Transcription

OUTSULATION PLUS MD SYSTEM An Exterior Wall Insulation and Finish System With Moisture DrainageThat Incorporates Continuous Insulation and An Air/Water-ResistiveBarrierOutsulation Plus MD SystemInstallation DetailsDS110

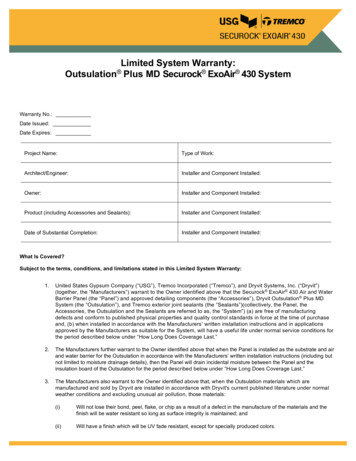

TABLE OF CONTENTSDETAILOUTSULATION PLUS MD SYSTEMAWRB APPLICATIONOPENING PREPARATIONAQUAFLASH SYSTEM OPTIONOPENING PREPARATIONBACKSTOP NT OPTIONOPENING FLASHING INTEGRATIONINSIDE/OUTSIDE CORNERSOUTSIDE CORNER - HIGH IMPACTGRADE TERMINATIONTERMNATION AT CONCRETE CURBTERMINATION AT ADA COMPLIANTSIDEWALKEPS PREPARATION ATWALL PENETRATIONSSTOREFRONT WINDOW SILL - JAMBSELF FLASHING WINDOW SILL - JAMBSTOREFRONT AND FLANGEDWINDOW HEADHEAD J-TRACK OPTIONTERMINATION ATWOOD FRAMED DECKTERMINATION ATWATERPROOF DECKPREPARATION AT PARAPET/WALL INTERSECTIONTERMINATION AT PARAPET CAP FLASHINGTERMINATION AT PARAPET SOLID SUBSTRATETERMINATION AT SLOPED ROOFTERMINATION AT ROOF STOPFLASHINGVERTICAL WALL/ SUSPENDEDSOFFIT TRANSITIONTRANSITION AT SOFFIT/FASCIA INTERSECTIONFASCIA/ UNINSULATED SOFFITTRANSITIONTERMINATION ATUNINSULATED SOFFIT VENTHORIZONTAL SLIP JOINTWITHOUT WEEPSHORIZONTAL SLIP JOINTWITH WEEPSHORIZONTAL JOINT SUBSTRATE CHANGEHORIZONTAL TERMINATIONAT STONE VENEERDETAILOPMD 0.0.01OPMD 0.0.02OPMD 0.0.03OPMD 0.0.04OPMD 0.0.05OPMD 0.0.06OPMD 0.0.07OPMD 0.0.08OPMD 0.0.09OPMD 0.0.10OPMD 0.0.11OPMD 0.0.12OPMD 0.0.13OPMD 0.0.14OPMD 0.0.15OPMD 0.0.16HORIZONTAL TERMINATIONAT STUCCOHORIZONTAL TERMINATIONAT WOOD SIDINGVERTICAL EXPANSION JOINT EIFSTHROUGH-WALL EXPANSION JOINTVERTICAL EXPANSION JOINT FLUSH OPTIONVERTICAL EXPANSION JOINT RECESSED OPTIONVERTICAL EXPANSION JOINT DOUBLE SEAL OPTIONVERTICAL TERMINATIONAT STONE VENEERPENETRATIONSSIGN ATTACHMENTAESTHETIC REVEALSRECESSED GRAPHICSPROJECTING GRAPHICSEPS SHAPESOPMD 0.0.32OPMD 0.0.33OPMD 0.0.34OPMD 0.0.35OPMD 0.0.36OPMD 0.0.37OPMD 0.0.38OPMD 0.0.39OPMD 0.0.40OPMD 0.0.41OPMD 0.0.42OPMD 0.0.43OPMD 0.0.44OPMD 0.0.17OPMD 0.0.18OPMD 0.0.19OPMD 0.0.20OPMD 0.0.21OPMD 0.0.22OPMD 0.0.23OPMD 0.0.24NOTEDRYVIT MAKES NO REPRESENTATION REGARDINGCONFORMITY OF ITS SUGGESTIONS TO MODEL BUILDINGCODES, ENGINEERING CRITERIA, SPECIFIC APPLICATIONS,OR PROJECT LOCATIONS. ALL COMPONENTS INDICATEDIN ILLUSTRATIONS, AS WELL AS OTHERS THAT MAY BEREQUIRED FOR THE INTEGRITY OF THE SYSTEM SHALL BEDESIGNED, DETAILED, AND ENGINEERED BYREPRESENTATIVES OF THE ARCHITECT, OWNER, ORCONTRACTOR TO BE IN CONFORMANCE WITH MODELCODES, ARCHITECTURAL, AND ENGINEERINGREQUIREMENTS PERTAINING TO SPECIFIC BUILDINGPROJECTS.OPMD 0.0.25OPMD 0.0.26OPMD 0.0.27OPMD 0.0.28OPMD 0.0.29DRYVIT MAKES NO WARRANTY, EXPRESSED OR IMPLIED,AS TO THE ARCHITECTURAL DESIGN, ENGINEERING, ORWORKMANSHIP OF PROJECTS UTILIZING DRYVIT SYSTEMSOR PRODUCTS.THE LIABILITIES OF DRYVIT SHALL BE AS STATED IN THEOUTSULATION PLUS MD LIMITED COMMERCIALWARRANTY. CONTACT DRYVIT FOR A FULL ANDCOMPLETE COPY OF THE WARRANTY.OPMD 0.0.30Outsulation Plus MD System Dryvit Systems, Inc. 1969Issued: 10/2016OPMD 0.0.31The architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.01FRAMING BY OTHERSBY OTHERSOUTSULATIONPLUS MD SYSTEMDRYVIT ADHESIVE IN VERTICAL NOTCHED TROWELCONFIGURATION APPLIED TO BACK OF EPSEPS INSULATION BOARDAPPROVED SUBSTRATENORMAL IMPACTDRYVIT AIR/WATER-RESISTIVE BARRIER COATINGDRYVIT BASE COATDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATDRYVIT BASE COATDRYVIT FINISHDRYVIT DRAINAGE STRIP ADHERED WITH DABSOF DRYVIT AP ADHESIVE (SEE NOTES 2 AND 3)FRAMING BY OTHERSDRYVIT ADHESIVE IN VERTICAL NOTCHEDTROWEL CONFIGURATION APPLIED TOBACK OF EPSEPS INSULATION BOARDAPPROVED SUBSTRATEHIGH IMPACTDRYVIT AIR/WATER - RESISTIVE BARRIER COATINGDRYVIT BASE COATDRYVIT PANZER REINFORCING MESHDRYVIT BASE COATDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATDRYVIT BASE COATDRYVIT FINISHDRYVIT DRAINAGE STRIP ADHERED WITH DABSOF DRYVIT AP ADHESIVE (SEE NOTES 2 AND 3)Outsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC, OR DELIBERATE IMPACT HAVETHE BASE COAT REINFORCED WITHPANZER MESH PRIOR TO STANDARD ORSTANDARD PLUS MESH. LOCATION OFHIGH IMPACT ZONES SHOULD BEINDICATED ON CONTRACT DRAWINGS. Dryvit Systems, Inc.Issued: 10/20162. AS AN OPTION DRYVIT DRAINAGETRACK CAN BE USED AT SYSTEMTERMINATION AT GRADE, REFER TOOPMD 0.0.08 FOR CONFIGURATION.3. DRYVIT DRAINAGE TRACK SHALL ONLYBE USED AT GRADE LEVEL TERMINATIONS.Outsulation Plus MD SystemThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.02FRAMING BY OTHERSAPPROVED SUBSTRATEDRYVIT BACKSTOP NT - TEXTUREDRYVIT BACKSTOP NT - TEXTUREOVER DRYVIT GRID TAPE DRYVIT AIR/WATER - RESISTIVEBARRIER COATINGOutsulation Plus MD System NOTE:1. FOR ADDITIONAL AIR/WATER-RESISTIVEBARRIER DETAILS, REFER TO DRYVITPUBLICATION DS840. Dryvit Systems, Inc.Issued: 10/2016AWRB ApplicationThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.03APPLY DRYVIT AQUAFLASH SYSTEM (SEE NOTES 1 AND 3)DRYVIT AIR/WATER-RESISTIVEBARRIER COATINGSTEP #1INSTALL DIAGONAL STRIP OF DRYVITAQUAFLASH MESH AT CORNERSAND EMBED IN AQUAFLASH LIQUID(SEE NOTES 1 AND 3)STEP #2INSTALL DRYVIT AQUAFLASHSYSTEM AT JAMBS(SEE NOTES 1 AND 3)INSTALL DRYVIT AQUAFLASHSYSTEM AT HEADS(SEE NOTES 1, 3 AND 4)STEP #3STEP #4Outsulation Plus MD System NOTE:1. DRYVIT AQUAFLASH SHALL EXTEND TOINTERIOR FACE OF OPENING.2. REFER TO HEAD, SILL AND JAMB DETAILSFOR FLASHING INTEGRATION.3. DRYVIT FLASHING TAPE SURFACECONDITIONER AND DRYVIT FLASHING TAPE MAY BE USED IN LIEU OF DRYVITAQUAFLASH SYSTEM. Dryvit Systems, Inc.Issued: 10/20164. INSTALL WINDOW UNIT AND ASSOCIATEDFLASHINGS PER MANUFACTURER'SRECOMMENDATIONS, CODE REQUIREMENTS ANDPROJECT DOCUMENTS.5. AQUAFLASH SYSTEM CONSISTS OF AQUAFLASHMESH AND AQUAFLASH LIQUID.6. FOR ADDITIONAL AIR/WATER-RESISTIVE BARRIERDETAILS, REFER TO DRYVIT PUBLICATION DS840.Opening Preparation AquaFlash System5 OptionThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.04APPLY DRYVIT GRID TAPE (SEE NOTES 1 AND 2)6" (153 MM) MIN.(TYP.)STEP #1STEP #2APPLY DRYVIT AQUAFLASH SYSTEM (SEE NOTES 2, 3 AND 5)DRYVIT AIR/WATER-RESISTIVEBARRIER COATING APPLIED TOFACE OF WALL (SEE NOTE 5)4" (102 MM) MIN.(TYP.)STEP #3STEP #4Outsulation Plus MD System NOTE:1. APPLY DRYVIT GRID TAPE ON HEAD, JAMB, ANDCORNERS OF OPENINGS AND SHEATHING JOINTS.2. TROWEL APPLY DRYVIT BACKSTOP NT-TEXTUREOVER THE DRYVIT GRID TAPE ALL THE WAY TO INSIDEFACE OF OPENING. ALL VOIDS MUST BE FILLED;MULTIPLE PASSES MAY BE REQUIRED. AS AN OPTION,DRYVIT GRID TAPE AND DRYVIT BACKSTOP NT-TEXTUREMAY ALSO BE APPLIED AT THE SILL PRIOR TO DRYVITAQUAFLASH SYSTEM OR FLASHING TAPE APPLICATION.3. DRYVIT FLASHING TAPE SURFACE CONDITIONER AND DRYVIT FLASHING TAPE MAY BE USED IN LIEU OFDRYVIT AQUAFLASH SYSTEM AT SILL, INCLUDINGCORNER SPLICES. Dryvit Systems, Inc.Issued: 10/2016TROWEL APPLY DRYVITBACKSTOP NT-TEXTURE(SEE NOTE 2)Opening Preparation Backstop NT OptionThe architecture, engineering, and design of the project using the4. INSTALL WINDOW UNIT AND ASSOCIATEDDryvit products is the responsibility of the project's designFLASHINGS PER MANUFACTURER'Sprofessional. All systems must comply with local building codes andRECOMMENDATIONS, CODE REQUIREMENTSstandards. This detail is for general information and guidance onlyAND PROJECT DOCUMENTS.and Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of any5. REFER TO HEAD, SILL, AND JAMB DETAILSproject. The project design professional determines, in its soleFOR FLASHING INTEGRATION.discretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail does6. FOR ADDITIONAL AIR/WATER-RESISTIVEnot violate Dryvit's warranty. This detail is subject to change withoutBARRIER DETAILS, REFER TO DRYVITnotice. Contact Dryvit to ensure you have the most recent version.PUBLICATION DS840.

OPMD 0.0.05REFER TO OPMD 0.0.03, AND OPMD 0.0.04FOR PREPARATION OF OPENING PRIORTO FLASHING INSTALLATIONSTEP #1REFER TO OPMD 0.0.12 &OPMD 0.0.13 FOR JAMBDETAILINSTALL WINDOW UNIT ANDASSOCIATED FLASHINGS ANDAPPLY DRYVIT AQUAFLASHSYSTEM OVER VERTICAL LEG OFFLASHING (SEE NOTES 1 AND 2)APPLY DRYVIT AQUAFLASH SYSTEM SPLICES LAPPING OVERLIP OF SILL PAN FLASHING.(SEE NOTES 1 AND 2)STEP #2Outsulation Plus MD System NOTE:1. REFER TO OPMD 0.0.12 AND OPMD 0.0.13FOR INTEGRATION OF FLASHING.2. DRYVIT FLASHING TAPE SURFACECONDITIONER AND DRYVIT FLASHINGTAPE MAY BE USED IN LIEU OF DRYVITAQUAFLASH SYSTEM.3. FOR ADDITIONAL AIR/WATER-RESISTIVEBARRIER DETAILS, REFER TO DRYVITPUBLICATION DS840. Dryvit Systems, Inc.Issued: 10/2016STEP #3Opening Flashing IntegrationThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.06APPROVED SUBSTRATEDRYVIT BACKSTOP NT -TEXTUREOVER DRYVIT GRID TAPE DRYVIT ADHESIVE IN VERTICAL NOTCHED TROWELCONFIGURATION APPLIED TO BACK OF EPSDRYVIT AIR/WATER-RESISTIVEBARRIER COATINGEPS INSULATIONDRYVIT BASE COATDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATDRYVIT BASE COATDRYVIT FINISHMUST OVERLAP8" (203 MM) MIN.(SEE NOTES 2, 3 AND 4)8"(203 MM)MIN.8"(203 MM)MIN.APPROVED SUBSTRATEMUST OVERLAP8" (203 MM) MIN.(SEE NOTE 3)DRYVIT AIR/WATER-RESISTIVEBARRIER COATINGDRYVIT BACKSTOP NT-TEXTUREOVER DRYVIT GRID TAPEDRYVIT ADHESIVE IN VERTICAL NOTCHED TROWELCONFIGURATION APPLIED TO BACK OF EPSDRYVIT BASE COATEPS INSULATIONDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATDRYVIT BASE COATDRYVIT FINISHOutsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC OR DELIBERATE IMPACT HAVE THEBASE COAT REINFORCED WITH PANZER MESH PRIOR TO STANDARD OR STANDARDPLUS MESH. LOCATION OF HIGH IMPACTZONES SHOULD BE INDICATED ONCONTRACT DRAWINGS.2. DOUBLE WRAP OUTSIDE CORNERS WITHREINFORCING MESH OR USE CORNER MESH.3. DO NOT LAP REINFORCING MESH WITHIN8" (203 MM) OF A CORNER. Dryvit Systems, Inc.Issued: 10/20164. OUTSIDE INSULATION BOARD EDGESSHALL BE OFFSET.Inside/Outside CornersThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.07APPROVED SUBSTRATEDRYVIT AIR/WATER-RESISTIVEBARRIER COATINGDRYVIT ADHESIVE IN VERTICALNOTCHED TROWELCONFIGURATION APPLIEDTO BACK OF EPSEPS INSULATIONDRYVITBACKSTOP NT -TEXTUREOVER DRYVIT GRID TAPE DRYVIT BASE COATDRYVIT PANZER 20REINFORCING MESH EMBEDDEDIN DRYVIT BASE COATDRYVIT CORNER MESH DRYVIT BASE COATDRYVIT STANDARDREINFORCING MESHOVERLAP 8" (203 MM) MIN.AT CORNERDRYVIT FINISH8"(203 MM)MIN.8"(203 MM)MIN.Outsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC OR DELIBERATE IMPACT HAVETHE BASE COAT REINFORCED WITHPANZER MESH PRIOR TO STANDARDOR STANDARD PLUS MESH. LOCATION OFHIGH IMPACT ZONES SHOULD BEINDICATED ON CONTRACT DRAWINGS.2. OUTSIDE INSULATION BOARD EDGESSHALL BE OFFSET. Dryvit Systems, Inc.Issued: 10/2016Outside Corner-High ImpactThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.08DRYVIT AIR/WATER-RESISTIVEBARRIER COATINGBY OTHERSDRYVIT ADHESIVE IN VERTICAL NOTCHEDTROWEL CONFIGURATION APPLIED TOBACK OF EPSOUTSULATION PLUSMD SYSTEMAPPROVED SUBSTRATEEPS INSULATION2'-0" (610 MM)MAX.(SEE NOTE 2)DRYVIT BASE COATDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATDRYVIT AQUAFLASH SYSTEM (SEE NOTE 4)DRYVIT DETAIL MESH WRAPPEDTO BACKSIDE OF EPS MIN. 2" (51 MM)8" (203 MM)MIN.DRYVIT DRAINAGE STRIP ADHEREDWITH DABS OF DRYVIT AP ADHESIVE(SEE NOTE 3)DRAINAGETRACK OPTIONSLOPE GRADE AWAYFROM FOUNDATION WALLDRYVIT BACKSTOP NT -TEXTUREOVER DRYVIT GRID TAPE 2'-0" (610 MM)MAX.(SEE NOTE 2)8" (203 MM)MIN.SEE NOTES 4,5 & 6)Outsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC, OR DELIBERATE IMPACT HAVETHE BASE COAT REINFORCED WITHPANZER MESH PRIOR TO STANDARD ORSTANDARD PLUS MESH. LOCATION OFHIGH IMPACT ZONES SHOULD BEINDICATED ON CONTRACT DRAWINGS.2. EXPANSION JOINT IS REQUIRED ALONGTOP OF FOUNDATION IF 2'-0" (610 MM)DIMENSION IS EXCEEDED. Dryvit Systems, Inc.Issued: 10/20163. ENSURE BOTTOM EDGE OF DRAINAGESTRIP IS LEFT FREE TO DRAIN.4. DRYVIT FLASHING TAPE SURFACECONDITIONER AND DRYVIT FLASHINGTAPE MAY BE USED IN LIEU OF DRYVITAQUAFLASH SYSTEM.5. DRAINAGE TRACK USAGE IS LIMITED TOTHE BASE OF THE SYSTEM AT FINISHEDGRADE LEVEL.6. LIGHTLY SAND SURFACE OF DRAINAGETRACK TO MAXIMIZE ADHESION.Grade TerminationThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.09DRYVIT AIR/WATER-RESISTIVEBARRIER COATINGDRYVIT ADHESIVE IN VERTICAL NOTCHEDTROWEL CONFIGURATION APPLIED TOBACK OF EPSBY OTHERSOUTSULATIONPLUS MD SYSTEMAPPROVED SUBSTRATEEPS INSULATIONDRYVIT BASE COATDRYVIT REINFORCINGMESH EMBEDDED INDRYVIT BASE COATDRYVIT FINISH2" (51 MM) MIN.DRAINAGETRACK OPTIONDRYVIT BACKSTOP NT TEXTURE OVER DRYVITGRID TAPE DRYVIT AQUAFLASH SYSTEMDRYVIT DRAINAGE STRIP ADHERED WITHDABS OF DRYVIT AP ADHESIVE (SEE NOTE 2)DRYVIT AQUAFLASH SYSTEM ORDRYVIT BACKSTOP NT-TEXTURE OVERGRID TAPE (SEE NOTES 3, 4 AND 5)DRYVIT DRAINAGE TRACKSET IN DRYVIT AP ADHESIVEDRYVIT DETAIL MESH WRAPPEDTO BACKSIDE OF EPS MIN. 2" (51 MM)Outsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUND FLOORAPPLICATIONS AND ALL FACADES EXPOSED TOABNORMAL STRESS, HIGH TRAFFIC, ORDELIBERATE IMPACT HAVE THE BASE COATREINFORCED WITH PANZER MESH PRIOR TOSTANDARD OR STANDARD PLUS MESH. LOCATIONOF HIGH IMPACT ZONES SHOULD BE INDICATED ONCONTRACT DRAWINGS.2. ENSURE BOTTOM EDGE OF DRAINAGE STRIP ISLEFT FREE TO DRAIN. Dryvit Systems, Inc.Issued: 10/20163. LIGHTLY SAND SURFACE OF DRAINAGETRACK TO MAXIMIZE ADHESION.4. DRYVIT FLASHING TAPE SURFACECONDITIONER AND DRYVIT FLASHINGTAPE MAY BE USED IN LIEU OF DRYVITAQUAFLASH SYSTEM.5. DRYVIT DRAINAGE TRACK SHALL ONLY BEUSED AT GRADE LEVEL TERMINATIONS.Termination At Concrete CurbThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.10BY OTHERSOUTSULATION PLUSMD SYSTEMAPPROVED SUBSTRATEDRYVIT ADHESIVE APPLIED INVERTICAL NOTCHED TROWELCONFIGURATION TO BACK OF EPSEPS INSULATIONDRYVIT AIR/WATER-RESISTIVEBARRIER COATINGDRYVIT BASE COATDRYVIT STANDARD REINFORCINGMESH EMBEDDED IN DRYVIT BASECOATDRYVIT BASE COATDRYVIT FINISHDRYVIT DETAIL MESH WRAPPED TOBACKSIDE OF EPS MIN. 2" (51 MM)2" (51 MM) MAX.OVERLAP3/4" (19 MM) MIN. (SEE NOTE 4)ADA COMPLIANT SIDEWALK SLOPEDAWAY FOR POSITIVE DRAINAGEMETAL PROTECTION SHEET,BY OTHERSFULLY ADHERED FOUNDATIONWATERPROOFING MEMBRANE,BY OTHERSDRYVIT DRAINAGE STRIP ADHERED WITHDABS OF DRYVIT AP ADHESIVEDRYVIT AQUAFLASH SYSTEMCOMPRESSIBLE FILLER BOARD,BY OTHERSOutsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUND FLOORAPPLICATIONS AND ALL FACADES EXPOSED TOABNORMAL STRESS, HIGH TRAFFIC, ORDELIBERATE IMPACT HAVE THE BASE COATREINFORCED WITH PANZER MESH PRIOR TOSTANDARD OR STANDARD PLUS MESH.LOCATION OF HIGH IMPACT ZONES SHOULD BEINDICATED ON CONTRACT DRAWINGS.2. USE OF THIS DETAIL IS LIMITED TOSLAB-ON-GRADE APPLICATIONS.3. INCORPORATE MEASURES TO PROTECTSTRUCTURE FROM MOISTURE INTRUSION,DAMPNESS, AND FROST HEAVE. Dryvit Systems, Inc.Issued: 10/20164. TO PREVENT DEBRIS ACCUMULATION, IT ISRECOMMENDED TO TERMINATE SYSTEM 2"ABOVE SIDEWALK.Termination At ADA Compliant SidewalkThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.11EPS INSULATION(SEE NOTE 2)DRYVIT DETAIL MESH WRAPPEDTO BACKSIDE OF EPS MIN. 2" (51 MM)DRYVIT DETAIL REINFORCING MESH9 1/2" (241 MM) X 12" (305 MM) (TYP.)(SEE NOTE 3)Outsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC, OR DELIBERATE IMPACT HAVETHE BASE COAT REINFORCED WITHPANZER MESH PRIOR TO STANDARDOR STANDARD PLUS MESH. LOCATION OFHIGH IMPACT ZONES SHOULD BEINDICATED ON CONTRACT DRAWINGS.2. LOCATE INSULATION BOARDS SUCHTHAT BOARD EDGES DO NOT ALIGN WITHCORNERS OF PENETRATION. Dryvit Systems, Inc.Issued: 10/20163. APPLY A PIECE OF 9 1/2" (241 MM) X 12"(305 MM) DETAIL REINFORCING MESHDIAGONALLY AT EACH CORNER.EPS Preparation At Wall PenetrationsThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.12DRYVIT AQUAFLASH SYSTEM(SEE NOTE 2 AND 3)3/4" MIN.(19 MM )WRAP DRYVIT DETAIL MESH 2" (51 MM) MIN. AT BACKSIDE OF EPS(SEE NOTE 4)DRYVIT BASE COATFRAMING BY OTHERSDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATAIR SEAL PER MANUFACTURER'SREQUIREMENTS, BY OTHERSDRYVIT COMPATIBLESEALANT, BY OTHERSSLOPED SHIM ASREQUIRED, BY OTHERSDRYVIT FINISHWRAP DRYVIT DETAILMESH 2" (51 MM) MIN.AT BACKSIDE OF EPS(SEE NOTE 4)CONTINUOUS FLASHING, BYOTHERS, TURN UP 1/2" (12.7 MM) MIN.AT JAMBS - SEE DETAIL BELOWDRYVIT COMPATIBLESEALANT, BY OTHERSDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATDRYVIT AQUAFLASH SYSTEM (SEE NOTE 2)DRYVIT ADHESIVE IN VERTICALNOTCHED TROWEL CONFIGURATIONAPPLIED TO BACK OF EPSEPS INSULATION BOARDEPS SHAPE (OPTIONAL)2 1/2"(64 MM) MIN.DRYVIT BASE COATAPPROVED SUBSTRATEDRYVITAIR/WATER-RESISTIVEBARRIER COATING1/2" (12.7 MM)SILL PAN FLASHINGDETAILOutsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC, OR DELIBERATE IMPACT HAVE THEBASE COAT REINFORCED WITH PANZER MESH PRIOR TO STANDARD OR STANDARDPLUS MESH. LOCATION OF HIGH IMPACTZONES SHOULD BE INDICATED ONCONTRACT DRAWINGS.2. DRYVIT FLASHING TAPE SURFACECONDITIONER AND DRYVIT FLASHINGTAPE MAY BE USED IN LIEU OF DRYVITAQUAFLASH SYSTEM. Dryvit Systems, Inc.Issued: 10/20163. DRYVIT BACKSTOP NT-TEXTURE OVERGRID TAPE IS AN ALTERNATIVE OPTIONAT JAMB AND HEAD CONDITION PERDETAIL OPMD 0.0.04.4. EDGE WRAPPING METHOD ISACCEPTABLE AT SILL AND JAMB IN LIEUOF BACK WRAPPING. DRYVITREINFORCING MESH MUST BE FULLYEMBEDDED IN DRYVIT BASE COAT AT EPSEDGE AND MUST EXTEND ONTOSUBSTRATE 2" (51 MM) MIN.Storefront Window Sill - JambThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.133/4" (19 MM ) MIN.APPROVED SUBSTRATEDRYVIT AIR/WATER-RESISTIVEBARRIER COATINGFRAMING BY OTHERSDRYVIT ADHESIVE IN VERTICALNOTCHED TROWEL CONFIGURATIONAPPLIED TO BACK OF EPSDRYVIT DETAIL MESH WRAPPED TOBACKSIDE OF EPS MIN. 2" (51 MM)DRYVIT AQUAFLASH SYSTEM(SEE NOTES 2 AND 3)EPS INSULATIONDRYVIT BASE COATPROVIDE AIR SEAL, BY OTHERS,AROUND INTERIOR OF WINDOWPER WINDOW MANUFACTURER'SREQUIREMENTSDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COATDRYVIT FINISHDRYVIT COMPATIBLE SEALANT,BY OTHERSSILL PAN FLASHING,BY OTHERSDRYVIT DEMANDIT OR COLOR PRIME ON SURFACE(S) TO RECEIVE SEALANTEPS SHAPE (OPTIONAL)3/4"(19 MM) MIN.TRANSITION FLASHING,BY OTHERSDRYVIT DETAIL MESHWRAPPED TO BACKSIDEOF EPS MIN. 2" (51 MM)DRYVIT ADHESIVE IN VERTICALNOTCHED TROWELCONFIGURATIONDRYVIT AQUAFLASHSYSTEM (SEE NOTE 2)DRYVIT COMPATIBLESEALANT, BY OTHERSOutsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC, OR DELIBERATE IMPACT HAVE THEBASE COAT REINFORCED WITH PANZER MESH PRIOR TO STANDARD OR STANDARDPLUS MESH. LOCATION OF HIGH IMPACTZONES SHOULD BE INDICATED ONCONTRACT DRAWINGS.2. DRYVIT FLASHING TAPE SURFACECONDITIONER AND DRYVIT FLASHINGTAPE MAY BE USED IN LIEU OF DRYVITAQUAFLASH SYSTEM. Dryvit Systems, Inc.Issued: 10/20163. DRYVIT BACKSTOP NT -TEXTURE OVERDRYVIT GRID TAPE IS AN ALTERNATIVEOPTION AT JAMB AND HEAD CONDITION PERDETAIL OPMD 0.0.04.4. ADHESIVE ONLY APPLICATION IS ACCEPTABLEWHEN USING DRYVIT AQUAFLASH SYSTEM.5. EDGE WRAPPING METHOD IS ACCEPTABLE INLIEU OF BACK WRAPPING. DRYVIT REINFORCINGMESH MUST BE FULLY EMBEDDED IN DRYVITBASE COAT AT EPS EDGE AND EXTEND ONTOSUBSTRATE 2" (51 MM) MIN.Self Flashing Window Sill - JambThe architecture, engineering, and design of the project using theDryvit products is the responsibility of the project's designprofessional. All systems must comply with local building codes andstandards. This detail is for general information and guidance onlyand Dryvit specifically disclaims any liability for the use of this detailand for the architecture, design, engineering or workmanship of anyproject. The project design professional determines, in its solediscretion, whether this detail or a functionally equivalent detail isbest suited for the project. Use of a functionally equivalent detail doesnot violate Dryvit's warranty. This detail is subject to change withoutnotice. Contact Dryvit to ensure you have the most recent version.

OPMD 0.0.14BY OTHERSAPPROVED SUBSTRATEOUTSULATIONPLUS MD SYSTEMDRYVIT AIR/WATER-RESISTIVEBARRIER COATINGDRYVIT ADHESIVE IN VERTICALNOTCHED TROWEL CONFIGURATIONAPPLIED TO BACK OF EPSEPS INSULATION BOARDDRYVIT BASE COATDRYVIT AQUAFLASH SYSTEMOVER CONTINUOUS FLASHINGWITH END DAMSDRYVIT REINFORCING MESHEMBEDDED IN DRYVIT BASE COAT(SEE NOTE 1)DRYVIT AQUAFLASH SYSTEMOR DRYVIT BACKSTOP NT TEXTURE OVER DRYVIT GRIDTAPE (SEE NOTE 2)EPS SHAPE (OPTIONAL)DRYVIT FINISHDRYVIT DRAINAGE STRIP ADHEREDWITH DABS OF DRYVIT AP ADHESIVEAIR SEAL PERMANUFACTURER'SREQUIREMENTS,BY OTHERSDRYVIT DETAIL MESH WRAPPEDTO BACKSIDE OF EPS MIN. 2" (51 MM)DRYVIT DEMANDIT OR COLOR PRIME ON SURFACE(S) TO RECEIVE SEALANT3/4" (19 MM)DRYVIT COMPATIBLE SEALANTWITH CLOSED CELL BACKERROD AND WEEP TUBES EVERY24" (610 MM). BY OTHERSSEALANT AND FLASHING,BY OTHERSWINDOWINTEGRALFLASHINGSTOREFRONT WINDOWFLANGED WINDOWOutsulation Plus MD System NOTE:1. DRYVIT RECOMMENDS THAT GROUNDFLOOR APPLICATIONS AND ALL FACADESEXPOSED TO ABNORMAL STRESS, HIGHTRAFFIC, OR DELIBERATE IMPACT HAVETHE BASE COAT REINFORCED WITHPANZER MESH PRIOR TO STANDARD ORSTANDARD PLUS MESH. LOCATION OFHIGH IMPACT ZONES SHOULD BEINDICATED ON CONTRACT DRAWINGS. Dryvit Systems, Inc.Issued: 10/20162. DRYVIT FLASHING TAPE SURFACECONDITIONER AND DRYVIT FLASHINGTAPE MAY BE USED IN LIEU OFDRYVIT AQUAFLASH SYSTEM.Storefront and Flanged Window HeadThe architecture, engineering, and design of the pro

to flashing installation step #2 step #3 refer to opmd 0.0.12 & opmd 0.0.13 for jamb detail note: 1. refer to opmd 0.0.12 and opmd 0.0.13 for integration of flashing. 2. dryvit flashing tape surface conditioner and dryvit flashing tape may be used in lieu of dryvit aquaflash system. 3. for additional air/water-resistive barrier details .