Transcription

WinAlign HD Alignment Systems Fast and accurate wheel alignment for multi-axle trucksw

New DSP760T alignment sensorsHunter's new DSP760T heavy-duty alignment sensorsreduce setup time and provide accurate alignmentreadings.PATENTEDRollingCompensation%% No jacking required%%Compensate allsensors at once%%Short roll compPATENT PENDINGSix Sensors Live%%Three axles live%%See allmeasurements atonce%%Diagnose tire wearconditions%%Reduce setup timethrough minimalsensor movementPATENT PENDINGPATENTEDTruck PusherFully IntegratedAlignment%%Easily move vehiclefor rolling comp%%Rechargeable battery%%Doubles as a wheelchock%%Auto-lockingturnplates%%Built-in turnplatebridges for rollingcomp

PATENT PENDINGTrailer Alignment%%Align withoutunhooking fromtractor%%Align using optionalkingpin adaptorwithout tractor%%Accurate to 15.24 m(600 in.)STANDARDSelf-CenteringAdaptors%%High versatility fortrucks and buseswith low-hangingbumpers or air dams%%Fits wheels 15 to 28inches in diameterSTANDARDCordlessOperation%%No egrated electroniccomponentsenhance reliability%%Lightweight,rubberized design%% Impact-proneareas protected byintegrated rubberbumpers

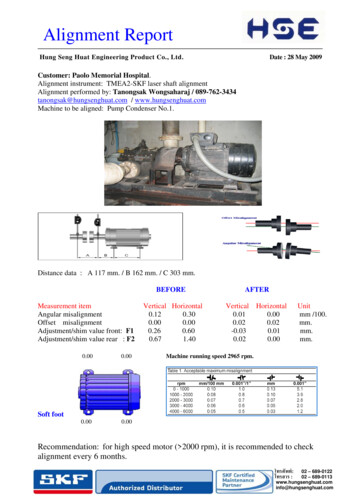

Previous setups used valuable shop time 012345678910111212:00 Standard procedures%%Position vehicle%%Select vehicle type%%Jack front axle%%Mount front sensors%%Compensate each sensor%%Pull turnplate pins%%Lower front axle%%Jack rear axle%%Mount rear sensors%%Compensate each sensor%%Lower rear axle%%Steer caster%%Jack middle axle%%Move fronts to middle%%Compensate each sensor%%Lower middle axle%%Print results12:00-15:00 TotalACTIVITY TRACKER3axles jacked to compensate2sensor movements203total walking steps8 additional minutes requiredbefore adjustment

Today, present your results in just 4 minutes!01234New procedure%%Position vehicle%%Select vehicle%%Mount sensors%%Roll forward to compensate%%Steer caster%%Print results4:004:00 TotalACTIVITY TRACKER0axles jacked to compensate0sensor movements8ltotal walking steps0additional minutes requiredbefore adjustmentFast printouts in 4 minutes!Use detailed printouts featuring your company’s logoto sell more work.

Check tire wear angles in under 3 minutes!01232:59Use detailed printouts featuring yourcompany’s logo to sell more work%%Get measurements on three axles%%Toe and camber on front axle%%Thrust and scrub on rear axlesStep-by-step procedure for HD alignment checks1. Pull in vehicle2. Recall the specs3. Mount six sensors4. Roll vehicle forward5. Retrieve the printout6. Sell the service

Console configurationsWinAlign HD%4 GB of DDR3 SDRAM Memory%240 GB SSD hard drive (or greater)%DVD-RW/CD-RW drive%Windows 10 operating system%Car and light truck software*%2 years of free VID updates%2 years of free HunterNet access%Industry-leading hardware and softwareIntel Core i3 Processor 3.70 GHz (or greater) WA470EShown with optional27 inch LCD monitorWireless network moduleOptionalAlignGuide trainingOptionalDSP760T or DSP740T sensor%Rolling compensation%Truck PusherOptional* Passenger car alignment sensors required.WA370EShown with optional27 inch LCD monitorWA360EShown with optional27 inch LCD monitorDSP700T sensor featuresDSP760TDSP740TAxles live32High-speed wireless radio communications%%Pro-Comp continuous compensation%%Rolling compensation%%Level Reminder on-screen leveling%%Sensor locking mechanism%%Interrupted measurement retention%%Light-weight construction%% DSP740TDSP760TSTANDARDSelf-centering wheel clampsStandard wheel clamps allow clampingof wheels 15-28 in. diameter.

When it comes to heavy-duty software,WinAlign HD is unmatched! The importance of software The most extensive vehicle informationdatabase. Vehicle-specific procedures guide yourtechnicians with step-by-step instructions. P atented power tools complete the workaccurately the first time, every time. W inAlign HD maximizes profit andproductivity in your alignment bay.WinAlign HD maximizesprofit and productivityOrdinary systems simplypresent alignment readings60 Axle configurations possiblePATENTEDExpressAlign WinAlign HD software supports more than 60customized truck, trailer and bus alignment proceduresas well as passenger car and light truck alignment.Perform every alignment with a streamlinedprocedure. ExpressAlign analyzes each job andpresents the optimal action sequence with theminimum steps required.Additional power features for light-vehicle work includes:CAMM feature Tools and Kits database Digital photos/videos* ExpressAlign procedure Shim Select II feature Work Management features

PATENTEDPATENTEDWinToeAutomatic Bushing Calculator Ensure a straight steering wheel every time withoutrepeated adjustments or using a steering wheel holder.Works with all vehicles on the road today, from cars toFreightliners.Calculate the proper bushing size and positionadjustment without wasting time with a zero bushing.Eases the process of servicing Ford F-150-450's.PATENTEDAdjustment VideosRear Axle Adjustment CalculationsCut adjustment times in half for rear axle corrections.Graphics let you get it right on the first try.Strengthen technician competency and extend profitopportunities with helpful adjustment videos.Frame Offset Angle DisplayMeasure frame offset angle and calculate adjustmentsto frame centerline, if a frame reference alignment isneeded.Before and after alignment results can beprinted in color.

AccessoriesPATENT PENDINGTruck Pusher – 20-2855-1Hunter’s battery operated pushereasily moves the vehicle foraccurate rolling compensation.Sensor storagePost: 20-2886-1, Cart: 20-2850-1Sensor storage post (left) or cart(right) provides convenient access andstorage for alignment instruments.Mini self-centeringwheel clamps175-284-1 (2 required)Allow mounting sensor tohub center of front rims.Frame referencesupport bar208-34-1Trailer guage221-738-1Trailer alignment gaugetool mounts sensors to thetrailer kingpin. Trailer axlesare adjusted to centerline.Trailer tow eye adapter175-486-1Remote indicatorCordless: 20-2882-1ERemote indicator is designed toprovide the operator with completecontrol while making adjustments tothe vehicle.Heavy-duty framedowel adapter20-3279-1Frame gauge kit20-3184-1Includes 2 adaptors,4 short frame hooks,and 4 long frame hooks.For Mercedes, Iveco Stralis,MAN TGA, Renault Magnum,EuroTrailer king pin adapter175-485-1Bus body referencestands – 20-3246-1Includes 4 standsTrailer dolly20-3161-1

Turnplate options for high-volume traffic%%Adjustable track width from half-tons to Class 8%%10,000 kg (22,000 lbs) per axle%%Built-in turnplate bridges for rolling compORLock turnplates with a switchor automatically through anFIA-equipped aligner.Manually slidelever to lock orunlock turnplates.Surface-Mount — align heavy-duty vehicles on your shop’s floor%%Permanent installation%%Accomodates existing pits20-3291-1 PowerSlide 20-3292-1 SlideLockRack-Mount — breathe new life into your existing rack%%Compatible with RKHD, PT, PE, and PF model racks%%Perform Quick Checks and alignments quicker and easier20-3334-1 PowerSlide 20-3333-1 SlideLockFlush-Mount — great for new construction or shop remodel%%Level profile reduces tripping hazards%%Clean installation and smooth approach20-3294-1 PowerSlide 20-3293-1 SlideLockOther tunplate optionsPortable TurnplatesAluminum construction withball bearing rotation andpolymer translation plates20-3271-1%%Multiple bays%%Multiple steer axles(multiple sets required)%%Mobile alignment service%%10,000 kg (22,000 lbs.) per axleTraditional Pinned TurnplatesNot suitable for rolling compensation%%Low-costsolution%%Matchinglegacy Hunterturnplates

Ordering Guide1. Choose your cabinet modelStandard cabinet accessories:Steering wheel holderBrake pedal depressorPower Requirements:115V or 230V, 1-ph, 50/60 HzWA670EWA570EWA560E2. Choose your alignment sensorsDSP760T6 cordless optical sensors with6 self-centering wheel adaptors, 6 storage brackets,2 sensor shaft extensionsDSP740T4 cordless optical sensors with4 self-centering wheel adaptors, 4 storage brackets,2 sensor shaft extensions3. Choose additional optional accessories20-2855-1 Truck pusher20-2886-1 Truck 2-sensor storage post with recharge powerCTN-1757Printer (USB)20-2850-1 Truck 6-sensor storage cart with recharge powerCTN-1833LCD monitor (27 inch) with mounting bracketCTN-1834LCD monitor (24 inch) with mounting bracket20-2902-1 Hub center adapters with storage brackets(2 each)20-2871-1 Mounting bracket for 24-27 in. monitor69-1025-2 Equipment cover20-2910-1 Hand-held XF radio remote control kit(For use with WA360E, and WA310E.Included with WA370E and WA470E.)221-646-1 Heavy-duty frame offset tool208-34-120-2880-1-EPlus cordless remote indicator20-2881-1-E20-3184-1 Frame gauge kitIcon remote indicator20-2882-1-E221-738-1 Trailer guageIcon cordless remote indicator175-486-1 Trailer tow eye adapter20-3291-1 Heavy-duty turnplates (surface mount)with PowerSlide 20-3292-1 Heavy-duty turnplates (surface mount)with SlideLock20-3334-1 Heavy-duty turnplates (rack mount)with PowerSlideFrame reference support bar20-3279-1 Heavy-duty frame dowel adapter175-485-1 Trailer king pin adapter20-3161-1 Trailer dolly20-1473-1 Trailer dolly alignment kit20-3246-1 Bus body reference stands (4 each) 20-3333-1 Heavy-duty turnplates (rack mount)with SlideLock20-3294-1 Heavy-duty turnplates (flush mount)with PowerSlide 20-3293-1 Heavy-duty turnplates (flush mount)with SlideLock25-24-1Heavy-Duty mechanical turning angle gauges(2 required)11250 Hunter Drive, Bridgeton, MO 63044, USATel: 1-314-731-3020, Fax: 1-314-731-0132Email: international@hunter.com1117BCopyright 2017, Hunter Engineering CompanyForm 995-TE-05, 11/17Supersedes form 995-TE-05, 04/14

20-3333-1 Heavy-duty turnplates (rack mount) with SlideLock 20-3294-1 Heavy-duty turnplates (flush mount) with PowerSlide 20-3293-1 Heavy-duty turnplates (flush mount) with SlideLock 25-24-1 Heavy-Duty mechanical turning angle gauges (2 required) 20-2886-1