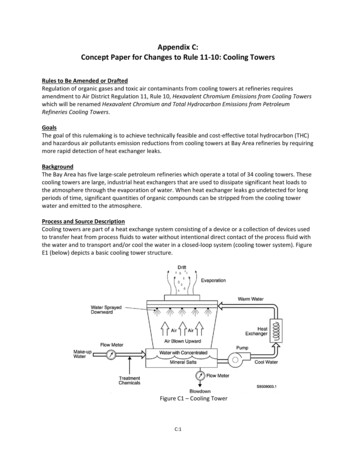

Transcription

SUPER TOWER INDUSTRIESCOOLING TOWERMANUFACTURERBND SeriesBHD SeriesFBND SeriesFBNZ SeriesFBNG SeriesFRP TankADVANTAGES·······Space SaverEnergy SaverLow Maintenance CostLow NoiseLow Drift LossCompact UnitQuake Proof Design

COMPANYCOMPANY PROFILEPROFILESUPER TOWER INDUSTRIESCOOLING TOWER MANUFACTURERSUPER TOWER INDUSTRIES is established as a professional company manufacturingcooling towers in Singapore and China, and has been actively involved in supplying,installing and maintaining top quality cooling towers all over Singapore.SUPER TOWER INDUSTRIES is certified and registered as a Cooling Tower Institute(CTI) Member in U.S.A. We hold a unique position in the industry, for not only do wesupply, install and maintain Cooling Towers, our factory in Singapore and China alsomanufactures all kinds of Cooling Towers such as : FRP Bottle type, Counter flow roundtype, Cross flow square type, special custom made type and other spare parts for all kindof Cooling Tower, example: crossflow square tower with side discharge.Our Cooling Tower are featured with energy saving, compact and light weight, reducednoise pollution, corrosion resistant, fireproof and quakeproof. We provide easy access toall kinds of Cooling Tower spare parts such as Sprinkler heads, Sprinkler pipes, SuctionStrainers, PVC infill, aluminium infilled, Drift eliminators, etc.New regulations were imposed by ENV in Singapore to control Legionnaires Disease onall Cooling Towers under Chapter 95 act. We (SUPER TOWER INDUSTRIES) arepleased to introduce and highlight that we have innovative design for supplying allmakes and models of round and square Cooling Tower's Drift Eliminator based on thelatest ENV Regulation.SUPER TOWER INDUSTRIES management spirit is firmly grounded in the belief thatwe must offer only the highest quality services to our clients and engage in businessrelationship which are not only beneficial to ourselves, but to our clients as well. Thisprincipal has been the guiding influence on all SUPER TOWER INDUSTRIES businessstrategies and goals.

Low Noise & Super Low Noise Cross-Flow Cooling TowerFeaturesFor centrifugal refrigerating machine and other cooling applications:BHD series- Low noise type- Super-low noise / Energy-saving typeThe advantages of the BHD series are:1Energy SavingThe fan power consumption isgreatly reduced by the lowerpressure loss filler togetherwith the bell-mounted fan stack.2Space-saving, light weight andpackage unitOperating weight, installationspace and time are lower thanthe conventional types since ourhigher-heat-exchanger-rate filler.3Low noise levelBoth the series satisfy the standardnoise level specified by CTI & JCI.4Anti-corrosivenessAll the main components aremade of the anti-corrosivematerials such as FRP and HDG steel.5No requirement of any specialfoundationAll the units supply with thestandard footings so the verysimple foundation is required.67Motor11.Fan12.Fan Casing13.DistributorUpper Water BasinInternal PipePVC InfillInternal Frame SupportCasing PlateInspection DoorQuakeproof designOur standard design is based on1.0th degree and 0.5th degreevertical. Any other specificationand design are ireproof materialAll the units are constructed withFRP - the fireproof material.LadderMake Up Water PipeWater Basin④⑤⑥⑦⑧⑨⑩⑪⑫⑬

Super Low Noise Cross-Flow Square Cooling TowerBHDseriesStandard Specifications – Part IModelDimensions (mm)No.MotorFan Dia.Piping Diametermm DN x noWeight (kkg)BHD-tLWH415/50HZKw x noØmm x noInlet x noOutlet x 01.1 x 1900 x 180 x 180 x 140/40 x 120/20 x 10.431.152BHD-75t1500247031001.1 x 11100 x 1100 x 1100 x 140/40 x 120/20 x 10.581.53BHD-85t1500247031501.5 x 11200 x 1100 x 1100 x 140/40 x 125/25 x 10.651.554BHD-100t1500247031502.2 x 11300 x 1100 x 1100 x 140/40 x 125/25 x 10.751.75BHD-125t1800277032502.2 x 11500 x 1125 x 1125 x 140/40 x 125/25 x 10.961.946BHD-150t1800277037303.0 x 11500 x 1150 x 1150 x 140/40 x 132/32 x 11.032.027BHD-175t1900281038504.0 x 11600 x 1150 x 1150 x 140/40 x 132/32 x 11.22.378BHD-200t2310321039504.0 x 11800 x 1150 x 1150 x 140/40 x 132/32 x 11.42.529BHD-225t2310321039504.0 x 11900 x 1150 x 1150 x 140/40 x 132/32 x 11.522.6410BHD-250t2590352039505.5 x 12000 x 1200 x 1200 x 150/50 x 132/32 x 11.674.911BHD-275t2590352039505.5 x 12100 x 1200 x 1200 x 150/50 x 132/32 x 11.795.0212BHD-300t3600277038303.0 x 21500 x 2150 x 2150 x 240/40 x 232/32 x 21.963.9613BHD-350t3800281038504.0 x 21600 x 2150 x 2150 x 240/40 x 232/32 x 22.44.7414BHD-400t4620321039504.0 x 21800 x 2150 x 2150 x 240/40 x 232/32 x 22.85.0415BHD-450t4620321039504.0 x 21900 x 2150 x 2150 x 250/50 x 232/32 x 23.045.2816BHD-500t5180352039505.5 x 22000 x 2200 x 2200 x 240/40 x 232/32 x 23.346.817BHD-600t6930321039504.0 x 31800 x 3150 x 3150 x 340/40 x 332/32 x 34.27.5618BHD-800t9240321039504.0 x 41800 x 4150 x 4150 x 440/40 x 432/32 x 45.610.0819BHD-900t9240321039504.0 x 41900 x 4150 x 4150 x 440/40 x 432/32 x 46.0810.5620BHD-1000t10360352042005.5 x 42000 x 4200 x 4200 x 450/50 x 432/32 x 46.6819.621BHD-1200t12950352042005.5 x 52000 x 5200 x 5200 x 550/50 x 532/32 x 58.352422BHD-1500t15540352042005.5 x 62000 x 6200 x 6200 x 650/50 x 632/32 x 610.0229.423BHD-2000t20720352042005.5 x 82000 x 8200 x 8200 x 850/50 x 832/32 x 813.3639.224BHD-2500t25900352042005.5 x 102000 x 10200 x 10200 x 10 50/50 x 10 32/32 x 1016.74925BHD-3000t31080352049005.5 x 122000 x 12200 x 12200 x 12 50/50 x 12 32/32 x 1220.0458.826BHD-3500t36260352049005.5 x 142000 x 14200 x 14200 x 14 50/50 x 14 32/32 x 1423.3868.627BHD-4000t41440352049005.5 x 162000 x 16200 x 16200 x 16 50/50 x 16 32/32 x 1626.7278.428BHD-5000t51800352049005.5 x 202000 x 20200 x 20200 x 20 50/50 x 20 32/32 x 2033.49829BHD-6000t62160352049005.5 x 242000 x 24200 x 24200 x 24 50/50 x 24 32/32 x 2440.08117.630BHD-7000t72520352049005.5 x 282000 x 28200 x 28200 x 28 50/50 x 28 32/32 x 2846.76137.231BHD-8000t82880352049005.5 x 322000 x 32200 x 32200 x 32 50/50 x 32 32/32 x 3253.44156.832BHD-9000t93240352049005.5 x 362000 x 36200 x 36200 x 36 50/50 x 36 32/32 x 3660.12176.433BHD-10000t103600352049005.5 x 402000 x 40200 x 40200 x 40 50/50 x 40 32/32 x 4066.819634BHD-20000t207200352049005.5 x 802000 x 80200 x 80200 x 80 50/50 x 80 32/32 x 80133.639235BHD-30000t310800352049005.5 x 1202000 x 120200 x 120 200 x 120 50/50 x 12032/32 x 120 200.4588

Super Low Noise Cross-Flow Square Cooling TowerBHDseries- Selection Chart -Standard Specifications – Part IIModelWet Bulb (27 C)Flow Rate (L/min)Wet Bulb (28 C) Flow Rate (L/min)Dimensions (mm)Inlet Temp37384042453540354345373843453535Outlet 077856785923040755250924032104210BHD-900t11700 10485814571255600763550906110814510690 00 11650904879156220848056556785904511875 600 13975 1085595007465101756785814010855 14245 13570 11670 10175 13840610578701295035204210BHD-1500t19500 17460 13560 11865932012710847510170 13560 17800 16950 14575 12710 17290762598301554035204210BHD-2000t26000 23300 18095 15830 12440 16965 11310 13570 18095 23750 22620 19450 16965 23070 10180 13120 2072035204210BHD-2500t32500 29120 22615 19790 15550 21200 14135 16960 22615 29680 28270 24310 21200 28835 12720 16395 2590035204210BHD-3000t39000 34950 27145 23750 18660 25445 16965 20355 27145 35625 33930 29180 25445 34605 15270 19680 3108035204820BHD-3500t45500 40765 31665 27705 21770 29685 19790 23750 31665 41560 39580 34040 29685 40370 17810 22955 3626035204820BHD-4000t52000 46580 36190 31670 24880 33930 22620 27145 36190 47500 45240 38906 33930 46145 20358 26240 4144035204820BHD-5000t65000 58245 45240 39585 31100 42410 28275 33930 45240 59375 56550 48630 42410 57680 25445 32780 5180035204820BHD-6000t78000 69895 54290 47500 37320 50895 33930 40715 54290 71250 67860 58360 50895 69215 30535 39360 6216035204820BHD-7000t91000 81545 63340 55420 43540 59380 39585 47500 63335 83130 79170 68090 59380 80750 35630 45920 7252035204820

Standard Low Noise Cross-Flow Square Cooling TowerBHDseriesW 300Foundation DrawingL - 100BHD50-275t

Standard Low Noise Cross-Flow Square Cooling TowerBHDseriesW 300Foundation DrawingBHD300-500t

Standard Low Noise Cross-Flow Square Cooling TowerBHDseriesW 300Foundation DrawingBHD-600t

Standard Low Noise Cross-Flow Square Cooling TowerBHDseriesW 300Foundation DrawingBHD800-1000t

Standard Low Noise Cross-Flow Square Cooling TowerBHDseriesW 300Foundation DrawingBHD-1200t On Wards

Single Cell Counter-Flow Square Cooling TowerFBND, FBNZ, FBNGseriesStandard iameterPiping DiameteraInlet(mm)bOutlet(mm)c Draind Overflow(mm)Weighte Manualf Auto ase on inlet water temperature is 37 C outlet water temperature is 32 C and ambient wet bulb temperature is 28 50900100050/10080/5034000Base on inlet water temperature is 43 C outlet water temperature is 33 C and ambient wet bulb temperature is 28 01609150900100050/10080/5034000Base on inlet water temperature is 60 C outlet water temperature is 35 C and ambient wet bulb temperature is 28 7576777778FBND Single Cell - Low Noise TypeFBNZ Single Cell - High Temperature TypeFBNG Single Cell - Super High Temperature TypeNote : Please kindly consult Super Tower Industries for other special temperature requirement.

Single Cell Counter-Flow Square Cooling TowerFBND, FBNZ, FBNGseriesFoundation DrawingFOUNDATION NZ200250350400500600700H - Height of cooling tower.LOADING 20025003500370041005500( ) - Recommended dimensions

Single Cell Counter-Flow Square Cooling TowerFBND, FBNZ, FBNGseriesFoundation DrawingFOUNDATION 0200017003000260040003500H - Height of cooling 50015500181001550018100( ) - Recommended dimensionsLOADING 0005500700080009000120002000022000

Standard Low Noise Counter-Flow Round Cooling TowerBNDseriesStandard Specifications – Part INo.DIMENSIONModelBND-tPIPING DIAMETERTOWER WEIGHTFanMotorDiameter415/50HCasing Highmm øH.P.Dmm ø Hmm øFanAir ipeMakeUpFOUNDATIONOverFlowDrainDNmm øDimensionemmDiametermm 8012006150176627 3857100176728 3857100176729 7178800176830 010018539500176931 00100220011301770

Standard Low Noise Counter-Flow Round Cooling TowerBNDseriesStandard Specifications – Part IIWET BULB 27 C- Selection Chart -WATER FLOW RATE L/minWET BULB 28 CWATER FLOW RATE 38434535356090INLET T 09944BND-2200T

Standard Low Noise Counter-Flow Round Cooling TowerBNDseries①Foundation And StructureDrawingNOITEMMATERIAL1MOTOR415V2FAN BLADEALUM ALLOY3CASINGFRP4SPRINKLER PIPEPVC⑥5SPRINKER HEADALUM ALLOY⑦6CENTER PIPEPVC⑧7INFILLPVC⑨8LADDERH.D.G.S.⑩9INFILL SUPPORTH.D.G.S.10AIR INLET LOUVREPP11CASING SUPPORTH.D.G.S.12WATER BASINFRP13AUX. SUCTION TANKFRP14TOWER SUPPORT STRUCTUREH.D.G.S. or FRP15WATER INLET / etInletO/FDM/AOutlet PipeInlet PipeInletBND 5-350tInletOutletBND 5-30tInletOutletBND 40-75tOutletBND 175-350tBND 100-150th 300Section A-AHOutletInletM/AInletPipeOutletInletOutlet PipeDh 500Section B-BBND 400-2200tBND 400-700tBND 800-2200t

Standard Low Noise Counter-Flow Round Cooling TowerBNDseriesNoise Level TableTESTINGPOINTSTANDARDLOW NOISESUPER LOW 875506370①② The testing point is for the comparison purpose between thesame amount cooling water. The testing point is 1.5M from the ground and is at 2 times ofthe tower diameter distance from the wall vertically and in theair input direction. The testing point is at times of the output diameter distancefrom the wind shaft in the 45 direction.③

SUPER TANK SPECIFICATIONNO.1m HeightTYPE1.5m HeightL x W (mm)Volume (m³)Dry Wt (kg)Wet Wt (t) Volume (m³)Dry Wt 4053x263306.3945564x2841073x3984x392m HeightWet Wt (t) Volume (m³)Dry Wt (kg)2.5m HeightWet Wt (t) Volume (m³)Dry Wt (kg)Wet Wt 950881003900112189x545903050991910 x x654108375012013547001552410 x 8001221404800160279x76312641001362810 x 309x87214447001541806002003110 x 88016049901752006300225329x98116250801773310 x 990180512019525569002553410 x 10100200566022025073002803512 x 10120240673026030086003403615 x 101503008100330375106004053718 x 101803609590390450115004903820 x 1020040010400450500129005603184523078515953.21948

SUPER TANK SPECIFICATION3m HeightVolume (m³)Dry Wt (kg)3.5m HeightWet Wt (t) Volume (m³)Dry Wt (kg)4m HeightWet Wt (t) Volume (m³)Dry Wt (kg)Connection Pipe SizeWet Wt 50

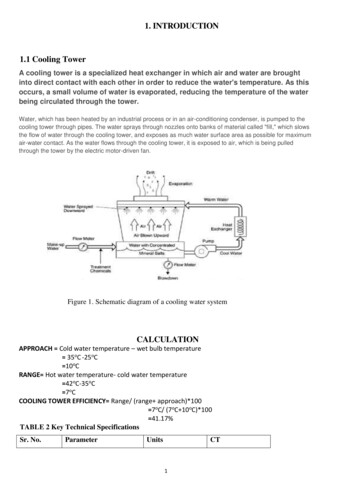

Suitable Model Selection Chart1000900800700600Take the following operating conditions as an example:Hot water temperature37 CCold water temperature32 CRange (hot-cold water temp. difference)5 CAmbient wet-bulb temperature27 CCirculating water flow rate450m³/h500How to read the chart1Trace up the Hot water temperature of 37 C vertically to find the intersectingpoint 1 with the 27 C ambient wet-bulb temperature curve.2Shift the point 1 to the right to find the intersection point 2 with the 5 C rangecurve.3Then trace up again from the point 2 to find the intersecting point 3 with the450m³/h circulating water flow rate.4If point 3 falls on the curve of a model, select this model. If point 3 fallsbetween two curves, select the larger model.5Because point 3 falls between the curves of 500 & 600, the selection is model600.Remarks1For cooling tower hot water temperature exceeding 50 C, heat-resistant versionshould be used (delivered by special order).2If suitable model cannot be found from the chart, please inquire us.60585654525048464442Hot water temperature C4038363432Circulation water flow rate m² / h400300200150100908070605040302030

HANDING INSTRUCTIONSA INSTALLATION1.LOCATION3.PIPINGTo keep the cooling tower in full swing, choose aplace according to the following conditions.a.The pipes above the cold water basin’s waterlevel especially the horizontal line atop thetower body should be as short as possible. Thishelps to keep backwater at minimum when thecooling tower stopsb.There are plural pipes leading to the distributionbasin. Be sure to equip a flow control valve witheach of the hot water inlet pipes. The internalpiping type is equipped with a simple flowcontrol valve. An overall flow control valveshould be equipped at the circulating waterpump outlet.c.To fix the tower-top pipe supports, usedistribution basin mounting bolts. The bolts atfan side can be screwed from inside, while thoseat louver side can be tightened after detachingthe style strip.a.Well- ventilated, clean.b.Exhaust air from the cooling tower is not circulatedand sucked again into the tower.c.Free from much dust and dirt, sulfurous acid andother hazard gases; these are major cause todamage the refrigerator condenser.d.Not in the vicinity of kitchen or restroom exhaustports, or ammonia type copying machine.e.Not near smokestack or stovepipe, or radiant heatfrom any other heat source.f.Open and not affected by sound echo.g.2.7m or more space between the cooling tower airinlet and the wall or other barrier.d.The inlet pipe should be positioned about50mm below the cooling tower top deck.2.PROCEDUREe.a.Prepare the foundation, referring to the relateddrawings.To prevent the make-up water inlet pipe fromdamage by freezing in winter, equip a drain cockat the bottom in between the valve and themake-up water inlet pipe connection.b.Make the foundation top even and level.5.Bring the circulating pump into full operationand adjust the flow control valve so that thewater level of the distribution basin is wellbalanced. The circulating water flow rate isthan adjusted with the overall flow controlvalve located at the circulating pump outlet.6.The ball tap of the automatic make-up waterinlet pipe should be adjusted so that waterinterrupted slightly below the overflow waterlevel.B BEFORE OPERATION1.Turn the fan blade by hand to make sure the bladetips are out of contact with the fan stack.2.Run the fan for a while and check for turningdirection (arrow-marked), unusual sound, excessvibrations, etc.3.Fill the cold water basin up to the top level of theoverflow pipe.4.Run the circulating pump for a while to force airout of the pipes until the pipes and cold waterbasin are filled up with water. Be careful not toallow air to be suck into the cooling water pipe.SUPER TOWER INDUSTRIESSingapore Office:280 Woodlands Industrial Park E5,Harvest @ Woodlands, #05-32Singapore 757322TEL : (65) 6555-1815FAX : (65) 6555-1851WEBSITE : www.supertower.com.sgEMAIL : sales@supertower.com.sgDistributor :

SUPER TOWER INDUSTRIES is certified and registered as a Cooling Tower Institute (CTI) Member in U.S.A. We hold a unique position in the industry, for not only do we supply, install and maintain Cooling Towers, our factory in Singapore and China also manufactures all kinds of Cooling Towers such as : FRP Bottle type, Counter flow round