Transcription

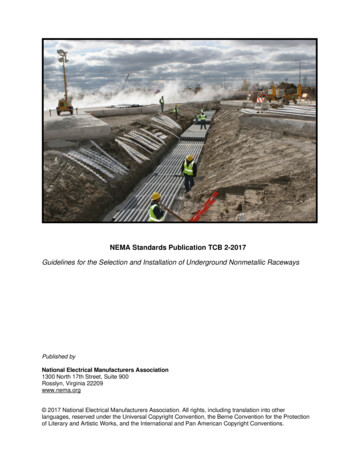

NEMA TCB 2-2012NEMA Guidelines for the Selection and Installation ofUnderground Nonmetallic RacewaysPublished by:National Electrical Manufacturers Association1300 North 17th Street, Suite 900Rosslyn, Virginia 22209www.nema.org 2013 National Electrical Manufacturers Association. All rights, including translation into otherlanguages, reserved under the Universal Copyright Convention, the Berne Convention for the Protectionof Literary and Artistic Works, and the International and Pan American copyright conventions.

TCB 2-2012Page iiNOTICE AND DISCLAIMERThe information in this publication was considered technically sound by a consensus among personsengaged in its development at the time it was approved. Consensus does not necessarily mean therewas unanimous agreement among every person participating in the development process.The National Electrical Manufacturers Association (NEMA) standards and guideline publications, of whichthe document herein is one, are developed through a voluntary standards development process . Thisprocess brings together volunteers and/or seeks out the views of persons who have an interest in thetopic covered by this publication. Although NEMA administers the process and establishes rules topromote fairness in the development of consensus, it does not write the documents, nor does itindependently test, evaluate, or verify the accuracy or completeness of any information or the soundnessof any judgments contained in its standards and guideline publications.NEMA disclaims liability for any personal injury, property, or other damages of any nature, whetherspecial, indirect, consequential, or compensatory, directly or indirectly resulting from the publication, useof, application, or reliance on this document. NEMA disclaims and makes no guaranty or warranty,express or implied, as to the accuracy or completeness of any information published herein, anddisclaims and makes no warranty that the information in this document will fulfill any particular purpose(s)or need(s). NEMA does not undertake to guarantee the performance of any individual manufacturer’s orseller’s products or services by virtue of this standard or guide.In publishing and making this document available, NEMA is not undertaking to render professional orother services for or on behalf of any person or entity, nor is NEMA undertaking to perform any duty owedby any person or entity to someone else. Anyone using this document should rely on his or her ownindependent judgment or, as appropriate, seek the advice of a competent professional in determining theexercise of reasonable care in any given circumstance. Information and other standards on the topiccovered by this publication may be available from other sources, which the user may wish to consult foradditional views or information not covered by this publication.NEMA has no power, nor does it undertake to police or enforce compliance with the contents of thisdocument. NEMA does not certify, test, or inspect products, designs, or installations for safety or healthpurposes. Any certification or other statement of compliance with any health- or safety-related informationin this document shall not be attributable to NEMA and is solely the responsibility of the certifier or makerof the statement. 2013 National Electrical Manufacturers Association

TCB 2-2012Page iiiFOREWORDThis guideline is intended to provide assistance as a guide to obtain the most appropriate and satisfactoryinstallation of rigid nonmetallic conduit (RNC) or raceway systems.This guideline is in no way intended to assume or replace any responsibilities of engineers, customerrepresentatives, owners, or other persons in establishing engineering design practices and proceduresbest suited to individual job conditions.NEMA Polymer Raceway Products SectionAnamet Electrical, Inc.AFC Cable Systems, a part of Atkore InternationalAllied Tube and Conduit, a part of Atkore InternationalChampion Fiberglass, Inc.FRE CompositesHubbell IncorporatedIPEX Electrical Inc.Legrand North AmericaPanduit CorporationRoyal Pipe SystemsSouthern Pipe, Inc.Thomas & Betts CorporationUnderground Devices, Inc.United Fiberglass of AmericaMattoon, ILNew Bedford, MAHarvey, ILSpring, TXSt. André-d'Argenteuil, PQ, CanadaShelton, CTMississauga, ON, CanadaWest Hartford, CTTinley Park, ILShelby Township, MINew London, NCMemphis, TNNorthbrook, ILSpringfield, OH 2013 National Electrical Manufacturers Association

TCB 2-2012Page iiTABLE OF CONTENTSSELECTION OF CONDUIT AND DUCT. 2TYPES OF RACEWAY. 2Raceway Designed for Encased Burial (EB) in Concrete . 2Raceway Designed for Direct Burial (DB) . 2PIPE STIFFNESS . 2HANDLING AND STORAGE OF CONDUIT AND DUCT . 3HANDLING . 3STORAGE . 3Framed Units . 3Coils and Reels. 4Bulk Storage. 4Elbows and Sweeps . 5Fittings, Spacers, and Accessories. 5Cleaners, Primers, Cements, and Adhesives . 5Inventories . 5HANDLING ON THE JOBSITE . 5Conduit and Duct . 5Coils and Reels. 5Solvent Products . 5Inventories . 5INSTALLATION OF CONDUIT AND DUCT. 6PROPER INSTALLATION . 6TRENCH EXCAVATION. 6Trench Wall. 7Trench Bottom . 7CONDUIT AND DUCT SEPARATION. 7Raceway Supports . 7Power Duct Banks . 8Communication Duct Banks . 9Combined Power and Communication Duct Banks . 9Considerations for Specifiers. 9JOINING OF RACEWAY . 9ENCASED BURIAL (EB) OF RIGID NONMETALLIC CONDUIT (RNC).10Conduit and Duct Laying .10Spacers .10Sequence of Laying.10Closure of a Run between Manholes .11Temperature.11Anchoring.11Concrete Pour .11Backfilling.12DIRECT BURIAL (DB) OF RIGID NONMETALLIC CONDUIT (RNC) .12Conduit and Duct Laying .12Temperature.13Bends or Grade Changes .13Raceway Embedment and Final Backfill.13Compaction.13EXPANSION FITTINGS .14FIELD BENDING.14SHORT-RADIUS ELBOWS.14CONDUIT AND DUCT REPAIRS .15PVC Raceway and RTRC .15PE .17CONNECTIONS TO CONDUIT SYSTEMS OF OTHER MATERIALS.17CONDUIT RODDING (FISHING) .17MANDRELLING.17

TCB 2-2012Page iiiAPPENDIX A: FIELD BENDING PROCEDURES FOR PVC CONDUIT .19JOINING.19TRENCH PREPARATION .20PROCEDURES FOR INSTALLATION OF CONDUITS FOR FIELD BENDS .20APPENDIX B: CONDUIT-IN-CASING CONSTRUCTION .23WHAT IS CONDUIT-IN-CASING CONSTRUCTION? .24WHY USE CONDUIT-IN-CASING CONSTRUCTION? .24Organization.24Protection.24Longevity .24CASING TYPES AND SIZES .24CONDUIT NORMALLY USED.25WHAT SUPPORTS THE CONDUITS?.25TYPICAL BORE SPACER EXAMPLES.26GROUT AND REASONS TO GROUT.28“NO GROUT” AND “BLOWN SAND” APPLICATIONS .28TYPICAL BORE SPACER CROSS-SECTIONS .29GROUT INJECTION TECHNIQUES.30OTHER METHODS AND PRACTICES .31APPENDIX C: SOLVENT-CEMENTING JOINTS FOR PVC RIGID NONMETALLIC CONDUIT,DUCT, AND FITTINGS .32TO PRIME OR NOT TO PRIME .

EPC-80 meeting NEMA TC 2; EPEC meeting NEMA TC 7; RTRC SW and HW. DB PVC duct, RTRC, EPC-40, EPC-80 and EPEC may also be encased in concrete (either in trenches or in casings or borings) for extra heavy or high dynamic load applications such as under railroad beds (see Appendix B). PIPE STIFFNESS . Pipe stiffness (PS), also known as duct stiffness (DS), is a useful test value for File Size: 1MBPage Count: 48