Transcription

PURELAB Innovation and FlexibilityLab Water Purification Solutionsfor your Research Needs

About ELGAELGA. The LabWater SpecialistsWe are the LabWater Specialists. We have beenworking with scientists since 1937 to guaranteeultrapure and pure water for their experimentsand lab work. We resource science and healthcaremarkets for a better world by bringing the world’sleading scientists a critical reagent.Why choose ELGA as your laboratory water partners?3 Customer-focused – what we create is for ourcustomerOur commitment to developing and providingyou with ultrapure water means that you canfocus and concentrate on obtaining accurate andreliable results.3 Innovative – the keystone of our thinkingOur UK R&D facilities are always looking toprovide products dedicated to supplying youwith the right water quality for your application.3 Sustainable – at the forefront of all of ouractivitiesAt ELGA we are experiencedin meeting the challengesthat arise during thedevelopment, installationand servicing of singlepoint-of-use purificationsystems as well aslarge projects involvingconsultation, consultantsand clients.2www.elgalabwater.comOur products are designed to have the lowestpossible impact on the environment at all stages:manufacture, in service and at end of life. We cancalculate the carbon value of all our productsthrough their lifetime.3 British Engineered – the standard for all ourproductsAll our systems are manufactured in the UK andwe are accredited to ISO:9001 and ISO:14001standards.Our Awards

My WaterA trusted brand deliveringyou choiceThe RangeWe understand how important it is for scientists toobtain a choice of water qualities that range fromRO grade for simple routine washing and rinsing,through to ultrapure water for the most criticalapplications.With this in mind, we have applied our expertise,gained since 1937 in water purification innovationto design the unrivalled PURELAB range. Our reliablewater purification systems are constructed from thehighest quality components to ensure optimalpurity, while a rapid and easy sanitization programcontributes towards an uninterrupted workflow.Built-in economical processes results in the lowestconsumables costs with the highest water qualityand precision.PURELAB Chorus 1& Halo DispenserPURELABChorus 1 CompletePURELABChorus 2 PURELABflex 1 & 2PURELABChorus 2 & 3PURELABflex 3 & 4At ELGA we do not speculate or work onassumptions about your water quality. On our firstvisit to your laboratory we will carry out a test, onsite, that analyzes your feed water quality.We understand that future needs change and sowe have developed a unique and modular set ofsolutions that can grow as you and your lab grow.You do not need to feel restricted to one solutionfor the next 10 years.*Type I Type IType II Type IIResistivity18.2 MΩ.cmResistivity 18 MΩ.cmResistivity 10 MΩ.cmResistivity1-10 MΩ.cmPURELABChorus 1Type IIIConductivity1-0.1 µS/cmConductivity1-50 µS/cmPURELABChorus 1CompletePURELABChorus 2 (RO/EDI/UV)PURELABChorus 2(RO/DI)PURELABChorus 3PURELABflex 1, 2, 3 & 4PURELABChorus 2 (RO/DI/UV)PURELABflex 1PURELABflex 1, 3 & 4*PureSure Technology/In-line filtration/Variety of purification packswww.elgalabwater.com3

TechnologiesThe various technologies used in ELGA equipment are able to remove impurities fromwater down to extremely low levels; some technologies focus on specific contaminantswhile others have a broader spectrum of targets. To achieve the correct water purity fora particular application, in a cost effective manner, technologies must be arranged incombination and their operation optimized.Activated CarbonCarbonMatrixSmall and largeorganic moleculesPores availableto both smalland largemoleculeadsorptionPores availableonly to smallmoleculeadsorbtionContains a maze of tiny pores with sizes ranging from 0.1– 2.9nmand a surface area of about 1000 square meters per gram. The natureof this surface allows adsorption of organic impurities from thewater and catalytic decomposition of free chlorine and, more slowly,chloramines.It is applied in: Pre-treatment cartridges Composite Vent filters Final Purification cartridgesMicroporous Depth FiltersPre-filtration using microporous depth filters, provides an entrapment/adsorption barrier for the removalof large suspended particles and some colloids from the water entering the ELGA purification process.Typically rated at 5 – 10µm and combined with an activated carbon treatment, these filters act to protectsubsequent RO systems from fouling and blockage.Reverse OsmosisFEEDWATERRO MODULEReverse osmosis (RO) is a process where pressure is used to push waterthrough a membrane filter in a cross-flow fashion. RO-membranes areextremely fine filters and reject water contaminants that are less than1nm diameter. Typically 95% of ionic impurity, most organic impurity,and nearly all particulates, bacteria and bio-molecules are removedfrom the permeate water; these are carried out of the RO module in awaste or concentrate water stream.PERMEATECONCENTRATE4www.elgalabwater.com

TechnologiesIon ExchangeIon exchange resins are often used as part of a final treatment step. Single-use purification packstypically use a mixture of ion-exchange resins and other media. When used to deionize water, chargedimpurities are retained on these resins, while H and OH - ions (which combine to form water) arereleased to replace them. This is a highly efficient process and can remove ions to give product-waterresistivity of up to 18.2 MΩ.cm.ElectrodeionizationElectrodeionization (EDI) combines ion-exchange resins and ion-selective membranes, which are usedto move ionic impurities into a waste or concentrate water stream leaving purified product-water. Asimpurities leave via the concentrate water stream, their build-up does not exhaust the resin, and thereforeprolongs resin lifespan. A single EDI unit may operate for many years before a replacement is required.Typically product water resistivity of 10 MΩ.cm is consistently achieved using this process. This technologycan be used as an alternative to single-use purification cartridges.Ultraviolet (UV) LightGlass Quartz HousingWater FlowUV LampTreatment of water with UV-C light is used to photooxidise organic impurities and/or inactivate microorganisms. Photo-oxidation of organic impurities resultsin polar or charged species that can subsequently beremoved by ion-exchange processes. Typically the UVlamp forms part of a ‘polishing’ treatment loop includingion-exchange, through which water is repeatedlycirculated to maintain quality. Water with Total OrganicCarbon (TOC) of 5ppbC and bacteria at 1CFU/ml can beachieved in ELGA products that use this approach.Sub-Micron FiltrationSub-micron filtration, including micro, ultra-micro and ultra filters (30–3000nm) are used as part of a‘polishing’ loop or at the point-of-use. Fine filtration is applied to remove bacteria (live or dead) andbiologically active molecules. These absolute filters have pores smaller than their intended target andcan retain the impurity while allowing water to pass through. Impurities that are removed by sub-micronfiltration, include bacteria, colloids, enzymes, endotoxins and particulates.www.elgalabwater.com5

PURELAB Chorus 1Type I WaterLiters per day:Depends on feedwater18.2 MΩ.cmKey Features3 Real-time TOC3 Fully re-circulating3 Integrated filtration3 Multiple dispensingLife Science Analytical Research General ScienceIdeally suited for: Mass SpectrometryIon ChromatographyUltra trace AnalysesQualitative AnalysesGas Chromatography Molecular BiologyCell CulturesElectrochemistryImmunochemistryAtomic Spectroscopy3 PureSure technologyFlexible. Configurable. Simple.Delivering the ultimate in water purity for absolute confidence in your resultsWhen you require the ultimate in water purity, PURELAB Chorus 1 provides the perfect solution.Consistently delivering water purity of 18.2 MΩ.cm (Type I /I) and underpinned by the advanced PureSure deionization system, the PURELAB Chorus 1 enables you to focus on attaining accurate results whileensuring an uninterrupted work flow.Advanced PureSure DeionizationA twin-bed ion-exchange process with inter-stageresistivity monitoring allows retention of anyimpurity released during exhaustion of a primarycartridge, by the secondary polishing cartridge. Thismethod gives guaranteed, optimum, product-waterquality, advanced warning of consumable change,and extended consumable service life.PrimaryPurificationPackModel shown is PURELAB Chorus 1with Advanced Halo DispenseIntegrated FiltrationUltrafiltration or microfiltration filters outendotoxins, proteins, nucleases and particulates.Full Spectrum UV TreatmentData CaptureData capture via USB for system performancevalidation and software PackIntermediateWater PuritySensor R1Output WaterPurity Sensor R2Fully RecirculatingEnsuring microbial purity and guaranteeing purewater at the point-of-use.Real-time TOC MonitoringProvides complete confidence in organic purity.

Process Flow PURELAB Chorus 1 – Ultrapure Water for Analytical Research ApplicationsPURELAB Chorus 1Life Science Analytical Science General ScienceProcess Flow PURELAB Chorus 1 Analytical t purified Water)Outlet toDispenserHalo Advancedor Halo Flexible DispenserWaterPuritySensorPOU Filters(Optional)Purified WaterOutletPumpPrimaryPurificationPackUV rainSpecificationsTREATED WATER SPECIFICATIONSAPPLICATIONLIFE SCIENCEANALYTICAL RESEARCHGENERAL SCIENCEDispense FlowrateUp to 2.0 l/min†Up to 2.0 l/min†Up to 2.0 l/min†Inorganics @25oC18.2 MΩ.cm18.2 MΩ.cm18.2 MΩ.cm1-3 ppb*1-3 ppb*3-10 ppb* 0.001 CFU/ml 0.001 CFU/ml 0.001 CFU/ml 0.001 EU/ml 0.001 EU/ml‡ 0.001 EU/ml‡Effectively neutralEffectively neutralEffectively neutralParticles (filtration) 0.01 μm 0.05 μm0.2 µm RNase 1 pg/ml 1 pg/mlDNase 5 pg/ml 5 pg/mlTotal organic carbon (TOC)BacteriaBacterial EndotoxinpHPurification pack capacityLiters to 18.2 MΩ.cm 94,100/(μS/cm (2.3 x ppm CO2))* Dependant on feed water – recommended feed 50 ppb TOC With LC134/145/197 POU filter/Biofilter†When connected to Halo, Advanced or flexible ‡ With LC197 BiofilterSource – originally from potablesupply, then pretreatedFEEDWATER REQUIREMENTFouling index (max)Preferably RO produced by PURELAB Chorus 3 or filtered service deionization (SDI) ordistilled. Note: mixed bed or twin bed deionized supplies should be cation limited atexhaustion1 for all models. A 5-10 micron membrane prefilter is recommendedfor all non-RO feedsService deionization (SDI) – MΩ.cm1 MΩ.cm minimum resistivity at exhaustionReverse Osmosis (RO) – μS/cmRecommended 30 μS/cmFree Chlorine0.05 ppm maxTOC 50 ppb max (RO feed)Carbon dioxide30 ppm (max recommended)Silica2 ppm (max recommended)ParticulatesFiltration down to 5-10 micron advisable to protect internal and/or point of use filtersTemperature1-35oC (Recommend 10-15oC)Flowrate (maximum requirement)130 l/hr (34 USG)Drain requirementsUp to 2 l/min (0.5 USG)Feedwater pressure0.7 bar (10 psi) maximum; 0.07 bar (1 psi) minimum* Fit LA652 Pressure Regulator where feedwater pressure exceeds specified limitsDimensionsWeightHeight 435mm, Width 375mm, Depth 340mm19 kg (42 lbs)19 kg (42 lbs)18 kg (40 lbs)www.elgalabwater.com7

PURELAB Chorus 1 CompleteType I WaterLiters per day:Up to 48018.2 MΩ.cmKey FeaturesIdeally suited for:3 Tap-to-ultrapure Mass Spectrometry Gas Chromatography Electrochemistry General Laboratory3 Fully re-circulating3 Integrated filtration3 Multiple dispensing Molecular Biology Atomic Spectroscopy Liquid Chromatography Immunochemistry SpectrophotometryFlexible. Configurable. Simple.One complete solution for the laboratoryPURELAB Chorus 1 Complete provides a complete solution from potable tap water supply to ultrapurewater, and is ideal for laboratories needing up to 480 liters of 18.2 MΩ.cm ultrapure water. With its easy touse ergonomic design, water can be measured and dispensed with confidence directly from the system orfrom a choice of additional Halo Dispensers.Fully RecirculatingRecirculation of purified water through ourmodular reservoir to maintain consistent peakwater purity at 18.2 MΩ.cm.ELGA Biofilter (optional)When fitted, PURELAB Chorus 1 Complete produceswater which is free from biologically activeimpurities.Single System SolutionPerfect single system solution for analytical and lifescience applications requiring 18.2 MΩ.cm.Reduced Maintenance TimesQuick and easy replacement of consumables aswell as semi-automated sanitization to reducemaintenance times.Space Saving DesignDesigned to be modular and stackable to savespace, whether wall-mounted or under the bench.Data CaptureEconomicalData capture via USB for system performancevalidation and software updates.Optional CO2 removal from the purified water(post RO) increasing the life of downstreamconsumables.8www.elgalabwater.com

CompletePURELAB Chorus 1 CompleteProcessFlowfor PURELABChorusChorus 1 CompleteProcessFlowPURELAB1 CompleteWater ingModule*ReverseOsmosis SanitizationPortFeedwaterInletPump feed fromReservoirRecirculation PumpOutletUVLampWater PuritySensorBoostPump*PurificationPack*Optional second RO module for the 20I variant onlyOutlet to HaloDispenser(optional)and ationsAPPLICATIONPURELAB Chorus CompleteTREATED WATER SPECIFICATIONSNominal output at 15oC10 l/hr20 l/hrDispense Flowrate 1.5 l/min 1.5 l/minInorganics @25oC18.2 MΩ.cm18.2 MΩ.cmTotal organic carbon (TOC) 5 ppb 0.001 CFU/ml 0.001 CFU/ml 0.001 EU/ml‡ 0.001 EU/ml‡Effectively neutralEffectively neutral0.2 µm0.2µm!RNase 1 pg/ml 1 pg/mlDNase 5 pg/ml 5 pg/mlBacteriaBacterial EndotoxinpHParticles (filtration)!Liters to 18.2 MΩ.cm 94,100/(μS/cm (2.3 x ppm CO2))Purification pack capacity With LC134/145/197 POU filter/BiofilterSourceFEEDWATER REQUIREMENT 5 ppb ‡With LC197 Biofilter With LC134/145 POU filter!Potable mains water supplyFouling index (max) 10Free Chlorine0.5 ppm maxCarbon dioxideIdeally 20 ppmSilica30 ppm (max recommended)Temperature1-35oC (Recommend 10-15oC)Flowrate (maximum requirement)Drain requirementsFeedwater pressure130 l/hr (34 USG)Up to 2 l/min (0.5 USG)4.0 bar (60 psi) min; 6 bar (90 psi) max*With boost pump: flooded suction (min) to 2.0 bar (30 psi) max* Fit LA652 Pressure Regulator where feedwater pressure exceeds specified limitsDimensionsHeight 679mm, Width 376mm, Depth 353mmWeight (with boost pump)17 kg (38 lbs)18 kg (40 lbs)Weight15 kg (33 lbs)16 kg (36 lbs)www.elgalabwater.com9

PURELAB Chorus 2 Type II WaterLiters per day:Up to 216 10 MΩ.cm(RO/EDI/UV)Key FeaturesIdeally suited for:3 Tap to Type II Electrochemistry Feed to Ultrapure Water Cell Culture Media / Buffer Preparation Spectrophotometry General Chemistry3 Fully re-circulating3 Multiple dispensingFlexible. Configurable. Simple.One complete solution for the laboratoryPURELAB Chorus 2 (RO/EDI/UV) features our patented recirculating EDI technology: the only EDI system onthe market that is able to fully recirculate to achieve 10 MΩ.cm.The PURELAB Chorus 2 provides additional bacteria and inorganic quality for sensitive analytical and lifescience applications above that of basic laboratory work. With its simple design and ease of use, water canbe measured and dispensed with confidence from the system or from a choice of additional Halo Dispensers.Fully Recirculating EDIELGA’s patented fully recirculated EDI provides aconstant supply of high purity that guarantees aminimum of 10 MΩ.cm water at all times.Ideal for High Volume LabsA cost-effective solution for laboratories requiringhigher output volumes thanks to the incorporatedEDI technology.Single System SolutionPerfect single system solution for analytical and lifescience applications.Reduced Maintenance TimesQuick and easy replacement of consumables aswell as semi-automated sanitization to reducemaintenance times.Space Saving DesignDesigned to be modular and stackable to savespace, whether wall-mounted or *under the bench.EconomicalData CaptureOptional CO2 removal from the purified water(post RO) increasing the life of downstreamconsumables.Data capture via USB for system performancevalidation and software updates.10www.elgalabwater.com*If fitted with Halo dispenser

PURELAB Chorus 2 (RO/EDI/UV)Process Flow PURELAB Chorus 2 (RO/EDI/UV)Process Flow PURELAB Chorus 2 (RO/EDI/UV)Water ingModule*ReverseOsmosis Pump feed fromReservoirRecirculation PumpOutletOptimizerCartridgeEDI ModuleBoostPump*Temperature DispenseSensorTapUVLampOutlet to HaloDispenser(optional)and ReservoirWater PuritySensorFeedwater SanitizationInletPortFlowSensor*Optional second RO module for the 20I variant onlyDrainDrainSpecificationsPURELAB Chorus 2 (RO/EDI/UV)TREATED WATER SPECIFICATIONSAPPLICATIONNominal output at 15oCNominal daily output10 l/hr*20 l/hr*216 l/day216 l/dayInorganics @25oC10 to 15 MΩ.cmOrganics (MW 200 Dalton) 99% rejectionTotal organic carbon (TOC) 10 ppbBacteria 0.001 CFU/ml pHEffectively neutralParticles (filtration)0.2µm!* Standard conditions are 4 bar inlet pressure at 15oC, fed with potable water and a clean pre-treatment cartridge. Refer to flowtables outside these conditions. ! With LC134/145 POU FilterSourcePotable mains water supplyFEEDWATER REQUIREMENTFouling index (max) 10Conductivity 1400 μS/cmFree Chlorine0.5 ppm maxHeavy Metals (max)0.05 ppmSilica30 ppmTemperature1-35oCFlowrate (maximum requirement)100 l/hr (27 USG)Drain requirements80 l/hr (21 USG)Feedwater pressure4.0 bar (60 psi) min; 6 bar (90 psi) max*With boost pump: flooded suction (min) to 2.0 bar (30 psi) max*Fit LA652 Regulator where feedwater pressure exceeds specified limitsDimensionsHeight 679mm, Width 376mm, Depth 353mmWeight (with boost pump)21 kg (46 lbs)22 kg (49 lbs)Weight18 kg (40 lbs)19kg (42 lbs)www.elgalabwater.com11

PURELAB Chorus 2 Type II waterLiters per day:Up to 480 10 MΩ.cm(RO/DI/UV)Key FeaturesIdeally suited for:3 Tap-to-Type II Electrochemistry Media / Buffer Preparation Spectrophotometry General Chemistry Feed to Ultrapure Water Cell Culture3 Fully re-circulating3 Multiple dispensingFlexible. Configurable. Simple.One complete solution for the laboratoryPURELAB Chorus 2 (RO/DI/UV) provides pure water (Type II ) from potable tap water supply for laboratoriesrequiring up to 480 liters per day and is able to fully recirculate to achieve 10 MΩ.cm at all times. Itprovides additional bacteria and inorganic quality for sensitive analytical and life science applications abovethat of basic laboratory work. With its simple design and ease of use, water can be measured and dispensedwith confidence from the system or from a choice of additional Halo Dispensers.Fully RecirculatingIn addition to simple composite vent filtration, thePURELAB Chorus 2 is the only fully recirculating TypeII pure water system on the market, maintainingconsistent peak water purity at 10MΩ.cm.ConfigurationAbility to configure multiple systems to increaseflow rate and save space through stackable solutionsthat can be wall mounted, on or *under the bench.Reduced Maintenance TimesQuick and easy replacement of consumables aswell as semi-automated sanitization to reducemaintenance time.Data CaptureData capture via USB for system performancevalidation and software updates.EconomicalOptional CO2 removal from the purified water (postRO) increasing the life of downstream consumables.*If fitted with Halo dispenser12www.elgalabwater.com

PURELAB Chorus 2 (RO/DI/UV)ProcessFlowPURELABChorus2 (RO/DI/UV)ProcessFlowPURELAB Chorus2 (RO/DI/UV) Water ingModule*ReverseOsmosis Outlet to HaloDispenser(optional)and rInletPump feed fromReservoirRecirculation PumpOutletWater seTapDrain*Optional second RO module for the 20I variant onlySpecificationsPURELAB Chorus 2 (RO/DI/UV)TREATED WATER SPECIFICATIONSAPPLICATIONNominal output at 15oCNominal daily output10 l/hr*20 l/hr*240 l/day480 l/dayInorganics @25 C1 to 15 MΩ.cmOrganics (MW 200 Dalton) 99% rejectionTotal organic carbon (TOC) 10 ppboBacteria 0.001 CFU/ml pHEffectively neutralParticles (filtration)Purification pack capacity0.2µm Liters to 15 MΩ.cm 74,700/(μS/cm (2.3 x ppm CO2))FEEDWATER REQUIREMENT* Standard conditions are 4 bar inlet pressure at 15oC, fed with potable water and a clean pre-treatment cartridge.Refer to flow tables outside these conditions. With LC134/145 POU filterSourcePotable mains water supplyFouling index (max) 10Conductivity 2000 μS/cmFree Chlorine0.5 ppm maxHeavy Metals (max)0.05 ppmSilica30 ppmTemperature1-35oCFlowrate (maximum requirement)100 l/hr (27 USG)Drain requirements80 l/hr (21 USG)Feedwater pressure4.0 bar (60 psi) min; 6 bar (90 psi) max*With boost pump: flooded suction (min) to 2.0 bar (30 psi) max*Fit LA652 Regulator where feedwater pressure exceeds specified limitsDimensionsHeight 679mm, Width 376mm, Depth 353mmWeight (with boost pump)17 kg (37 lbs)18 kg (40 lbs)Weight15 kg (33 lbs)16kg (35 lbs)www.elgalabwater.com13

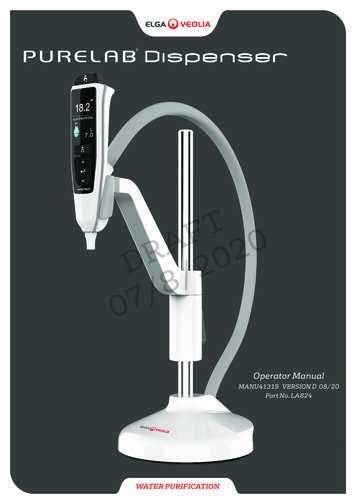

Halo Dispense SolutionsThe Halo Dispenser offers dispensing andmonitoring solutions to customers enabling theultimate flexibility when using PURELAB Chorus 1,Chorus 1 Complete & Chorus 2 .A choice of three dispensing solutions is availableto suit different applications, budget andconfiguration. With Halo Dispenser you have theultimate flexibility.Clear DisplayPrioritized information displayed at all times(system status, alarm) for absolute confidence asyou dispense.Multiple PositioningPosition the dispenser independent from the waterpurification system. Optimize your lab space.Flexible Dispensing3 Variable flow3 Auto-volume dispense3 Hands free3 Locked dispense3 Hand-held dispensing3 Profile dispenseHalo GlowThe unique glow changes colour and flashesalerting you to changes in system performance.Real-Time TOC Monitoring*Water purity is monitored right up to the point ofuse for complete peace of mind with real-time TOCmonitoring for critical applications.* Only on PURELAB Chorus 114www.elgalabwater.comHalo DispenserFixedHalo AdvancedDispenserHalo FlexibleDispenserFixedFlexible3 Variable flow rate dispense3 Drop-by-drop control3 Locked dispense3 Purity monitoring to point-of-use3 Auto volume dispense3 Profile dispense3 Flexible handset

(RO/DI)Type IIKey FeaturesLiters per day: Up to 480 3 Easy configurability10 MΩ.cm3 ModularPURELAB Chorus 2Ideally suited for: Stills Replacement General Chemistry Buffer Preparation Hydroponics Washing / Rinsing Sterilizer Feed pH solution Preparation Steam Generators Autoclaves Feed to Type I PolishersModular. Flexible. Reliable.Reliable delivery of Type II water purityWhen Type II water is all you need, then PURELAB Chorus 2 (RO/DI) is the reliable solution with theflexibility to suit your requirements. It dispenses up to 480 liters of pure water per day from a potablewater supply for general laboratory applications.EconomicalOptional CO2 removal from the purified water (postRO) increasing the life of downstream consumables.Option to reduce water consumption for lowhardness feed waters.ModularMultiple PURELAB Chorus 2 units can feed intoone reservoir and systems can be expandedpost-installation. As such, the cost of futureupgrades is minimized. Duplex systems alsoguarantee maximum uptime.Data CaptureDeionizationThe Reverse Osmosis feed contains optimized resinmixes to maximize consumables capacity.SimplicityData capture via USB for system performancevalidation and software updates.Reduced Maintenance TimesQuick and easy replacement of consumables as wellas simple sanitization to reduce maintenance time.Simple to install, operate and maintain withprioritized information displayed at all times(system status, alarm) for absolute confidence asyou dispense.www.elgalabwater.com15

PURELAB Chorus 3Type III waterLiters per day:Up to 720RO water(RO)Key FeaturesIdeally suited for:3 Easy Configurability Buffer Preparation Hydroponics Washing / Rinsing Steam Generators Autoclaves Sterilizer Feed General Chemistry Feed to Type I polishers3 Auto rinse3 ModularModular. Flexible. Reliable.Reliable delivery of Type III water purityWhen general laboratory grade water is all you need, then PURELAB Chorus 3 is the reliable solutionwith the flexibility to suit your requirements. It can also be used as a feed to other ELGA water systems.EconomicalOptional CO2 removal from the purified water (postRO) increasing the life of downstream consumables.Option to reduce water consumption for lowhardness feed waters.ModularMultiple PURELAB Chorus 3 units can feed intoone reservoir and systems can be expanded postinstallation. As such, the cost of future upgradesis minimized. Duplex systems also guaranteemaximum uptime.Data CaptureData capture via USB for system performancevalidation and software updates.ConfigurationAbility to configure multiple systems to increaseflow rate.SimplicitySimple to install, operate and maintain withprioritized information displayed at all times(system status, alarm) for absolute confidence asyou dispense.Auto RinseMaintains purity of water during periods of low use.16www.elgalabwater.comReduced Maintenance TimesQuick and easy replacement of consumables aswell as semi-automated sanitization to reducemaintenance time.

Process Flow PURELAB Chorus 2 (RO/DI) – Pure Water for General Laboratory ApplicationsPURELAB Chorus 2 & 3Process Flow PURELAB Chorus 2 terInletOutletReverseOsmosisProcessOutlet mosisFlow PURELAB Chorus 3 (RO) – General Grade Water for Laboratory ApplicationsProcess Flow PURELAB Chorus 3 (RO)PurificationPackBoost PumpDegassingModule(optional)DrainQuantity of Reverse OsmosisModules dependent onChorus eOsmosisReverseOsmosisOutletOutlet oost Pump(optional)DrainTREATED WATER SPECIFICATIONSSpecificationsAPPLICATIONNominal output at 15oCNominal daily outputInorganics @25oCPURELAB Chorus 2 (RO/DI)10 l/hrTotal organic carbon (TOC)pH10 l/hr240 l/day20 l/hr480 l/day 95% rejection 99% rejection 95% rejection 5 CFU/ml 50 CFU/ml 30 ppbBacteria*Purification pack capacity480 l/day1 to 10 MΩ.cmOrganics (MW 200 Dalton)Particles20 l/hr240 l/dayPURELAB Chorus 3 (RO) 50 ppbEffectively neutralEffectively neutralLiters to 1MΩ.cm 103,200/(μS/cm (2.3 x ppm CO2))N/A 99% rejection30 l/hr720 l/day 99% rejectionStandard conditions are 4 bar inlet pressure at 15oC, fed with potable water and a clean pre-treatment cartridge.Refer to flow tables outside these conditions. * Bacterial specification is before the water goes into the reservoirFEEDWATER REQUIREMENTSource – originally from potablesupply, then pretreatedPotable mains water supplyFouling index (max)10ConductivityFree ChlorineSilicaFeedwater pressure0.05 ppm0.05 ppm1-35oCFlowrate (maximum requirement)Drain requirements 2000 μS/cm30 ppmTemperatureWeight (with boost pump)Weight0.5 ppm max30 ppm1-35oC100 l/hr (27 USG)100 l/hr (27 USG)2.0 bar (30 psi) maximum;0.5 bar (7.5 psi) minimum**2.0 bar (30 psi) maximum;0.5 bar (7.5 psi) minimum**80 l/hr (21 USG)**Fit LA652 Regulator where feedwater pressure exceeds specified limitsDimensions10 2000 μS/cm0.5 ppm maxHeavy Metals (max)Potable mains water supply19 kg (42lb)17 kg (37 lbs)80 l/hr (21 USG)Height 435mm, Width 376mm, Depth 340mm20 kg (44 lbs)18 kg (40 lbs)17 kg (37 lbs) 18 kg (40 lbs) 19 kg (42lb)15 kg (33 lbs) 16 kg (35 lbs) 17 kg(37 lbs)www.elgalabwater.com17

Storage ReservoirsOur unique range of storage solutions are designedto maintain optimum purity of stored water andprovide effective protection against airbornecontaminants.They are designed to accommodate PURELABChorus water purification systems by maximizingthe space in a single integral, compact unit or to sitindependently to suit the layout of your laboratory.Multiple positioningMultiple positioning / mounting options to suityour laboratory layout.Polyethylene constructionInert opaque polyethylene construction withsmooth inner surface.Dispense tapPositioned to minimize accidental operation ordamage (choice of positions).Advanced vent filtrationAuto fillMonitoring of reservoir water levels withautomated refill ensures purified water is alwaysavailable.Hygienic OverflowHygienic overflow in the unlikely event of watersystem malfunction.Easy displayDirect display of stored purified water on the frontof the reservoir for easy identification.Capacity: 30 litersDimensions (mm):660 (h) x 376 (w) x 340 (d)Flow Rate: 8 l/min18www.elgalabwater.comCapacity: 60 litersDimensions (mm):570 (h) x 532 (w) x 522 (d)Flow Rate: 10 l/min260 2203 2Capacity: 15 litersDimensions (mm):470 (h) x 376 (w) x 340 (d)Flow Rate: 6 l/min203 2203 2450 4Prevents the ingress of airborne bacteria,particulates, organic vapours and CO2.Capacity: 100 litersDimensions (mm):806 (h) x 532 (w) x 522 (d)Flow Rate: 10 l/min

DispenserType I, II & III dependenton use of DI packLiters per day:Dependent on feedwaterPURELAB flex 1Key FeaturesIdeally suited for:3 Flexible dispensing General Lab3 Customise settings3 Fully re-circulating3 Integrated filtration Type II Applications Dispensing with DI packSimplicity and Elegance.The best dispenser for your distribution systemThe PURELAB flex 1 is designed as a dispensing and monitoring system when connected to a reservoiror distribution loop. It also works as a simple deionization system.Customized SettingsBe in control of your PURELAB flex by customizingthe settings to suit your application.SimplicitySimple to install, operate and maintain withprioritized information displaye

gained since 1937 in water purification innovation to design the unrivalled PURELAB range. Our reliable water purification systems are constructed from the highest quality components to ensure optimal purity, while a rapid and easy sanitization program contributes towards an uninterrupted workflow. Built-in economical processes results in the .