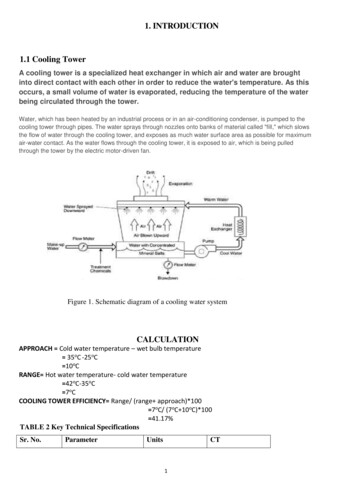

Transcription

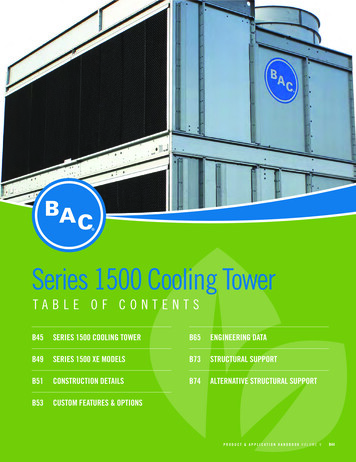

Series 1500 Cooling TowerTABLE OF CONTENTSB45 SERIES 1500 COOLING TOWERB65 ENGINEERING DATAB49 SERIES 1500 XE MODELSB73 STRUCTURAL SUPPORTB51 CONSTRUCTION DETAILSB74 ALTERNATIVE STRUCTURAL SUPPORTB53 CUSTOM FEATURES & OPTIONSPRODUCT & APPLICATION HANDBOOK VOLUME VB44

BAC’s Series 1500 Cooling Tower parallels the technology and successes of BAC’sSeries 3000 Cooling Tower in a compact footprint. The Series 1500 Cooling Tower isthe industry’s most serviceable unit without compromising performance and fit. Newlyredesigned, the Series 1500 Cooling Tower offers Extreme Efficiency (XE) modelswhich are at least two times more efficient than the minimum requirements establishedin ASHRAE 90.1 and further reduce the unit’s operating cost. Its serviceability,superior winter operation, and single air intake make it an outstanding choice for newinstallations and an ideal replacement unit.B45Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M

BAC’s Series 1500:No CompromiseSingle Air Intake, Induced Draft, Crossflow Capacities92 to 747 Nominal Tons in a Single CellUp to 3,150 USGPM for Process ergyConsumptionΔEasiest toService andMaintainLowMost ReliableInstallation Year-RoundCostOperationIBC CompliantPRODUCT & APPLICATION HANDBOOK VOLUME VB46

Series 1500 BenefitsThe Series 1500 Cooling Tower is the industry’s most serviceable unit without compromisingperformance and fit. With expanded models almost doubling the capacity range and aperformance increase of up to 13%, the Series 1500 Cooling Tower provides an excellentsolution for all your application needs.››Reduced Energy Consumption Performance increase of up to 13% Meets or exceeds ASHRAE 90.1-2013 efficiencyrequirements Offers excellent performance andserviceability in a compact footprint Further reduce energy cost with XE Models400-Ton Example:Series �12’x10’x15.5’12’x12’x16.7’Nominal Tons401395423Easy Service Accessa—aFan HPFootprint (L x W x H)NOTE: The unit selections for this example were based on maintaininginstalled layout parameters, which includes footprint and layout dimensions,as well as first cost of the unit.400-Ton Example: Annual Operating Cost for a 25, 35 and 40 HP Motor 10,000 1,100Savings 8,000 6,000 3,400Savings 900Savings 2,700Savings 4,000Series 1500 - 25 HPCompetitor - 35 HP 2,000Competitor - 40 HP 025HP35HP40HPOffice Bldg (2000 EFLH)25HP35HP40HPHospital (2500 EFLH)NOTE: Energy Cost Savings Based on a 400-Ton System ( 0.12 kWH) for equivalent full load hours (EFLH).B47Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M

››The Most Serviceable Tower 26% less annual maintenance cost compared to other compactfootprint productsDifference was based on comparing costs to complete maintenance NOTE: items listed in O&M Manual. Direct access to: Sloped cold water basin Hot water basin which can be inspected during full operation ofthe system pump Drive system through a spacious plenum and oversized doors onboth sides of the unitFactory Pre-Assembled External Access Platform Factory pre-assembled access options available for ease ofmaintenance››Reliable Year-Round Operation Superior winter operation Standard independent fan motors provide capacity control andredundancy Meets wind and seismic requirements of the International BuildingCode Tested per the California’s Office of Statewide Health Planning andDevelopment (OSHPD) requirements››The Ideal Replacement Unit for ExistingShake Table TestingBAC’s or Competitors’ Equipment When replacing centrifugal fan towers, the Series 1500 CoolingTower reduces installation AND operating costs Save up to 7,000 on installation costs for replacement projects: Fits on existing steel support No enclosure modifications because of the layout flexibility ofthe single air intake Minimal piping changes Reuse startersPRODUCT & APPLICATION HANDBOOK VOLUME VB48

Models- Series 3000The Series 1500 XE models are tailored for projects that require extreme efficiency units tominimize energy costs, reduce sound levels, and contribute to LEED Credits. Series 1500 XEmodels are at least two times more efficient than the minimum requirements established inASHRAE Standard 90.1 - 2013.400-Ton Selection Series 1500 vs Series 1500 XEModel Comparison of First & Operating CostLowest Operating Costs 50% reduction in operating costs for a400-Ton system Payback of less than 2 years 350,000 300,000 121,750Savings 250,000 200,000 150,000Reduced Sound Levels Additional sound reduction up to 50% (3dB) Fans optimized to minimize sound levels and 100,000Operating CostsFirst Costs 50,000 0Series 1500Series 1500 XE Modelsmaximize efficiency Additional sound reducing options availableNOTE: Operating costs based on fan kW x 0.12kWh x 2500EFLH(equivalent full load hours) x 20 years (2011 ASHRAE Handbook HVACApplications) x 3% per year energy inflation factor.B49Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M

Increased Operating Reliability BALTIDRIVE Power Train Fan System 40% longer L10 bearing life than the standard Series1500 models 5-year motor and drive warrantySeries 1500 XE Cooling TowerInnovation & DesignProcess6 PointsLEED Certification ContributionsRegional Priority4 PointsIndoorEnvironmentalQuality15 Points Industry leading energy efficiency Provides energy cost savings Helps contribute to Energy and Atmosphere LEED Sustainable Sites26 PointsMaterials &Resources14 PointsCredits (EAc1)Energy & Atmosphere35 PointsWater Efficiency14 PointsLEED Point Breakdown for New ConstructionLowest Operating CostsReduced Sounds LevelsIncreased Operating ReliabilityHelps Contribute to LEED CreditsCOMPARESELECTSPECIFYPRODUCT & APPLICATION HANDBOOK VOLUME VB50

5ROTO & DVEBACMRISeries 1500Construction Details34215867B51Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M W YEAR YARRANT

1Heavy-Duty Construction5 G-235 (Z700 metric) mill galvanized steel is theheaviest galvanizing available ensuring durability High efficiency heat transfer surface optimizesthermal performance and energy efficiency Meets wind and seismic requirements of theInternational Building Code (IBC) Polyvinyl chloride (PVC) is impervious to rot, decay,and biological attack Shake table tested and verified seismic ratingsensure operability after an event Flame spread rating of 5 per ASTM E84 Tested per the California’s Office of Statewide HealthPlanning and Development (OSHPD) requirements2BALTIDRIVE Power Train Independent fan drives are standard providingcapacity control and redundancy Elevated off of the cold water basin to reducemaintenance6Combined Inlet Shields Corrosion resistant Premium quality, solid backed, multi-groove belt toensure reliable operation Maintenance free Corrosion resistant cast aluminum sheaves reducedrive maintenance compared to cast iron sheaves Reduces sunlight and algae growth Heavy-duty bearings with a minimum L10 of 150,000hours (500,000 hour average life) ensures reliabledrive operation3BACross Fill with IntegralDrift Eliminators (NOT SHOWN) UV-protected finish7Cold Water Basin Premium efficient/inverter duty fan motors asstandard Sloped cold water basin for easy cleaning 5-year motor and drive warranty Adjustable water make-up assembly Suction strainer with anti-vortex hood Internal walkway as standard to minimizemaintenanceLow Horsepower Axial Fans High efficiency fans maximize the capacity for eachmodel Quiet operation to minimize sound levels from thedischarge of the unit8Hinged Access Doors Inward hinged door on each end wall allows easyaccess to the drive system Permanently attached to the unit4Water Distribution System Easy safe access to the interior of the unit Steel covers in easy to remove sections reducemaintenance Low pump head gravity distribution basins reducessystem pump energy Large orifice, non-clog nozzles reduces maintenanceof the distribution system Standard weir dams can accommodate a flow rangeof 50% to 100%PRODUCT & APPLICATION HANDBOOK VOLUME VB52

Series 1500Custom Features & Options››Materials of ConstructionDetermining the appropriate material of construction for a projectdepends on several factors, including water quality, climate andenvironmental conditions, availability of time and manpower formaintenance, unit lifetime requirements, and budget. BAC provides thewidest variety of material of construction options in the industry and hasthe ability to provide a solution to meet all conditions and budgets. Oneexample is the TriArmor Corrosion Protection System which providessuperior corrosion resistance and durability at a tremendous value.Standard Construction InstallationCustomerValued STANDARD CONSTRUCTIONG-235 mill galvanized steel is the heaviest commercially availablegalvanized steel, universally recognized for its strength and corrosionresistance. To assure long-life, G-235 mill galvanized steel is used asthe standard material of construction for all Series 1500 units. Withproper maintenance and water treatment, G-235 galvanized steelproducts will provide an excellent service life under the operatingconditions normally encountered in comfort cooling and industrialapplications.CustomerValued TRIARMOR CORROSION PROTECTION SYSTEM (OPTION)The TriArmor Corrosion Protection System consists of heavygauge G-235 mill galvanized steel panels fully encapsulatedby a thermosetting hybrid polymer and further protected by apolyurethane barrier applied to all submerged surfaces of thecold water basin. The triple layers of protection form a completelyseamless cold water basin for the most leak resistant and durablebasin in the industry. Other components, such as the strainer,within the basin will be constructed of stainless steel. The TriArmor Corrosion Protection System was specifically designed for evaporativecooling applications and released in 2006 after a decade ofextensive R&D and field testing. To date, there are thousands ofsuccessful installations in North America. Every basin is leak testedat the factory and warranted against leaks and corrosion for 5 years.TriArmor Corrosion Protection System Triple Layer ProtectionApplication of TriArmor Corrosion Protection SystemB53Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M

THERMOSETTING HYBRID POLYMER (OPTION)A thermosetting hybrid polymer, used to extend equipment life,is applied to select G-235 mill galvanized steel components ofthe unit. The polymerized coating is baked onto the G-235 millgalvanized steel and creates a barrier to the already corrosionresistant galvanized steel. The thermosetting hybrid polymer hasbeen tested to withstand 6,000 hours in a 5% salt spray withoutblistering, chipping, or losing adhesion. STAINLESS STEEL (OPTION)Several stainless steel material of construction options are available. WELDED STAINLESS STEEL COLD WATER BASINA welded stainless steel cold water basin is available. Allsteel panels and structural members of the cold water basinare constructed from stainless steel. Seams between panelsinside the cold water basin are welded, providing an advantageover bolted stainless steel cold water basins for minimizingsusceptibility to leaks at basin seams. The basin is leak tested atthe factory and welded seams are provided with a 5-year, leakproof warranty. STAINLESS STEEL HOT WATER BASINThe hot water basin and basin covers are constructed of stainlesssteel. ALL STAINLESS STEEL CONSTRUCTIONAll unit structural elements and the hot and cold water basins areconstructed of stainless steel. Seams between panels inside thecold water basin are welded, providing an extreme advantage overbolted cold water basins for minimizing susceptibility to leaks atbasin seams. The basin is leak tested at the factory and weldedseams are provided with a 5-year leak-proof warranty.Thermosetting Hybrid Polymer Construction InstallationWelded Stainless Steel Cold Water BasinPRODUCT & APPLICATION HANDBOOK VOLUME VB54

Series 1500Custom Features & Options››Drive System OptionsCustomerValuedCustomerValued INDEPENDENT FAN OPERATIONB55The independent fan consists of one fan motor and drive assemblyfor each fan to allow independent operation, adding an additionalstep of fan cycling and capacity control. This ensures completeredundancy for the fan and motor system.Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O MBALTIDRIVE Power Train Fan System W YEAR YARRANT STANDARD BALTIDRIVE POWER TRAINThe BALTIDRIVE Power Train utilizes special corrosion resistantmaterials of construction and state-of-the-art technology to ensureease of maintenance and reliable year-round performance. This BACengineered drive system consists of a specially designed powerbandand two cast aluminum sheaves located at minimal shaft centerlinedistances to maximize belt life. As compared to a gear drivesystem, this specially engineered belt drive system provides manyadvantages. The BALTIDRIVE Power Train requires only periodicinspection of components and belt tensioning, which is simplewith a single nut adjustment, and requires less downtime. Only fanbearing lubrication is required for routine maintenance. Belt drivesystems also have the added advantage of being suitable for variablefrequency drive (VFD) applications without requiring expensiveoptional accessories.VEBAC5ROTO & DRIM The fan drive system provides the cooling air necessary to rejectunwanted heat from the system to the atmosphere. All BAC drive systemsuse premium efficient cooling tower duty motors and include BAC’scomprehensive 5-year motor and drive warranty. Cooling tower dutymotors are specially designed for the harsh environment inside a coolingtower and have permanently lubricated bearings, drastically decreasingthe maintenance requirement of the motor. BAC belt drive systemsare the most durable and maintenance friendly drive systems on themarket, including single nut adjustment for belt tensioning to make belttensioning simple.

DUAL DRIVE (OPTION)The dual drive option consists of a single motor and drive systemattached to two fans. This option is available to reduce the wiringand starter changes on replacement projects. BALTIGUARD FAN SYSTEM (OPTION)The BALTIGUARD Fan System consists of two standard singlespeed fan motor and drive assemblies. The drive assemblies aresized for full speed and load. This provides 100% motor redundancyand the greatest level of reliability. VIBRATION CUTOUT SWITCH (OPTION)A factory mounted vibration cutout switch is available to effectivelyprotect against rotating equipment failure. BAC can provide eithera mechanical or solid-state electronic vibration cutout switch in aNEMA 4 enclosure to ensure reliable protection. Additional contactscan be provided on either switch type to activate an alarm. Remotereset capability is also available on either switch type.BALTIGUARD Fan System Provides Built in Redundancy EXTENDED LUBRICATION LINES (OPTION)Extended lubrication lines are available for lubrication of the fanshaft bearings. Fittings are located on the exterior casing panel nextto the access door.Extended Lubrication Lines withGrease Fittings by the Access DoorPRODUCT & APPLICATION HANDBOOK VOLUME VB56

Series 1500Custom Features & Options››Cold Water BasinThe cooling tower water collects in the cold water basin which providesthe required head pressure for the cooling system pump. Duringoperation the Series 1500 cold water basin helps eliminate any stagnantzones which are susceptible to biological growth. The Series 1500cold water basin facilitates easy inspection and maintenance of basinaccessories and connections.CustomerValued STANDARD MECHANICAL WATER LEVEL CONTROLMechanical make-up valves must operate continuously in the moistand turbulent environment existing within evaporative coolingequipment. Due to this environment, the operation of the valvemust be simple, and the valve must be durable. BAC’s high qualitymechanical water level control assembly is standard with all units,and has been specially designed to provide the most reliableoperation while being easy to maintain. This accessory is omitted forremote sump applications.Mechanical Water Level Control ELECTRIC WATER LEVEL CONTROL (OPTION)BAC’s Electric Water Level Control (EWLC) is a state-of-theart conductivity actuated, probe type liquid level control. Thehermetically sealed EWLC is engineered and manufacturedspecifically for use in evaporative cooling systems and is equippedwith an error code LED which illuminates to indicate status,including when the water and/or probes are dirty. The EWLC optionreplaces the standard mechanical make-up valve, and includes aslow closing, solenoid activated valve in the make-up water line tominimize water hammer. EWLC is recommended when more precisewater level control is required and in areas that experience subfreezing conditions.Electric Water Level ControlB57Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M

CustomerValued BASIN HEATERS (OPTION)Evaporative cooling equipment exposed to below freezing ambienttemperatures require protection to prevent freezing of the water inthe cold water basin when the unit is idle. Factory-installed electricimmersion heaters, which maintain 40 F (4.4 C) water temperature,are a simple and inexpensive way of providing such protection.H E AT E R k W D ATA0 F (-17.8 C) Ambient HeatersModel NumberNumber ofHeaterskW perHeater-20 F (-28.9 C) Ambient HeatersNumber ofHeaterskW 116S15E/XES15E-1218210212Basin HeaterNOTE: This table is based on 460V/3 phase/60 Hz power. BASIN SWEEPER PIPING (OPTION)Basin sweeper piping is an effective method of reducing sedimentthat may collect in the cold water basin of the unit. A completepiping system, including nozzles, is provided in the cold water basinto connect to side stream filtration equipment (provided by others).For more information on filtration systems, consult “Filtration Guide”found on page J241. LOW AND HIGH LEVEL ALARM FLOAT SWITCHES (OPTION)Low and high level alarm float switches are available to provideadded control to your equipment operation. Level alarms can alertoperators to an abnormal operating condition to ensure the highestsystem efficiency with minimal water usage.Basin Sweeper PipingPRODUCT & APPLICATION HANDBOOK VOLUME VB58

Series 1500Custom Features & Options››Multi-Cell Unit OptionsSpecial care must be taken for multi-cell installations to ensure balancedwater levels in the cold water basins across cells. If measures are notput in place to ensure balanced basin water levels, a potential exists thatone basin may overflow and dump water, while the water level in anothertower goes low and requires make-up. This leads to unnecessary waterwaste. To prevent this from occurring, BAC provides two options forbalancing water levels and recommends that the installation be designedto ensure balanced flows to and from each tower. FLUME BOX – STANDARD ON ALL MULTI-CELL UNITSA flume box is provided as standard for multi-cell units to ensurebalanced water levels in the cold water basins across all cells. Seethe “Connection Guide” on page J176 for more information. EQUALIZER (OPTION)Flume BoxEqualizer connections are available as an option for multi-cellcooling towers in lieu of a flume box. Use of an equalizer allowsfor easy isolation of a cell for winter operation, maintenance, orinspection while continuing system operation. See “Cooling Towersin Parallel” on page J167 for more information.››Water Distribution SystemThe Series 1500 Cooling Tower utilizes a low pump head gravitydistribution system with large orifice, non-clogging nozzles that requiresless pump energy than a pressurized distribution system.CustomerValued STANDARD SINGLE INLET CONNECTIONB59The Series 1500 comes standard with a single inlet connection.Basin covers match the material of construction of the hot waterbasin and come in easy to handle sections for access and inspectionof the distribution system. The use of gravity distribution minimizespump head requirements and allows for maintenance during unitoperation. BAC’s patented non-clog nozzles ensure even flow over thefill area and are simple to remove for maintenance.Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O MStandard Single Inlet Connection

STANDARD WEIR DAMSReducing water flow through a unit below the recommended levelmay potentially create uneven water distribution through the heattransfer section, causing scale build up, splash out/drift, and icing.The hot water basin can accommodate a flow range of 50% to 100%of the design flow.››FillBACross Fill, BAC’s patented crossflow hanging fill, was developedafter years of extensive research. BACross Fill is made of PVC and isoptimized to provide the most efficient thermal capacity. PVC is virtuallyimpervious to rot, decay, and biological attack. The fill is elevated abovethe cold water basin floor to facilitate cleaning and maintenance. Theintegral eliminators effectively strip entrained moisture from the leavingair stream with minimum pressure drop to prevent water loss withnegligible impact on efficiency.Weir DamsCustomerValued STANDARD FILLStandard fill can be used in applications with entering watertemperature up to 130 F (54.4 C). The fill and drift eliminators areformed from self-extinguishing PVC having a flame spread rating of 5per ASTM E84. HIGH TEMPERATURE FILL (OPTION)An optional high temperature fill material is available whichincreases the maximum allowable entering water temperature to140 F (60 C).BACross Fill ManufacturingPRODUCT & APPLICATION HANDBOOK VOLUME VB60

Series 1500Custom Features & Options››Shipping and RiggingBAC units are factory-assembled to ensure uniform quality with minimumfield assembly. Each unit has been designed with rigging and assemblyin mind and includes features to minimize the number of tools requiredand installation time. KNOCKDOWN UNITS (OPTION)Knockdown units are available for jobs where access to the coolingtower location is limited by elevators, doorways, or similar obstacles,where lifting methods impose very strict weight limits, or where theshipping cost of a fully assembled tower is excessive. All materialsof construction and design features are the same as those of afactory assembled unit. Welded stainless steel cold water basinsand TriArmor Corrosion Protection System cold water basins areexcluded due to the need for in-plant assembly.Single Piece Lift››Sound OptionsRecognition of the importance of sound restriction is growing and canbe a very important design criterion for any project. BAC maintains thewidest selection of sound mitigating options in the market place and canprovide the most cost effective option to meet any requirement.Low Sound FanCustomerValued STANDARD FANThe fan provided for all Series 1500 Cooling Towers is selected tooptimize low sound levels and thermal performance. LOW SOUND FAN (OPTION)The Low Sound Fan option reduces sound up to 8 dBA. Addinga high solidity fan decreases sound levels by decreasing fanspeed, which proportionally decreases sound levels. The thermalperformance with the Low Sound Fan has been certified inaccordance with CTI Standard STD-201. WHISPER QUIET FAN (OPTION)For the most extreme sound limitations, BAC’s Whisper Quiet Fanreduces sound up to 14 dBA and is CTI Certified.Whisper Quiet FanB61Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M

SOUND ATTENUATION (OPTION)Factory designed, tested, and rated sound attenuation options areavailable for both the air intake and discharge. Consult your localBAC Representative regarding available options.NOTE: The panel opposite the air intake, called the blank-off panel, is inherentlyquiet. Positioning the blank-off panel towards the sound sensitive direction insulatessensitive areas from higher sound levels.››Air IntakeCombined Inlet Shield InspectionIn a cooling tower, airborne debris can be entrained in the water throughthe unit’s air intake. Reducing the amount of debris that enters thetower lowers maintenance requirements and helps to maintain thermalefficiency.CustomerValued COMBINED INLET SHIELDS (CIS)The Combined Inlet Shields’ (CIS) bent flow path blocks sunlightfrom the cold water basin and acts as a screen to prevent debris fromentering the unit. These benefits result in a significant reductionin algae growth, debris accumulation and scale build-up. CIS areconstructed from corrosion and UV resistant PVC, and are CTICertified. and are installed in easy to handle sections to facilitateremoval, inspection, and replacement. The use of CIS results inlower maintenance costs and ease of maintenance over the life of theunit.Combined Inlet ShieldsPRODUCT & APPLICATION HANDBOOK VOLUME VB62

Series 1500Custom Features & Options››Access OptionsBAC provides a broad offering of access options. Our evaporativeequipment is designed to be the most easily maintainable for sustainingcapacity over a longer life. All BAC platforms and ladders are designed tobe OSHA compliant to ensure personnel safety and code compliance.NOTE: Platforms, ladders, handrails, safety gates, and safety cages can be added atthe time of order or as an aftermarket item.CustomerValued STANDARD INTERNAL WALKWAYAn internal walkway is standard, allowing access to the spaciousplenum area for maintenance and inspections of the basin,make-up, fill, and drive system.CustomerValued EXTERNAL PLATFORMS AND LADDER PACKAGES (OPTION)Internal WalkwayExternal platforms and ladder packages are available to provide safeaccess to key components such as the water distribution system ofthe unit for maintenance. These specially designed platforms aresecured for compact shipping in the cold water basin to minimizeshipping costs and are ready for field assembly. HANDRAIL PACKAGES (OPTION)Handrail packages are available to provide safe access to the top ofthe unit for maintenance of the distributions system. The designedpackages are secured for compact shipping in the cold water basin tominimize shipping costs and are easily assembled in the field. INTERNAL SERVICE PLATFORM AND LADDER PACKAGES(OPTION FOR TWO PIECE UNITS)For access to the motor and drive assemblies, an internal ladderand upper service platform with handrails is available on largerunits. Safety gates are standard for all handrail openings, and allcomponents are designed to meet OSHA requirements. INTERNAL LADDER (OPTION)A moveable internal ladder is available, providing access to the motorand drive assemblies.B63Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O MHandrail PackageNOTE: Site safety guidelines should dictate accesspackages selected for the project.

ACCESS DOOR PLATFORM AND LADDER PACKAGES (OPTION)An access door platform is available to allow access to the unitwhen installed on elevated supports. This option allows for safeaccess to the unit, as well as a working platform to stage tools formaintenance.››Installation FlexibilityYears of operating experience and extensive R&D have resulted ina design that minimizes costs associated with enclosures, supportrequirements, electrical service, piping, and rigging, making the Series1500 Cooling Towers the industry’s most serviceable unit withoutcompromising performance and fit.External Ladder and Platform PIPING FLEXIBILITYBAC offers a multitude of connection options and locations to ensurethe proper fit for any application, potentially eliminating pipingmodifications and therefore reducing material and labor. SUPPORT STEEL FLEXIBILITYSeveral support steel configurations are available, including theability to utilize pre-existing support steel for replacement units,significantly reducing cost. SINGLE-SIDE AIR INTAKESingle-side air intake units can be placed close to solid walls,reducing the size of enclosures and allowing for more profitable useof premium space. Also, the panel opposite the air intake, called theblank-off panel, is inherently quiet. Positioning the blank-off paneltowards the sound sensitive direction insulates sensitive areas fromhigher sound levels.Steel Support FlexibilityPRODUCT & APPLICATION HANDBOOK VOLUME VB64

Series 1500 Engineering DataNOTE: Do not use for construction. Refer to factory certified dimensions. This catalog includes data current atthe time of publication, which should be reconfirmed at the time of purchase. Up-to-date engineering data, freeproduct selection software, and more can be found at www.BaltimoreAircoil.com.Plan View1'-4"L/2Water InletFace DFace AAHCH12'-2"Water OutletL11'-10"NOTES:1. The specific size of the inlet and outlet connection may vary with the cooling water design flow rate. Consult unit print for dimensions.B65Q U E S T I O N S ? C A L L 4 1 0 . 7 9 9 . 6 2 0 0 O R V I S I T W W W. B A LT I M O R E A I R C O I L . C O M

NOTE: Do not use for construction. Refer to factory certified dimensions. This catalog includes data current atthe time of publication, which should be reconfirmed at the time of purchase. Up-to-date engineering data, freeproduct selection software, and more can be found at www.BaltimoreAircoil.com.Plan View1'-4"1'-4"L/2Water InletFace AWater InletFace DAHCH1L/22'-2"Water OutletL2 1/2"11'-10"NOTES:1. The specific size of the inlet and outlet connection may vary with the c

The Series 1500 Cooling Tower is the industry's most serviceable unit without compromising performance and fit. With expanded models almost doubling the capacity range and a . performance increase of up to 13%, the Series 1500 Cooling Tower provides an excellent solution for all your application needs. › Reduced Energy Consumption