Transcription

Preliminary Fire ExtinguishingU.S.Departmentof TransportationFederalAviation AdrninistKltionTechnical CenterAtlantlc City International Airport, N.J. 08405

NOTICET h i s document i s d i s s e m i n a t e d under t h e s p o n s o r s h i pof t h e U. S. Department of T r a n s p o r t a t i o n i n t h e i n t e r e s tof i n f o r m a t i o n exchange. The United S t a t e s Governmentassumes no l i a b i l i t y f o r t h e c o n t e n t s o r u s e t h e r e o f .The United S t a r e s Government d o e s n o t endorse p r o d u c t so r m a n u f a c t u r e r s . Trade o r m a n u f a c t u r e r s ' names appearh e r e i n s o l e l y because t h e y a r e c o n s i d e r e d e s s e n t i a l t o t h eo b j e c t i v e of t h i s r e p o r t .

Technical Report Documentation Page1. Report No.2. Government Accession No.DOT/ AA/CT- 891603. Recipient's Cotalog No.I5. Roport Oote4. Title ond SubtitleJanuary -1990PRELIMINARY FIRE EXTINGUISHING TESTS WITH HANDHELDBOTTLES: A COMPARISON OF EXTINGUISHING C0MPOUNI)S6.Prforming Orgonixation Code8. Performing Organixotion Report NO.7. Author's)T. M. Guastavino and F. FannDOT/FAA/CT-TN / O9. Performing Orgarixotion Name m d Addresn10. Work Unit No. (TRAIS)Federal Aviation AdministrationTechnical CenterAtlantic City International Airport, NJ 0840511. Contract or Grant No.13. Type of Report ond Period Cowred12. Sponsoring Agency Nome ond AddreasU.S. Department of TransportationFederal Aviation AdministrationTechnical CenterAtlantic City International Airport, NJ 08405Technical Note14. Sponsoring Agency CodeACD-24015. S u p p l w t t o rNotesyIn 1982, the Federal Aviation Administration (FAA) Technical Center completed atest and evaluation project on use of handheld extinguishers in transportcategory aircraft. Some of the tests involved the comparative effectiveness ofhandheld extinguishers in a specific fire scenario: a triple non-fireblockedaircraft seat ignited with gasoline. The test work included the identificationand quantification of effluent gas species produced by the fire and theextinguishing chemicals.The present study describes the comparative effectiveness of the extinguishersused in the above tests and some newer systems in two distinct fire tests. Thefirst test is the "crib" test used by Underwriters Laboratory, Inc. to ratehandheld extinguishers. The second test is the same seat test used in theearlier work.The tests employed aircraft approved water extinguishers and Halon 1211extinguishers as benchmarks. New formulations using surfactants andextinguishing powders in aqueous solutions were tested against the benchmarkperformance levels. In these tests, certain new solutions were able to meet orexceed the performance of the benchmark agents.(17. Key WordsHandheld Fire ExtinguishersFire TestsNew Chemical FormulationsForm DOTF 17fM.7(8-72)10. Ois iLutiocrStotemmtDocument is on file at the TechnicalCenter Library, Atlantic City InternationalAirport, New Jersey 08405Ropreductiom of completed p q e authorized

TABLE OF CONTENTSPageEXECUTIVE ib TestAircraft Seat TestSTATE OF THE ART SYSTEMSFORMULATIONS FOR NEW SYSTEMSTEST RESULTSState of the Art SystemsNew SystemsSUMMARYCONCLUSIONSREFERENCESLIST OF ILLUSTRATIONSFigurePage1Wood Crib for Underwriters Laboratory Class "A" Fire Test22State of the Art Systems (2 Sheets)4iii

EXECUTIVE SUMMARYI n 1982, t h e F e d e r a l A v i a t i o n A d m i n i s t r a t i o n (FAA) T e c h n i c a l C e n t e r completed at e s t and e v a l u a t i o n p r o j e c t on u s e of handheld e x t i n g u i s h e r s i n t r a n s p o r tc a t e g o r y a i r c r a f t . Some of t h e t e s t s i n v o l v e d t h e comparative e f f e c t i v e n e s s ofhandheld e x t i n g u i s h e r s i n a s p e c i f i c f i r e s c e n a r i o : a t r i p l e n o n - f i r e b l o c k e da i r c r a f t s e a t i g n i t e d w i t h g a s o l i n e . The t e s t work i n c l u d e d t h e i d e n t i f i c a t i o nand q u a n t i f i c a t i o n of e f f l u e n t g a s s p e c i e s produced by t h e f i r e and t h ee x t i n g u i s h i n g chemicals.The p r e s e n t s t u d y d e s c r i b e s t h e comparative e f f e c t i v e n e s s of t h e e x t i n g u i s h e r sused i n t h e above t e s t s and some newer systems i n two d i s t i n c t f i r e t e s t s . Thef i r s t t e s t i s t h e "crib" t e s t used by U n d e r w r i t e r s Laboratory, Inc. t o r a t ehandheld e x t i n g u i s h e r s . The second t e s t i s t h e same s e a t t e s t used i n t h ee a r l i e r work.The t e s t s employed a i r c r a f t approved w a t e r e x t i n g u i s h e r s and Halon 1211e x t i n g u i s h e r s a s benchmarks. New f o r m u l a t i o n s u s i n g s u r f a c t a n t s ande x t i n g u i s h i n g powders i n aqueous s o l u t i o n s were t e s t e d a g a i n s t t h e benchmarkperformance l e v e l s . I n t h e s e t e s t s , c e r t a i n new s o l u t i o n s were a b l e t o meet o rexceed t h e perfarmance of t h e benchmark a g e n t s .

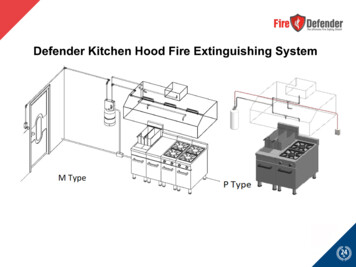

INTRODUCTIONPURPOSE.The purpose of t h i s r e p o r t was t o i n v e s t i g a t e p o t e n t i a l l y new f i r e e x t i n g u i s h i n gf o r m u l a t i o n s and compare them t o systems c u r r e n t l y used i n a i r c r a f t . Twod i s t i n c t f i r e t e s t s were used f o r comparison of e x t i n g u i s h i n g a g e n te f f e c t i v e n e s s . The f i r s t was t h e "crib" t e s t of U n d e r w r i t e r s L a b o r a t o r y , I n c . ,( r e f e r e n c e 1 ) . The second t e s t employed a i r c r a f t t r i p l e s e a t s i n t e s t s s i m i l a rt o t h o s e p r e v i o u s l y u n d e r t a k e n t o e v a l u a t e t h e e f f e c t i v e n e s s of Halon 1211extinguishers (reference 2).BACKGROUND.The h a l o g e n a t e d f a m i l y of chemical f i r e e x t i n g u i s h e r s i s used a l m o s t u n i v e r s a l l yf o r a i r c r a f t f i r e s a f e t y a p p l i c a t i o n s . T h e i r e f f e c t i v e n e s s on a l l " c l a s s e s " off i r e s , e a s e o f a p p l i c a t i o n and t h e absence of problems l i k e o b s c u r a t i o n ,s l i p p e r i n e s s , and cleanup have made them a p r e f e r r e d system. The F e d e r a lA v i a t i o n A d m i n i s t r a t i o n (FAA) i n v e s t i g a t e d two v e r s i o n s of t h e s e systems i n 1982and r e p o r t e d no n e g a t i v e r e s u l t s w i t h t h e i r usage. The p r e s e n t s t u d y wasi n i t i a l l y s t a r t e d t o e v a l u a t e t h e c a p a b i l i t y of a i r c r a f t - a p p r o v e d Halon and w a t e rsystems i n f i g h t i n g f i r e s i n v o l v i n g advanced carbon composite m a t e r i a l s .A d d i t i o n a l emphasis f o r t h i s s t u d y was "The Montreal P r o t o c o l on Substances ThatD e p l e t e t h e Ozone Layer" ( r e f e r e n c e 3). The implementation of t h erecommendations of t h e M o n t r e a l p r o t o c o l would c u r t a i l t h e a v a i l a b i l i t y of t h eh a l o g e n a t e d family of f i r e e x t i n g u i s h e r s . T h i s s t u d y r e p r e s e n t s t h e i n i t i a l s t e pi n a p r o j e c t e d e x t e n s i v e program t o i n v e s t i g a t e a l t e r n a t i v e f l r e f i g h t i n g systemsf o r use i n a v i a t i o n .DESCRIPTIONSCRIB TEST.The C r i b T e s t is d e s c r i b e d i n "Standard f o r S a f e t y :F i r e Extinguishers Rating,"UL 71 1, U n d e r w r i t e r s L a b o r a t o r y , Tnc. ( r e f e r e n c e 1).The wood c r i b i s c o n s t r t i c t e d of l a y e r s of 2 x 2 x 10-inch k i l n d r i e d Spruce. Theg e n e r a l c o n f i g u r a t i o n and s u p p o r t of t h e c r i h i s i l l u s t r a t e d f n f i g u r e 1. Thea l t e r n a t e l a y e r s a r e e v e n l y spaced. A "1A" c r i b i s made of 50 members i n 1 0l a y e r s of 5 members p e r l a y e r . The o u t s i d e members a r e n a i l e d t o g e t h e r f o rsupport.The c r i b is c o n s t r u c t e d on a n g l e i r o n s u p p o r t s p l a c e d on c o n c r e t e b l o c k s 16i n c h e s above t h e f l o o r .I g n i t i o n of t h e c r i b i s accomplished by t h e b u r n i n g of 1 q u a r t of normal heptanei n a s q u a r e pan, 21 x 2 1 x 4 i n c h e s , p l a c e d s y m m e t r i c a l l y under t h e v e r t i c a l a x i sof t h e c r i h .

The following observations and recordings a r e made f o r t h e c r i b t e s t :Times RecordedMin. Sec.ComentsI g n i t i o n of Pan F i r e00Fuel F i r e Consumed00S t a r t Extinguishing00Work from 3 s i d e sStop Extinguishing( B o t t l e Empty)00 /-Record Time,Amount Used,Flame Suppression, F i r eControl, Glowing Coals,Obscuration, S l i p p e r i n e s sS t a r t Timer /-Time RecordedF i r e R e s t a r t , Glowing CoalsF l a r e Up, e t e .T e s t EndedRecord ObservationsFIGURE 1,WOOD CRIB FOR UNDERWRITERS LABORATORY CLASS "A"FIRE TEST

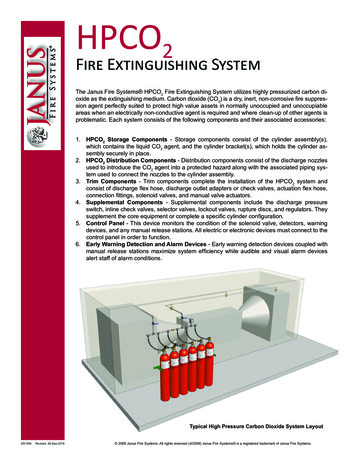

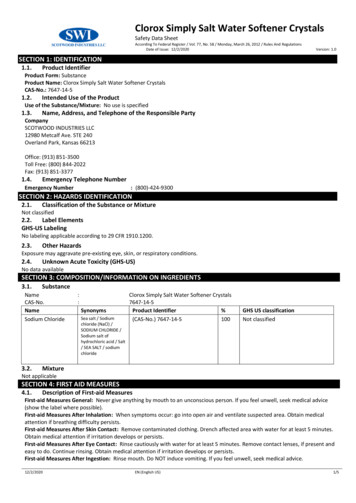

AIRCRAFT SEAT TEST.The a i r c r a f t S e a t T e s t i s r e p o r t e d i n D O T / F A A / C T - / ( r e fI e r e n c e 2 ) . A t r i p l e"unblocked" a i r c r a f t s e a t * i s doused w i t h a l i t e r of normal h e p t a n e and i g n i t e dimmediately. The f i r e is p e r m i t t e d t o burn f o r a p e r i o d of time and t h e n i sa t t a c k e d w i t h e x t i n g u i s h e r s on t h r e e s i d e s . T y p i c a l b u r n i n g materials a r ep o l y u r e t h a n e foam i n t h e c u s h i o n s and wool b l e n d s i n u p h o l s t e r y f a b r i c s .The f o l l o w i n g o b s e r v a t i o n s and r e c o r d i n g s a r e made f o r t h e s e a t t e s t :Times RecordedMin. Sec.CommentsDousing w i t h F u e l0000Amount of F u e l UsedIgnition0001Start FirePreburn TimesRe cordedS t a r t Extinguishing3End T e s t00Record Flamecontrol*", E f f e c t i v e n e s s ,Amount of Media Used,Restart?00T y p i c a l T e s t Time Ending,Record R e s u l t s and O b s e r v a t i o n s*Flew r e g u l a t i o n s went i n t o e f f e c t subsequent t o t h e r e f e r e n c e d e x t i n g u i s h e rt e s t s . These r e g u l a t i o n s l e d t o u s e of f i r e b l o c k i n g l a y e r s c o v e r i n g t h eu r e t h a n e s e a t cushions. The p r e s e n t t e s t s were done w i t h o u t b l o c k i n g l a y e r s s ot h a t comparisons could be made w i t h t h e e a r l i e r t e s t s .**control i s when t h e flames a r e stopped.must n o t r e f l a m e w i t h i n 2 minutes.Red smoldering may b e p r e s e n t , b u tSTATE OF THE ART SYSTEMS (See F i g u r e 2)Chemicals UsedSodium B i c a r b o n a t ePotassium B i c a r b o n a t e ( P u r p l e K)Ammonium PhosphateCarbon DioxideHalon 1211WaterLoaded Stream***P h y s i c a l FormPowderPowderPowderI n e r t GasVaporizing LiquidTap WaterPotassium A c e t a t eNon-Freezing WaterSolutionFire Class CapabilityBCBCAB CBCABCBCAAB***Meets "Class A" of Aerospace Standard AS245A, Water Solution-Type Hand F i r eE x t i n g u i s h e r s . Manufactured by W a l t e r Kidde.

yellow pagesIbA n y Fire ExtinguisherDo N o t I n c i n e r a t eIdHave your extingulsher recharged o r replaced Immediately even if only partially discharged. A momentary discharge could cause total loss o f pressure. Take your extingusher t o a qualified fire extingulsher servlce agency forrecharging, repatrs. o r retest. Look forUFireExtingutshers"tn the telephone direclory.Non-refillable extingutshers should b e discarded and areplacement should be obtalned immediately forcontinuedfire protection.D O NOT DISPOSE OF USED EXTINGUISHER BYTHROWING I N A FIRE. I T COULD EXPLODE, CAUSINGSERIOUS BODILY INJURIES.D O NOTrefill your extingulsher with any materlal otherthan that specified o n the nameplate. The use of any othermater alcould cause faulty performance o r cause damaget o theextingu shercaustngit to rupture, resulttng I n bodilytnjurles.Only parts recommended by Badger-Powhatan shouldbe used for replacement I n servicing your extinguisher.AFTER USEMARINETYPEEXTINGUISHERS.U.S COASTGUARDMARINEAPPROVALIS ONLY VALID WHEN THE EXTINGUISHER I S EOUIPPEO WITH ANAPPROVEO MARINE TYPE BRACKET. SEE EXTINGUISHER LABELUNDERWRITERSMANIFEST FOR APPROVEO BRACKET DESIGNATION.For:ServiceechargeRepairFIGURE 2.STATE OF THE ART SYSTEMS ( 1 of 2)IIlhtsext ngu sherhas not been prevtously dtscharged and hasnot been misused, damaged alter purchase or Improperly malntamed. Badger- owhatanw llreplacelhtsextinguisherif it is foundto be defectivewithin one year alter dateof manulactureshown onthe exthnguisher label.Thls warranty 1s extended only to the ortgmal consumerpurchaser.TO obtatn warranty performance. the extingulsher should bebroughttoorlglnal placeol purchase where it will beexamlned.anda replacement made if thls warranty applies. For additional warranty mformation.the purchaser may write: Consumer Information,Badoer-Powhatan. P.O. Box 6159. Chartottesvilte.Va. 22906.A IMPLIEDLWARRANTIES. IF ANY. SHAU EXPIRE ONEYEAR FROM THE DATE OF MANUFACTURE. Some states do notailow limitatrons on how long an implied warranly lasts, so theabove iimltallon may no1 apply to you.BADGER-POWHATANIS NOT RESPONSIBLE FOR DAMAGETO PROPERTY CAUSED BY THE FAILURE OF THIS EXTINGUISHER TO OPERATE PROPERLY.IFTHIS EXTINGUISHER ISUSED CN A C O M M E R A LSETnNG. BADGER-POWHATANISNOT RESPONSIBLE FOR ANY INJURIES TO PERSONS ORDAMAGE TO PROPERTY CAUSED BY THE FAILURE OF THEEXTINGUISHER TO OPERATE PROPERLY. Some states do notallow the exclusion Or llm latlonof Incidental or consequentialdamages. sothe aboveitmltatlonorexclusron may not apply to youThis warranly gives you speclflc legal rights. and you may alsohave other rtghts which vary from state to stateLlMlTED WARRANTYIf your extmgu sherbears thts symboli t can b e tfsed o n live electrtcalequcpment.If your extlngulsher bears thls symbol.i t can be used o n gasoline, oil, grease.and other flammable liqulds.If yourextinguisher bears thls symbol.i t can be used o n paper. cloth, wood,upholstery, and other ordinary combustibles.FIRE CLASSlFlCATlOM SYMBOLSrionnual

.-IALWAYSAPPLY THE AGENTAND WORK IT AWAY wtTnA SWEEPING YOTIONTO THE BASE OF THE FlRECt2. Get everyone out.3 Plan your retreat.4. The contents are discharged by pressure -DO NOTSTAND ADISCHARGE AT A PERSON'S FACEMINIMUM OF 6' to 10' FROM THE FIRE.5 Hold the ext ngu sherfirmly In an uprlght position.6. Stay low to amid inhalation of smoke and aim discharge just under the flames, ustng a side to s d emotion.sweeptng the entlre width of the fire. For wall fires, start atthe bottom, sweep from side to side, and progress uward.For floor fires. sweep from side to slde and move fomard asfire dim ntshesto reach far edge of fire7. NEVER move Into area where fire was bummg eventhough 11appears to have been extingu shed.You could betrapped and burned ifthe lire reflashes.8. NEVER use water ext ngu sherson electrical fires.9. NEVER use exttngu shersat distances of less than 6to I0 feet.1. Call the fire department.I n care of fireOPERATION AND USEBe sure you understand the nstructlonsso that there willbe no delay 11a ttre occurs Before using your ext ngu sher.also read the operatmg tnstruct onson the exttngu sherlabel carefully Be sure you understand the nstructtonsInlh smanual and on the extlngu sherlabel Also be sure thatihose persons havmg access to th sextmgu sherare Informed of 11s operatson The total dlschsrge of entingulsher contents is a matter of seconds. therefore. anydelay should be svoldedBEFORE INSTALLING YOUR FlRE EXTINGUtSHER.CAREFULLY READ THE FOLLOWING OPERATIONALINSTRUCTIONS.Vaporizing LiquidAn inert GasTap WaterPotassium BicarbonateBASIC AGENTSodium BicarbonateAmmonium PhosphateFIGURE 2.ISTATE OF' THE ART SYSTEMS (2 o f 2)TopF; ,4FLOOR LINE-Mount your extmgu sheruprlght in a locatlon that IS easyto reach Clean dry locattons near exlts are recommendedBe sure that mountlng hardware (screws, rtvets, etC Is ofthe proper type and slze to assure a poslttve mounflngYour ext ngu shershould be mounted so that the top ISnot more than 3M to 5 feet from the floorDo not locate tn an area that w l lexceed 120 FtemperatureWater ext ngu shersshould be protected from freermgunless a loaded stream agent has been addedDo not use any other than Badger's AC-40 LoadedStream-1I1Exttngu shenshouldbe installed in accordancewlth theNat onalFtre Protection Assoc ation' standard "PortableFtre Extlngulshen," NFPA No. 10.'AddressBatteryrnarch Pa*,Oulncy. Mass 02269INSTALLATIONa@LABA-B e-Am @El@MAY BE USED ONI Potassium Acetate,I1 Non-Freezing Water Solution IIIBe sure that the extmguisher IS tn 11s proper locatlon sothat there WIN be no delay In case of flreYour extlngursher should be checked once each monthor more frequently 11necessary to determine that1 The pomter on the pressure gauge IS in the greenoperable area2 The nozzle opening has not been closed wlth somefore gnobject3 A rcng pull pln IS prov dedto prevent acc dentaldlscharge This ptn IS secured by means of a plast cwarelockseal On some models, the carry handle IS sealed Inplace by a lape crosslng over the lower portlon Check tomake sure that the lockseai IS intact A broken iockseai ISan mdtcat onof tampermg and that there may have been apartlal or total loss of contentsat lead every six months. and4 We ghthe ext ngu shertf below the wecght des gnatedunder 'Mamtenance' on theext ngu sherlabel, the exttngu shershould be rechargedINSPECTION & CARELoaded StreamHalon 1211I1WaterCarbon DioxideTYPE EXTINGUISHERT g u l a T ( o r d i n a r y ) Dry ChemicalMulti-Purpose (ABC) Dry ChemicalP u r l e"K" Drv ChemicalIFlRE EXTINGUISHERS AND AGENTS

FORMULATIONS FOR NEW SYSTEMSLoaded Stream TypesP o t a s s i u m A c e t a t e NonfreezingWater S o l u t i o n s ( P e r c e n t by *-----107------23Formula No.Potassium A c e t a t eE t h y l e n e GlycolFoaming Agent**Freezing Point***Aqueous Film Forming Foam (AFFF) 3 p e r c e n tMIL SPECF-24385CF f u o r o p r o t e i n Foam L i q u i dN a t f o n a l Foam Co.3 percentXL3

Water Solutions of Sodium Bicarbonateand Potassium Bicarbonate (Purple K)(Percent by Veight)Formula No.VPa tassium Bicarbonate48*Sodium BicarbonateEthylene Glycol,WaterSurfactantFoaming Agent--646-----Freezing Point-5 OFCornmen tsViscous*Maximum Practical Solution Concentrationsviscous

Water Solutions of Ammonium Phosphates(Percent by Weight)'Formula No.IXXXIXI 1Monoammonium Phosphate25*25*------Diammonfum PhosphateEthylene GlycolWaterSurfactantFreezing Point------629*2 9*66669666560---3---55 OF5 OF*Maximum Practical Soluble Concentration, Diammonium Phosphatehad Higher Solubflf ty in Water (reference 4) than MonoammonfumPhosphate.

TEST RESULTSSTATE OF THE ART SYSTEMS.ABC Power (2 314 l b s . min.)Crib TestTimeMin. Sec.CommentsStart FirePan F i r e OutS t a r t TestOne B o t t l e UsedF i r e OutNo R e s t a r tSeat T e s t s-ATimeMin. Sec.Douse with Fuel,1gnit'eDouse with Fuel,Ignf t e00-BTimeMin. Sec.CommentsP i n t of Fuel000000Quart of FuelS t a r t T e s t (A)F i r e Out, OneB o t t l e UsedS t a r t Test (B)0100Seat T o t a l l yBurning01503 B o t t l e s Used, Good FlameKnock-Down, Burn UnderControl0300No Ref laming

Sodium Bicarbonate Powder(2 314 l b s . min.)Crib TestTimeMin. Sec.CommentsStart Fire0110Pan Fire Out11304 Bottles UsedFlames Down But RestartsQuickly1200End TestStart TestSeat TestsTimeMin. Sec.Douse with FuelComments0000Pint of Fuel0020Fire OutNo RestartStart TestStare BC Powder

TimeMin. Sec.CommentsStart FireS t a r t Test0110Pan F i r e Out100012004 B o t t l e s UsedFlames Down ButR e s t a r t s Quickly1210End TestS e a t TestTimeMin. Sec.Douse with Fuel00Ignite03S t a r t PK Powder03CommentsQuart of Fuel302 B o t t l e s UsedF i r e Out00No R e s t a r t

Carbon Dioxide (C02)Crib T e s t sThe C02 handheld e x t i n g u i s h e r s w i l l n o t e x t i n g u i s h a "lAf' c r i b . A t y p i c a l b o t t l eof C02 (5 l b s . ) w i l l have l i t t l e e f f e c t o r c o n t r o l of a "lA" c r i b f i r e . Fiveb o t t l e s (25 l b s . ) w i l l not e x t i n g u i s h a "1A" c r i b f i r e .Seat Test With C02ATGMin. See.-BTimeMin. Sec.CommentsP i n t of FuelQuart of FuelDouse with Fueland I g n i t e00S t a r t Extinguishing (A)0015Upholstery Burning, ButNot Foam0025F i r e Out,No R e s t a r tS t a r t Extinguishing (B)"25 l b s . used.000000a0100Seat T o t a l l yBurning0P455 B o t t l e s Used, Flames a r e xinguished*t0245No Flames0300-Test Stopped

Halon 1211.Crib TestThe handheld Halon 1211 b o t t l e w i l l not e x t i n g u i s h a "1A" c r i b f i r eIt r e q u i r e s 3 b o t t l e s of Halon 1211 ( 9 l b s . ) t o e x t i n g u i s h a "1.A" c r i b(3 I b s . ) .without f i r e r e s t a r t (weights checked b e f o r e and a f t e r t e s t s ) .Seat Tests with Halon 1211-Min. See.BTimeMin. Sec.CommentsDouse with FuelP i n t of Fuel.Quart of Fuel.S t a r t Extinguishing (A)Upholstery Burning, ButNot FoamF i r e OutS t a r t Extinguishing (B)Seat T o t a l l y Burning3 B o t t l e s Used, F i r e S t i l lBurningF i r e Smoldering, But NotFlamingTest Stopped With WaterThis t e s t was repeated with t h e same r e s u l t s .

Tap WaterI n a l l of t h e w a t e r and w a t e r s o l u t i o n s t e s t s , 1000 c e ' s of media a r e used p e rb o t t l e . The p r o p e l l a n t i s a C02 c a r t r i d g e .Crib TestTimeMin. Sec.CommentsStart FireF u e l F i r e OutS t a r t ExtinguishingOne B o t t l e Has L i t t l e E f f e c tSecond B o t t l eThird B o t t l eS l i g h t E f f e c t on Flames, ButMany Red CoalsFlames Growing L a r g e rEnd T e s t

NEW SYSTEMS.Loaded Water TypeFormula No. ICrib TestTimeMin. Sec.Comments00S t a r t Pan F i r e15Fuel Consumed00S t a r t Extinguishing45F i r s t Bottlea30Second B o t t l e Used Flames O u t ,But Glowing Coals P r e s e n t00Coals Glowing Red, But NoR e s t a r t of FlamesSeat T e s t sS e a t Test With Loaded WaterMin. Sec.BTimeMin. Sec.Start Fire00S t a r t Extinguishing (A)00CommentsP i n t of FuelQuart of FuelUpholsteryBurningF i r e Out, One B o t t l e UsedS t a r t Extinguishing (B)Seat T o t a l l yBurning3 B o t t l e s Used, Flames Outof ControlFlames Growing

Loaded WaterFormula No. I1Crib TestsTimeMin. Sec.CommentsStartFuel ConsumedS t art ExtinguishingBottle EmptyFlames SuppressedSome Glowing Red CoalsFire RestartedFf re Growhg SlowlyEnd Test"

Loaded WaterFormula No. 111Crib T e s t sTimeMin. Sec.StartCommentsStart FireF u e l ConsumedS t a r t ExtinguisherB o t t l e EmptyFlames OutSome Red CoalsRed Coals GlowingNo FlamesF l o o r i s very s l i p p e r y

Loaded WaterFormula No. I VCrib TestsTimeMin. Sec.CommentsS t a r t Pan F i r eF u e l ConsumedS t a r t ExtinguishingB o t t l e EmptyA L i g h t Covering of Soapy FoamCovers Wood Members; FlamesSuppressed, But Many Red CoalsFlames R e s t a r t i n gGood F i r eThe f l o o r around t h e t e s t a r e awas v e r y s l i p p e r y .

Water S o l u t i o n of Potassium BicarbonateFormula No. VCrib T e s t sTimeMin. Sec.StartComments00000115F u e l Consumed1000S t a r t Extinguishing1045B o t t l e EmptyA Whitish F r o t h Covers t h eWood, But D i s s i p a t e s SlowlyF i r e Out, No R e s t a r tFloor S l i p p e r y

Water Solutions of Sodium BicarbonateFormula No. VSIICrib TestsTimeMin. Sec.CommentsStartFuel. ConsumedStart ExtinguishingB o t t l e EmptyFroth on WoodNo RestartFloor Slippery

Water S o l u t i o n s of Monoammonium PhosphateFormula No. IXCrib TestsTimeMin. Sec.CommentsStartF u e l ConsumedS t a r t Ext i n g u i . s h i n gB o t t l e EmptyF i r e OutNo CoalsNo R e s t a r t

Water Solutions ofDiammonium Phosphate Plus S u r f a c t a n tFormula No. X I 1Crib T e s t sTimeMin. See.StartFuel ConsumedS t a r t ExtinguishingF i r e OutB o t t l e EmptyNo CoalsF i r e Out, No CoalsSeat TestsTimeMfn. See.CommentsStart FireQuart of FuelS t a r t ExtinguishingSeat To t a l . l y Burning3 B o t t l e s UsedF i r e Under ControlSmall F i r e Smoldering,But Not I n c r e a s i n g

SUMMARYTable 1. shows that, with use of various compositions of powders and surfactantsin aqueous solution, a range of fire-fighting capabilities can be generated.This provides a promising approach far possible Halon substitutes for aircrafthand extinguishers.Beyond fire-fighting effectiveness, there are other issues that would have to beaddressed. They are primarily issues af shelf-life, corrosiveness, and freezingpoint.

TABLE 1.SUMMARY OF TEST RESULTSCrib Test'"A''crib*Seat TestQuart of F u e l , 60 Sec P r e b u r nHalon 1 2 11FAIL3 B o t t l e s t o ManagefControlTap WaterFAIL3 Bottles FailureFormula IFAIL3 Bottles FailureFormula I1FAILFormula T I 1PASSFormula I VFAILLoaded Water.------------------FAIL5 B o t t l e s t o ExtinguishPASS3 B o t t l e s t o ControlPowder (Sodium B i c a r b o n a t e )FAILPowder (Potassium Bicarbonate)FAIL-----2 B o t t l e s t o ControlBicarbonatesFormula VPASSFormula V I I IPASSPhosphatesFormula I XPASSFormula XPASSFormula X IPASS----------------Formula X I 1PASS3 B o t t l e s t o ManagefControPResults with------* Nottestedone b o t t l e

CONCLUSIONS1.Water s o l u t i o n s of t h e powder systems a r e more e f f e c t i v e than t h e c u r r e n tloaded water systems employing potassium a c e t a t e .2.Water s o l u t i o n s of t h e phasphates plus s u r f a c t a n t a r e t h e most e f f e c t i v esystems.3.A water s o l u t i o n of diammanium phosphate and s u r f a c t a n t performs s u p e r i o r t oHalon 1211 i n the wood c r i b t e s t and equal t o Halon 1211 i n t h e urethanefoam, wool f a b r i c upholstery s e a t t e s t s .4.The a c e t a t e and phosphate s a l t s work t o r e t a r d r e s t a r t af flaming i n t h et e s t s . This is not t r u e of t h e bicarbonates.5.The l e n g t h of time between i g n i t i o n and s t a r t of extinguishing i n t h e s e a tt e s t i s an i n f l u e n t i a l parameter i n t h e e v a l u a t i o n of t h e comparativee f f e c t i v e n e s s of the extinguishing m a t e r i a l s . The longer t h e burn time, t h emore d i f f i c u l t t o c o n t r o l .6.The a i r c r a f t s e a t t e s t f i r e responds t o extinguishing mare l i k e a Class Bf i r e than a Class A f i r e .REFERENCES1.Underwriters Laboratory, Inc.,Rating. UL 711.Standard f o r Safety:F i r e Extinguishers2.H i l l , R., and S p e i t e l , L., In-Flight A i r c r a f t Seat F i r e ExtinguishingT e s t s , FAA Report No. DOT/FAA/CT-82/111,1982.3.The Montreal Protocol on Substances That Deplete t h e Ozone Layer, 1986.(Federal Register/Vol. 52, No. 239, 1987.)4.Solyer, I., Griffen, C., and Duvall, D., Intumescent F i r e Extinguishingsolution ,' U.S.Patent 4, 588, 510; 1986.-

The purpose of this report was to investigate potentially new fire extinguishing formulations and compare them to systems currently used in aircraft. Two distinct fire tests were used for comparison of extinguishing agent effectiveness. The first was the "crib" test of Underwriters Laboratory, Inc., (reference 1).