Transcription

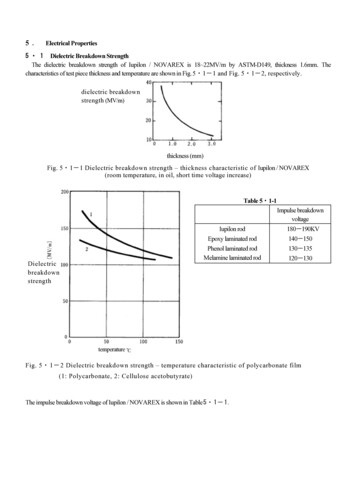

Natural EsterDielectric FluidOverviewEnvirotemp FR3 NWPPA E&O ETF MeetingSpokane, Wa.April 11, 2016Jeff Valmuswww.cargill.comCONFIDENTIAL. This document contains trade secret information. Disclosure, use or reproduction outside Cargill or insideCargill, to or by those employees who do not have a need to know is prohibited except as authorized by Cargill in writing.

What is Natural Ester DielectricFluid? Natural ester (dielectric fluid) insulating liquid is madefrom the oil of naturally grown vegetables Several different varieties have been made but the mostwidely used is FR3 which is made from soybean oil Initially designed to be an environmentally friendlyalternative to less flammable dielectric fluids like PCBsand High Molecular Weight Hydrocarbons28 Commercially began using in transformers in 1996

Validated by industryMeets IEEE and IEC standards- More than 250 series of testsconducted on FR3 fluid- IEEE C57.154 and IEC 60076-14High temperature insulationsystem standard enables up to 85rise new transformer designsClassified as a lessflammable fluid (K-class)- Underwriters Laboratory- FM Global3Cargill FR3 fluid overviewEnvironmental testing- Carbon neutral according to BEES 4.0lifecycle analysis- Ultimately biodegradable by EPA- Non-toxic and non-hazardous in soil andwater by OECDIndustry recognition- 2013 Presidential Green Chemistry Award- 2013 EPA Design for the Environment (DfE)designation (SaferChoice label)- USDA BioPrefered Program- EPA Environmental Technology VerificationCalifornia Environmental TechnologyCertification- FERC ruling – Retrofills with FR3 fluid maybe capitalized

Proven, global installationsOver 1,000,000 natural ester fluidfilled transformers in service globallyOver 100 utilities, including manycomplete adapters 25,000 medium & large power transformers- PGE, EWEB, SCL, PG&E, SMUD, etc. 15,000 indoor units- Many Munis, Coops, and RECs 50,000 substations 10,000 retrofillsFR3 fluid approved for transformersup to 500kV HV testing validates usage through 500kV Siemens 420kV loaded in 2013, Germany 500kV transmission line for Electronorte,Brazil 345KV transmission line for Bureau ofReclamation, US10Over 100 global OEMs applyingand promoting technologyTypes of installations Industrial/CommercialUtilityNetwork transformersNew and retrofill applications

How are Natural Esters different from mineral oil Fire safety No fires, cleanup, downtime, or replacement costsProtects nearby equipment and buildingsGreatly reduced risk to personnelReduced clearance requirements and preventative equipmentEnvironmental FR3 fluid produced from domestic soybeansEnvironmental safety (no hazardous fumes, fires, reducedspill mitigation)Petroleum independentReduced carbon emissionsBiodegradable/non-toxic, recyclable, and sustainableOptimized transformer performance 5Insulation system up to 8X* extended lifespanTransformer asset extended lifespanIncreased overload capabilityEnables smaller, lighter (75-85C rise) designs

Fire point is most critical factor for transformer fire safety Natural ester dielectric fluid fire point 360oC Zero fire history in natural ester fluid filledtransformers* UL Classified and FM Approved* Eliminate deluge systems and fire walls Reduced clearances Simplified containment designs6

BuildingNaturalester fluidMineraloil transformertransformerReducedclearanceFire wallAutomatic firesuppressionsystemMineral oilcontainment andsuppression rocks7Natural estersimplifiedborder

Simpler containment systemTypical Containment system for Mineral OilDesigned to 110% of larger equipment oil volume rainwater fire fighting system water, automatic or manualRocks for flamesuppresionOil / Water separation tankSumpOil Rocks volumeSimplified sump proposed forEnvirotemp FR3 (if required)Fluid volume rain waterDesigned for larger equipment oil volume rain waterManual or Automaticdraining system8

Natural ester fluid is a better choicefor the communities you serve Made from a renewable resource- 98% vegetable oil-Carbon neutral*-Contains no petroleum, halogens, silicones or sulfurs Non-toxic, non-hazardous in water and soil- OECD oral and aquatic toxicity test Biodegrades in 28 days or less- Ultimately biodegradable according Environmental Protection Agency (EPA) Recyclable and Sustainable* According to BEES 4.0 lifecycle analysis9

Best-in-class environmental propertiesBiodegradableNon-toxic10FR3 fluid is biodegradable and non-toxic on both soil and water.

Using FR3 fluid results in simpler, lesscostly spill remediationFR3 fluidMineral Oil––––––Low viscosityFast seepage (infiltration)May reach water reservoirBiodegradation very slowVery high remediation costCauses a sheenSoilWaterTap Water11– Non toxic– Seepage very slow– Ready and completebiodegradation– Very low remediation cost– No sheenSoilTap WaterWater

Industry recognized best-in-classenvironmental fluid12

Transformer Design andOperational Optimization13

Improve reliability: Extend insulation andasset life 5-8x longer than mineral oilUnique chemistry ofFR3 fluid protectsinsulating paper by: Protecting life of insulation paper is the numberone fluidoil ofHydrolysisnaturalester factor that determines asset cantlythemoreproducesfatty acids.than mineraloil Thisprocess removes dissolved waterFR3 fluid has 10 times thewater saturation (PPM) FR3 Fluid is in ions in the fluid willbe reduced due to hydrolysisover time.14

Life “Triangle” flexibility extendstransformer life or increases loadcapacity IEEE C57.154 High temperatureinsulation system standard Current standard 110oC hot spot with 65AWR limits transformer capability FR3 fluid in TR designed for MO willextend insulation system life 15Envirotemp FR3 fluid-basedinsulation systems can be run 20oCwarmer without degrading lifeS.E.E. Overhead Distribution Committee Meeting, April 30, 2015132

Life Extension andImproved Reliability Insulation system will not betransformer failure mode Improved reliability and reducedcatastrophic failure potential Extend residual life of transformer,while gaining fire andenvironmental safety16

Life Extension:SMUD achieves total cost savings throughextended asset lifeCOMPARE MINERAL OIL 30-YEAR LIFE WITH 40-YEAR EXTENDEDLIFE WITH FR3 FLUIDTransformerdescriptionPurchasepricePV TOC withmineral oil dielectric(30-year life)PV TOC with FR3fluid (40-year life)PV TOCdifferencePresent valuebenefit overpurchase price15kVA PoleType 385 1,317 1,187 13034%50kVA 1Phase Pad 1,102 3,001 2,688 31328%150kVA 3Phase Pad 4,385 7,967 7,026 94121%17

FINANCIAL ANALYSIS SUMMARY – Tampa Electric56% SAVINGS OVER 40 YEARS. 8.7MILLION PER YEARALL DISTRIBUTION PAD/POLENET PRESENT COST OF INVESTMENT (1ST COST)NET PRESENT COST OF LOSSES (COL)NET PRESENT TOTAL OWNING COST (TOC)NET PRESENT SAVINGS ON FIRST COSTSFIRST YEAR % INCREASED FIRST COST% NET PRESENT SAVINGS ON FIRST COSTSNET PRESENT SAVINGS ON TOCMINERAL OILFR3 FLUID 25,635,713 164,032,188 189,667,902% NET PRESENT TOTAL SAVINGS (FC&TOC ON INVESTMENT WITH FR3)56.70%5 NET PRESENT SAVINGS TO CUST (COL WITH FR3 VS COL WITH MINERAL OIL1P OVERHEAD POLE TXNET PRESENT COST OF INVESTMENT (1ST COST)NET PRESENT COST OF LOSSES (COL)NET PRESENT TOTAL OWNING COST (TOC)NET PRESENT SAVINGS ON FIRST COSTSFIRST YEAR % INCREASED FIRST COST2.62%MINERAL OILFR3 FLUID 11,965,954 68,696,825 80,862,779% NET PRESENT SAVINGS ON FIRST COSTSNET PRESENT SAVINGS ON TOC% NET PRESENT TOTAL SAVINGS (FC&TOC ON INVESTMENT WITH FR3)5 NET PRESENT SAVINGS TO CUST (COL WITH FR3 VS COL WITH MINERAL OIL 9,868,006 68,539,242 78,407,248 2,097,9487.29%35.50% 2,255,53040.24%5 NET PRESENT SAVINGS TO CUST (COL WITH FR3 VS COL WITH MINERAL OIL1P AND 3P PAD MOUNT TXNET PRESENT COST OF INVESTMENT (1ST COST)NET PRESENT COST OF LOSSES (COL)NET PRESENT TOTAL OWNING COST (TOC)NET PRESENT SAVINGS ON FIRST COSTSFIRST YEAR % INCREASED FIRST COST% NET PRESENT SAVINGS ON FIRST COSTSNET PRESENT SAVINGS ON TOC% NET PRESENT TOTAL SAVINGS (FC&TOC ON INVESTMENT WITH FR3) 21,203,178 159,729,498 180,932,676 4,432,5357.87%28.77% 8,735,2260.23%MINERAL OILFR3 FLUID 13,669,760 95,335,363 109,005,123 11,335,173 91,190,225 102,525,428 2,334,5878.36%24.17% 6,479,69567.09%4.35%

Overload Capability Existing transformerland-locked (footprint)? At or above rated load? Ability to handleincreased load withsame equipment19

SDG&E Overload Study In comparing a 50kVA unit at 65AWR MO allows for a four hour peakoverload of 149% versus FR3 at 178% and 8 hour peak of 130%compared to 154%. A 50kVA FR3 unit at 75AWR allows for a 4 hour overload of 158% versus149% for MO at 65AWR. Unit can be designed smaller and still havegreater overload capacity. OEMs Conclusion:“FR3 65C increases overload by 25-30% over Mineral Oil 65Cand FR3 75C increases overload by 5-10%.”20

OEM Loading Capability of 50kVA Distribution TransformersSolar PV Peak Load Capability HECOMOMO and FR3 50kVA 65C RiseExtra LOL per 130%Base Equivalent LoadPeak Overload Duration(hrs) FR3 is capable of 20-30% higher overloads than MOwithout sacrificing insulation life.21

Transformer Optimization Reduce the size ofthe footprint Reduce first cost Reduce no loadlosses and optimize /kv22

Example: Achieve first cost savingswithout sacrificing reliabilityCurrentBehavior Smaller installed kVAImproved Loss profileLess size and weightLonger life potentialImproved reliabilityAssumptions:– 4.00/NL Watt– 0.50/LL Watt– TOC for FR3 fluid favorable50 75.5%1.60.3Expected 1.0Life23Cargill FR3 fluid overview

Total Owning Cost v. LoadingMO 100% Load 1.0 (Service Life approx. 20 years) 3,000.00FR3 100% Load @ 65C 7.4X MO LifeTOC 2,500.00 2,000.0037.5 FR3 65 C 1,500.0050 M 65 C 1,000.00FR3 100% Load @ 75C 3.2X MO Life37.5 FR3 75 C 500.00 0.0025%50%75% 100% 125% 150% 175%Loading

CPFL in Brazil reduced first cost with moreefficient distribution transformer designBRAZIL’S LARGEST PRIVATELY-OWNED ELECTRICITY COMPANYMIGRATING ITS ENTIRE NETWORK TO FR3 FLUID. 5,000 GREENTRANSFORMERS ALREADY IN OPERATION.Conventional Three-Phase TransformerPower: 45 KVATensions at HT: 11400 V a 13800 VTensions at LT: 127/ 220VWeight: 959 lbs. (435kg)Liters: 24 gal. (90 liters)Price/kVA: R 84.4025Green Three-Phase TransformerPower: 88 KVATensions at HT: 11400 V a 13800 VTensions at LT: 127/220 VWeight: 772 lbs. (350kg)Liters: 21 gal. (81 liters) (biodegradable oil)Price/kVA (estimated): R 53.40

In Conclusion:Natural Ester Dielectric Fluid Prevents fires from occurring in operating transformers Is environmentally friendly, renewable, recyclable and sustainable Is applicable for new and retrofill transformers and voltage regulators Provides for extended life and a lower overall cost with positive NPV Allows for smaller kVA installation with lower losses and initial costs Overload capability without additional loss of life26

Thank You27

Appendix28

Fluid Comparison29

Dielectric fluid comparisonMineral OilNatural EsterSynthetic EsterSilicone OilDiagnosticCapabilityYesYesYesLessFire cNon-toxicLess toxicToxicBiobasedNoYesNoNoOxidationGoodLimited )AgingAverageBestBetterAverageCost 30

Fluid differences impact nceMineral OilFR3 Fluid65 AWR85 AWR110ºC hottest spot130ºC hottest spotAllows for overload or life extensionReliability-dielectricstrengthDielectric strength declinesas heat increases due towater saturationAbility to hold 10 times more waterRetains dielectric strength as heat increasesSelf DryingHydrolysis “consumes” the waterFire safetyEnvironmentalfootprintFlash point 155ºCFlash point 330ºCFire point 160ºCFire point 360ºCNon-biodegradableCostly spill remediationNon toxic, non-hazardous in soil and waterCarbon neutralBiodegradable in 28 daysField experience31120 years of fieldexperienceSPCAA Presentation – May 13, 201420 years of field experience

Technology Comparative SummaryMINERAL OILNATURAL ESTER (FR3 FLUID)SYNTHETIC ESTER Low TemperaturesDiagnostic Testing CapabilityFires when happen major hazardFire Hazard in Sensitive AreasIncreasing Environmental RegulationInstability of Supply & PriceLowest CostCAST RESIN DRY TYPE100% Fire SafetyReadily BiodegradableSustainable, Renewable SupplySuperior Moisture ToleranceExtends solid insulation lifespanSealed transformer onlyDiagnostic testing capabilityHigher cost100% Fire SafetyReadily BiodegradableBest Moisture ToleranceLow TemperatureSuperior Oxidation resistanceDiagnostic testing capabilityApplicable in true free-breathingtransformers Highest CostSILICONE Main use Indoor Locations (susceptible to dirt/moisture) Higher Temperatures & Losses Sensitive to Overload & Harmonics Regular Cleaning Required Minimal Diagnostic Testing Service Life Concerns Large size Highest Initial & Operating CostGood Fire Safety & Overall ReliabilityLow TemperatureNot above 36kVLess Diagnostic Testing CapabilityInferior Coolant & DielectricNot Suitable as Switching MediumNot BiodegradableHigher Cost

FR3 fluid-filled transformer advantagesversus dry-type transformers Lower noise Lower temperature Higher efficiency Longer life Higher over loadability Higher BIL Full diagnostic capability Contamination resistance Improved fire safety Smaller footprint Lower initial price3333Dry type transformers do burn!

Dry-type vs. less flammable liquid filled:Practical size comparisons34

Comparative transformer performanceEFFICIENCYTransformer energyefficiency isdetermined by dividingits nameplate rating bythe sum of itsnameplate rating plusits total lossesA small difference inenergy efficiency canbe significant whenvalued over the life ofthe transformer2500 kVA transformer35

Comparative transformer performanceEFFICIENCYLiquidCastDry6.7612.1812.25kW h Billing Rate: x 0.06 0.06 0.06Annual Hours: x876087608760Total Losses @ 50% Load (kW):Cost of Energy for Losses: 3,553 6,402 6,439Excess Annual Energy Costs:Base 2,849 2,88610-Yr* Excess Energy Costs:Base 28,488 28,855ALSO: transformers losses are dissipated as heat, which must be removed from a controlled temperatureenvironment by air conditioning. For both examples the 10-year air conditioning cost difference is 14,00036

History37

What Is Envirotemp FR3 fluid? Natural ester insulating liquid Vegetable Oil A wide variety available Not all “edible” Biobased, sustainable supply Key is to find balance between properties8

FR3 fluid timelineDGA Standard Published2015High Temp Insulation SystemStandards PublishedIEC Standard Published2010Envirotemp Dielectric FluidsBusiness Purchased by Cargill19Jun12IEEE Standard Published2005ASTM Standard Published2000FR3 Fluid Commercially Available1995199039FR3 Fluid Applied to 1st TransformerFR3 Fluid Formulation Developed

Transformer history(1890-present)Diagnostics put into practiceFree BreathingDesigns18801900Common failure mode: mineral oil(sludge, a bi-product of oxidation)impacted heat signs1930Common failure mode: shiftedto solid insulation; constrainedby operating temperature19601990High temperaturematerials standardsNaturalEsters20102020Common failure mode:solid insulation; operatingtemperature increasedCommon failure mode:solid insulation; operatingtemperature increased55oC AWR, 95oC HST65oC AWR, 110oC HST85oC AWR, 130oC HST

Dielectric fluid is used inside of transformersDielectric Fluid Functions:1. Electrical Insulator2. CoolantDiagnostic capabilitiesDielectric Fluid(fills inside of tank)41

Transformer Design Constraints –Insulation SystemTransformer insulation system is primaryfailure mode Degrades over time, based upon temperature,loading degree/cycle, & contaminants (water &oxygen)Design limits defined by insulation system hotspot temperature (HST) FR3 fluid demonstrates 20oC additional thermalcapability (compared to MO)Hottest SpotTemperature( )Economic value & opportunity 42FR3 fluid’s thermal capability enables lower costper kVA, longer life, reduced transformer price,and positive NPV.AverageWinding Rise (K)(Top Temp - BottomTemp)/2

Standards43

Current List of StandardsNew OilNatural EstersASTM D6871IEC 62770Mineral OilASTM D3487IEC 60296Use and MaintenanceIEEE C57.147IEEE C57.106IEC 60422TransformersIEEE C57.12.00IEC 60076 seriesIEEE C57.154IEC 60076-14IEEE C57.12.00IEC 60076 seriesIEEE C57.154IEC 60076-14Loading Guide(use MO std)IEC 60076-7Dissolved GasesIEEE C57.155IEEE C57.104IEC 60599Fire– FM Global Property Loss Prevention Data Sheets, 5-4 Transformers– IEC 61936-1 Power installations exceeding 1 kV a.c. – Part 1: Common rules4

Fire safety: FM Global risk mitigationTable 2a. Separation Distance Between Outdoor Liquid Insulated Transformers and BuildingsHorizontal Distance1Two Hour FireNoncombustible Combustible VerticalLiquid VolumeApproved TransformerResistant Construction Construction Construction ft Distance ftor Equivalentgal (m3)ft (m)ft (m)(m)(m)Liquid5 (1.5)YesN/A3 (0.9)Less Flammable25 (7.6)25 (7.6) 10,000 (38)5 (1.5)(Approved Fluid)No 10,000 (38)50 (15.2)50 (15.2)15 (4.6) 500 (1.9)5 (1.5)15 (4.6)25 (7.6)25 (7.6)Mineral Oil(orN/A500-5,000 (1.9-19)15 (4.6)25 (7.6)50 (15.2)50 (15.2)unapproved fluid) 5,000 (19)25 (7.6)50 (15.2)100 (30.5) 100 (30.5)1) All transformer components must be accessible for inspection and maintenance.Table 2b. Outdoor Fluid Insulated Transformers Equipment Separation Distance1Liquid VolumeApproved Transformeror Equivalentgal (m3)Distance ft (m)Liquid3 (0.9)YesN/ALess Flammable5 (1.5) 10,000 (38)(Approved Fluid)No 10,000 (38)25 (4.6) 500 (1.9)5 (1.5)Mineral Oil(orN/A500-5,000 (1.9-19)25 (4.6)unapproved fluid) 5,000 (19)50 (7.6)1) All transformer components must be accessible for inspection and maintenance.45distance fromtransformerdistance fromcontainmentedgedistance fromtransformerdistance fromcontainmentedge

FR3 fluid inapplication46

FR3 fluid has equivalent or superiordielectric strength to mineral oilBASED ON THE PERFORMED TESTS AND SEVERAL PUBLISHEDPAPERS, SEVERAL CONCLUSIONS CAN BE MADE:EnvirotempFR3 FluidTransformer Designturn-to-turncoil-to-coilbushing-to-tank wallcreeptap changer selector rodIn-Servicewater erstreaming electrificationbubble formation better47MineralOil --- the same----– worseEnvirotemp FR3 MineralFluidOilElectrode Geometry – OilGapuniformmildly divergentstrongly divergentElectrode Geometry –Creepmildly divergentstrongly divergent - -

FR3 fluid is compatible with commontransformer materialsLIST BELOW SHOWS MATERIALS TESTED AND APPROVED WITH FR3 FLUID48

Overload Capability:SDG&E Loading Calcs DOE 2016 designs, 65C Nameplate 12kV with taps, 120/240 Conventional4hr Peak Load -Normal LOL498 hr Peak Load -Normal LOLkVAActual AWR65C kVAMineral OilFR3Mineral n/a162%n/a140%

Loading Capability of Distribution Transformers 50kVA SolarPV Peak Load Capability HECO50kVA DesignCurrentMO 65CFR 65CMO 55C FR 55C MO 45CActual Winding Rise (C)64.863.363.354.054.543.7Peak Load with normal LOL126136177165200200Peak Load with 5-10X LOL167173200200228234Weight (lbs.)630604604650625742Height (in)404040444244 Neither FR3 or MO 65AWR design could reach 200 percent overload for 4 hours withoutLOL. FR3 at 55AWR or MO at 45AWR could achieve desired overload conditions with LOL.Mineral oil unit would have to be taller and heavier than the FR3 designed unit50

Loading Capability of Distribution Transformers 25kVA SolarPV Peak Load Capability HECO25kVA DesignCurrentMO 65CFR 65CMO 45CActual Winding Rise (C)58.449.049.037.5Peak Load with normal LOL131170200213Peak Load with 5-10X LOL177200232261Weight (lbs.)365378378454Height (in)44424242 In the 25kVa design FR3 at 65 AWR could meet the design requirement. Would require MO unit to be designed at 45 AWR to achieve desired results. Weight of MO unit would be much heavier than FR3 unit.51

Testing52

FR3 fluid performance and diagnostic testingis similar to MO with a few modificationsRULE OF THUMB – “WHAT DO YOU DO WITH MINERAL OIL?” Some traditionally acceptable indicator of mineral oil performance may not apply(interfacial tension) BDV and DDF are the best parameters to evaluate the general contamination FR3 fluid is a mixture of relatively polar triglycerides (long-chain fatty estermolecules) Have unsaturation and ability to form hydrogen bonds Mineral oil is non-polar and hydrophobic Difference in basic chemistry accounts for disparate valuesPerformance TestModificationFR3 fluid vs. MOresultNotes (Refer G2300 p13)DielectricBreakdownVoltageStand time 30 minutes, ASTM: 2mm gap,IEC: 2.5 mm gapSameNoneWater ContentUse relative saturation to comparedifferent type of dielectric fluidsHigherMaintains dielectric strength athigher absolute water contentsViscosityNoneHigherIndicator of oxidation53

Diagnostic testing results and modificationsDiagnostic testTest modification requirementsFR3 fluid vs.MO resultNotes (Refer G2300 p14-17)Water ContentNoneHigherHelps dry transformer insulationDissipation FactorNone – meticulously clean cell if usingfor FR3 and MOHigherHigher transformer power factorAcid NumberNoneHigherFR3 fluid generates long chain fatty acids that are mild andnon-corrosiveInterfacial TensionNoneLowerNot useful for FR3 fluid – use dissipation factorResistivityNoneLowerLower transformer insulation resistancePour PointHeat fluid to 50C, cool to room tempHigherEffects low temperature mechanical movementGassing TendencyNoneNANAOxidation InhibitorUse GC instead of IR methodUse DSC to evaluate inhibitor additivesNAReplenish inhibitor if content falls below 0.12%Oxidation StabilityUse IEC 62770 methodNANAPCB ContentPacked column, sulfuric acid treatmentNoneNot found in vegetable oilsFlash and FirePointsNoneHigherUpgrades fire safetyDissolved GasAnalysisNoneDifferentStray gases differ from mineral oilCorrosive SulfurNoneNoneNot found in vegetable oilsFuranic CompoundNone - for new FR3 fluidDifferentInterferences from degradation productsParticle CountDilute FR3 fluid 75% with filteredheptane or hexaneNAAir bubbles in FR3 fluid may not dissipate and are detectedas particles54

Dissolved gas analysis in a nutshell1. Refer to IEEE C57.155 for stray gassing levels If only one data set, use IEEE C57.104 “Condition” method as firstbest guess (account for stray gassing) If Condition warrants it, take another sample2. Check gassing rate Gassing rate low: done Gassing rate significant: continue to 33. Use IEEE “Key Gases” method and Duval triangle method to diagnose4. Use additional methods as needed55

ColdTemperature FR3 fluid-filled transformers are currentlyenergized and operating admirably innumerous “cold weather” locations Northern Canada Alaska, International Falls Scandinavia Cold Start, Storage & Handling GuidesAvailable Use recommended mineral oil ‘cold startprocedures’56Missoula, Montana; FR3 fluidretrofill completed at -25oC.

FR3 fluid maintains dielectric strengthregardless of ambient temperaturePOUR POINT DOES NOT DETERMINE FLUID PERFORMANCEIN COLD TEMPERATURESInside of a transformer, the temperature of the fluid is dependent upon:- Ambient temperature- Volume of Fluid- Time at Ambient Temperature- Rate of CoolingEnergizing cold FR3 fluid transformer at fullrated load causes no unusual temperatures57FR3 fluid breakdown voltage is maintainedto at least -50 C

Follow IEEE cold start proceduresSAME COLD START PROCESS AS MINERAL OIL.DIFFERENT REASONS. Mineral oil contains free water– Use cold start procedure required used to avoiddielectric failure (heat slowly to dissolve water) FR3 fluid maintains dielectric strengthhowever may thicken in extended transformerinactivity– Use cold start procedure required to regainviscosity (may hamper mechanical movement) The time required to gel is variable,dependent on volume of fluid, temperatureand rate of cooling– E.g. Honey zone -20 C for at least 2 weeks– No clear transition solid-liquid58

Oxidation Stability FR3 is recommended in all non-freebreathing transformers Both mineral oil and natural esters oxidize– takes years, not days The fluids oxidize differently Products of mineral oil oxidation form sludgeprecipitates Products of natural ester oxidation form oligomers(larger molecules) that stay in solution Thin film polymerization is an avoidable concernthat must be accounted for in handling procedures The long term effect on the transformer isthe same: less efficient heat transfer59

Drying ProcessDO NOT USE HOT AIR (DRYING) OVENS FORIMPREGNATED ASSEMBLIES Drying of new materials (not yet impregnated) No restrictions regarding oven types Drying of impregnated materials Clean the surfaces using a compatible solvent(kerosene, alcohol or warm mineral oil) Keep all insulation material immersed ininsulation fluid or nitrogen gas Wrap the windings and insulation materialscompletely using plastic film (stretch) forpreventing contact with ambient air Dry impregnated coils using hot FR3 fluid,kerosene vapors or nitrogenHot air oven is not recommended for previously impregnated materials,due to oxidation of thin films of FR360

Oxidation stability is a consideration forroutine maintenanceREDUCE EXPOSURE TO AIR TO MINIMINZE POTENTIAL FOR THINFILM POLYMERIZATION For smooth surfaces (e.g. steel), limit theexposure to air and UV to 7 calendar days For porous surfaces (e.g. paper), limit theexposure to air and UV to 20 calendar days Clean the surfaces using a compatible solvent(kerosene, alcohol or warm mineral oil, temp. 60 C) Keep all insulation material immersed ininsulation fluid or Wrap the windings and insulation materialscompletely using plastic film (stretch) forpreventing contact with ambient air Avoid hot air (drying) ovens61

The Transformation62

Tata Power: Designs 20MVA withcapacity of 28MVA, 16% savingsTHIRD LARGEST UTILITY IN INDIA – 2 20MVA TRANSFORMERS WILL BE PLACED INFINANCIAL DISTRICT AS PART OF GOVERNMENT “SMART CITY” INITIATIVENew transformer design Increased capacity by 8 MVA, while reducing the footprint by 17% Yields cost-savings of about 16% Reduces noise levels from 73 decibels to 59 Increases fire safety Enhances the transformers’ environmental profileNext steps Exploring high temperature capabilities with new designs forgreater performance efficiencies Incorporate first-ever pad-mounts in India (already converted powerand distribution to FR3)63Presentation Title-DateFirst power transformer with FR3fluid for Tata Power

Advantages available today and newadvancements on the horizonIn the past65C AWR/110 HST MOInsulation failure mode 64100 kVA65 C AWR110 C HST20.55 yearsInsulation system likely failure mode155 C fire pointPetroleum based fluidLimited overload potentialAvailable today75C AWR/120 HST FR3Increased load capability 100 kVA75 C AWR120 C HST 20.55 yearsImproved reliability Robust insulation system Improved fire safety 360 C fire point Best in class environmentalpropertiesWorking towards85C AWR/130 HST FR3Reduced size/footprint 100 kVA85 C AWR130 C HST20.55 yearsImproved reliability Robust insulation system Improved fire safety –360 C fire point Best in class environmentalproperties Reduced initial price

Typical Containment system for Mineral Oil Designed to 110% of larger equipment oil volume rain water fire fighting system water, automatic or manual Rocks for flame suppresion Sump Oil Rocks volume Oil / Water separation tank Simplified sump proposed for Envirotemp FR3 (if required) Designed for larger equipment oil volume rain water