Transcription

E 30.000.4/01.17Accumulator Technology. Product Catalogue.Accumulator Technology.Product Catalogue.

1.HYDAC ACCUMULATOR TECHNOLOGYFLUID ENGINEERING EFFICIENCY VIA ENERGY MANAGEMENT.HYDAC Accumulator Technology has over50 years' experience in research &development, design and production ofHydac accumulators.Bladder, piston, diaphragm and metalbellows accumulators from HYDACtogether form an unbeatable range and ascomponents or units, support hydraulicsystems in almost all sectors.The main applications of our accumulatorsare:zzEnergy storage,zzEmergency and safety functions,zzDamping of vibrations, fluctuations,pulsations (pulsation damper), shocks(shock absorber) and noise (silencer),zzSuction flow stabilisation,zzMedia separation,zzVolume and leakage oil adjustment,zzWeight equalization,zzEnergy recovery.Using accumulators improves theperformance of the whole system and indetail this has the following advantages:zzImprovement in the functionszzIncrease in service lifezzReduction in operating and maintenancecostszzReduction in pulsations and noiseOn the one hand, this means greatersafety and comfort for operator andmachine.On the other hand, HYDAC accumulatorsenable efficient working in all applications.2.E 3.000.15/01.17Basic criteria, such as:zzDesign pressure,zzDesign temperature,zzFluid displacement volume,zzDischarge / Charging velocity,zzFluid,zzAcceptance specifications and alsozzInstallation optionsare important parameters required forsizing the correct accumulator.In addition the knowledge developed byour accumulator specialists will help toselect the right type of accumulator. Thecomprehensive range of HYDACaccessories simplifies installation andmaintenance according to thespecification.2QUALITYQuality, safety and reliability are paramountfor all HYDAC accumulator components.They comply with the current regulations(or standards) for pressure vessels in theindividual countries of installation.In taking delivery of a HYDAC hydraulicaccumulator therefore, the customer isassured of a high-quality accumulatorproduct which can be used in everycountry in the world, depending on thecertification.For more details, please turn to Section 4.All the processes involved, fromdevelopment, engineering and productionto approval and delivery are defined byHYDAC's certified management systemand the relevant international accreditationfor the manufacture of pressure vessels.In conjunction with the customer servicedepartment at HYDAC's headquarters,service is possible worldwide.HYDAC's worldwide distributor networkmeans that trained staff are close at handto help our customers.This ensures that HYDAC customers havethe support of an experienced workforceboth before and after sale.

Page1.HYDAC ACCUMULATOR TECHNOLOGY22.QUALITY23.SAFETY INFORMATION44.REGULATIONS55.PRODUCT OVERVIEW5.1.BLADDER ACCUMULATORS5.1.1CataloguesectionPageE 3.0002Low pressureE 3.202215.1.2StandardE 3.201295.1.3High pressureE 3.203375.2.PISTON ACCUMULATORS5.2.1StandardE 3.301415.2.2Series SK280E 3.303535.2.3High pressureE 3.302575.3.DIAPHRAGM ACCUMULATORSE 3.100635.4.METAL BELLOWS ACCUMULATORSE 3.304715.5.HYDRAULIC DAMPERSE 3.701775.6.SPECIAL ACCUMULATORS5.7.ACCUMULATOR STATIONSE 3.653975.8.ACCUMULATOR ACCESSORIES5.8.1Hydraulic accumulators with back-up nitrogen bottlesE 3.5531035.8.2Charging and testing unitE 3.5011115.8.3Safety and shut-off blockE 3.5511235.8.4Safety equipment for accumulatorsE 3.5521475.8.5Supports for hydraulic accumulatorsE 3.5021555.8.6ACCUSET SBE 3.5031656.INDUSTRIES AND APPLICATIONS6–89 – 107. / 8. WEBSITE / SPECIFICATION FORMS10 – 179.SIZING18 – 1910.NOTE19E 3.000.15/01.17CONTENTS3

3.SAFETY INFORMATIONE 3.000.15/01.17Accumulators are closed vessels which aredesigned and built to hold pressurizedfluids. They are charged with nitrogenwhich is separated from the fluid sectionby a piston, bladder or diaphragm.Hydraulic accumulators are specificallydesigned to store and then dischargepressurized fluids.The regulations for commissioning andoperating hydraulic accumulators whichare in force at the place of installation mustbe observed. The plant operator is solelyresponsible for ensuring compliance withthese regulations.Relevant instructions are provided in theOperating Instructions for our products.4Manufacturers of hydraulic accumulatorsand products with hydraulic accumulatorsmust observe the following principles:zzRemoval or reduction of risks, insofar asthis is reasonably possible,zzApplication of appropriate protectivemeasures against risks which cannot beeliminated,zzIf required, training of the users onthe residual risks and instructionson appropriate special measures forreducing the risks during installation and/or operation.For safe handling and operation, theoperator must draw up a risk assessmentfor the installation site, particularly incombination with other components andrisks.The resulting measures must beimplemented accordingly.In the case of fundamental risks affectinghydraulic accumulators, e.g.zzExcessive pressure andzzIncrease in temperature (in the event offire)we already have the relevant productsavailable.On no account must any welding, solderingor mechanical work be carried out on theaccumulator shell. After the hydraulic linehas been connected it must be completelyvented. Work on systems with hydraulicaccumulators (repairs, connectingpressure gauges etc.) must only be carriedout once the fluid pressure has beenreleased.3.1. RISK OF EXCESSIVEPRESSUREProducts:Safety and shut-off block for the fluid sidein various sizes and versions.See catalogue section:zzSafety and Shut-off Block SAF/DSVNo. 3.551Gas safety valve and gas safety block forthe gas sideBursting discs for gas and fluid sidessee catalogue section:zzSafety Equipment forHydraulic AccumulatorsNo. 3.5523.2. RISK OF RISE INTEMPERATUREProducts:Safety and Shut-off Block with solenoidoperated valve (open when de-energised)in conjunction with temperature monitoring.See catalogue section:zzSafety and Shut-off Block SAF/DSVNo. 3.551 or on requestTemperature fusessee catalogue section:zzSafety Equipment forHydraulic AccumulatorsNo. 3.552

4.REGULATIONS4.1. EUROPEAN PRESSUREEQUIPMENT DIRECTION(PED)The European Directive 2014/68/EUwill come into effect in July 2016. It willreplace Directive 97/23/EC and willgovern the design, fabrication, conformityassessment and placing on the market ofpressure equipment and assemblies witha maximum permitted pressure of morethan 0.5 bar. It guarantees free movementof goods within the European Community.The EU member states are not permittedto prohibit, restrict or hinder pressureequipment being placed on the market andput into service on the basis of pressurerelated risks, provided that the equipmentin question meets the requirements of theEuropean Pressure Equipment Directive,has undergone a conformity assessmentand is labelled with a CE marking.Hydraulic accumulators with a capacity ofV 1 l and a maximum permitted pressurePS 1000 bar or with a pressure capacityPS V 50 bar l for gases of fluid group2 (non-hazardous fluids) are subjectto Article 4, section 3 of the EuropeanPressure Equipment Directive and do notreceive the CE marking.Inspection of the equipment andinstallation, operational safety and repeattesting are controlled as before by nationallaws.The equipment relating to safety isdescribed in AD2000, ISO 4126 andEN 14359.The repeat testing intervals are stipulatedin the new German industrial safetyregulations.4.2. OTHER REGULATIONSPressure accumulators which are installedoverseas (outside the EU), are suppliedwith the relevant test certificates requiredin the country of installation.HYDAC pressure vessels can be suppliedwith virtually any test certificate.Depending on the authority, the differentmaterial requirements must be observedDetails of some selected approvals are asfollows:4.2.2 C ERTIFICATE CODE P(KHK certificate)For the Japanese market, HYDACTechnology GmbH has had approval asa "Self Inspecting Manufacturer" sincethe year 2000. Consequently, HYDACis authorized to manufacture and testpressure vessels for the Japanese marketand to import them into Japan.4.2.3 C ERTIFICATE CODE A9(MANUFACTURER LICENSINGCHINA)Since 1998 HYDAC Technology GmbHhas had approval from the Chineseauthority "SELO" as a manufacturer ofpressure vessels and valves. HYDAC istherefore authorised to import bladder,piston and diaphragm accumulators, andsafety valves, into the Chinese market.4.2.4 C ERTIFICATE CODE A11(KGS code)Since concluding the registrationprocedure in 2012 HYDAC TechnologyGmbH is authorized to supply pressurevessels and safety equipment accordingto the Korean Gas Safety (KGS) Code forKorea.4.2.5. CERTIFICATE CODE A6(TR-CU)Since 2014, regulation TR‑CU 032/2014(technical regulation of the customs union"on the safety of pressure equipment") hasapplied for the countries of the EurasianEconomic Community.HYDAC Technology GmbH has beencertified in accordance with the regulationto supply its product range.4.3. CERTIFICATE TABLEThe following table lists the codesrecommended for use in the model codefor different countries of installation.The country of installation must be statedat the time of ordering (see code in ModelCode for the particular product:Certificate Code).Countries not included in the list maybe possible on request. Alternative testcertificates and differing values may alsobe possible on request.European member statesand EFTA statesAustriaBelgiumBulgariaCyprusCzech RepublicDenmarkEstoniaFinlandFranceGermanyGreat ficatecode (AKZ)Selection of othercountriesAustraliaBelarusCanadaChinaHong KongJapanKorea (Republic)New ZealandRussiaSouth AfricaTurkeyUkraineUSACertificatecode (AKZ)F 1)A6S1 1)A9A9PA11TA6S2UA10SU1)Such pressure equipment may beplaced on the market in the jurisdiction(application area) of "the National Board ofBoiler and Pressure Vessel Inspectors".Registration required in the individual territories orprovincesothers on request4.4. TRANSPORTREGULATIONS FORPRESSURE VESSELSThe transport of gas-charged accumulatorsmust be carried out with the utmostcare and in compliance with all relevanttransport safety regulations (e.g. inthe public domain, dangerous goodsregulations, etc.).E 3.000.15/01.174.2.1 CERTIFICATE CODE S (ASME)Since 1985, HYDAC Technology GmbHhas been authorized to label pressureequipment that was manufactured incompliance with the ASME regulations withthe "ASME" certification mark.5

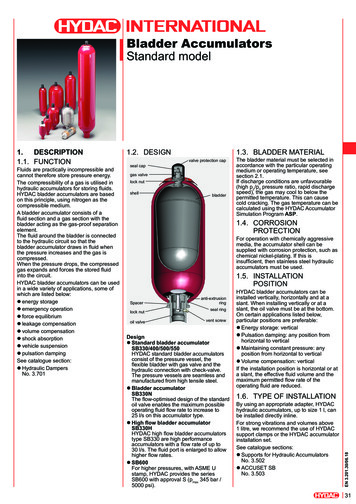

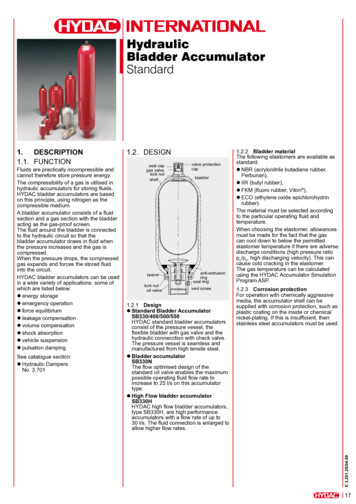

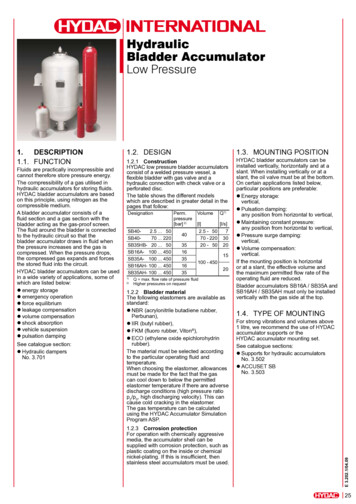

5. PRODUCT OVERVIEWThe following overview shows the standard product range of HYDAC hydraulic accumulators.Other versions and sizes may be available – please inquire.5.1. BLADDER ACCUMULATORS5.1.1 Low pressurePermitted operating pressure:up to 40 barNominal volume:2.5 . 450 lAdvantages of HYDAC bladderaccumulators:zzhigh discharge velocities,zzno pressure differential between fluidside and gas side,zzcompact, low-maintenance,zzhigh charge and discharge frequencies.5.1.2 StandardPermitted operating pressure:up to 550 barNominal volume:0.5 . 200 l5.1.3 High pressurePermitted operating pressure:up to 1000 barNominal volume:1 . 54 l5.2. PISTON ACCUMULATORS5.2.1 StandardPermitted operating pressure:210 . 350 barNominal volume:up to 3300 l5.2.2 Series SK280Permitted operating pressure:280 barNominal volume:0.16 . 10 lAdvantages of HYDAC pistonaccumulators:zzminimal pressure differential betweenfluid side and gas side,zzlarge effective volume,zzvariable installation position,zzmonitoring of the piston position possibleusing a variety of systems,zzparticularly suitable for back-upconfigurations,zzextreme flow rates,zzno sudden discharge of gas when sealsare worn.5.2.3 High pressurePermitted operating pressure:up to 1000 barNominal volume:up to 50 lE 3.000.15/01.175.3. DIAPHRAGM ACCUMULATORS65.3.1 Diaphragm accumulatorsWeld and screw typePermitted operating pressure:up to 750 barNominal volume:up to 4 lAdvantages of HYDAC diaphragmaccumulators:zzfunction-optimized and weight-optimizeddesign,zzunlimited choice of installation positions,zzno pressure differential between fluidside and gas side,zzlow-maintenance and long service life.

5.4. METAL BELLOWSACCUMULATORS5.4.1 Metal bellows accumulatorPlease contact usAdvantages of the HYDAC metal bellowsaccumulator:zzdurablezzwear-freezzmedia resistant over a wide range oftemperaturesSee also flyerzz"Heavy Diesel Engines - Metal BellowsAccumulators"No. 10.129.15.5.1 DampersPermitted operating pressure:10 . 1000 barNominal volume:0.075 . 450 lAdvantages of the HYDAC hydraulicdamper:zzreduces pressure pulsations,zzimproves the suction performance ofdisplacement pumps,zzprevents pipe breaks and damage tovalves,zzprotects measuring equipment and itsfunction in a system,zzreduces noise level in hydraulicsystems,zzreduces maintenance and servicingcosts andzzextends service life of the system.5.5. HYDRAULIC DAMPERS5.5.2 SilencerPermitted operating pressure:330 bar5.6. SPECIALACCUMULATORS5.6.1 Weight-reducedhydraulic accumulatorsOver 80 % reduction in weight comparedto equivalent carbon steel accumulators.The choice ranges from weight-optimizedaccumulators, e.g. by using aluminium,through to light-weight and ultra lightweight accumulators.See also flyerzz"Weight-reduced accumulators"No. 3.3055.6.2 Spring type accumulatorsare equipped with a spring.The energy is produced by the springforce, instead of gas.Further information on request.5.7. ACCUMULATORSTATIONSE 3.000.15/01.17HYDAC supplies fully assembled pistonaccumulator stations which are ready foroperation, complete with all the necessaryvalve controls, ball valves and safetyequipmentzzas an individual accumulator unit orzzin a back-up version with nitrogen bottlesto increase the effective volume.7

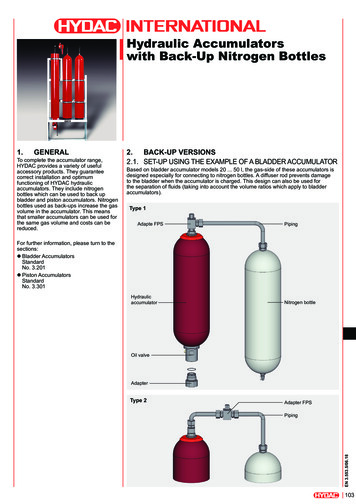

5.8. ACCUMULATORACCESSORIES5.8.1 Hydraulic accumulators withback-up nitrogen bottlesHYDAC also offers nitrogen bottles whichcan be used to back up bladder

Product Catalogue. Accumulator Technology. Product Catalogue. E 30.000.4/01.17. 2. E 3.000.15/01.17 1. HYDAC ACCUMUL ATOR TECHNOLOGY . FLUID ENGINEERING EFFICIENCY VIA ENERGY MANAGEMENT. HYDAC Accumulator Technology has over . 50 years' experience in research & development, design and production of Hydac accumulators. Bladder, piston, diaphragm and metal . bellows accumulators from HYDAC .