Transcription

Data SheetE3 MODULEVEL Displacer Operated Level TransmitterRegistered AddressABLE Instruments & Controls LtdCutbush Park, Danehill, Lower Earley,Reading, Berkshire, RG6 4UT. UK.ReadingTel: 44 (0)118 9311188 Email: info@able.co.ukWebable.co.ukAberdeenTel: 44 (0)1224 725999 Email: ab@able.co.ukE-commerce247able.comRegistered in England No. 01851002. VAT No. GB 417 2481 61

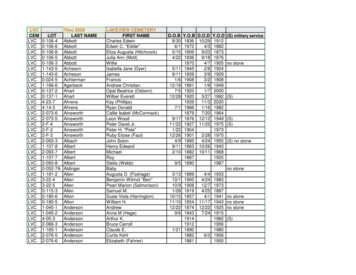

E3 Modulevel Displacer operatedlevel transmitterDESCRIPTIONE3 Modulevels are 2 wire, loop powered level transmittersutilising buoyancy principle to detect and convert liquid levelchanges into a stable output signal.The linkage between the level sensing element and outputelectronics greatly simplifies mechanical design and construction. The in-line vertical design of the transmitterreduces instrument weight and the effects of process vibration on electronic circuitry components while simplifyinginstallation.For continuous level, density or liquid-liquidinterface2014/68/EUF E AT U R E S Operation functions include: - interface measurement and detection- continuous level measurement- density measurement2 line x 8 characters LCD and 3 button keypad.Easy bench configuration. No need for level simulation.Two-wire, intrinsically safe loop powered level transmitter.360 rotatable housing can be dismantled withoutdepressurizing the vessel.Special options, materials and custom engineered features.Suited for SIL 2 / SIL 3 loops (full FMEDA report andcertificate available).A P P L I C AT I O N SMEDIA: liquids with a S.G. as low as 0,23 up to 2,2 and interfaces with a minimum density difference of 0,10 kg/dm3.VESSELS: most process vessels up to 450 C (850 F) process temperature and pressures up to 355 bar (5150 psi) orstorage vessels e.g:- feedwater heaters- condensate drip pots- scrubbers- separators- receivers- flash tanks- knock out drums- boilersA G E N C Y A P P R O VA L SAgencyApprovalATEX/IECII 1G Ex ia II C T4, intrinsically safeII 1/2G Ex d II C T6, flameproof enclosureFMintrinsically safeClass I Div.1, Groups A,B,C,DClass II Div.1, Groups E,F,GClass III, Type 4X T4, IP66FMexplosion proofLRSClass I Div.1, Groups B,C,DClass II Div.1, Groups E,F,GClass III, Type 4X T5, IP66Lloyds Register of Shipment(marine applications)Russian Authorisation Standards ¿¿ Consult factory for proper model numbers and classifications.

P R I N C I P L E O F O P E R AT I O NLevelLiquid level change acts upon the range spring supporteddisplacer causing vertical motion of a core within a linearvariable differential transformer (LVDT).The enclosing tube acts as a static isolation barrierbetween the LVDT and the process media.As core position changes with liquid level, voltages areinduced in the secondary windings of the LVDT.These signals are processed in the electronic circuitry andused to control the output signal.InterfaceE3 Modulevel is capable of tracking the interface level oftwo immiscible liquids with different densities. Each unit iscustom-made with a displacer specially designed for theuser’s application. This allows it to detect the position of aclean interface or an emulsion layer and convert it into astable output signal. Contact the factory for assistance inspecifying an E3 for interface service. Note that for properinterface detection, the entire displacer must always beimmersed in liquid.LVDTMoving LVDT CoreElectronics incl.digital display /3 button key padEnclosing tubeRange springSpring protection capDisplacerExternal cageDensityYet another capability of E3 Modulevel is to track thechanging density of a liquid over a known density rangeand convert that into a stable output signal. As the density of the liquid changes, so does the mass of the liquid displaced by the specially designed displacer. The resultingchange in buoyancy force on the displacer causes themovement of the LVDT core necessary to convert the density change to the output signal.P A C T w a r e P C romagnetic compatibilitySurge ProtectionM E C H A N I C A L S P E C I F I C AT I O N SDescriptionCage materialsWetted partsProcess ConnectionSpecificationcarbon steel or 316/316L (1.4401/1.4404) (other materials at request)Inconel (other materials at request)316/316L (1.4401/1.4404) or 316 (1.4401)Threaded: 1 1/2" NPT-F or 2" NPT-F or 1 1/2" Socket Weld or 2" Socket WeldFlanged: Various ASME or EN/DIN flangesFrom 356 mm (14") up to 3048 mm (120") - other lengths at requestSpringDisplacerDisplacer lengthsELECTRICAL WIRINGSafe areaHazardousareaI.S.0%100 %AMS FDT/PACTware 9

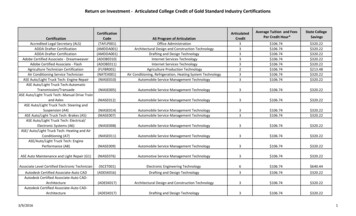

DIMENSIONS in mm (inches)Transmitter HeadIntegralRemote102 (4.02)cable entry105(4.12)83(3.28)102 (4.02)235 (9.25)cable entry22(0.87)262(10.32)72(2.81)27 (1.06)98(3.86)Ø 9,5 (0.37)100(3.95)159(6.28)103(4.04)70 89(3.50)70(2.75)Cable must be ordered separately(refer to section “Selection data / Options”).cable entrySide/bottom cageE33/E34 - J/K/LSide/side cageE35/E36 - J/K/L407 (16)407 (16)ALevelRangeAALevelRange 2 (0.08)LevelRange 2 (0.08)LevelRange 2 (0.08)133 (5.24)133 (5.24)C1" nPT-F drain(plug not supplied)BBTemperature extensions407 (16)A133 (5.24)IntegralBRemoteDigit 4Dim. DDigit 4Dim. DM, N, P610 (24)E701 (27.6)A, B, C10cable entry167 (6.57)Side/bottom cageE33/E34 - J/K/LD295(11.61)45 206(8.10)Top MountedE31/E32 - J/K/L407 (16)143(5.63)D, E, F508 (20)712 (28)ND600 (23.6)

DIMENSIONS in mm (inches)Dimension A for all modelsCage rating150 / 300 / 600 lbsPN 16 . PN 100900 / 1500 lbsPN 160 / PN 2502500 lbsPN 320150 / 300 / 600 lbsPN 16 . PN 100900 / 1500 lbsPN 160 / PN 2502500 lbsPN 320SG range0.23 - 0.540.55 - 1.091.10 - 2.200.55 - 1.090.55 - 1.094 th digit9 th digitJ/A/M/DK/B/N/EDimension A236 (9.29)186 (7.32)1/2/3L/C/P/FK/B/N/E186 (7.32)245 (9.65)1/2/3N/E320 (12.60)236 (9.29)8245 (9.65)320 (12.60)Dimensions B and C for external cage models (E33/E34/E35/E36)Flanged process connectionsFlange size1 1/2"Flange rating150 / 300 / 600 lbs600 lbs900 lbs1500 lbs2500 lbsSlip on - ASME RFWeldneck - ASME RJWeldneck - ASME RJWeldneck - ASME RJWeldneck - ASME RJPN 16 / PN 25 / PN 40PN 63 / PN 100PN 160PN 250PN 320EN 1092-1 Type B1EN 1092-1 Type B2EN 1092-1 Type B2EN 1092-1 Type B2EN 1092-1 Type B2150 / 300 / 600 lbs600 lbs900 lbs1500 lbs2500 lbs2"DN 40PN 16PN 25 / 40PN 63PN 100PN 160PN 250PN 320DN 50Threaded / Socket weld process connectionsSize1 1/2"2"Connection typeCage rating150 / 300 / 600 / 900 lbs1500 lbs2500 lbs150 / 300 / 600 / 900 lbs1500 lbs2500 lbsSlip on - ASME RFWeldneck - ASME RJWeldneck - ASME RJWeldneck - ASME RJWeldneck - ASME RJEN 1092-1 Type B1EN 1092-1 Type B1EN 1092-1 Type B2EN 1092-1 Type B2EN 1092-1 Type B2EN 1092-1 Type B2EN 1092-1 Type B2Connection sC180 (7.09)180 (7.09)195 (7.68)186 (7.32)229 (9.02)268 (10.55)268 (10.55)281 (11.06)281 (11.06)313 (12.32)180 (7.09)200 (7.87)200 (7.87)consult factoryconsult factory268 (10.55)288 (11.34)consult factoryconsult factoryconsult factory185 (7.28)185 (7.28)215 (8.46)212 (8.35)250 (9.84)185 (7.28)188 (7.40)202 (7.95)208 (8.19)215 (8.46)consult factoryconsult factoryB273 (10.75)273 (10.75)302 (11.89)302 (11.89)329 (12.95)273 (10.75)276 (10.87)293 (11.54)299 (11.77)consult factoryconsult factoryconsult factoryDimensions81 (3.19)89 (3.50)102 (4.02)84 (3.31)98 (3.86)111 (4.37)CNotApplicable11

QUALITY ASSURAnCE - ISO 9001THE QuALITY ASSuRANCE SYSTEM IN PLACE AT MAGNETROL GuARANTEES THE HIGHEST LEVEL OF QuALITY DuRING THE DESIGN,THE CONSTRuCTION AND THE SERVICE OF CONTROLS.OuR QuALITY ASSuRANCE SYSTEM IS APPROVED AND CERTIFIED TO ISO 9001 AND OuR TOTAL COMPANY IS COMMITTED TO PROVIDINGFuLL CuSTOMER SATISFACTION BOTH IN QuALITY PRODuCTS AND QuALITY SERVICE.PRODUCT WARRAnTYALL E3 MODuLEVEL LEVEL TRANSMITTERS ARE WARRANTED FREE OF DEFECTS IN MATERIALS AND WORKMANSHIP FOR18 MONTHS FROM THE DATE OF ORIGINAL FACTORY SHIPMENT.IF RETuRNED WITHIN THE WARRANTY PERIOD; AND, uPON FACTORY INSPECTION OF THE CONTROL, THE CAuSE OF THE CLAIM IS DETERMINED TO BE COVEREDuNDER THE WARRANTY; THEN, MAGNETROL INTERNATIONAL WILL REPAIR OR REPLACE THE CONTROL AT NO COST TO THE PuRCHASER (OR OWNER) OTHER THANTRANSPORTATION.MAGNETROL SHALL NOT BE LIABLE FOR MISAPPLICATION, LABOR CLAIMS, DIRECT OR CONSEQuENTIAL DAMAGE OR EXPENSE ARISING FROM THE INSTALLATIONOR uSE OF THE EQuIPMENT. THERE ARE NO OTHER WARRANTIES EXPRESSED OR IMPLIED, EXCEPT, SPECIAL WRITTEN WARRANTIES COVERING SOMEMAGNETROL PRODuCTS.uNDER RESERVE OF MODIFICATIONSEuropean Headquarters & Manufacturing FacilityHeikensstraat 69240 Zele, BelgiumTel: 32-(0)52-45.11.11 Fax: 32-(0)52-45.09.93e-mail: info@magnetrol.bewww.magnetrol.comBuLLETIN N :EFFECTIVE:SuPERSEDES:BE 48-135.4OCTOBER 2018April 2017

eb ableco.uk E-commerce 2able.com Aberdeen Tel 4 0)122 2599 Email ab@able.co.uk Readin Tel 4 0)11 31118 Email info@able.co.uk Reistered ddress ABLE nstruments ontrols Ltd