Transcription

MOVING FROMPIPELINE TOPROCESSAPPLICATIONS HIGHER RELIABILITY LOWER MAINTENANCE “OUT-OF-BOX” STARTUPCERTIFICATE QSR-169720 OLD KATY ROADHOUSTON, TEXAS 77055 USA19203 HEMPSTEADHOUSTON, TEXAS 77065 USA

Daniel On-Line Gas Chromatographs forPipeline and Process Applications.The best combination of advanced technologyand rugged instrumentation to help you makethe most of your existing manpowerDaniel Industries Houston headquartersTodayÕs trend toward downsizing means instrument technicians have more to do, and less time todo it. Instrumentation has to be more reliable andeasier to use than ever before. Daniel gas chromatographs are your best choice.Superior technology and service life60 years of industry leadershipHeadquartered in Houston Ð a strategic location for the extensive Gulf Coast hydrocarbon process industry Ð Daniel also manufactures in Scotland and supplies field supportfrom offices in Canada, Singapore, and theMiddle East, and has agents and representatives in over fifty countries. To meet DanielÕs higher performance standards,our GC technology is developed in-house GC valves Ð 5 million injections betweenrebuilds Micro-packed columns Ð improve baseline separation, reduce carrier consumption, fasteranalysis Advanced applications with single or dualdetectors Software and electronics Ð virtually unlimitedchromatogram storage and diagnostic tools withlaptop/PC Superior transient protection in controller Improved Modbus communicationsHigher reliability and lower maintenanceReady to use, right “out of the box”Daniel GCÕs must pass a rigid operational testwith on-line calibration standards in environmental chambers at temperatures from 0û to 130ûF.Daniel dependability results from our dedicationto in-house testing and quality control.Daniel has produced the highest quality chromatographs for decades. Quality control is the keyto our success.and the reason for our chromatographsÕ reputation for ease-of-use, accuracyand dependability.Our in-house environmental testing is the mostthorough in the industry. Daniel gas chromatographs must endure our walk-in environmental testchambers Ð cycling between 0û and 130ûF for up to72 hours.The result? Out-of-box start-up and years of reliable operation.2Model 575 - For transportable,on-line and laboratory useThe Danalyzer Gas Chromatograph is packaged in alaboratory version with an integral 2350 controller.Laptop interface makes this versatile GC ideal for usein the lab or in the field.Our chromatograph technology is packaged andapplied differently with three types of detectorsand two different oven designs. All Danielchromatographs share a common operationaltechnology so plant and laboratory personnel workon the same operating system.Our advanced microprocessor-based electronicsand software eliminate the need for expensiveportable service panels and strip chart recorders.Daniel chromatographs simply require alaptop/PC for diagnostics at the chromatograph, inthe control room, or offsite, to control all functions(optional keypad available). Advanced zoom features and chromatogram overlay provide resolutionfor advanced diagnostics and allow troubleshootingfrom any location. Technicians can recall currentand historical chromatogram overlays for easycomparison.

Laptop/PC Based DiagnosticsPowerful and flexible Last run, current run, last calibration chromatogram stored in GC Hot-key shortcuts to raw data, analysis results, and other data directlyfrom chromatogram screen Ticks downward for timed events, ticks upward for peak integrationExtensive memory to store and recall historical chromatograms in PCFixed time or auto slope detection for peak integrationSimplified troubleshootingChromatogram overlays for trouble-shooting and calibration Zoom functions allow troubleshooting with resolution to 25 milliseconds forany stored chromatogramTimed events, peak integration parameters, and chromatograms presented onone screen for editingHigh resolution zoom to individual data-base points displayed in relation tobase line3Last calibration/initial calibration overlayVirtually unlimited possibilities for advanced troubleshooting and analysisSimplifies troubleshooting for inexperienced technicians

Superior TechnologyChromatograph ValvesDetectorsDaniel 6-port and 8-port valves, unique to the GC market, have greatly extended service life. This comes from minimum internal movement Ð about 1/10,000inch, which also contributes to rapid operation. Flow paths for the sample arearranged so internal moving parts never contact the sample flow. As a result,abrasive mechanical wear on machined valve surfaces is eliminated. Thisunique double diaphragm design eliminates all springs, O-rings, and the needfor lubrication.Daniel Process GCÕs incorporate three types of detectors: TCD (Thermal Conductivity Detector)FID (Flame Ionization Detector)FPD (Flame Photometric Detector)Each type of detector is mounted in a precision assembly which maintains uniform flow paths to minimize dead volume. Single or dual detector TCDÕs aregenerally used for analyzing higher concentrations, FIDÕs for trace concentrations of hydrocarbons, and FPDÕs for trace sulphur analysis.The TCD used will tolerate loss of carrier for extended time periods withoutdamage.TCD (Thermal Conductivity Detector)FID (Flame Ionization Detector)Daniel ultra-long-life valves and micro-packed columns are key to superior chromatography, and higher reliability.Daniel chromatograph valves can be operated over 5 million times withoutmaintenance in most process applications Ð reliability five to twenty times thestated reliability of competitive valves in similar service! For most applications,chromatograph valves are warranteed for life.Photo courtesy of Finnigan Corp.FPD (Flame Photometric Detector)Micro-packed columnsSince 1980, Daniel has beenrefining and improving its processfor creating micro-packed columns.2350 Controller Advanced SoftwareDaniel micro-packed columnsoffer a superior combination of theThe ability to monitor dualdetectors simultaneouslyopens up new applicationswith greater speed.Applications such as naturalgas extended analysis (C 1 C 9 in five minutes) or natural gas with helium are all now possible. The primary benefit is faster analysistimes for many on-line applications.features found in both capillary andconventional packed columns. Theresult is improved chromatographywith extended column life Ð several years in most applications without measurable degradation orbleed. Daniel micro-packedcolumns produce sharper peaks forimproved component separation,short analysis time, and very lowcarrier-gas consumption.Recorders are not necessary; laptops can be used as the primary interface toallow for almost unlimited chromatogram storage and retrieval. Optional printers can be serial or the less-expensive, easier-to-install parallel type.The inset photo shows the micro screeninserted at each end of a column to retainuniform packing in columns up to 9 feetlong.4

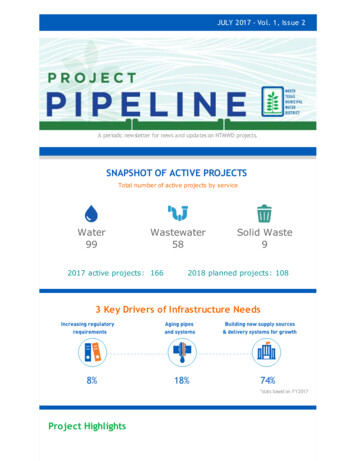

Applications2350 Chromatograph ControllerUsed with all Daniel GCÕs andavailable in various mounting configurations as noted below.The 2350 is designed to minimize engineering, training, and effort in measurementaccounting. It mounts in a 19Ó rack, as a2251 retrofit, or in an explosion proofNEMA 4X enclosure and can control up to12 streams. The Model 2350 offers fourindependent Modbus serial ports plus aparallel printer port. Two analog outputs arestandard and can be expanded to 10. Anoptional keyboard/display and internalmodem is available for local or remote diagnostics (PC). Plug in transient protectionmodules meet the highest European standards for electrical protection.DANALYZERThe Pipeline BTU ChromatographModels 500 and 1000 forthe process industry.The Danalyzer Gas Chromatograph is installedModels 500 and 1000 are the same basicfor custody transfer measurement on moreDanalyzer technology.pipelines worldwide than all competitive unitscombined. The weatherproof/X-proof designMODEL 500makes the Danalyzer GC temperature tolerantThe 500 series uses a heat sink oven at tem-from -17û to 55ûC (Oû to 130ûF) for outdoorinstallations.peratures up to 85ûC (185ûF) and accepts upThe large data archive stores the last 1200to 12 streams of liquids or gases.analyses, 400 calibrations and 64 variables foraveraging and trending.The Danalyzer GC offers fast four minuteanalysis time with complete baseline separationDanalyzer gas chromatograph with integralX-proof controller.of all components, improving peak integrationDETECTOR(S):TCD (Single or Dual)OVENS:Heat Sink (no air required)CONTROLLER:19Ó rack, panel mount,or X-proof (integral orseparate)AREA CLASS:Class 1, Div 1, GroupsC, D (group B with airpurge)Model 500 with lowersample system ovenfor critical nitrogen, methane, and carbon dioxide measurement. This superior component measurement improves the final BTU calculation,with repeatability to 0.5 BTUÕs in 1000 without ambient temperature control. A temperaturecontrolled environment with weekly calibrationsimproves analyzer performance to 0.25 BTUÕsMODEL 1000per 1000! All diagnostics and configuration,including chromatograms, can be accessed local-The 1000 series offers increased applicationly or from a remote location via modem.flexibility including a choice of 3 detectorsDETECTOR(S):TCD (Single or Dual)for sulphur compounds and low-level hydro-OVENS:Heat Sink (no air required)carbon concentrations. The conventional airCONTROLLER:Separate (19Ó rack, panel mount,or X-proof)bath oven operates up to 150ûC (300ûF) toAREA CLASS:Class 1, Div 1, Groups C, Dvaporize heavier hydrocarbons and acceptsup to 12 streams of liquids or gases.Model 1000 with lowersample system ovenTypical outdoor installation in U.S. Gulf Coast region.5DETECTOR(S):TCD, FID, FPD, Dual TCDOVENS:Conventional Air BathCONTROLLER:19Ó rack, panel mount,or X-proof (integral orseparate)AREA CLASS:Class 1, Div 1, Groups C, Dstandard X or Z purgerequired for Div 1 or 2,Group B

OvensCommunicationsDaniel offers two choices in analytical oven design for its chromatographs:Field-configurable versions of Modbus communication protocols provide fordirect DCS interfacing. Provisions for these versions are integrated into the GCcontroller firmware. Four serial ports accommodate redundant data highwaysand chromatograph diagnostics directly from the chromatographs without theexpense of additional service panels or work stations. GC diagnostic software isincluded in the initial cost and operates on conventional laptops/PCÕs for use atthe central PC based workstation, or at the chromatograph. Heat sinkConventional air bathThe Heat Sink OvenInstalled in thousands ofunits worldwide, the HeatSink oven integrates a TCD,micro-packed columns, andGC valves in a single temperature-controlled assembly.The entire oven is electrically approved for Class 1,Div 1, Groups C and D without the need for instrument air, for oven heat, or forsafety reasons.This unique oven design, with heat up to 85ûC (185ûF), is standard in theDanalyzer, Laboratory and Model 500 Process GCÕs.PC-BASEDWORKSTATIONModemOffsiteDCSTo Printer/LoggerREDUNDANT MODBUSThe Air Bath OvenThe Air Bath oven usesa conventional instrumentair-heater design. It issupplied in the Model1000 Process GC forapplications requiringheat up to 150ûC (300ûF)and/or FID, FPD, or TCDdetectors. Dual TCDÕs ora combination of a TCD and FID can be mounted internally.GC 1GC 2GC 3Model 1000Model 500DANALYZERGC 4UP TO32 GCGC 32Optional Laptopfor Local CommunicationSimplified DCS interfacing. Integrated firmware handles various implementations ofModbus protocol. Multiple serial ports can be field configured to provide redundantmodbus data highways. Simple DCS interfacing; serial communications up to 19.2 K baud on fourindependent ports (RS-232, RS-422, and/or RS-485). All data, including chromatograms, can be uploaded or downloaded by localor offsite communications via modem.ConfigurationDaniel GCÕs offer the ultimate in configuration flexibility:Trending Auto setup for critical valve timing lets GC establish its own correct timingfor chromatograph valves Configurable baseline check included with autocalMultiple trending screens make comparisons easy. Dual-component historicaltrending (for example C 2 / C 3 ratio trends) provides valuable information tosystem users. Averages are fully configurable with up to 64 variables. Up to 12 streams with four sets of timed events and four sets of calibrationtables Edit component tables and timed events directly from chromatograph screen View raw data and analysis results Laptop/PC storage of all GC applications The last 1200 analyses are saved in the GC controller for trending anyanalytical calculation. The last 400 calibrations are saved in the GC controller.SafetyDaniel chromatographs are designed to minimize personnel exposure toprocess media. The versatile software and communications capabilities makepossible full-function remote diagnostics to greatly reduce plant service or tripsÒto the fieldÓ.6

DANALYZER, MODEL 500, AND LAB GC2350 CONTROLLERPower:Transient Protection:Environment:Dimensions:115 VAC 15% @ 0.55 Amps, 50/60 Hz230 VAC 15% @ 0.275 Amps, 50/60 Hz63.25 VA power consumption without currentoutputsPower:115 VAC 15%, 220 VAC 15%, 50/60 Hz100 watts running, 350 watts startupEnvironment:-17 to 55ûC (0 to 130ûF)C.E. tested & certified to highest levels (3 & 4)of IEC 801 STD.Operating range @ -17 to 55ûC (0 to 130ûF)Storage range -40 to 85ûC (-40ûF to 185ûF)Humidity @ 0-95% RH (non-condensing)Dimensions:(w/o sample system):19Ó rack size: 22.5cm H x 48.5cm W x 24.13cm D(8.75ÓH x 19ÓW x 9.5ÓD)Approximate Weight(w/o sample system):Panel retrofit size: 21.5cm H x 28cm W x 23cm D(11ÓH x 8.5ÓW x 9ÓD)X-proof size: 29.5cm H x 33cm W(11.5ÓH x x13ÓW)Danalyzer Ð 165cm H x 41cm W x 53.5cm D(65ÓH x 16ÓW x 21ÓD)Model 500 Ð 154cm H x 51cm W x 53.5cm D(65ÓH x 20ÓW x 21ÓD)Lab GC Ð 25.4cm H x 74cm W x 56cm D(10ÓH x 29ÓW x 22ÓD)Danalyzer Ð 56.69 kg (125 lbs.)*Model 500 Ð 36.28 kg (90 lbs.)Lab GC Ð 31.75 kg (70 lbs.)* Includes sample system mounted on lower plateApproximate Weight:19Ó rack size: 11.34 kg (25lbs.)Panel retrofit size: 9.98 kg (22 lbs.)X-proof size: 27.21 kg (60lbs.)Area Classification:Area Classification:Rack and panel mount Ð General PurposeX-Proof Class 1, Div 1, Groups C, DIntegral controller with GC Ð suitable forClass 1, Div. 1 or Div. 2, Groups B, C, or D withX purge or Z purge per NFPA 496Danalyzer and Model 500 Ð Class 1, Div 1,Groups C, D (no air)*Lab GC Ð General purpose* Group B with air purgeMounting:Free-standing or wall mountColumns:1/16Ó micro-packedOven:Heat sink, max 85ûC (185ûF)Valves:Daniel 6-port, 8-port, other 4-port for liquidsample injectionCarrier Gas:Zero-grade helium, nitrogen or hydrogen@ 90 psigINPUT/OUTPUTAnalog Inputs:8 4-20mA filtered with transient protectionAnalog Outputs:2 4-20mA standard, optional 4 or 8 more(software calibrated)Digital Inputs:1 GC common alarm, optically isolatedwith transient protection5 user assignable alarms, optically isolatedwith transient protectionDigital Outputs:5 open collector, optically isolated withtransient protectionDetector Inputs:TCD, FID, and FPDSingle or dual detector inputsCommunications Ports:4 field-configurable Modbus ports,RS-232, 422, or 485. (Max RS-422 ports is 2)Optional Modem:Internal or external telephone modem300 baud to 9600 baudMODEL 1000Environment:0 to 55ûC (32 to 131ûF) for T.C.D. and F.I.D.20ûC 5ûC (70ûF 10ûF) for F.P.D.Approximate Weight(w/o sample system):(Eliminates need for laptop)SYSTEM CONFIGURATIONCPU:115 VAC 15%, 220 VAC 15%, 50/60 Hz400 watts running, 1100 watts startupDimensions:(w/o sample system):OptionalKeyboard/LCD Display: 18 buttons / 8 lines x 41 charactersMemory:Power:1 megabyte standard for storage of last 400calibrations and last 1200 analysesMemory expandable to 4 megabytes foraverages with optional memory boardNEC V-53Chromatogram Storage: Last run and last calibration for each method198cm H x 61cm W x 61cm D(78ÓH x 24ÓW x 24ÓD)68 kg (150 lbs.)Area Classifications:Class 1, Div 1, Groups C, D (X-proof, no purge)Class 1, Div 1, Groups B, C, D (X purge)Class 1, Div 2, Groups B, C, D (X or Z purge)Mounting:Free-standing or wall mountColumns:1/16Ó micro-packed, 1/8Ó packed, or CapillaryOven:Air bath, max 150ûC (302ûF)Valves:Daniel 6-port, 8-port, other 4-port for liquidsample injectionMethods:4 timed events, 4 component tablesNumber of Streams:12Carrier Gas:Zero-grade helium, nitrogen or hydrogenGating Options:Fixed-timeAuto, Slope detection and peak identificationon all peaks in predetermined windowInstrument Air:Flow Ð 4 SCFM for oven heat @ 40 psigPressure Ð 90 psig for valves (40 psig option withvalve actuation from carrier gas)7

TYPICAL OUTLINE AND DIMENSIONSDANALYZER AND MODEL 500MODEL 1000Front ViewFront ViewWithout Sample System Oven73.5"(1867)69.0"(1753)Door SwingClears 16"of ArcINSTRUMENTAIR IN1/4"CARRIER IN1/4"FLOWPANELANALYZERHEAT SINKOVENELECTRONICSENCLOSURE1/2" NPTCustomer Interconnection forA/C at Rear ofAnalyzer64.0"(1626)78.0"(1981)CAL. STD. IN.ANALYZERAIR BATH OVEN31.75"(806)SAMPLECONDITIONINGSYSTEM PLATEOR OVENSAMPLE CONDITIONINGSYSTEM PLATE OR OVEN0.0"NOTE: Dimensions in parentheses are in millimeters.12.0"(305)16.0"(406)24.0"(610)7.0" (178)1.25"(31.75)Daniel Measurement and ControlHouston, Texas, USA, Telephone: (713) 467-6000, Fax: (713) 827-3880Calgary, Alberta, Canada, Telephone: (403) 279-1879, Fax: (403) 236-1337Swinton Grange, England, Telephone: 44 -1653 - 695551, Fax: 44 -1653 - 600425Singapore, Telephone: 65 - 5380498, Fax: 65 - 5386210O F F I C E S A N D R E P R E S E N TAT I V E S W O R L D W I D Ew w w. d a n i e l i n d . c o m 1999, Daniel Measurement and Controlis a registered trademarkPrinted in USAAll specifications are subject to change without notice as part of a continuing program of product improvement.DMC-1784-10M-7/99

TCD (Thermal Conductivity Detector) FID (Flame Ionization Detector) FPD (Flame Photometric Detector) Each type of detector is mounted in a precision assembly which maintains uni-form flow paths to minimize dead volume. Single or dual detector TCDÕs are generally used for analyzing higher concentrations, FIDÕs for trace concentra-