![[ ANSI C37.20 And NEMA SG-5 ]](/img/5/metal-clad-en.jpg)

Transcription

[ ANSI C37.20 and NEMA SG-5 ]

We build a better future!ANSI C37.20 and NEMA vironmentalQualification

CONTENTS04General06Application Data08Features10Circuit Breaker Compartment Features12Standard Modules14Technical Data18Specification Guide

ANSI C37.20 and NEMA SG-504GeneralDescription and ApplicationThe HMS Vacuum Medium Voltage Metal-cladSwitchgear is an integrated set of drawoutvacuum circuit breakers, buses, and controldevices coordinated electrically andmechanically for medium voltage circuitprotection.Metal-clad integrity provides maximum circuitseparation and safety.Included are isolated and grounded metalcompartments and completely insulatedconductors ensuring that no live parts will beexposed by the opening of a door.It is typically used on circuits with feeder circuits,transmission lines, distribution lines and motors.The HMS Vacuum Medium Voltage Metal-cladSwitchgear is available at voltage ratings of4.76 kV through 15 kV, for indoor or outdoorapplications.The metal-clad switchgear and all componentsare designed, manufactured, and tested inaccordance with the following standards :Typical4.76 kV and 15 kV Switchgear ANSI C37.20.2 NEMA SG-5 IEEE

Medium Voltage Metal-clad Switchgear05DefinitionQuality AssuranceThe Metal-clad Switchgear is a group of unitscharacterized by the following features :The HHI Power Distribution Organization QualityAssurance Program has been continuouslyimproved. The main interrupting device is removable andoutfitted with a mechanism for moving itmanually between connected and disconnectedpositions. It is equipped with self-aligning andself-coupling primary and secondarydisconnecting devices. The interrupting devices, buses, voltagetransformers, and control power transformers arecompletely enclosed by grounded metal barriers,which have no intentional openings betweencompartments. A metal barrier in front of theinterrupting device ensures that no live parts areexposed by opening the door in the connectedposition. All live parts are enclosed within grounded metalcompartments. Automatic shutters cover primary circuitelements when the removable element is in thedisconnected, test, or removed position.It currently employs a total quality approach toprovide reliable equipment and satisfy customerneeds.The program conforms to the requirements ofISO 9001.Environmental QualificationHMS Vacuum Medium Voltage Metal-cladSwitchgear equipment has been evaluated bycomprehensive analysis and testing formaintainability and life expectancy.Documentation in accordance with IEEE 323-1983is available for Class 1E Nuclear applications. Primary bus conductors and connections arecovered throughout with track-resistantinsulating material.Seismic Capability Mechanical interlocks are provided to maintain aproper and safe operating sequence.HMS Vacuum Medium Voltage Metal-cladSwitchgear equipment is designed and tested towithstand high levels of seismic vibration withoutservice interruption. Instruments, meters, relays, secondary controldevices, and their wiring are isolated, wherenecessary, by grounded metal barriers from allprimary circuit elements.Equipment for nuclear plants, qualified per IEEE344-1987, is availiable with full documentation.

ANSI C37.20 and NEMA SG-506Application DataHMS Type SwitchgearRear View Showing Cable Compartments

Medium Voltage Metal-clad Switchgear07Applicable Industry StandardsANSI-American National Standards Institute.IEEE-Institute of Electrical and Electronic Engineer, Inc.C37.06AC High Voltage Circuit Breakers Rated on aSymmetrical Current Basis -Preferred Ratings and RelatedRequired CapabilitiesC37.09Design/Proof TestsTest Procedure for AC High Voltage CircuitBreakers Rated on a Symmetrical Current BasisC37.010Application Guide for AC High Voltage CircuitBreakers Rated on Symmetrical Current BasisC37.011Application Guide for Transient RecoveryThe HMS Vacuum Medium Voltage Metal-cladSwitchgear meets applicable ANSI, IEEE andNEMA standards.The design criteria dictate that performance isdemonstrated all test above the requirements ofstandards.Voltage for AC High Voltage Circuit Breakers Rated on aSymmetrical Current BasisC37.012The basic ANSI test series includes short circuit,BIL, dielectric, continuous current, mechanicallife, and thermal and environmental conditions.Application Guide for Capacitance CurrentSwitching for AC High Voltage Circuit Breakers Rated on aDesign tests are called type tests at times.Symmetrical Current BasisC37.20.2 Standard for Metal-clad and Station TypeCubicle SwitchgearProduction TestsC37.54Production tests are used to check the qualityand uniformity of workmanship and materials,and to verify during production that the productdelivered to the customer meets the designspecifications and applicable standards.Conformance Test Procedure for Indoor AC HighVoltage Circuit Breaker Applied as Removable Elements inMetal-enclosed SwitchgearC37.55Conformance Test Procedure for Metal-cladSwitchgear AssembliesNEMA National Electrical Manufacturers AssociationSG-5 Power Switchgear Assemblies

ANSI C37.20 and NEMA SG-508FeaturesHMS Type SwitchgearBottom Circuit BreakerDoor OpenedCompactnessSpace-saving compactness is the mostnoticeable characteristic of this Hyundai twohigh HMS Vacuum Metal-clad Switchgear.One standard frame size saves and simplifieslayout. It also permits the complete allocationof space for future frame additions.This Hyundai switchgear makes it possible tosave space with every installation.Standard frames are designed to houseauxiliary equipment, voltage transformers,lightning arresters and bus tie transitions.

Medium Voltage Metal-clad Switchgear09Front Access PortWith the access port opened, the breaker position,contact position and operation counter are easilyobserved.With easy access to the racking mechanism, thebreaker can be moved from the connected positionthrough the test position to the disconnected position.FeaturesEconomy and Convenience:Service Continuity: Completely engineered product. Re-usable interrupting device. Standardized construction. Self-contained operating mechanism. Ease of match and line. Multiple-shot reclosing Standardized ratings. Automatic transfers for multiple-source systems. Complete line of solid state relays. Limiting of damage to a single compartment. Integrally-mounted ground sensors. Bus differential protection minimizes bus faultdowntime. Vacuum interrupters. Stored-energy breakers permit faster transfer ofbanks of feeders.Safety and Ease of Maintenance: Segregated compartments. Pressure relief flaps. Three-phase interruption-no single phasing. Speed and positive action for bringing asynchronized generator on the system. Drawout voltage transformers in stationary control.Power transformers with drawout primary fuses. Positive automatic stops in each position duringracking.Safe compartment-complete accessibility of allcomponents: Bus sectionalized through a tie breaker.This unit is divided into six completely segregatedareas, with front formed doors with concealed hinges. Safe manual closing of stored energy breaker. Instrument compartment. Access port to racking mechanism. Circuit breaker compartment. Current transformer compartment. Bus compartment. Cable compartment. Auxiliary device compartment.

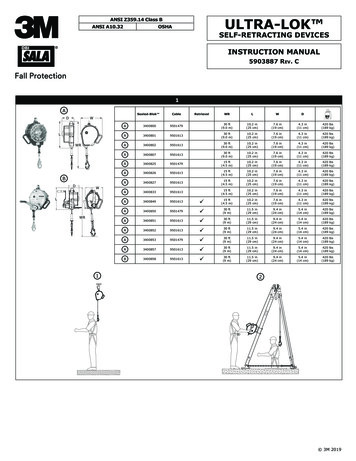

ANSI C37.20 and NEMA SG-510Circuit Breaker Compartment Features3 Terminal Blocks1 Mechanism Operated Cell (MOC) SwitchesNumbered eight point recessed screw type terminal blocksare mounted on stand off removable panels to preventenclosure penetration by device mounting hardware.Terminal block points designated for user interconnectionshave one side of the block reserved for this purpose.An eight-contact MOC switch is standardly supplied toprovide open-closed status of the vacuum circuit breaker’sprimary contacts.MOC switches are optionally available in sixteen andtwenty-four contact configurations.Normally open(a) and normally closed(b) contacts areequally divided.2 Low Voltage CompartmentWith the vacuum circuit breaker in the drawoutconnected position, a segregated grounded metalenclosed low voltage compartment is formed to provideaccess to the secondary wiring and devices withoutpersonnel exposure to primary voltage.❷❶14 Secondary Wiring and Devices❸Secondary wiring and all interconnected door mounteddevices, control fuses, MOC and TOC auxiliary switches,terminal, and CT shorting blocks are readily accessible inthe low voltage compartment.Standard secondary wiring is in accordance with relatedNEC regulations.❹❺❻❼❽❿❾13 MOC Switch ActuatorThe cell mounted MOC switch actuatorinterfaces with the vacuum circuit breaker’soperating mechanism linkage only in thedrawout connected position.

Medium Voltage Metal-clad Switchgear116 Truck Operated Cell (TOC) Switches5 Current Transformer (CT) MountingCurrent transformers are of the toroidal type and can be mountedon both line and load primary bushings behind the shutter.Each primary bushing will accommodate up to two ANSI standardaccuracy class CT’s or one special high accuracy class CT.Adding new CT’s or changing CT ratios is easily and quicklyperformed without disturbing primary buses.7 User Interconnecting Secondary Wiring4 Safety ShutterThe stationary primary disconnects are covered by agrounded matal safety shutter whenever the vacuumcircuit breaker is out of the drawout connected position.The safety shutter is driven open as the vacuum circuitbreaker moves between drawout test and connectedpositions to permit mating of the primary disconnects.As an additional safeguard to the shutter closing springs,cam action assures the complete closing of the safetyshutter when the vacuum circuit breaker is removed.A provision for padlocking the safety shutter in the closedposition is standard.11 Grounding ContactA copper ground bus rigidly connected to the switchgearground bus system is engaged by a grounding contact onthe drawout element to provide a maintained ground onthe uninsulated portion of the drawout element wheneverits secondary and/or primary disconnects are mated.12 Dual Guide RailsFloor mounted full-length dual guiderails assure positive alignment of thevacuum circuit breaker within itscompartment to achieve the propermating of all primary, secondary andgrounding contacts.An optional eight contact TOC switch is available toprovide connected/not connected drawout status ofthe vacuum circuit breaker.Movement of the circuit breaker during rackingbetween test and connected drawout positionscauses a contact position change in the TOC switch.Normally open(a) and normally closed(b) contactsare equally divided.User interconnecting secondary wiring mayenter from above or below.As applicable, an integral wireway is providedfor routing user wiring to the low voltage compartment.8 Drawout Position IndicatorAn indicator on the vacuum circuit breaker pointsto an indicator on the circuit breaker compartmentfloor to clearly illustrate the drawout position.This indication can be observed through theaccess panel or with the circuit breakercompartment door open.10 Stationary Secondary DisconnectorThe stationary secondary disconnectorsautomatically mate with the vacuum circuitbreaker’s moving secondary disconnectors inthe test and connected drawout positions tointerconnect circuits for the spring charging motor,close, and trip devices and indicating lights.9 Interference BlockThe interference block in thecompartment mates with theinterference angle on the vacuumcircuit breaker to accept insertion ofcorrectly rated drawout elements andto reject insertion of incorrect rateddrawout elements.

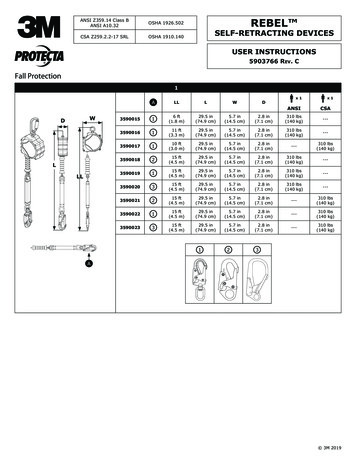

ANSI C37.20 and NEMA SG-512Standard ModulesTypical Arrangements1200 ABreaker1200 ABreaker1200 ices1200 ABreaker1200 ABreaker1200 ABreaker1200 ABreaker1200 ABreaker1200 ABreaker2000 evicesDrawoutAuxiliaryDevices3000 ABreaker(4.76 kV Only)(4.76 kV Only)2400(94.49〞)900(35.43〞)(4.76 kV ces**1200 A or2000 ABreaker orDrawoutAuxiliaryDevices**1200 A or2000 ABreaker orDrawoutAuxiliaryDevices1200 A or**2000 ATieBreakerMain BusConnectedDrawoutAuxiliaryDevicesOnly*3000 ATieBreakerMain BusConnectedDrawoutAuxiliaryDevices*1200 A or**2000 ATieBreakerMain BusConnectedDrawoutAuxiliaryDevices*Only**1200 A or2000 ABreaker orDrawoutAuxiliaryDevices**1200 A or2000 ABreaker orDrawoutAuxiliaryDevices(4.76 kV Only)* Auxiliary Compartment Adjacent to Tie Breaker Required.** Only One 2000 A Breaker in Any Vertical Frame.

Medium Voltage Metal-clad Switchgear13Typical Section Views - Two High ConstructionCT’S1200AGSCT’STERM BLOCKSTERM BLOCKSTERM BLOCKSCT’S1200AGS1200AGS1200ATERM BLOCKSTERM BLOCKSTERM BLOCKSGS1200A1200ACT’SCT’SCT’SGSGSTERM BLOCKS2000A2000ATERM BLOCKSTERM BLOCKSPT’SBreaker / Breaker (Top and Bottom Entry)CT’SPT’STERM BLOCKSPT’STERM BLOCKSTERM BLOCKSBreaker / Breaker (Top Entry)TERM BLOCKSTERM BLOCKSBreaker / Breaker (Bottom eaker / Breaker (BottomTie)(Tie Entry)*Can be also Suitable for top EntryBreaker / Breaker (Top Tie)(Bottom Entry)*Can be also Suitable for top EntryTERM BLOCKSPT’SPT’STERM BLOCKSTERM BLOCKSTERM BLOCKS2000AGSTERM BLOCKSTERM BLOCKS1200ATERM BLOCKSCT’STERM BLOCKSAuxiliary / Breaker (Top Entry)Auxiliary / Breaker (Bottom Entry)3000ACT’SAuxiliary / Breaker (Bottom Entry)*4.76 kV Only3000ACT’SAuxiliary / Breaker (Top Entry)*4.76 kV Only

ANSI C37.20 and NEMA SG-514Technical Data4.76 kV/15 kVTwo High Construction

Medium Voltage Metal-clad Switchgear15Table 1 - Technical DataModel NameHMSRated Maximum Voltage (kV rms)4.7615Rated InsulationNormal Frequency Withstand Voltage (rms, 1min)1936Levels (kV)Normal Impulse Withstand Voltage 1.2 / 50 6095Rated Continuous Current (A)1200 / 2000 / 30001200 / 2000Rated Short-time Current (2 sec)50 kA40 kACircuit BreakerVCBVCBBus-Bar SystemSingleSingleInstallationIndoorIndoorOutd

ANSI C37.20 and NEMA SG-5 04 Description and Application The HMS Vacuum Medium Voltage Metal-clad Switchgear is an integrated set of drawout vacuum circuit breakers, buses, and control devices coordinated electrically and mechanically for medium voltage circuit protection. Metal-clad integrity provides maximum circuit separation and safety.File Size: 1MBPage Count: 20

![[ ANSI C37.20 and NEMA SG-5 ] - tekhar](/img/5/metal-clad.jpg)