OF APPLICATION OF LOAD P ARE DEFINED IN THE FIGURE ON THE PRECEDING PAGE.ALLOWABLE 0.13 mm (0.005 in.) DEFLECTIONS ARE MEASURED AT THE POINT OF APPLICATION OF LOAD P, AND DO NOT INCLUDEDEFLECTIONS OF THE BLADE.MAXIMUM RECOMMENDED LOADS ARE BASED ON ALUMINUM WITH A MODULUS OF ELASTICITY OF 73 GPA (10,600,000 1AAAB401AOffset 0815061004Load 31832974417945521247911781,263284SEE DRAWING ON PRECEDING PAGE 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-28

RISER FORPASS ART25.411.0 DRILL THRU(4) HOLES13.5 STARTcbBA38.0aXXX15.0STARTEXCEPT AS NOTED TOLERANCES SHALL BE:1 PLACE MACHINING 0.31 PLACE FABRICATION 1.52 PLACE 0.03 GENERAL 0.03 BETWEEN DOWELS 0.13 TO SCREW HOLESNOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.WELDED CONSTRUCTION - STRESS RELIEVEVENT TO SUITIDENTIFY WITH NAAMS CODE NUMBERAS SHOWN XXX 1997 Auto/Steel Partnershipwww.naamsstandards.orgINCH STOCKa 1 - HRSb 1 - STL TBGc 1 - HRSASTM A-36 3/4” X 5” X 5”ASTM A-36 2” X 2” X 3/16” WT X BASTM A-36 3/4” X 3” X 4”METRIC STOCKa 1 - HRSb 1 - HRSc 1 - HRSASTM A-36 20MM X 125MM X 125MMASTM A-36 50MM X 50MM X 4 WT X BASTM A-36 20MM X 75MM X 100MMThis document is Uncontrolled when printed.AE-29B

RISER FORPASS 0330.0300.0 1997 Auto/Steel Partnershipwww.naamsstandards.orgThis document is Uncontrolled when printed.E-30

DROP AWAYLEAF RISERTM(TOP MOUNT MACHINE BASE MOUNTING)Assembly03/19/21TOLERANCES:NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.1 PLACE MACHINING 0.3WELDED CONSTRUCTION - STRESS RELIEVE VENT TO SUIT1 PLACE FABRICATION 1.5IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX2 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON �13.5(4) HOLES135.0070.00240.0REF.OL65.0020.0 TOTUBINGaF7Ø10.0(2) HOLESSEE PAGES N-26.2 THRU N-26.4FOR MOUNTING OPTIONSAOLH6Ø10.0(2) .085.0START20.0STARTM12 X 1.75TAP THRU(4) .01200.020.0XXXbBAc50.0 1997 Auto/Steel PartnershipOLOL20.0STARTwww.naamsstandards.orgINCH STOCKa 1 - HRSb 1 - STL TBGc 1 - HRSASTM A-36 1” X 9 1/2” X 9 1/2”ASTM A-36 8” X 8” X 1/2” X BASTM A-36 1” X 9 1/2” X 12”METRIC STOCKa 1 - HRSb 1 - STL TBGc 1 - HRSASTM A-36 25MM X 240MM X240MMASTM A-36 200MM X 200MM X 13MM X BASTM A-36 25MM X 240MM X 300MMThis document is Uncontrolled when printed.E-31

DROP AWAYLEAF RISERTM(SIDE MOUNT MACHINE BASE MOUNTING)Assembly03/19/21TOLERANCES:NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.1 PLACE MACHINING 0.3WELDED CONSTRUCTION - STRESS RELIEVE VENT TO SUIT1 PLACE FABRICATION 1.5IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX2 PLACE 0.08 BETWEEN MACHINED SURFACES 0.03 BETWEEN SINGLE DOWEL AND A HEEL SURFACE 0.03 BETWEEN DOWELS IN THE SAME PLANE 0.10 BETWEEN DOWELS IN DIFFERENT PLANES 0.13 TO SCREW HOLES, NON RV900ARV105ARV120ARV135ARV150Ø10.0(2) HOLESØ13.5(4) .0035.00H6Ø10.0(4) HOLESM12 X 1.75TAP THRU(4) 15.01565.0INCH STOCKa 1 - HRSb 1 - STL TBGc 1 - HRSd 1 - HRSASTM A-36ASTM A-36ASTM A-36ASTM A-361/4” X 7 1/2” X 7 1/2”8” X 8” X 1/2” X B1 3/8” X 6” X 6”1” X 9 1/2” X 12”METRIC STOCKa 1 - HRSb 1 - STL TBGc 1 - HRSd 1 - HRSASTM A-36ASTM A-36ASTM A-36ASTM A-366MM X 190MM X 190MM200MM X 200MM X 13MM X B35MM X 150MM X 150MM25MM X 240MM X 300MMSEE PAGES N-26.2 THRU N-26.4FOR MOUNTING OPTIONSaA5.0c12.0OLXXXOL35.0035.00BAbd20.0OL 1997 Auto/Steel is document is Uncontrolled when printed.E-32

full length to aws d1.1 both sides of joint b (4) holes Ø 8 f7 (2) holes 15.0 (4) holes Ø 10 (2) holes f7 65.00 20.0 195.0 ref. 0 0. 0 0 1 0 0. 0 3 65.00 130.00 20.0 170.0 110.0 a 55.0 a 35.00 a - 35.00 "a" 20.0 110.0 0.03 a s 110.00-a-100mm min finish req'd ol 85.0 ol ol maximum recommended loads on page e-2 riser angle bracket .