Transcription

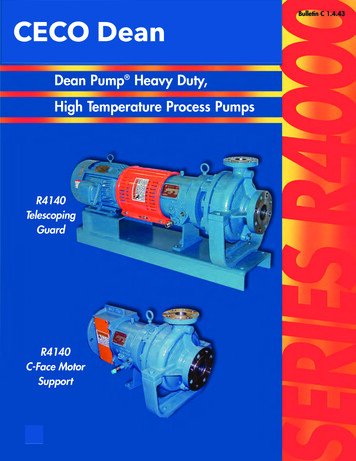

Bulletin C 1.4.43Dean Pump Heavy Duty,High Temperature Process PumpsR4140TelescopingGuardR4140C-Face MotorSupport

Dean Pump Series R4000Centrifugal Process Pumps Capacities to 5000 GPM (1135 m3/hr) Heads to 800 feet (245 m) Pumping temperatures to 850 F (454 C) Working pressures to 500 PSIG (3445 kPa)ExperienceDean Pump is recognized as the industry leader in the design and manufactureof horizontal hot oil/hot water centrifugal process pumps used extensively in thefollowing industries: chemical and petrochemical plants, power plants, plastics, heattransfer OEMs, commercial (hospitals, universities, laboratories), government facilities,pharmaceutical, and food processing.Dean Series R centrifugal process pumps are designed to insure long, continuousservice life at low cost. Each phase in the production of these pumps is meticulouslymonitored by an independent quality control department.Pump SizesThe Dean Series R pump is an end-suction, center line supported, back pull out designregularly available in 27 sizes and divided into four size classifications: the R4140 Series in 17 sizes the R4170 Series in 3 sizes the R4180 Series in 5 sizes the R4240 Series in 2 sizesMaterialsStandard materials of construction include carbon steel and 316SS. (StandardMaterials of Construction chart is available on Page 3).Parts InterchangeabilityThe Series R provides the ultimate in standardization. With wide parts interchangeability among pump sizes, fewer parts are required for inventory. A complete stock ofspare parts is readily available from Dean Pump or its network of stocking distributors,thereby reducing shipping time to a minimum.Shaft SealingDean Pump offers a broad line of mechanical seals and standard packing sets to solvethe most difficult sealing problems. Jacketed standard bore (stuffing box), and largetaper bore, seal chambers are available for specific applications.2

DEAN PUMP R4000 CENTRIFUGAL PROCESS PUMPSMECHANICAL DESIGN 25012575–3002007309BG630941 oz7311BG631136 oz7312BG631264 oz7317BG6316120 oz3"31/2"31 /4"3"37/8"12 /8"41/2"41/4"21/4"47/8"5"3"3"21/2"31 /4"5/8"11/2"3/8"63G373"27/8"12 IALCLASSMAXIMUMWORKING PRESSUREPUMPING TEMPERATUREMINIMUMMAXIMUMHYDROSTATIC TEST PRESSURER4140/R4170 R4180/R424040†500 psig @ 650 F-20 F800 F @ 350 psig50500 psig @ 100 F-20 F850 F @ 305 psig850psig750psigCONSTRUCTIONOFPart rbon Steel316SS(Cl. 40)(Cl. 50)C.I. (1)316 (3)Steel (2)316 (8)Steel (6)316 (3)Steel (2)316 (8)Steel (5)Steel (4)Iron (7)316 (3)Iron (7)316 (3)D.I. (16)Steel & GlassSteel (2)C.I. (1)316 (8)304 (9)Steel (2)316 (8)Steel (2)316 (8)316 (8)304 (9)316 (8)316 (8)Steel (6)316 (3)Steel (4)304 (9)Steel (5)304 (9)C.I. (1)316 (3)Steel (6)316 (3)Steel (2)——C.I. (1)C.I. (1)C.I. (1)Steel (2)Steel (10)316 (8)Steel (2)Steel (2)C.I. (1)316 (8)C.I. (1)Steel (2)SteelBronze & Viton †Bronze & Viton †Grafoil (11)Buna (14)—C.I. (1)Steel (2)316 (3)Steel (2)316 (3)——SS Tubing with Steel FinsImpellerImpeller KeyCasingCasing Drain PlugCasing Stud NutCasing StudCasing Back Cover RingCasing RingCradle SpacerBull’s Eye Oil Level IndicatorSpacer to Bearing Housing CapscrewBearing Housing FootShaft SleeveShaft Sleeve KeyImpeller Bolt (Nut on R4170)Impeller WasherImpeller Lock WasherImpeller Washer PinSeal Chamber GlandPacking GlandGland StudGland NutLantern RingCasing Back CoverBack Cover to Cradle Cap ScrewRadial BearingThrust BearingBearing HousingSeal RingBearing End CoverBearing End Cover Cap ScrewPump ShaftThrust Bearing Lock NutThrust Bearing Lock WasherThroat BushingCasing FootCasing Foot DowelRetaining Ring (All Except R4240)Labyrinth Seal—FrontLabyrinth Seal—RearCasing GasketEnd Cover GasketBearing Housing VentMotor Support (C Face)Impeller Ring—Back (Optional)Impeller Ring—Front (Optional)Mechanical Seal StationaryMechanical Seal RotaryOil ERIAL SPECIFICATIONS (REFER TO NUMBERS IN PARENTHESES)† Carbon Steel with Cast Iron trim. Also available with 316SS trim.WARNING: Use the “Allowable Working Pressure VS. Pumping Temperature” chart (below,right) to determine the allowable working pressure at any allowable pumpage temperature forthe material of construction selected.Seal Chamber Temperature VS. Pumping Temperature(1)(2)(3)(4)(5)(6)(7)(8)Cast IronAISI 1020316SS — ASTM #A744 Grade CF8MAISI 4140, ASTM #A193-B7 SteelASTM #A194 Grade 2 SteelASTM #A216 Grade WCB Cast Steel ( -20 800 F )Hardened I—304SSAlloy Steel —125,000 TS. 100,000 YPGrafoil — Registered trademark of Union Carbide Corp.Manila PaperFibre Sheet — Non-Asbestos FibreBuna N RubberSteel Finned, Stainless Steel Tube with Steel End FittingsDuctile Iron — ASTM-A536 Class 65-45-12with respect to the GPM of cooling water flowing throughthe cooling jacket surrounding the seal chamber.SEAL CHAMBER PRESSURE - R4000 SERIES PUMPS**With Impeller Balance Holes—Seal Chamber Pressure Equals Pump Suction Pressure Plus .06 x Pump Developed Pressure in PSIWithout Impeller Balance Holes—Seal Chamber Pressure Equals Pump Suction Pressure Plus .75 x Pump Developed Pressure in PSIPumps are normally furnished with balance holesPUMPING TEMPERATURE – 02008000-100PUMPING TEMPERATURE – F350050010030010040005020050Carbon Steel (Class 600Pumping Temperature - Fo*GPM Flow Rate of Cooling Water Based on 70 F (21 C) Inlet TempSpecifications are subject to change without notice3700200080015001000500900Working Pressure - KPaRATR4000 Series Pumps – Allowable Working Pressure VS Pumping TemperaturePumping Temperature - C316SS Max. Temp.R FLATEGW140Carbon Steel Max. Temp.OW250E C160Minimum Temperature Limit - 20 Deg. F.SEAL CHAMBER TEMPERATURE F30048111519Working Pressure - P.S.I.G.1/minSEAL CHAMBER TEMPERATURE C350† Registered Trademark of the E.I. DuPont Co.Horsepower Rating — Maximum@ 3500 rpm@ 1750 rpm@ 1160 rpmBearings, Type Ball Bearings, Oil LubricatedThrust Bearing (Angular Contact Pair)Radial BearingApproximate Oil Capacity of Bearing HousingSeal Chamber Dimensions (Large Taper Bore)Length (Depth)Inside Diameter (Bore Diameter)Shaft Sleeve DiameterStandard Bore (Stuffing Box) DimensionsLength (Depth)Inside Diameter (Bore Diameter)Shaft Sleeve DiameterLantern Gland WidthLantern Gland to Open End of Stuffing BoxPacking Size, SquareNumber of Rings with Lantern RingSpacingNumber of Rings Lantern OmittedPump Shaft DimensionsSpan Between Bearings CL to CLSpan Between Radial Bearing CL and Impeller CLDiameter at CouplingDiameter Between BearingsDiameter at ImpellerL3/D4SleevedSolidSTANDARD MATERIALSPart No.* Denotes parts interchangeable in all pump sizes of same type.Direction of Rotation (Viewed from Coupling End) . . . . . . . . . . . . . . . . . . . . . .CCWCasing Thickness, Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5/16"Corrosion Allowance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/8"Impeller — Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Single Plane BalancedOptional Extra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dynamically BalancedFlanges — ANSI Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class 300Facing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Standard Raised FaceOptional Extra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ring Type JointFinish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125 RaSeal Chamber & Bearing Housing Jacket Pressure, Maximum . . . . . . . . . . .125 psigSuction Pressure, Maximum . . . .Max. Working Pressure Less Pump Developed Head

1. CASING COVERJacketed standard bore or large taper bore. Designedto provide the best environment for the specificapplication and service conditions.2. INTEGRAL ONE-PIECE CASING FLANGESFlanges dimensioned according to ASME/ANSI B16.5Class 300. Raised face flanges are standard. Ring typejoint flanges (Class 300) are available as an option.3. SEALING FLEXIBILITYChoice of packed box or mechanical seal. Wide rangeof sealing arrangements (inside/outside, single/double,balanced/unbalanced, etc.) available to meet specificapplication and service conditions.244. CLOSED IMPELLERAllows thermal expansion of the pump shaft at highpumping temperatures without interference of the impellerwith the casing or the casing cover. Keyed to shaft withpositive locking device. Replaceable wear rings optional.5. SHAFT SLEEVEReplaceable “hook type” shaft sleeves provided asstandard. Allows replacement of the wearing surfacewithout having to replace the pump shaft or the bearings.The design allows the shaft sleeve to expand thermally,independent of the pump shaft. The standard sleevematerial is 316SS. Sleeves of alloy construction,hard-facing, hardened chrome 11-13%, or ceramiccoatings are available as options. Solid sleeveless shaftsare also available.6. CENTERLINE CASING SUPPORTThe pump is supported at the horizontal centerline of thecasing so that the thermal expansion of the casing will notaffect the shaft alignment.7. CASING FEETThree different foot designs are available. The standard isa “yoke” design, available on R4140/4170 only, whichallows the pump to fit on an ASME/ANSI B73.1baseplate (as well as Dean’s “Economy” baseplates).6The second “pedestal” design allows for mounting onAPI-type baseplates.The last design is a “water-cooled” pedestal design(as shown) used specifically for severe service conditionsand applications.88. COOLING PIPINGOptional tubing (as shown) connects the “watercooled” pedestal design with the casing cover jacket.Also available is optional tubing that connects thecasing cover jacket with the finned tube oil cooler,and/or tubing that connects the cooled pedestal feetwith the casing cover jacket.4

9. HEAVY DUTY SHAFT AND BEARINGSCarbon steel pump shaft (316SS optional) isdesigned for a maximum deflection of less than0.002” (0.05mm) at the mechanical seal faces. Theduplex mounted angular contact thrust bearings andthe single row, deep groove, radial bearing are sizedfor a 2 year minimum life and a 10 year averagelife.1013810. STANDARD LABYRINTH SEALSRugged bronze construction with Viton O-rings.Magnetic face seals are also an option for all pumps.11. LUBRICATION OPTIONSOil bath lubrication is standard. The extra large oilreservoir is designed for cooler bearing operation.The bearing housing is set up to accommodate oilmist lubrication and grease lubrication as available options. The finned tube oil cooler is providedas standard, to directly cool the oil for lowerbearing temperature.91412. FILL PLUGEasy access to fill plugs supplied on both sides ofthe bearing housing. Designed to minimize thepossibility of overfilling.13. ONE INCH OIL SIGHT GLASSAllows for simple and easy monitoring of oil leveland condition. The sight glass can be installed oneither side of the bearing housing, in the field, forbest location and ease of viewing. A combinationautomatic (bottle) oiler/sight glass is an availableoption.1514. BREATHER VENTA filtered bearing housing breather is standard. Anoptional expansion chamber is available that is usedwith the optional magnetic oil seals when a sealedbearing housing is desired.12131115. PILOT AND BOLT HOLESThe bearing housing of the R4140 is supplied with apilot fit and four bolt holes at the motor end. Theholes allow for mounting of the telescoping couplingguard. The pilot fit also allows for use of an optional“C-Face” motor support. The support permits selfaligning of the motor shaft to the pump shaft.575

6Fully confined compressiongasket (spiral wound, controlled compression gasketis an available option)Class 300, raisedface flangesPositive impellerlocking deviceOptional impellerwear ring shown(Casing wear ringsare standard)Double volute casingson larger sizesHighly efficient seal chambercooling jacket concentratedaround the mechanical seal“Hook-type”shaft sleeveHydraulically balancedenclosed impeller, keyedto shaftBearing frame finnedtube oil coolerDuplex mounted angularcontact thrust bearingsLabyrinth seals standard.Magnetic seals optionalfor all pump sizes.Top mounted, filteredbreather ventJACKETED STANDARD BORE (STUFFING BOX) SEAL CHAMBERCenterline mounted(water cooled pedestalsare optional)End-suction, topcenterline dischargeDEAN PUMP R4000 WITH SEAL CHAMBER COOLING AND BEARING FRAME COOLING

7Fully confined compressiongasket (spiral wound, controlled compression gasketis an available option)Class 300, raisedface flangesPositive impellerlocking deviceOptional impellerwear ring shown(Casing wear ringsare standard)Double volute casingson larger sizesCenterline mounted(water cooled pedestalsare optional)Self-venting large taper boreseal chamber“Hook-type”shaft sleeveHydraulically balancedenclosed impeller, keyedto shaftLARGE TAPER BORE SEAL CHAMBEREnd-suction, topcenterline dischargeBearing frame finnedtube oil coolerDuplex mounted angularcontact thrust bearingsLabyrinth seals standard.Magnetic seals optionalfor all pump sizes.Top mounted, filteredbreather ventDEAN PUMP R4000 WITH LARGE TAPER BORE SEAL CHAMBER

8Fully confined compressiongasket (spiral wound, controlled compression gasketis an available option)Class 300, raisedface flangesPositive impellerlocking deviceOptional impellerwear ring shown(Casing wear ringsare standard)Double volute casingson larger sizesCenterline mounted(water cooled pedestalsare optional)“C-FACE” MOTOR SUPPORTDuplex mounted angularcontact thrust bearingsLabyrinth seals standard.Magnetic seals optionalfor all pump sizes.Bearing frame finnedtube oil coolerTop mounted, filteredbreather vent“Hook-type”shaft sleeveHydraulically balancedenclosed impeller, keyedto shaftHighly efficient seal chambercooling jacket concentratedaround the mechanical seal.Large taper bore also available.End-suction, topcenterline dischargeOptional “C-Face” motorsupport, provides selfaligning of the motor shaftto the pump shaft.DEAN PUMP R4140 WITH SEAL CHAMBER COOLING AND “C-FACE” FLANGED MOTOR SUPPORT

DEAN PUMP PARTS INTERCHANGEABILITY OF 27 PUMP SIZESR4140Pump SizeR4170Casing ImpellerCasing Adaptor Bearing HousingCover CradleAssemblyPump SizeCasing ImpellerCasing AdaptorCover CradleBearing HousingAssemblyCasing ImpellerCasing AdaptorCover CradleBearing HousingAssemblyCasing ImpellerCasing AdaptorCover CradleBearing x3x8.53x4x13.53x4x8.5R4180Pump 5.54x6x103x4x15.51x2x11.51.5x3x11.5BearingHousing Foot4x6x15.52x3x11.5R4240Pump x13.5Casing covers with jackets and large taper bore sealcavities are available on all pumps. Bearing housings withfinned tube oil coolers are standard on all pumps.3x4x13.59

HEAD CAPACITY RANGE CHARTSTwo Pole MotorCapacity Cubic Meters Per Hour 2900 RPM - 50 Hertz255075100125150175200225250275800Total Head Feet 3500 RPM - 60 Hertz70011/2 X 3 X 131/21406002 X 3 X 131/21201X 2 X 111/250011/2 X 3 X 111/21003 X 4 X 131/240011/2 X 3 X 10 2 X 3 X 10803 X 4 X 103004 X 6 X 10 #1 (R4180)2 X 3 X 81/2604 X 6 X 81/2200 1 X 3 X 81/2403 X 4 X 81/211/2 X 3 X 81/21000Total Head Meters 2900 RPM - 50 Hertz1602001002003004005006007008009001000 1100 1200 1300 1400Capacity U.S. Gallons Per Minute 3500 RPM - 60 HertzFour Pole MotorCapacity Cubic Meters Per Hour 1450 RPM - 50 Hertz468 1020406080 100200400600 8002605524050Total Head Feet 1750 RPM - 60 Hertz453 X 4 X 151/22006 X 8 X 151/24 X 6 X 151/21808 X 10 X 151/211/2 X 3 X 131/216040353 X 4 X 131/22 X 3 X 131/2301406 X 8 X 121/21X 2 X 111/212011/2 X 3 X 111/22 X 3 X 111/2253 X 4 X 111/2 4 X 6 X 111/210011/2 X 3 X 1080202 X 3 X 103 X 4 X 104 X 6 X 10#1 (R4180) 4 X 6 X 10#2 (R4140)601X 3 X 81/22 X 3 X 81/211/2 X 3 X 81/240153 X 4 X 81/2104 X 6 X 81/25200101001000Capacity U.S. Gallons Per Minute 1750 RPM - 60 Hertz106000Total Head Meters 1450 RPM - 50 Hertz2 X 4 X 151/2220

EXTENDED SEAL LIFE AND FLEXIBILITYJACKETED STANDARD BORE(STUFFING BOX) SEAL CHAMBERLARGE TAPER BORESEAL 46R4188R4244R4248 Designed to remove heat and vapor out of the seal chamber andaway from the seal faces. Designed to remove heat from the sealing device only.WORKING PRESSURE VS TEMPERATUREused to determine the allowable working pressure at any allowableprocess fluid temperature for the material of construction selectedPUMPING TEMPERATURE – DEGREES C.-50050100150200250300350400450Carbon 00PUMPING TEMPERATURE – DEGREES F.112000316SS Maximum Temperature3003000Carbon Steel Maximum Temperature40080015001000500900WORKING PRESSURE – KPa3500500Minimum Temperature Limit: -20 FWORKING PRESSURE – PSIG4000

Dimensions of R4140 with “Economy” BaseplateAll Dimensions in ameCSize11.52341.523411.52341.523AB143T 13.25 6.50145T 13.75 6.50182T 14.63 7.50184T 15.63 7.50213T 18.13 9.50215T 19.63 9.50254T 23.13 10.75256T 24.88 10.75284T 26.88 12.63284TS 25.50 12.63286T 28.38 12.63DischargeO.D. Thick. B.C.4.875 .688 3.506.125 .813 4.506.50 .87558.25 1.13 6.63101.25 7.886.125 .813 4.506.50 .87558.25 1.13 6.63101.25 7.884.875 .688 3.506.125 .813 4.506.50 .87558.25 1.13 6.63101.25 7.886.125 .813 4.506.50 .87558.25 1.13 3/44-3/48-5/88-3/4HDHB D 8.25 D 10 D 11.545 12.00 13.75 15.2545 12.00 13.75 15.2545 12.00 13.75 15.2545 12.00 13.75 15.2545 12.00 13.75 15.2545 12.00 13.75 15.2552 12.38 14.13 15.6352 12.38 14.13 15.6352 12.38 14.13 15.6352 12.38 14.13 15.6352 12.38 14.13 15.63SuctionA1A2DSize O.D. Thick. B.C. Bolts38.25 1.13 6.63 8-3/4 8.13 8.13 8.2538.25 1.13 6.63 8-3/4 8.13 8.13 8.2538.25 1.13 6.63 8-3/4 8.13 8.13 8.254101.25 7.88 8-3/498.1310612.50 1.44 10.63 12-3/4 10.25 8.131038.25 1.13 6.63 8-3/498.751038.25 1.13 6.63 8-3/498.75104101.25 7.88 8-3/4 10.38 8.7510612.5 1.44 10.63 12-3/4 11.75 10 11.5026.5.87558-5/8 9.75 9.751038.25 1.13 6.63 8-3/4 9.75 9.751038.25 1.13 6.63 8-3/4 10.25 9.75104101.25 7.88 8-3/4 11.25 10 11.50612.50 1.44 10.63 12-3/4 11.75 10.50 11.5038.25 1.13 6.63 8-3/4 11.50 11.50 11.5038.25 1.13 6.63 8-3/4 11.50 11.50 11.504101.25 7.88 8-3/4 12 11.50 6TS 27.00 12.63324T 29.88 14.75324TS 28.37 14.75326T 31.38 14.75326TS 29.88 14.75364T 33.13 15.63364TS 31.50 15.63365T 34.13 15.63365TS 32.50 15.63404TS 33.50 17.50405TS 35.00 17.506040 Guion Road Indianapolis, IN 46254P: 317.293.2930 TOLL-FREE: 800.801.9265 F: 317.297.7028info@deanpump.com HDHB D 8.25 D 10 D 11.552 12.38 14.13 15.6358 13.00 14.75 16.2558 13.00 14.75 16.2558 13.00 14.75 16.2558 13.00 14.75 16.2558 13.75 14.75 16.2558 13.75 14.75 16.2558 13.75 14.75 16.2558 13.75 14.75 16.2560— 14.63 16.1360— 14.63 .637.758.758.758.758.759.889.889.889.8811.011.0 2010 MET-PRO CORPORATIONDEAN PUMP IS A REGISTERED TRADEMARK OF MET-PRO CORPORATION 09-5900 810

Dean Series R centrifugal process pumps are designed to insure long, continuous service life at low cost. Each phase in the production of these pumps is meticulously monitored by an independent quality control department. Pump Sizes The Dean Series R pump is an end-suction, center line supported, back pull out design