Transcription

P R E - PA I N T E DMetal Roofing & CladdingGUIDE

insideCONT ENT SIntroduction3Product Overview4Huge range of Possibilities7Colours7Reflectivity7Atmospheric Environments8Warranty10Design & InstallationFundamentals12Design Issues13Basic Chemistry and theProperties of Metals14Holes, Penetrations, Fixtures,Fittings and Fasteners16Maintenance17Step by Step Guide forColorCote roofing & cladding 18Sustainability and recycling20Where to go for moreinformation, ideas or help?211

2

IntroductionYour roof and cladding are two of the largest and most obvious visual features of your home.When you’re building or renovating there are a number of important questions you need to ask to getthe right roof or cladding for your home. You want products that will give you the look and protectionyou are after and will stay looking good for years and years.ColorCote Pre-Painted Metal Roofing & Cladding Guide gives you the knowledge and understandingyou need to have informed discussions on pre-painted metal roofing and cladding with architects,designers, builders and other trades people.This knowledge will help you: Get the fundamentals right and avoidpotential pitfalls, increase the lifespan of your roofing andcladding, save thousands of dollars in repair, maintenanceand replacement costs.Decisions need to be made on a product’ssuitability for the house design, its suitability forits geographic or climatic environment, its lifespanand maintenance requirements -- not just theinitial up front cost. Spending a little bit more nowand getting it right can save you thousands ofdollars and lots of extra work over the life of yourLike many aspects of building or renovating aroofing or cladding. It is important to rememberhome, mistakes with your roofing and claddingtoo that the cost of your roof is only about 5% ofcan be expensive – not just in financial terms butthe total cost of your home.in worry, stress and manual labour.3

Product OverviewColorCote pre-painted steel andColorCote ZR8 aluminium roofing and claddingSuitable for moderate climaticproducts have been manufactured inNew Zealand for more than 30 years.environments, ZR8 has a hot-dippedaluminium/zinc alloy-coated steelTo ensure all its colours and coatingssubstrate. It has a waterborne orare more than equal to the worst thepolyester top coat baked on a polyesterNew Zealand climate can throw atprimer, giving an extremely durablethem, Pacific Coilcoaters runs a rigorouspaint system that resists UV damagetesting regime, with exposure sites atand provides excellent gloss and colourMuriwai Beach on the untamed westretention.coast of the North Island and in theColorCote ZM8 Auckland industrial suburb of Penrose.Suitable for moderate and severeThere is a six-tier range of ColorCote pre-painted metal roofing and claddingproducts – AR8 /ARX , ZM8 ,ZMX , ZRX and ZR8 – all using thelatest coating technology. They haveeither a steel (with a corrosion-resistantzinc coating) or aluminium substrateand each product has a different level ofprimer and type of top-coat dependingon the environment in which it is to bemarine environments, ZM8 has ahot-dipped aluminium/zinc/magnesiumalloy-coated steel substrate which givesit enhanced cut-edge and wet-areaperformance. It has a waterborne orpolyester top coat baked on a polyesterprimer, giving an extremely durablepaint system that resists UV damageand provides excellent gloss and colourretention.used.ColorCote ZMX There are ColorCote systems to suit all New Zealand homes. Which is bestfor your home is determined by yourclimatic environment or geographiclocation.4ZMX has a hot-dipped aluminium/zinc/magnesium alloy-coated steelsubstrate which gives it enhanced cutedge and wet-area performance. It hasa thicker coating of polyester primerfor improved corrosion resistance anda 70% PVF2 top coat. This system givesoutstanding gloss, colour retentionand durability in severe and industrialenvironments.ColorCote ZRX ZRX has a hot-dipped aluminium/zinc alloy-coated steel substrate with athicker coating of polyester primer forimproved corrosion resistance and a70% PVF2 top coat. This system givesoutstanding gloss, colour retentionand durability in severe and industrialenvironments.AR8 and ARX Using type 5052 or 5005 marine gradealuminium alloy substrates, polyesterprimer, a choice of waterborne,polyester or 70% PVF2 top coats,AR8 and ARX are designed foruse in severe and very severe marineenvironments and are ideal for cladding.

5

6

Huge Range of PossibilitiesColorCote pre-painted metal roofing and cladding systems provide design flexibility unmatchedby any other roofing or cladding material. ColorCote can be roll-formed or pressed into a rangeof profiles that look great and are warranted to last.It is easy to install and can be adapted to almost any design or construction concept.It has the strength to span wide spaces with simple and lightweight support systems and can bebent or curved to suit an almost unlimited range of innovative designs and roof pitches.ColoursThe expansive ColorCote range of colours gives homeowners a great-looking choice whateveryour architectural or design taste.There are more than 80 colours in the ColorCote palette – natural, earth and autumn shades,pastels, bold primary colours, metallics and even black and white. If none of these colours suit,custom colours can be manufactured on request.ReflectivityNew Zealand local authorities and councils are looking to reduce the impact of construction andbuildings on the visual landscape, particularly in rural, coastal and alpine areas.Councils are wanting new buildings to blend in with the natural environment and are enforcingreflectivity levels based on standard ASTM E903-96 which measures the average values forreflected solar radiation from building products – the lower the value the less reflectedlight/glare.That is why ColorCote has developed its Naturals range of earthy low reflectivity colours (eachwith low reflectivity, colour and gloss) to fit in with the New Zealand landscape. The reflectivityvalue for each Naturals colour is listed on the Naturals colour chart.See www.colorcote.co.nz or your local council website for more details.7

www.colorcote.co.nzAtmospheric EnvironmentsUS A G EMILDMODERATEINDUSTRIALG U I D EISO Category 1-2ISO Category 2ISO Category 3-4ISO Category 3MARINESEVERE MARINEAreas far inlandInland other thanfar inlandAreas around majorindustrial complexesAreas influenced bycoastal saltsBegins anywhere from 100-400metres in from the beach front ofbreaking surf and can extend inlandPRODUCT TYPE 2-4AtmosphericEnvironmentsIt is very important to use the correct5environment will mean a shorter productare. Prevailing winds and regionallifespan, an onerous maintenancetopographical variations can amplifyschedule and no protection under Pacificthe true range of severe marineCoilcoaters’ warranty programme.environments to many kilometres inlandfrom the sea.ColorCote pre-painted metalIt is also important to recognise thatroofing or cladding system for themanufacturers’ environmental usageA simple rule of thumb is that if youappropriate atmospheric environment.tables are only rough guides to localcan see the sea from your property anInstalling a system designed forclimatic and geographical conditions.aluminium substrate (ARX or AR8 )moderate environment in a very severeSalt-laden sea air does not stopshould be used.where the chart says the boundaries8ISO Category 4

VERY SEVEREISO Category 5Very Severe MarineOffshore and anywhere within100-400 metres from the water line of areasof breaking surf but can extend inlandIndustrial and Geothermal6Using the best paint system for thejob and choosing between a steel oraluminium substrate (depending on theenvironment) will add years to the life ofyour roof. and save you money too!!If in doubt contact Pacific Coilcoaters forthe worst of the salt residue) could usespecific recommendations.ZR8 but the cladding should still beThe design of your house can alsoARX .It can be a false economy to buy aproduct on cost alone – particularlysomething like pre-painted metaldictate which system should be used. ForIn severe marine environments careroofing and cladding that is protectingexample a house with a minimum pitchneeds to be taken with cut edges andyour home from the elements.roof with parapets two kilometres frompenetrations --including screw holesthe surf should use ARX .-- to prevent the spread of corrosionThe same house with a steeper pitchedroof (which allows rainwater to wash off(with aluminium substrates this is not ascritical).Sometimes the initial installed price maybe a little more up front, but over a 30– 50 year lifespan you’ll come out wayahead.9

WarrantyMost roofing companies will give you a warrantyfor their products.However, all warranties are not the same. Just becausea company is willing to give you a warranty won’t makeyour roof or cladding any more durable or resistant tothe elements.Some roofing companies might be prepared to give youa 15-year warranty on a basic roofing system in a harshor marine environment. You might think you’re savingmoney but look closely at the fine print: somebody’sgoing to have to climb up on the roof every month andscrub it down with a hose and brush.Who’s going to do that? You?Even worse; if you don’t meet the onerous conditions,and the roof starts to fail after a few years, you’ll have toreplace it at your own cost.10

Pacific Coilcoaters’ written warranty. Our warranties are specificSeismicto a particular building, where it is sited, and the type ofBecause of New Zealand’s geographic position on the Pacificroofing and cladding product used. Because we make sure yourim-of-fire, our homes have to be designed to resist notuse the right product for the job and its environment,only our weather but also volcanic or earthquake activity.only normal maintenance – usually a wash every six monthsA ColorCote roof is strong and secure and also relatively– is required. Residential warranty terms and warrantylightweight. A ColorCote pre-painted steel roof on theapplications can be accessed by visiting the ColorCote average 150 sq. metre home weighs less than a tonne.website: www.colorcote.co.nz.By contrast, a concrete tile roof on the same house couldAll ColorCote roofing and cladding products come with aTo avoid problems later, or for specific advice on your proposedroofing or cladding designs, you can email or fax your plansweigh more than eight tonnes and would require additionalstructural, engineering and labour costs.to Pacific Coilcoaters before you start construction. PacificCoilcoaters will let you know which is the best coating andsubstrate solution for the design you want and will alsorecommend fixings based on environmental and designconsiderations. This means you’ll get the correct ColorCote product for your home and also means the solution providedwill come with a pre-approved warranty.11

Design &InstallationFundamentalsWhen designing your home make sure youtake time to look carefully at your roofing orcladding plans.Good design and a bit of good oldfashioned commonsense can save you a lotof time, effort, aggravation and heartache.If you see anything in this section that youthink might cause a problem for your hometalk to your architect, builder or rooferabout it.Or contact Pacific Coilcoaters atwww.colorcote.co.nz.12

Design IssuesThe design of your house will affect the life of yourpre-painted roofing and cladding. It is best to avoidoverhangs and designs that create unwashed areas.These are not naturally washed down by rainwaterallowing dirt, salts and other corrosive elements tobuild up.Good design can get rid of most unwashed areas at theplanning stage. You also need to think of how the roofis going to be maintained. All roofs need to be washeddown on a regular basis so you need to think of how youare going to access the roof. If the pitch of the roof is toosteep to walk on safely you might have to hire a cherrypicker or crane every time maintenance is required.Orientation of the roof is important too, particularly insevere environments. It is important when looking atthe aspect of the roof that the metal profile is protectedfrom the effects of salt-laden air being driven in from thesea under the roof profile and accelerating corrosion. Insevere and very severe environments it is also importantthat the right roof profile is chosen.In such exposed environments care should also be takenwhen installing spouting. The spouting profile needs tobe correctly fixed to prevent corrosive wind-driven waterand salts being driven up under the sheets of roofing andcausing possible early product failure.Spouting, valleys and low pitched roofs also need to havethe correct fall to prevent ponding which can acceleratepotential corrosion.The underside of all pre-painted metal roofing, includingsoffits, should be enclosed. The underside paint systemis usually only a wash coat which is not designedfor exterior exposure and has only limited corrosionresistance.13

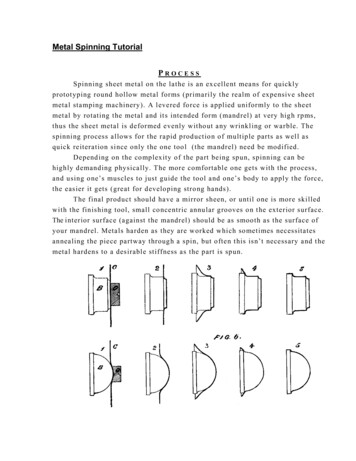

Basic Chemistry and theProperties of MetalsWhen different types of metals come into contactwith each other, and particularly when water ispresent, chemical reactions take place which result inthe metal higher up the galvanic hierarchy of metals(i.e. metals more resistant to corrosion) eating awaymetals lower down the order. Brass, copper, lead andstainless steel are higher up the galvanic hierarchythan the aluminium/zinc-coated steel and aluminiumused as ColorCote pre-painted metal substrates.Direct contact between these dissimilar metals willcause the ColorCote systems to quickly corrode.14

Water coming from copper and brass pipes orOther materials that will cause problems:spouting can cause corrosion to pre-painted metal Cement will have a corrosive affect on the paintroofing and cladding too.The best solution is to make sure there is no directcontact between dissimilar metals.If necessary, inert membranes can be used tosystems and must be wiped off immediately Tanalised timber and some other timbers suchas cedar can cause galvanic corrosion. In mildatmospheres seal the timber surface with an inertmembrane at the points of contact. In severe andisolate two different metals. This is the case whenvery severe conditions the two surfaces must beColorCote AR8 and ARX are fixed using stainlessfully isolated by a rubber or neoprene gasket.steel fasteners. A special low carbon washer is usedbetween the two metals. Concrete and plaster can cause discolouration tothe paint coating which should be protected by aninert membrane where they come into contact.15

Holes, Penetrations, FastenersFixtures and Fittings It is important to use the correct fastener to installCare needs to be taken every time you make a hole inyour pre-painted metal roofing and cladding or fix orscrew something onto it.Holes and penetrations can let in moisture andaccelerate corrosion if not sealed or flashed properly.So can fixtures and fittings on your roof such as airconditioning units, fans, aerials, satellite dishes, andsolar panels. Flues and chimneys need to be designedto allow fumes and smoke to dissipate. The roof nearthese will need to be washed regularly to removecontaminants.There are also dissimilar metal issues to be aware of16your ColorCote pre-painted roofing or claddingsystem. The fasteners should be matched to theexpected life of the roof.For ZR8 and ZM8 , class 4 coated screws arerecommended and give the best service life.Galvanised nails with ZR8 or ZM8 pre-paintedwashers can also be used.For ZMX and ZRX , class 4 coated screws arerecommended but galvanised nails are not to beused.Stainless steel or monel metal fasteners are not to beused on ZR8 , ZM8 , ZMX and ZRX systems.with fixtures and fittings on roofs. Television aerialsFor ARX or AR8 systems, 304 stainless steel orand copper waste pipes from gas water heaters arealuminium screws must be used. Holes should bejust two examples that need to be fully isolated fromdrilled oversize to allow for movement and profiledpre-painted metal roofing.metal washers used to isolate the different metals.

MaintenanceAll roofing and cladding products require regularThat’s why it’s important you get the correct pre-paintedmaintenance to keep them looking good, to prolong theirmetal roofing and cladding system for your houselife and to meet the terms of any product warranty.whether you’re living in the city, beside the sea or out inThe best way to reduce the amount of maintenancethe country.required is to pick the right product for the environment.The harsher the environment the more important it is thatThe extremes of temperature, harsh UV rays and salt-a regular maintenance schedule is followed – particularlyladen sea air all eventually take their toll on all Newregular washing down of roofs and cladding -- toZealand buildings.maximise service life and appearance.Basic Maintenance Needs: All roofing and cladding needs to be washed down If you are not comfortable doing it yourself get awith clean water and a soft-bristle brush or spongeprofessional in. It must be done on a regular basis toon a regular basis. For larger areas water blasting atmeet the terms of your warranty.pressures up to 20Mpa might be more appropriate. Clean and clear gutters and downpipes regularly too.How often depends on the pre-painted system andthe severity of the building environment. Give specialattention to unwashed areas and around penetrationsand fixtures and fittings. Pacific Coilcoatersrecommends roofing or cladding should be washeddown a minimum of every six months, or more often ifcontaminants build up. Take sensible safety precautions when climbing on aroof. Secure your ladder properly, use non-slip shoesand safety harnesses if necessary, and don’t go up on aroof in wet, windy or icy conditions. Make sure fasteners are also washed and inspected forsigns of corrosion. Replace them immmediately if theyare showing signs of failure or rust.17

Step by StepGuide forColorCote roofingandcladding11Check with your roofmanufacturer or PacificCoilcoaters that yourproject meets preapproved ColorCote warranty conditions.www.colorcote.co.nz1018Select a suitable builderand/or roofing andcladding fixer.Talk to your architect or designer aboutAre there any big spans, curves or bends?your ideas. Work with him or her toWill that impact on which ColorCote systemget the look you want. Ask any of theyou choose? What roofing or cladding profilequestions above or any others youris suitable for this design? Do you need toresearch has raised.check with you architect/designer or the roof9manufacturer?8

123Look at various homes in the areaDoes the design of the roofing orCan you design out anyyou’re looking to build. Comparecladding enhance the overall designsheltered or overhangingthe different styles of roofing orof the house? Will the design beareas or other featurescladding and try and visualise howeasy to build and maintain? Does itthat allow the buildthey might look on the type ofmatter?up of salts and otherhouse you have in mind.contaminants and whichmight affect the longterm performance of theroofing and cladding?How can you keeppenetrations and aerialsand other fixtures to aminimum?Colour: How doesthe roof colour workwith the overall housecolour scheme? Is it45an expression of yourpersonality? Will thecolour scheme jar withits environment? Doesit matter? Are there anylocal authority restrictionson the colours you canuse?Which way’s north? How much sun will the siteWhich ColorCote pre-painted metal system shouldget and which way should you orientate youryou use? Your environmental profile will tell you. Whatliving and outdoor activities? Do you need tois the natural environment like? What sort of climaticconsider the roof’s aspect to avoid wind/weatherconditions? How far from the ocean or harbour?issues?Prevailing winds? Harsh winters or summers? Any seismic7or geothermal activity nearby? Industrial sites or airports?619

Sustainabilityand RecyclingPacific Coilcoaters has an on-goingcommitment to sustainability and continuousproduct and process improvement. Recentdevelopments include water-based coatingsystems and nil-heavy metal paint systems.The company has developed processes tominimise water use with on-site cooling,recirculation and recycling processes.Fumes generated during the paint curingprocess are reused to fuel the paint curingovens, reducing the plant’s overall energycosts. Excess heat from the drying process is20also used to heat the factory in winter.All ColorCote products are coated withpaint systems which are lead and cadmiumfree and suitable for rainwater collectionsystems.All ColorCote pre-painted steel andaluminium products are fully recyclable. Anyscraps or old roofing material can be recycledin New Zealand.Pacific Coilcoaters recycles or reuses all itsmetal scrap.

Where to go for moreinformation, ideas or help?Pacific Coilcoaters recommends you always use a registered architect orreputable designer for your roofing and cladding designs.The following links may be helpful:New Zealand Institute of Architects (NZIA): www.nzia.co.nzArchitectural Designers New Zealand (ADNZ): www.adnz.orgAll metal roofing and cladding should be installed according tothe Metal Roofing Manufacturers’ Code of Practice.For more details see:Metal Roofing Manufacturers Inc: www.metalroofing.org.nzRoofing Association of NZ: www.roofingassn.org.nzFor overall building/construction information:Registered Master Builders’ Federation: www.masterbuilder.co.nzNew Zealand Certified Builders’ Association: www.certified.co.nz

968 Great South Road, PO Box 12 046, Penrose, Auckland.Telephone: 64 9 579 9199 Facsimile: 64 9 579 7515 Copyright PCC 2011www.colorcote.co.nzCOLORCOTE , ZR8 , ZRX , ZM8 , ZMX , AR8 and ARX are Registered Trade Marks of Fletcher Steel Ltd.Pacific Coilcoaters is a trading division of Fletcher Steel Limited a Fletcher Building Limited Business.

ColorCote pre-painted metal roofi ng and cladding systems provide design fl exibility unmatched by any other roofi ng or cladding material. ColorCote can be roll-formed or pressed into a range of profi les that look great and are warranted to last. It is easy to install and can be adapted to almost any design or construction concept.