Transcription

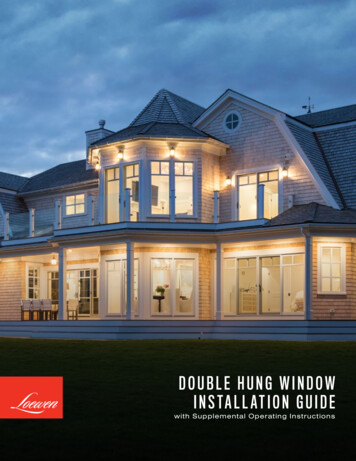

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EDOUBLE HUNG WINDOWIN S TA L L AT I O N G UID Ewith Supplemental Operating Instructions1

ILMOPEOWRE TNA DNOT UNBOLTEI CHEUSN G W I N D O W I N S T A L L A T I O N G U I D EIMPORTANT NOTICES& INFORMATIONSite PreparationAdvisoryThis manual is intended forconstruction professionals withThe building envelope must be correctly prepared with weatherproven competency installing doorsresistant barriers – that meet local and state codes. All frameand windows for large openings.and sill surfaces must be correctly prepared for air, water, andWindow installations are complex andstructural integrity by the builder or contractor before attemptingshould not be attempted with simpleinstallation. In order to meet warranty requirements, all systemswritten documentation.are required to be installed by a certified installer. Read these instructions in their entirety prior to installingwindows. Contact Loewen at 1.800.563.9367 for clarification. Loewen is not responsible for site measurements nor thestructural and architectural requirements for the installationof the windows. Building design, construction methods, building materialsand site conditions unique to your project may requiremethods different from these instructions. Choosing the appropriate method is the responsibility of you,your architect, or your construction professional. Confirm with sealant/foam/barrier manufacturers that allmaterials used are compatible with one another. Remove shipping blocks and related staples prior toinstallation. All drawings are shown not to scale. To ensure accuracy, make sure you have the latest approvedshop drawings and assembly and installation guides. Any local, regional or national building code requirementssupersede these instructions. Safety is top priority for Loewen. Use proper workprocedures and protective equipment.2

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EVerify The Rough Opening Measure the rough opening and the window to determine that the sizeis correct. Recommended rough opening is between 3/4” (19mm) - 1”(25mm) larger than the window width and height. Ensure that the rough opening is plumb, level and square, and thewalls in the opening are not twisted.a) 1 1/2” (38 mm) solid blocking is required at the sill and sides ofthe opening.b) Ensure proper header is in place before installation.c) Make necessary corrections.Vital Preparation Information Specifically for Double HungSquareness of the window along with proper shimming and adjustment of the jamb jacks is required to ensure thatthe frame weatherstrip makes adequate contact with the sash. This is vital to the product performance. Ensure that nodaylight is visible between the sash and frame.Jamb Jack AdjustmentUse the Jamb Jacks Screw to obtain an even gap between Sash andFrame. Using a T25 Torx screwdriver, turn the Jamb Jacks ScrewHeadclockwise to move the Jambs away from the Sash or counterclockwise tomove the Jambs towards the Sash. Adjust until the gap is consistent fromthe top of the sash to bottom and both sides.Check RailSee page 14 for further information on Jamb Jack installation andadjustment.SillAdjust the shims at the Check Rail as necessary.Do not remove shipping strap prior to installation of unitinto rough opening.3

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EPREPARATION INSTRUCTIONSFor detailed preparation installation instructions, see ourdedicated Window Installation Guide.WindowInstallation GuideNew ConstructionTools Required Laser Level Hammer Pry Bars Ladders Utility Knife Screw Gun Applicator Foam Gun “J’ Roller Tape Measure Caulk GunMaterials Required High Impact Composite (not wood) shims/spacers 1 1/2” or 2” #8 Screws (stainless steel recommended) Expansion Foam - Closed Cell (low-expansion only) Window & Door Flashing Tape (6” recommended) Window & Door Sealant Interior Trim4

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS1. Removing the Shipping InsertImportant: Sash can be both heavy and awkward to handle during removal. You may requireextra assistance to prevent personal injury and/or damage to the window.Loewen Double and Single Hung windows have a Shipping Insert which protects the unit during shipping. This Insertshould be removed before installation.1. R emove the Foam1 aShipping InsertBlock which supports1 bFoam Blockthe Shipping Insert.Alternate Locationto Cut Insert2. P ress the top of the2Press HereShipping Insert todeform it and releasingthe Top Sash.5

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS1. Removing the Shipping Insert (continued)3. With the Shipping Insert bent, raise the Bottom Sash.34. R etract the Tilt Latches by turning the Camlock and tilt4the Bottom Sash inward. Remove the Shipping Insert andreinstall the Bottom Sash vertically.In some cases units may be shipped with the sash separate from the frame. On these units a screw in the jamb linermaintains balance shoe position during shipping. To remove once frame is installed in the rough opening:1. Place sash pivots into balance shoe cams (see page 22)2. Tilt sash up as far as possible while still being able to access screw head3. Carefully remove screws on both sides4. Finish tilting and locking sash in vertical position (see page 22)6

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS2. Parts2.1 M etal Clad Casing & SillNosing Assembly2.2 P arts DesignationsCasing Options1. Casing at Jamb (3 1/2” Flat Casing shown) 2” Brickmould2. Casing at Head (3 1/2” Flat Casing shown) 3 1/2” Flat Casing3. Sill Nosing (BC Sill Nosing shown) Williamsburg Casing4. Head Casing End Cap - 3 1/2 Flat Casing Only Nost & Cove Casing5. Frame Cladding6. Accessory Retainer Clip7. Casing Shipping Clip8. Sill Nosing End CapSill Nosing Options9. Jamb - Frame Standard Sill Nosing10. Sill BC Sill Nosing11. Sill Nosing Shipping Clip Heritage Sill NosingNote 2” Brickmould comes with standard sill nosing. Optional casings are Williamsburg, Adams and 3 1/2” Flat Casing.These casing options automatically come with the BC Sill Nosing but are also available with the Heritage Sill Nosing.7

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS2. Parts (continued)132.3 E xploded View242See 2.4 for BottomCorner close up832.4 B ottom Left Corner576981110

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS3. Installation & PreparationFollow these instructions to install the site casing system to Loewen window systems3.1 R emove protective packaging anddispose of as per local requirements.Gently place the unit on a clean &dry flat surface with the exterior sidefacing upward.3.2 O ptional casings will bepre-assembled and resting on thedisposable casing shipping clips.The casing shipping clips keep thecasings from accidentally engagingthe accessory clip during shipping andhandling. Remove the #6 x 1-1/2” panhead screws located on each sill nosingshipping clip (11). Keep the screws forinstallation of sill nosing. Separate theCasing/Sill Nosing assembly from thewindow by lightly lifting upwards, setcasing assembly aside.9

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS3. Installation & Preparation (continued)3.3 R emove factory installed sill nosingcasing shipping clip on the frameof the unit and discard. Ensure thataccessory retainer clips are locatedCasing Shipping Clip25mm (1”) from each corner and thenno greater than 508mm (20”) apart.Sill Nosing Shipping ClipAccessory Retainer Clip3.4 S eparate Sill Nosing from the SideCasing by removing the #6 x 1-1/2”pan head screws. Two screws arelocated at each bottom corner.Sill Nosing endcaps come appliedfrom factory10

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS4. Unit & Casing System InstallationImportant: Always practice safety! Wear the appropriate eye, ear and hand protection,especially when working with power tools.4.1 I nstall and seal the window unit intowall opening as per standard Loeweninstallation instructions.Screws on the nailing flange may need to be loosened or re-positioned while adjusting theJamb Jacks.11

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS4. Unit & Casing System Installation (continued)4.2 S tarting along the top and moving downthe sides, push the casing assemblyonto the frame mounted accessoryretainer clips using light pressureas to not dent the casing. Insure fullengagement of the casing to the frame,there should be no more than a 1/16”gap between the back of the casing andthe wall surface.4.3 A pply continuous bead of Tremsil600 along the sill between sillcladding and sill nosing. Apply SillNosing to Sill. Fill both sill cornerkeys through sill port hole usingwood/metal joint sealant. Continuefilling corner keys until sealantContinuous beadof Tremsil 600becomes visible around the entireperimeter of the frame cladding atthe sill nosing interface.12Port hole forsealant injectionof sill corner key

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EINSTALLATION INSTRUCTIONS4. Unit & Casing System Installation (continued)4.4 F or Combination units only. At framemullions, fill both frame end cavitieswith wood/metal joint sealant. ThenScrew portfor nosingapplicationfollow sill nosing to sill applicationinstructions in (3.5)Fill frame cavitieswith wood/metaljoint sealant sillapplication4.5 S ecure Sill Nosing to side FrameUnder side of sillCladding with two #6x1-1/2” panhead screws.Screw ports toattach casingsSee Step (4.3)Screw port for sideframe claddingSide of sill4.6 A ttached casing with #6 x 1 1/2” panhead screws.Sill attachmentscrewsSill Nosing13

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EUSING THE JAMB ADJUSTING SYSTEMInstalling the Jamb Jack1. I nsert the Jamb Jack Screw (parts shipwith the window), into the Jamb JackJamb JackInsertInsert. Using a T25 Torx screwdriver,drive the Jamb JackScrew until thereJamb JackScrewis a “click”.Torx ScrewdriverSize T252. M easure the width at the Head, Sill and CheckRail. Use the Jamb Jacks Screw to obtain aHeadconsistent frame opening for the sash. Usinga T25 Torx screwdriver, turn the Jamb JacksScrew clockwise to move the Jambs awayCheck Railfrom the Sash or counterclockwise to movethe Jambs toward the Sash. Adjust until theHead, Sill and Check Rail frame openings areall equal. Adjust the shims at the Check RailSillas necessary.Install sash and check for even gaps between sash and frame on both sides if adjustment is required remove sash andadjust jamb jack screw to ensure an even gap between frame and sash top to bottom and on each side.3. Reinstall the Fuzzy Pad.Fuzzy PadScrews on the nailing flange may need to be loosened or removed while adjusting the Jamb Jacks.14

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D EPAINTING & FINISHING THE UNITBe sure to follow the Loewen Finishing Instructions when finishing your window. For details, go to nce-warranty/finishing-your-product/When finishing the Sash, do not remove any weather-strip. If the weather-strip is removed, the window’s performance maybe diminished. When removing the Sash Pivots, take note that the lower screw is longer than the upper screw. Ensure thatthese same fasteners are replaced in their correct locations or damage may occur to the Insulating Sealed Unit.Top SashBottom SashThe Lock on the lower Sash and the Keeper on the upper Sash are shipped factory applied and can be removed forpainting/finishing. When reapplying the Lock to lower Sash, move to locked position and position Lock onto Lock Railaligning key on Lock to keyway on spindle.15

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSRemoving the Interior Sash Stops on Liberty Units1. U se a screwdriver to remove the InteriorSash Stop screws.2. W ith the Bottom Sash Lowered, removethe Interior Sash Stop screws abovethe Lock Rail.16

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSRemoving the Interior Sash Stops on Liberty Units (continued)3. R aise the Bottom Sash and remove theInterior Sash Stop screws below theSill Rail. Separate the Interior SashStop from the frame. The Bottom Sashcan now be removed.Important: Brace the bottom sash to prevent it from falling inward when removing the interiorsash stop.Note: Impact units ship with short screws holding the interior sash stop in place. When reinstalling the sash stop, replace with the supplied longer screws.17

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Bottom SashDouble Hung & Liberty Double Hung UnitsLoewen Double and Single Hung windows have a tilt feature enabling the homeowner to wash the exterior withoutremoving the Sash from the Frame.1. U nlock the window and raise the BottomSash approximately 100 mm (4”) fromthe Sill.2. R otate the Camlock an additional ¼ turnto retract the Tilt Latches from the Jamb.Note: if lock is removed, Spindle can berotated with a flat screwdriver to retractTilt Latches.Important: Sash can be both heavy and awkwardto handle during removal. You may require extraassistance to prevent personal injury and/ordamage to the window.18

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Bottom Sash (continued)Double Hung & Liberty Double Hung Units3. Slowly tilt the Bottom Sash inward untilit is horizontal, pivoting the Sash aboveSill Rail. Carefully rest the top of theBottom Sash on a stable padded supportto protect against damage to the BottomSash or personal injury while cleaning.3b. I n the case of the Liberty Impact DoubleHung, a vinyl sash catch is factoryapplied in place of the tilt latches.Vinyl SashCatch19

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Bottom Sash (continued)Double Hung & Liberty Double Hung Units4. W ith the Bottom Sash horizontal, lift bothsides of the Sash evenly for 50 mm (2”)until the Sash Pivots are free from theBalance Shoe Cam. Note: Do not rackthe Sash out of the Frame. Lift both SashPivots out of the Balance Shoes at thesame time or damage to the BalanceShoe Cam may occur.BalanceShoeBalanceShoe CamBalanceTrack20

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Bottom Sash (continued)Double Hung & Liberty Double Hung Units5. O nce the Sash Pivots are free from theBalance Shoes, lift one side higher thanthe other until the Sash Pivot is free fromthe Balance Track along each Jamb,being careful not to bump the edges ofthe Balance Track with the Sash Pivotswhich may damage the Jambs.Important: Sometimes theBalance Clip may be misaligned,preventing the Sash Pivots fromlifting out of the Balance Shoe. Ifthis is the case, use a Screwdriverto reposition the Clip beforeattempting to remove the Sash.21

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSReinstalling the Bottom SashDouble Hung & Liberty Double Hung Units1. W ith the top of the Bottom Sash towardyou, and the exterior side facing up, holdthe Sash with one side slightly raised.Guide the Sash Pivots into the BalanceTrack one side at a time ensuring thepivots are 50 mm (2”) above the BalanceShoes.2. M ove the Sash to a horizontal positionand lower each side simultaneouslyinto the Balance Shoe Cams. Ensureeach Pivot is fully seated in theBalance Shoe Cam before tiltingthe Top Sash back into place withthe Camlock rotated to retract theTilt Latches as they pass the Jamb.Note: if lock is removed, Spindle canbe rotated with a flat screwdriver toretract Tilt Latches.22

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Top SashDouble Hung & Liberty Double Hung Units1. L ower the Top Sash approximately halfway.2. R etract the Tilt Latches on either side ofthe Head Rail until they release from theJamb.23

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Top Sash (continued)Double Hung & Liberty Double Hung UnitsNote: The Top Sash does not tilt on a single hung window.3. Hold the Tilt Latches in the retractedposition until they clear the Jambs asyou tilt the Top Sash inward until it ishorizontal.4. W ith the Top Sash horizontal, lift bothsides of the Top Sash evenly 50 mm(2”) upward until the Pivots are free fromthe Balance Shoe Cams. Note: Do notrack the Sash out of the Frame. Lift bothpivots of out the cams at the same timeor damage to the Balance Shoe Cam mayoccur.24

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Top Sash (continued)Double Hung & Liberty Double Hung UnitsNote: The Top Sash does not tilt on a single hung window.5. O nce the Pivots are free from theBalance Shoe Cams, lift one sidehigher than the other until the Pivotis free from the Balance Trackalong each Jamb, being careful notto bump the edges of the BalanceTrack with the Pivots which maydamage the Jambs.Important: Sometimes theBalance Clip may be misaligned,preventing the Sash Pivots fromlifting out of the Balance Shoe. Ifthis is the case, use a Screwdriverto reposition the Clip beforeattempting to remove the Sash.25

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSReinstalling the Top SashDouble Hung & Liberty Double Hung Units1. W ith the Top of the Sash toward you, andthe exterior side facing up, hold the Sashwith one side slightly raised. Guide theSash Pivots into the Balance Track oneside at a time ensuring the Sash Pivotsare 50 mm (2”) above the Balance Shoes.2. M ove the Sash to a horizontal positionand lower each side simultaneously intothe Balance Shoe Cams. Ensure eachPivot is fully seated in the Balance ShoeCam before tilting the Top sash backinto place.3. Fully retract the Tilt Latches.26

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSReinstalling the Top Sash (continued)Double Hung & Liberty Double Hung Units4. G ently tilt the Sash back into positionwhile ensuring that the Tilt Latches areretracted so that they do not damage theJambs.5. O nce the Sash is vertical, ensurethat the Tilt Latches are properlyengaged along the each Jamb.27

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Single Hung Top SashImportant: Brace the top sash to prevent it from falling inward when removing the sash stops.1. R emove the Vertical Interior Sash Stopswhich lie along the side stiles.2. R emove the Horizontal Interior Sash Stopswhich lie along the Top Stiles.28

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSTilting & Removing the Single Hung Top Sash (continued)3. Cut the Top Sash Retaining Clip.4. T ilt the Top Sash Inward and Liftthe Sash out of the Balance Shoesusing the Sash removal instructionsdescribed for the Double Hung.29

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSReinstalling the Single Hung Top Sash1. I nstall a new Sash Retaining Clip intothe Head Rail. Install a new HeadWeatherstrip.2. I nsert the Sash into the Frame, ensuring23the Pivots are engaged into the BalanceShoe Cams.3. Gently tilt the Sash back into a verticalposition.4. R e-install the Sash Stops.Sash Stops30

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSSetting Balance Shoe HeightImportant: The Balance Shoes are under great tension when engaged. Use great caution.Should a Balance Shoe require repositioning, complete these steps before installing the Sash.1. M easure the Balance Shoe location onthe opposing Jamb to within 3 mm (1/8”)of its true position.OppositeJamb2. T emporarily mark that dimension witha pencil in along the Balance Trackcontaining the Shoe that has slipped.CurrentJamb31

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSSetting Balance Shoe Height (continued)3. Using a ¼” flathead screwdriver, rotatethe Balance Shoe Cam 90º to thereleased position. In this position, theopen face of the cam points inward. UseCaution: The Balance Shoes are underextreme tension.4. H olding the screwdriver firmly, slidethe Balance Shoe down toward themark made in the step above.5. L ock the Balance Shoe by rotatingthe screwdriver counter-clockwiseso that the open face of the Campoints up. Slowly remove thescrewdriver from the Balance Shoe,ensuring that it is fully engaged.Verify that the Balance Shoelocation is within 3 mm (1/8”) of theopposite one to prevent damagewhen installing the Sash.32

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSRemoving the Screen1. R aise the Bottom Sash, grasp the PlungerHeads on either side of the screen andgently retract the Pins.2. S lide the bottom of the Screen outward.Grasp the Screen Frame and pull downslightly.3. Turn the Screen sideways and bring theScreen inside.33

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSInstalling the Screen1. S lide the screen sideways outwardthrough the Frame.2. T urn the Screen upright and place the TopPlungers into the Grommets located in theHead.3. P ull the Screen against the Frame legwhile holding the Plunger Heads to retractthe pins. Release Screen Plungers intothe Grommets.Grommet34

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSRemoving the Lower Jamb Covers1. R emove lower sash weatherstrip. Theninsert a pry bar into the inside BalanceTrack near the Sill so that the tip rests justunder the inner leg of the Lower JambCover.2. P ry gently upward with the pry bar (2a) until the Lower Jamb Cover begins to lift (2b). Press the tip down and underthe Lower Jamb Cover, bending the Jamb Liner (2c) and pry upward until the Lower Jamb Cover is removed (2d).2 a2 b2 c2 d35

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSRemoving the Lower Jamb Covers (continued)3. Slide the pry bar upward along the LowerJamb Cover, repeating step 2 until theLower Jamb Cover is completely free fromthe Jamb.Removing the Upper Jamb Covers1. A fter removing the Lower Jamb Cover,slide a flat screwdriver tip underneath thebottom end of the Upper Jamb Cover.Gently pry the Cover up.2. C ontinue sliding the screwdriver under theUpper Jamb Cover, prying as you go untilyou have completely removed the UpperJamb Cover.36

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSReplacing Balance Shoes and Adjusting Hybrid BalancesImportant: Balance components are under extreme tension. Use care when operating.Disconnecting Block & Tackle Balances from the Balance Shoes1. I nsert the Balance Tool into the Blockand-Tackle Balance Clip.2. E nsure that the Balance Tool fullyengages the Block-and-TackleBalance Clip.BalanceChipBalanceTool37

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSReplacing Balance Shoes and Adjusting Hybrid Balances (continued)3. With a smooth motion, pull the Clip downand out of the Balance Shoe.Disconnecting Hybrid Balances from the Balance Shoes4. H ook the Balance Tool onto the HybridBalance Foot.5. E nsure that the Balance Tool fullyengages the Hybrid Balance Foot.38

LO E W E N D O U B L E H U N G W I N D O W I N S TA L L AT I O N G U I D ESUPPLEMENTAL OPERATING INSTRUCTIONSReplacing Balance Shoes and Adjusting Hybrid Balances (continued)6. W ith a smooth motion, pull the Foot out ofthe Balance Shoe.Adjusting Hybrid BalancesThe weight range of some Hybrid Balances can be adjusted 3-4 lbs7. With the Hybrid Balance disconnectedfrom the Balance Shoe, rotate the Foot toadjust the Balance Strength. (A) Turn counter-clockwise to increasethe lifting force (maximum four turns). (B) Turn clockwise to reduce the liftingforce (maximum four turns).1 a1 b39

Information subject to change without notice.Distributed by Loewen Inc. in the USA and C.P. LoewenEnterprises Ltd. in Canada and internationally. Trade Marksowned by C.P. Loewen Enterprises Ltd. Used under license. C.P. Loewen Enterprises Ltd. All rights reserved.P3176A 0421LOEWEN.COM

LOEWEN DOUBLE HUNG WINDOW INSTALLATION GUIDE INSTALLATION INSTRUCTIONS 1. Removing the Shipping Insert Loewen Double and Single Hung windows have a Shipping Insert which protects the unit during shipping. This Insert should be removed before installation. Important: Sash can be both heavy and awkward to handle during removal. You may require