Transcription

NASASPACEVEHICLEDESIGNCRITERIANASA SP-8082(STRUCTURES,)STRESS.C NRR0Si0NMETALSCRACKINGCC@ ON

J r v v vL

catedcriteriaa needare beingfor uniformdevelopedcriteriafor thein the followingdesignof spaceareas of sare completed.Guidanceand ControlChemicalPropulsionof this work will be issued as separateA list of all publishedmonographsmonographsas soon as theyin this series can be foundat the end ofthis document.Thesemonographsare to be regardedand specificationsby NASAThis monographTaskwas ion;B.F.D. B. edthe attention23365.AugustAerospaceof NASANASACorporation;plans1971H.J.of USpacecraftand R. W. StaehleindividualsAdam,of Grummanassistedto updateof the Langleyin er;of McDonnellDouglasand I. G.DynamicsFlightCenter;TheBoeingR.E.O'BrienR. H. Raring of NASA Office of Advanceare herebyF. X. Drummof GeneralofTheMemorialand reviewingby the followingWhitesonLittlefieldCenter.of Battellethe materialLaboratory;M. DublinC. MarshallC. FResearchwas W. K. BoydcontributionsGeorgeLangleyauthorSiegel.of design requirementsoffices.S. Naval ResearchCenter:of OhiochangesThethe significantBrownto the formulationunder the cognizanceof otherIn particular,Corporation:as guidesand projectwas W. C. Thornton.A numberthe drafts.CentersCorpora-R. E. JohnsonCompany;ofNorthResearchofE. E.American& Technology:State University.thisin theof the tOffice,as appropriate.are invitedLangleyResearchand shouldCenter,Commentsbe forwardedHampton.andtoVirginia

For sale by the NationalTechnicalInformationService, Springfield,Virginia22151- Price 3.00

GUIDE TO THEThe purposestructure.of this monographIt summarizesand identifiescitedsupportingprecededbyefficiencya briefof flightworthythe significantand operationalin thispresentinformation.materialSection2, reviewsof theandand RECOMMENDEDprogramsof theseriesexperiencedesignemploytheINTRODUCTION,to date.effort,andsameSectionbasic1. andTheand assessesstateof technology.This sectionpreparescurrentadesign practicesSelectedserves as a surveyproperandreferencesareof the subjectthattechnologicalbaseforthePRACTICES.3. stateflightworthiness.what rules,criteriaguides,can serveor limitationsmustbe imposedas a checklistforguiding4.tosatisfya designtoorits ovidein yAll monographsOF THE ART.CRITERIA,ensuredevelopment,sectionsbasis for designdevelopmentby a list of REFERENCES.to supplyCRITERIAThemajorMONOGRAPHa uniformin research,structureimportantprovidesTheto improvein theis to providefor use in space vehicleaccumulatedIt can be usedUSE OF edureare suggested.to the formulationstateis described;Thesepractices,of requirements .111howwhenthisin conjunctionfor vehiclecannotwiththecriteria.bedone,the criteria,design and evaluation.

, ! ii i,txi

CONTENTS1.INTRODUCTION2.STATE 4.OF THE ART2.1Crack2.2Time to orsFactorsof Stress711.(Compositionand Heat Treatment).of Stress-CorrosionCrackingfor DetectingStress-Corrosionfor RIA3.1Identificationand Control3.2Selection3.3Fabrication3.4Stress Limitations3.5Protective3.6Tests3.7Inspectionof the Environmentof Alloy Compositionsand Processingand RACTICES4.1Identificationand Control4.2Selection4.3Fabrication4.4Stress Limitations4.5Protective4.6Tests4.7Inspection23of the Environmentof Alloy Compositionsand Processingand Tempers.Techniques.23242527272830.31REFERENCESNASA SPACE VEHICLEDESIGNMONOGRAPHSTO DATEISSUEDCRITERIA.35

.r

STRESS-CORROSION CRACKINGIN METALS1. INTRODUCTIONStress-corrosionmetalsundernor staticonecrackingthe identsof eof N2 04failuremethanol,of earfastenersandsufferedfromhasby the tap waterthe assemblyhave beenhavehousingsinterferencestructuresbushings.In peciallyproneto edcracksin metalsmaterials.fatigue,resultsin theIt scussed,notdiscussotherby cyclictensileintroductionnuts)thehigh-recently,in thealloytank.Likewise,becauseof matingpartsfailure.Forand es1962Awithfuel.fit-upassemblyfastenersfromused inthe use of aof stress-corrosionfrequentMorenickel,testingof aluminumhavemadecracking.criteriathewhichas in the("B"have failed from stress-corrosionThis monographcrackingfittingsproofby improperthe failureand otherof rocketused as the pressurizingsingle causefromsometest was pressurizedduringcausedthe greatestresultedaluminumfastenersstressesinare extensivelyof a titaniumto thatcontaincrackingFor example,tank undershatteredcorrosionhave been m,crackingfailureandstress. Neitherall metalall of whichin an explosivesteelbrittlestress-corrosionwhen a titaniuma densitytensileas aluminum,have beenof AMS 6434thatexample,steelresultedgeneratedor by inadequateseriousof themwhichcrackstosystemsin bothVirtually,steels, and titanium,occurredcasesand staticsuch cracks.susceptiblemetaloccursdue to stress-corrosionand somesimilar catastrophicstress-corrosionaresuchwhichof corrosionsteels, stainlessvehicles.fracturewill ealloyslow-alloyanhydrousis a brittleandcausedhavebyoftenof AN sof ackingof environmentalstress and corrosion,intoto preventmetalof space vehicles.of stress-corrosionoccurscrackingnor hydrogen-stressthestress-corrosionlattice.in nonmetallicsuch as corrosioncracking,Althoughwhichprimary

i)emphasisthroughout the monographis on high-strengthaerospacematerials,namelyaluminum, low-alloy steels,and titanium alloys, the information presentedis alsoapplicableto otheralloy systems.Stress-corrosiondrackingis an insidiousphenomenon,asis illustratedby the followingcharacteristics: Thecracksaredifficult to detectbecause(a) They areso fine that thereis generallyno macroscopicindicationthat aflawexists(b) Theremaybenovisibleindicationof the corrosionitselfEnvironmentscausingcrackingare often quite innocuous,such as ntof chlorideion in ordinarydrinkingwatercancausecrackingof a thick sectionof stainlesssteelin a fewhoursand a trace of oxygenin N204 hascauseda catastrophicfailure of atitanium alloy tank. Evenseeminglyundetectableamountsof ammoniain theair cancausecrackingof copper-basealloys.An appliedload is not necessaryto initiate stress-corrosioncracks.Eitherresidualstressesfrom ons or assemblystressesmay be large enough for the initiation andpropagationof a crackin the presenceof a corrodent.A stress-corrosioncrack can incubatea fatiguecrack or a "brittle fracture"cradkwhichotherwisemightnot occur.The principalvariableswhich significantlyinteractto influencestress-corrosioncrackingareasfollows: Alloy compositionandrelatedmetallurgicalfactors Sustainedsurfacetensilestress eitherresidual,assembly,or applied Environment,includingtemperatureandtimeCertain alloys and heat treatmentsin a given metal systemare more resistanttostress-corrosioncrackingthan others.For example,crackingresistanceusuallyimprovesin aluminumand titanium alloys with reductionin alloy content or with certainheattreatments.Dependingonalloy compositionandthe natureof the corrosiveenvironment,

the cracks may cross grains (transgranularcracking) or follow grain ys may exhibit both modesof cracking.Usuallythe fracturemodeis similarfor agroupof relatedalloys.Besidesthe corrosiveenvironment,sustainedtensilestressis necessaryto causecrackingwhichinitiates on the surfaceof the metal.Thiscrackinghasnot beenobservedfor metalsurfacesin compression.In general,the higherthe stress,the shorterthe time to failure. Stressesnearthe yieldpoint of the materialaremostsevere,but stresslevelsas low as5 to 10percentof theyield stresswill sometimesinitiate cracking.Typically, stress-corrosioncrackingoccurswhen the tensilestressesfrom appliedloadscombinewith residualandassemblytensilestressesto exceedthe thresholdlevel.Crackingis most commonin aqueousenvironments;however,certainmoist gasesandsomeliquid andsolid metals(or their rof offendingenvironmentalconstituentsis formidableandincludesthosefoundin the ation,salt air, caustics,andacids.Even distilled water will causecrackingof somealloys.Generally,the higherthetemperatureand the more concentratedthe solution, the greaterthe likelihood ofstress-corrosioncracking.Stress-corrosioncracks have a great influence on the related subjectsof fatigue,nondestructivetesting,fracture mechanics,andacceptancetesting.The fatiguelife of apart canbe significantlyreducedby a stress-corrosioncrackformed beforethe part hasbeenplacedin cyclic service.The detectionof stress-corrosioncracksis difficult sincethey canbevery ionswhichcallattention to them. edto detectthesecracks.The fracture mechanicsaspectsof mechanicalcrackgrowthandcontrolarepresentedin the publishedmonograph,FractureControl of Metallic PressureVessels(ref. 1). Sincestress-corrosioncrackingis likely to occur asa resultof residualstressesfrom manufacturingprocesses,assembly,and time in storage,acceptancetestsoftendetect the cracks;thesetestsarediscussedin theAcceptanceTestingmonograph(ref. 2).

rIi

2. STATE OF THE ice.giventhatthe use of higherrelationshipbetweencracking.TheIt is wellto crackingcrack in the same environmentHowever.it is generallycrackingis an unattainablestress-corrosionis acriticalstress-corrosiona numberofforthto byinintheregreaterthatof stress-corrosiontowardordinarilyexistsits trengthtosteelsaresteels readilylevels.mechanismsuggeststo explainthatare operating;interactionsfor anystress-corrosiongiven situationthus. it wouldthatan entirelycomprisethethe problemsbe saidappearofthat itmechahismexplorecrackingare referredstress-corrosioncracking(refs. 3 throughof factorsin stress-corrosionvariablesaffectingThe environment,it cancracks.ofby anodichave beenare too extensivethatin general,processesThe fact that propagatingor acceleratedcurrentsanin thecracksseemscantofor most systems.ingreaterdepthto the proceedings6). Othercrackingstress-corrosionincludingthata part along with f stress-corrosionwishthe variousof stress-corrosion:as playingcathodicmechanicalwhoto discusscomplicated.is impliedapplyingreaders theexample,low stressof factorsmechanismtooand propagationThe importantexpectedwill resultby the trendandthe low-alloy,evidencestress-corrosionnumberfora singleof this monographandprecludeas a resultmaterialstrength,whereasprocessis nocracking.putbe stoppedthegoal. Thecracking,of theknown,thatcombinationIt is not the intentinitiationagreedmembersof alloys,at relativelyhaslife of anythereconditionsFor any given familyin the ing.beencrackingthe stress-corrosionthehas becomethestress-corrosionWhile someenvironmentalaggressiveof structuralmaterials.alloys.to predictnotthe exactthe r assessingabilityand completelyfailureandtechniquesthein someHowever,strengthandalloys,alloy underphenomenon,metalsenvironmenttestingof prematurenew.corrosionstructuralanddata is dangerousis nota directsingleproceduresmetalsto test eachnotionproblemcrackingofin anybutTheconservativeTheotherin developingbehaviorspecificanyuse of high-strengthmadecrackingthanthemechanisticof the four majorpapersand books(refs. 7 throughcrackingtime and temperatureare:15).aspectsconferenceshave also treatedofona

essWhilethereis no known universalenvironmentwhich causesstress-corrosioncrackinginall alloys,thosecontainingchlorideand/or other halideionsdo promotecrackingin awide range of alloy loy derableexperiencewith stress-corrosioncrackingof r example,it is knownthat stress-corrosioncrackinginthe high-strength2000 and7000 seriesof aluminumalloys occursmostoften in naturalenvironmentssuch as marine and loy steelsandprecipitation-hardened(PH) alloyswill crackwhenstressedin industrialandmarineenvironments.Titaniumalloys,on the otherhand,areresistantto crackingundersimilarexposures.Themost critical problems with titanium are flaw growth in sea water and otherchloride-containingsolutions,and crackingby hot, dry salt at elevatedtemperaturesoffrom 532to 810K(500to 1000 F),althoughno servicefailuresby hot-saltcrackinghaveoccurred.Austenitic stainlesssteelsare alsosusceptibleto stress-corrosioncrackinginchloride environmentsbut, with the exceptionof sensitizedmaterials,not when thetemperatureis belowabout322K(120 uchas heattreatingandwelding,orthose stressesresultingfrom assembly,are difficult to control and accountfor themajority of stress-corrosioncrackingfailures.Applied loadsin the absenceof internalstressesrarely causestress-corrosioncracking,andno crackingoccursin the absenceofstress.Other important aspectsof stress-corrosioncrackingwhich will be discussedin moredetailbelowincludecrackmorphologyandtime to failure.2.1 Crack teeitherHowever.in general,example,haveof the alloythepredominatelybetweenfollowsappearanceof a brittlefracture.Dependingof the corrosiveor across grains;that is, it may be intergranularthe fracturecrackingalloys, transgranulartheand the naturein carbonmodesteels,an intergranularcrack pathsof a groupcopperpath;of relatedalloys,nickelin austeniticare tainlessonthe crackingthemayor transgranular.will be similar.and aluminumForalloyssteels and magnesiumalloys can crack in eitherway.

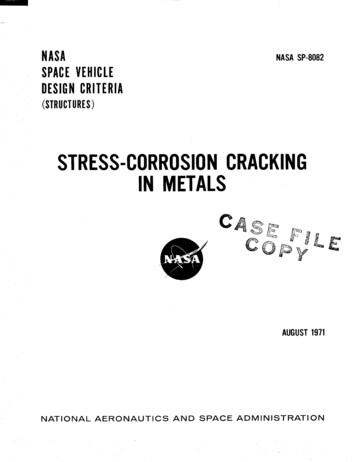

Other typical characteristicsof stress-corrosioncracksare their highly branchingnatureand the presenceof significantsecondarycracks.Figure1 is a photomicrographoftransgranularcrackingin austeniticstainlesssteel,which alsoillustratesthe branchingnature of this type of failure. Examplesof intergranularstress-corrosioncrackingareshownin the ptfotomicrographsof figure2. Both transgranularandintergranularcrackingare revealedby scanningelectron micrographsof aluminumand titanium alloys infigure3. The high secondary-crackdensitytypicalof stress-corrosioncrackingis clearlyevidentin the fractureof a titanium-alloypressurevesselshownin figure4.The presenceof grain boundaryprecipitatesand/or a thin region next to the grainboundary with enrichedor impoverishedalloy content has been suggestedas thenecessaryprerequisiteto intergranularcracking(ref. 16). In icatesthat the cracksfollow certaincrystallographicplanes.2.2 Time to CrackingIn general,stress-corrosionand (2) propagation.a few minutesandtheto sfailurecrackingafterthea crackdependingstress.formsServicethealloys(ref. 6). The rate of propagationin mechanicalfastfracturethe metal).For alloyscopper-basealloys,of crackLittlealloysornosusceptibilitymaterialstheis on the ordersizeand high-strengthcorrelationhasapplicationto knowcatastrophicthatis. thestress-corrosiontheofdepthcrackingrathersteels, wherebeenfoundcrackingFracturealloysof a longat yield-pointcracksaluminumum/sbeginningstress effectsor betweentoughnesslargestslowerthe speedcrack-likestressesflawstainlessfactorandand ratethefordominatethoseof thethe ratesmaterialandthatforsinceinit iscan be tolerated(ref. 1). The criticalbe expectedby the formulaitsare importantcracking,crackcanof corrosion.of crack propagationhowever,stress levelsis definedsteels,inhand,properties,whichthan thatof soundOn the otherto stress-corrosionat operatingofi.e., 2.77 um/s (10 mm/hr),toughnessstress-corrosionwithmission.is muchalloys,isin completefor a number(1 weensusceptiblemay occuras the intervalthan stress are the dominantof magnitudesize of thefailuresteels,of 0.277is an orderto stress-corrosiongeneralbeforeprocessesin a given alloy family.desirablecarbonforsize, resultingis quiteof stress-corrosion(approximatelyusedthe majorof its specifiedof propagationat rupturecorrosionpropagationratesuch as plainrate of crack propagationtitaniumthelife is definedfromof the environment,sinceto a critical(1) initiationcrack may varyparameterlife of the part,with the completionOncephases:the natureinitiation-timeserviceand propagatesand endinghas initiated,into two distinctof a stress-corrosionon the alloy,Theor structure.of a vehiclecrackyears,to the expectedof componentmanufacturecan be dividedThe time for the initiationflawto initiate0.2(Kiscc/Oy)2.

Slae},sSSalu!eJ,s o!}.!uaTsneo 6U! loeJouo!soJJo3-ssaJTsJelnueJ6sueJJ,leo!dA 6u!Moqs qdeJOoJo!uJo oqd - "L aJn0!-I"e!Oaa enbv: ,ueqa .3"S laeagJ.o eJnl.eu 0u!qoueJqa ,ONX 9oO

150X50-3A2.9AI(Annealed)Figure 2. - ioncracks in nconel alloys.

1500X1500XFigure 3. - Scanning electronmicrograph showingtypical intergranularstresscorrosion crackingof 7075 aluminum alloy (left) and transgranularintergranular cracking of Ti Alloy in N204 (right).

1ooxTra nsverse sectionshowing crack initiation at internalsurfacet .:,: .:.2.::IOOX::. : .i:[ nternal surfaceFigure4. - Stress-corrosioncrackingof a Ti-6AI-4V pressurevesselexposedto N204.whereKiscc is the maximuma given ffects.doeswhichhas um,Therepromotenotedmayoccurand inorganicand aluminumstainlesssteelschloride,in N2 04, in methanol,environment-alloyandof the alloy.nickelperhapsnotcombinationsto be anycracking.Stress-corrosionin liquidliquids.andin -corrosion11crackingto theassociatedwithsalts, gases,andlithiumin hot,and in both liquid and solid cadmium.wherepatternare the crackingsteel in moltenandrelatingof the phenom-is usuallyof such failurescaustics;are thoseNo occurrencecrackingExamplesalloys in mercury;alloysthe least understoodappearstress-corrosionin a vacuum.butof a flaw inFactorsin stress-corrosionenvironmentalthat does not cause propagationand Oy is the yield strengthEnvironmentalOf thestress intensitydryofand zinc;sodiumA list of offendinghas been encountered

is presentedin tableI. The table illustrates the broad range of crack-producingenvironmentsandthe nearlyuniversalpresenceof chloridein someform.Additional environmentswhich causecrackingof a given alloy are constantlybeingidentified. Consequently,a reevaluationof the behaviorof the alloy is n exampleof the problemsthat angesis the crackingof titaniumalloysin N204containingtracesof O , while the samealloysareimmuneto crackingif a traceof hosewhich causenegligiblecorrosionof theTABLEI.ENVIRONMENTSIN WHICHSTRESS-CORROSIONCRACKINGHAS lloysseaindustrialandand cacid;steamand02hydrofluoro-high-temperatureor tracesof istilledfumingnitricacid; N204 02;water;chlorinatedhydrocarbons;sodiumchlorideat umRedNH4C1chlorides;water dmaterials); 02 at 586K (599 cidschloridemoltenpolythionicNickel-baseandsea utionstemperatures);alloysindustrialor Na-Pbammonia;moist ionsH2S or HCN;and 63K(554 F);andsolidcadmium;drysaltsHCL;

metalor alloy in the absenceof stress.In fact, few instancesof stress-corrosioncrackinghaveoccurredin environmentswherethe corrosionrate of the materialexceeded4 to 8pm/s(5 to 10mils/yr).As is the casewith most chemicalreactions,increasingtemperaturespromote theoccurrenceof stress-corrosioncracking.Somealloys may crack at room temperaturewhile others reqmre boiling temperaturesof the environmentalsolutions.The mostsusceptiblealloys,however,usuallycrackat temperaturesbelow363K(194 F).The concentrationof the environmentis alsoimportant.As the solutionconcentrationrises,the tendencyfor stress-corrosioncrackingincreases.For example,nickel-basealloyscrack only in concentratedcausticsystemsand thenonly at high ennotedfor otheralloy systems.Anotherimportant aspectof the environmentis the type of exposureto whichthe alloyis subjected.Alloys exposedto alternate wetting and drying conditions are moresusceptibleto y.2.4 acking.altersForall of thethereexample.are quite percentthose ers. Table II gives further evidence of the range of crackingtransversedirectionwhichcan be obtainedin aluminumgivenin g alloysall practicalofcommercialsomeare alloyto stress-corrosionare forand Heat Treatment)to crackinglessin allsusceptibilityin the shortalloys by sto crackingcontents,theincreases,steelscracking(ref. 14).reachinga maximumagain becomemoreAs thecarbonat aboutresistantlevelis0.12 percent.to maximumthisnickel.quiteAlloysresistantcontainingof the effectsusceptibilitymoreto the well-knownthanof alloy compositionto cracking40-percentchloride-stress13is in the Fe-Cr-Nioccursnickelcorrosionalloy system.at approximatelyor less thancracking1-percent(ref. 5).9-percentnickelare

TABLE II. - RELATIVESUSCEPTIBILITYTO aptedfrom ref. 12',612Veryneed23214,220218,A1-Mg-resistantto stress-corrosionbe considered.Almag35As cast-T4AllX3547cracking.OnlytheeffectAs cast2-T6,-T62-T614-T64As castAs cast4of elevated1temperatureonstress-corrosionResistantto stress-corrosioncracking.Althoughfailureshave occurredunderextremelaboratoryconditions, these alloys can be used withoutmany stress-corrosion-crackingdesign limitations.Susceptibleto stress-corrosioncracking.These alloys can be used withoutexpectingstress-corrosioncrackingonly if the phenomenonis consideredas an importantfactorin design limitations.Very susceptibleto stress-corrosioncracking.These alloys should not be used where high sustainedtensilestresses are appliedin the short transversedirection.When possible,stress-relievingtempersshouldbe usedto avoid quenched-inresidualstresses.14(a)

In titanium alloys, the addition of molybdenum,vanadium,and to a lesserextentcolumbium,improvesresistanceto cracking,whereaselementssuchas aluminumandoxygendecreaseresistance(ref. 6). TableIll givesexamplesof the compositionalfactorsaffectingthe susceptibilityof precrackedtitanium alloysto stress-corrosioncrackinginsalt water, but their relativesusceptibilitycannotbe ascertainedin all casesfrom theavailabledata.In the past,it wascommonlyacceptedthat However,thevalidity of sucha generalizationis questionableinlight of the observedcrackingof high-purityiron whiskersandof 99.999-percentcopper.On the other hand,a markedimprovementin crackingresistancehasbeenobservedinsomealloy compositionspreparedfrom extremelypure metals.Iron-chromium-nickelalloys of the 18Cr-8Nitype containinglessthan 20 ppm total impuritiesare highlyresistant to stress-corrosioncracking.TABLEIII. -- STRESS-CORROSIONCRACKINGBEHAVIOROF PRECRACKEDTITANIUM ALLOYSIN 3-PERCENTSODIUMCHLORIDESOLUTIONS[Adaptedfrom ref. ercentoxygenTi-8Mndegree of susceptibilitybutnot listed in order of 9)Ti-3A -4VTi-6A Ti-7 A 1-2Cb-1TaTi-7A1-3Cb[as -8AI-IMo-IVAlloysscreeningindicatedby preliminaryteststo be insensitiveto salt-watercrackfor the -6,5A1-5Zr-IVTi-7A1-2.5Mo[as receivedandbeta annealed WQ 867K(ll00 F),aged for 7.2 ks(2 hr)l15

Susceptibilityto stress-corrosioncrackingis influencedby a numberof other metallurgical variablesin addition to alloy composition,such asgrain sizeand shape,rollingdirection, temperingtemperature,compositionand distribution of precipitates,anddegreeof phasetransformation.High-strengthaluminum alloys exhibit the least resistanceto cracking in the graindirection transverseto the rolling or forgingdirections(short transverse).In suchcases,thresholdstresslevelsfor initiation of crackingmay belessthan34.5MN/m2 (5000psi)in the short transversedirectionascomparedwith morethan 137.9MN/m2 (20 000psi)in the longitudinal direction. This effect is directly related to the distribution ofsecond-phaseprecipitatesduring rolling. Heat treatmentsalso influencecrackingofaluminumalloys sincethey too can changethe compositionand morphologyof cking of a given alloy composition.As shown in tableII, 7075aluminumin the T6 temperis very susceptibleto crackingwhereasthe samealloy in theT73 temperexhibitsahigh degreeof resistance.Heattreatmentsarealsoeffectivein reducingsusceptibilityto stress-corrosioncrackingofotheralloy systemsincludingmild umalloys.However,asin the caseof ctivein developingimmunityto crackingalsolowerthe strengthof the cecrackingof Stressto stress-corrosionat or aboveof thewilltreatmentthe yieldalloyoccuris basedcrackingcauseif theonpointincreasesof the material.initiationmetalinducingwithincreasingOnly sustainedand propagationsurfacesurfacestresstensileof stress-corrosionis in compression.compressivetensileIn fact,stresses(e.g.,and gth.heat-treatingstress.may resultan essesResidualor rollingchangesCold-forming,fromoccursof crystallineand grindingin the metalare kn

stress-corrosion cracking are referred to the proceedings of the four major conferences on stress-corrosion cracking (refs. 3 through 6). Other papers and books have also treated a number of factors in stress-corrosion cracking (refs. 7 through 15). The important variables affecting stress-corrosion cracking are: