Transcription

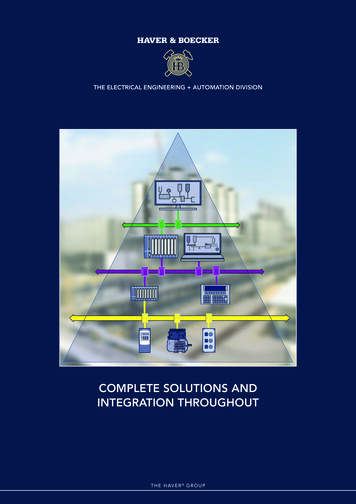

HAVER CHEMICALSStationary packing SyStemSelementra and integra The HAVER & BOECKER Company

ELEMENTRA STATIONARy PACKING SYSTEMyour speed requirements determine whether the HAVERELEMENTRA packing machine is equipped with one, two,packagingtrianglethree or four spouts.The ELEMENTRA is available in manual, semi-automatic orfully automatic versions. That means a manual or automaticproductbag placing is possible.To boost productivity, it is also possible to add a HAVER &BOECKER automatic bag placer.valve bagspacking machineHaVer & Boecker has optimum solutions forn Every bulk material propertyn Every commercially available valve-bag type and dimensionn All customer requirements, tailored to fulfil localrequirementsoptimum concepts, analyses, tests Successful and complete system solutions are based on HaVer & Boecker’sanalytical approach and its broad-based expertise and experience with:n Continuous research and developmentn Vertical Impeller Filling Systemn Its own, self-developed test methodsn Air Filling Systemsn Its own in-company laboratoriesn Horizontal Impeller Filling Systemn Detailed sampling for determining product flowcharateristicsn Exact air permeability tests on empty bags usingprecision instrumentsn Further Filling Systems:– Gravity Filling Systems– Auger Packer– Pump Packern Economically sound conceptsSTATIONARY PACKING SYSTEMELEMENTRA for filling granulated, mixed and powder productsn Assessment and design of the paper and plasticpackaging meansn System Componentsn HAVER & BOECKER Bag Application Technologyn INTEGRA n HAVER & BOECKER Palletizing Systems ELEMENTRAelementra are stationary packing machines for filling fine and coarse bulk materials into25 to 50 kg valve bags made of paper, polyethylene or polypropylene. also mixed and granulated productscan be filled with our elementra .Classifying the bulk materials with HAVER &BOECKER sieves2DEAERATION TESTERAIRFLOW TESTER bag testing unit3

ELEMENTRA HAVER & BOECKER VERTICAL IMPELLERyour benefitsn Production rate of up to 350 bags/hrn Precise weighing during the fillingprocessn High compaction levelsn Low aeration amount during filling produces highdensity packagingn Minimal spillagen Rapid emptying of the packing silo and fillingmachine via a second (optional) impeller outletHaVer Filling shut-off valvesn Easy accessibility for effective maintenance andcleaningn Modern drive system design and optimally designedwear parts assure maximum operation time for ahigher availability and a low-wear filling of abrasiveproductsPinch valveHAVER & BOECKERVERTICAL IMPELLERFrom the 1-spout filling machinewith manual operation through tothe 4-spout integra with emptybag cellular feeder123Slide valve4HaVer & Boecker valve bag filling machines using the vertical impeller filling system are a highly successful technologyfor filling loose, powder-type bulk material into valve bags according to the gross weight system.45

ELEMENTRA HAVER & BOECKER HORIZONTAL IMPELLERyour benefitsn Special adaptability to differentmaterials and material flowcharacteristicsn Large material inlet cross sectionn High filling speedsn Continuous material feeding (no clogging, no bridging)n High filling speeds while maintaining tight weighttolerancesHAVER & BOECKERHORIZONTAL IMPELLERthrough continuous development, HaVer & Boecker’s horizontal impeller filling machine is designed to pack highlyHAVER & BOECKER horizontal impellerflow-resistant, powder-type, loose materials that are prone to clogging.67

ELEMENTRA HAVER & BOECKER AIR ENTRAINMENTyour benefitsthe air filling machine according to then Gentle product handlinggross weight filling system is used forn Material components do not become separated during thefilling free flowing materials as well aspacking processfilling technically difficult powder-typeand granular products.n Production rates of up to 400 bags/hr per filling spoutThe pressure chamber aeration concept provides optimumn Fully aerated pressure chambern High weight precisionproduct flow with minimal air consumption. Aeration ratesdepend on the product characteristics and are individuallyn Homogeneous product/air mixturen Dust minimizationadjustable.n Automatic cleaning programthe universal air filling system has gained wide acceptancen Operator friendly designn Trouble-free filling of paper, PE and PP valve bagsfor filling fine to granular products into valve bags.Inline filling machines are available for manual or fullyautomatic operation and for integration into existing packingn Entire system requires minimal maintenancen MEC weighing electronics with spout control and settingoptionsplants with up to four filling spouts.Universal application for filling many products types, whichAs an option, this adjustment process may be automated via thevary in particle size and density, where the air flow rates cansort selection of the HAVER & BOECKER weigher electronics.be optimally adjusted independent of each other and wherethe air pressure can be centrally regulated.HAVER & BOECKERConical valve in our universal air filling systemAIR ENTRAINMENTConical valve in our inclined bottom air fillingsystemButterfly valvethe ideal area of application is the packing of products that consist of a mixture of fine and coarse particles.Cone from above8Fully aeratedMaintenance flap at the pressurechamberMaintenance flap at the filling box9

ELEMENTRA FURTHER FILLING SYSTEMSStraight free-fall tube for bridging productsgraVity Filling SyStemauger packerpump packerthe HaVer & Boecker gravitythe HaVer & Boecker auger packerthe HaVer & Boecker pump packerpacker is the all-round solution foris used for the compact filling of badlyis appropriate for filling of productsgrainy, granular and lumpy products.flowing light products.with low density.The product is filledThe constantThe product trans-according to theproduct flow intoport is made bygravity principle –the auger housingmeans of a double-without additionalis achieved by theacting diaphragmconveying air orcontinuously opera-pump. Since themechanical assistance.ting agitatorsystem is self-priming, it is often possi-For optimum product densification thepositioned above the dosing auger.ble to do without a packing silo. Thispacker can be extended to incorporateThe rotation speed of the dosing augerfilling system can be completed by aa vibrating compactor.is adjusted to your product and yourpressing station.requirements for weight-accurate coarseand fine flow product dosing.your benefitsn Cost efficiency through the compact,low-maintenance machine designn Ease of operation through the clearmachine designn Fully automatic ultrasonic valve seaGravity packerBent free-fall tubePump packerling possibleyour benefitsn Space savings from the low machineheight of only 1,560 mmn Material savings through the compact filling of very fluidized productsn Improved product storage from thefilling of tight bagsyour benefitsn Bag filling with low amount of airn Compact bags due to an integrablepressing station for improvementof performance and shaping of thebagsn Optimal weight accuracyn Ultrasonic valve sealing possibleFURTHER FILLING SYSTEMSGRAVITY, AUGERAND PUMP PACKERthe ideal area of application is the packing of products that consist of a mixture of fine and coarse particles.10Gravity filling systemAuger packerPump packer11

ELEMENTRA HAVER & BOECKER COMPONENTSFor our different filling systems, we offer a variety ofsystem components:n spillage rejectorn pressure jawsn various types of filling tubes n various types of bag chairsHaVer & Boecker Bag cHair VariantS123n bag sealing technologyMinimal bag valve extensionPressure jaws1 - Bag chairs for manual removal, manually height adjustableFor machines with the manual removal of filled bag, the bag chairmay be adjusted to suit the length of the bag using just a fewmotions of the hand.2 - Bag chairs for automatic, vertical bag discharge manually adjustable (optionally motor-driven, continuous)When only one bag size is used or when bag changeovers areseldom, then the tip-chair for automatic discharge may be heightadjusted using standard tools.3 - Bag chair for automatic vertical bag discharge, motorized,continuous height adjustment via bag type pre-selectionFor different bag lengths and frequent sort changes, the automatic bag chair height adjustment (through a gear reduction motorand spindle) is recommended. Adjustment is done simply by asort selection key during product or bag changeovers.HAVER & BOECKER Filling tube variantsFilling tube: conical designHAVER & BOECKERCOMPONENTS12Filling tube: with inflatable sleevea separate valve closing unit on every filling spoutthe spillage rejecting flapFor greater cleanliness over the entire filling and subsequentoffers a big improvement in bag cleanliness. During discharge,transport process - until the bag reaches the consumer - wethe rejecting flap prevents the bag from becoming conta- recommend equipping your ELEMENTRA with an ultrasonicminated with product that could drip out of the filling tube.bag closing unit.The rubber flaps are activated automatically.Smooth handling of filled bags in upright positionSpillage rejecting flap during filling processSpillage rejecting flapduring bag discharge13

ELEMENTRA HAVER & BOECKER BAG PLACING TECHNOLOGYIn contrast to manual bag placing, they ensure the highthe automatic bag placer lV-Z (traversing linearly, cellularefficiency of a packing machine. Empty valve bags – from afeeder) by HaVer & Boecker is a compact and flexible,bundle or a reel – are placed mechanically onto the fillinglinear high-capacity placing system. it is the optimumspouts of the packing machine and adapted to its speed.solution for the automation of your multiple-spout inlineThe placing process is consistent and reliable. The types ofpacking plant.bags that can be used are glued valve bags made of paper,polyethylene or polypropylene. The placing technology iseasily adaptable to different bag sizes.the automatic bag placer compact by HaVer & Boeckercan be used with stationary packing machines withyour benefitsn Capacity of up to 1,300 bags/hrn HAVER & BOECKER valve bag placing technology,modular integratedn High availability and maximum efficiency in allperformance areas1 to 4 filling spouts.n Universally usable with respect to bag materials andyour benefitsn Capacity of up to 900 bags/hrn Compact designprovisioning of empty bagsn Reliable processes and sensitive control systemsn Low-wear drive engineeringn Easy and fast adjustment to different bag sizes and typesn Integrated bundle magazine carriage with a storagecapacity of 200 to 250 bagsn If required, usage of different types of empty bagmagazinesyour output requirement deter-mines what kind of emptybag provisioning system will be used.Depending on the required storage capacity and the availablespace, different empty bag provisioning systems can be used:n Vertical bundle magazine (400 to 500 bags)n Empty bag cellular feeder (450 to 550 bags, dependingon its length)n Reel magazineELEMENTRA with movable automatic bag placer - bundle systemThe system can be quickly and flexibly adapted to differenttypes of bags. HAVER & BOECKER automatic bag placersHAVER & BOECKERBAG PLACINGTECHNOLOGYare of modular and compact design and require little space.Magazine carriageVertical magazineFlexible installationyour automatic bag placer will be adapted to your local andspecific conditions! This is made possible by the constructionof the HAVER LV-Z according to the proven modular system.automatic bag placers by HaVer & Boecker for valve bags automate and enhance the packaging process.The empty bag provisioning system can be installed on theright or left side of the ELEMENTRA . This way the fillingplant can be manually operated and maintained from thefront without barriers.Empty bag cellular feeder1415

INTEGRA STATIONARy ASSEMBLED PACKING SYSTEMSThe INTEGRA is a completely assembled filling system forloose materials inside a dust-encapsulating housing thatother integra system characteristics:n Compactness minimal space requirementsconsists of the following components:n Encapsulated (less noise and dust emissions)n Filling machinen Easy installation and start-up, easy to repositionn High operational reliabilityn Valve sealing systemor move if neededn Bag placern Greatest possible flexibility, rapid changeoversn Control systemto other bag types or productsn Operating unitn Large maintenance doors, easy access to all componentsn Bag discharge beltn Scratch-resistant safety glass for easy viewingn Operating terminalIt is a turnkey unit that is ready to operate and allows rapidon-site installation and start-up. Only the product and energyn Operator guidance in dialog (text messages) andmachine settingsupply systems need to be at hand at the customer’s as wellas a final assembly for a 3-spout and a 4-spout system.integra Explosion protection is a part of the technology that has todo with prevention of the occurrence of explosions and their1Spoutsimpacts. This belongs to the field ofSafety Engineering and has the purpose2of preventing damage by technicalproducts, systems, and other equipmentto persons and property. Explosion3protection consists of technical solutions such as ignitionprotection types and legal requirements such as the ATEXDirectives of the European Union.STATIONARY PACKING SYSTEMINTEGRA performance overview4t1234up to bags/hrto range from10 to 50 kgt3006009001200depending on theproductThe INTEGRA has received the European type approval fromDEKRA EXAM. Qualified HAVER personnel check systems thatrequire monitoring in the ATEX range.For 1 to 4 spoutsControl panelINTEGRA Bag placingtechnologya completely assembled filling systemHaVer & Boecker is a traditional middle-sized company. our success is based on quality, innovative spirit, globalopenness and mutual trust and cooperation. We are a family owned company that has remained true to itself sinceConveyingsystem1887 and therefore we feel close to our partners and customers worldwide today. this goes without saying for allbusiness areas, and it’s always the main focus of the company. Subsidiary companies and representatives on allcontinents work to uphold the reputation of this ambitious global market leader.1617

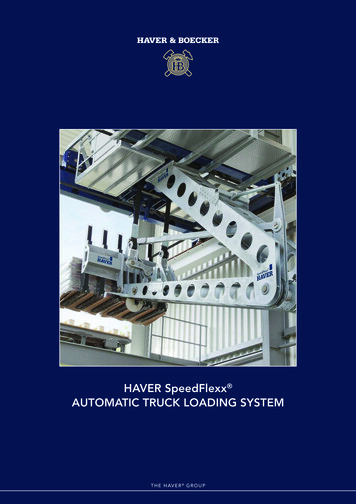

ELEMENTRA AND INTEGRA HAVER & BOECKER PALLETIZING SYSTEMSthe automatic HaVer & Boecker palletizing SystemsIn order to successfully implement these goals in your com-your bags are packed. They are tight, clean and offer opti-pany we offer an extensive programme of packaging systemsmum protection of your products. But: They have not yetand palletizers in close cooperation with our subsidiaryarrived at your end-users' sites. Before they have to beNEWTEC BAG PALLETIZING:stacked accurately and the pallets have to be packed carefullyin order to:n Protect the filled bags against damagen Optimally use the available loading space and avoid lossof space due to irregular bag pilesn Avoid loss of time during handling and transport becauseof badly stacked palletsn Prevent the pallets from tumbling due to irregular bagpilesn pallettizer g300for bag palletizing by a robotic gripping armThis palletizer is especially suitable for low-outputapplications of up to 300 bags/hr with bag weights of5 up to 50 kg.n palettizers - Series 500/1000/2000 to 5000Bag palletizing row by rowThese palletizers are equipped with simple, reliable andproven kinematics. The modular machine design ensuresoptimum palletizing results. This model is particularlydesigned for applications of up to 5,500 bags/hr with bagweights of 10 to 50 kg.together we are strongOptimally stacked and packed pallets help you save timeand money. As overall costs can thus be reduced, theprofit is increased. In addition, nicely stacked pallets haveThe palletizer - G 300 series - is designed for low capacities of up to 300 bags/hr of 5 to 50 kg.The palletizer - 4000 series - is used in the building materials industry andis suited for capacities of 2,500 - 4,000 bags/hr.an excellent advertising impact.HAVER & BOECKERPALLETIZING SYSTEMSmade by neWtec Bag palletiZing – your products are firmly and cleanly palletized.1819

PM 341 E 4010 1215 1.5 FeThe machines and equipment shown in this brochure as well as the technical parameters represent only examples of customer-specific technical solutions. We reserve the right to make changes at any time without notice!The symbol indicates a registered trademark of HAVER & BOECKER oHG in Germany. Some of the trademarks are also registered in other countries.

FURTHER FILLING SYSTEMS 10 ELEMENTRA Pump packer graVity Filling SyStem the HaVer & Boecker gravity packer is the all-round solution for grainy, granular and lumpy products. The product is filled according to the gravity principle - without additional conveying air or mechanical assistance. For optimum product densification the