Transcription

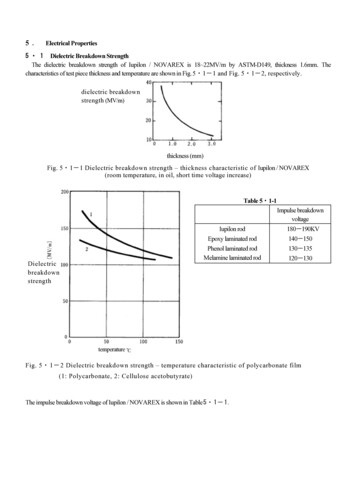

5 . Electrical Properties5 ・ 1 Dielectric Breakdown StrengthThe dielectric breakdown strength of Iupilon / NOVAREX is 18 22MV/m by ASTM-D149, thickness 1.6mm. Thecharacteristics of test piece thickness and temperature are shown in Fig. 5・1‐1 and Fig. 5・1‐2, respectively.dielectric breakdownstrength (MV/m)thickness (mm)Fig. 5・1‐1 Dielectric breakdown strength – thickness characteristic of Iupilon / NOVAREX(room temperature, in oil, short time voltage increase)Table 5・1-1Impulse breakdownvoltageIupilon rodDielectricbreakdownstrength180‐190KVEpoxy laminated rod140‐150Phenol laminated rodMelamine laminated rod130‐135120‐130temperatureFig. 5・ 1‐ 2 Dielectric breakdown strength – temperature characteristic of polycarbonate film(1: Polycarbonate, 2: Cellulose acetobutyrate)The impulse breakdown voltage of Iupilon / NOVAREX is shown in Table 5・1‐1.

A comparison with other resins is shown in Fig. 5・1‐3.Rubber modified etalAcrylate( PMMA)EthylcelluloseChlorofluoroethyleneCellulose propionateTeflonPolycarbonateABSCellulose butyrateCellulose acetateFig. 5・1‐3 Dielectric breakdown strength of various resins(short time voltage increase: ASTM-D149)5・ 2Insulation ResistanceThe volume resistivity of Iupilon / NOVAREX isASTM-D257-58‐ 30〜 ‐ 3 1017Ω ・ cm23 2. 110 1 6125 2. 010 1 4The surface resistivity of polycarbonate isIn the dry state 1015ΩImmersed in water for 4 hours( DIN53482, φ80, 2mm thickness) 1015Ω

A comparison of volume resistivity with other resins is shown in Fig. lycarbonateAcrylate( PMMA)PolypropyleneGlass fiber reinforcednylonNylonCellulose propionatePolyacetalGlass fiber reinforcedpolystyreneRubber modifiedPVCEthylcelluloseCellulose acetateCellulose butyrateFig. 5・ 2‐ 1Volume resistivity of various resins (ASTM-D257)5・ 3 Dielectric Constant and Dielectric Dissipation FactorThe dielectric constant and dielectric dissipation factor of Iupilon / NOVAREX areASTM-D150-54T, 50Hz, normal temperatureDielectric constant26.5PF/m(3.0)Dielectric dissipation factor0.0009The temperature characteristics and frequency characteristics of dielectric constant and dielectricdissipation factor of Iupilon / NOVAREX are shown in Fig. 5・3‐1 and Fig.5・3‐2, respectively.Also, a comparison of dielectric constant with other resins is shown in Fig. 5・3‐3.Resins with low dielectric constant are suitable for use as insulator and those with high dielectricconstant are suitable for use as capacitor. Iupilon / NOVAREX can be used for both applications. Also, its feature is thatchange due to temperature and frequency is small.

dielectricdissipation factor(PF/m)dielectricconstanttemperatureFig. 5・3‐1Temperature characteristics of dielectric constant and dielectric dissipation factor of Iupilon / NOVAREXdielectricconstant (PF/m)dielectricdissipationfactorfrequency(HzFig. 5・3‐2 Frequency characteristics of dielectricconstant and dielectric dissipation factor of polycarbonate)

ePolystyreneAcrylate( PMMA)ABSRubber modified PVCPolycarbonateEthylcellulosePolyacetalCellulose propionateCellulose butyrateCellulose acetateNylonFig. 5・3‐3 Dielectric constant of various resins (ASTM-D150, frequency 60 x 106Hz)5・4 Other Electrical Properties5・ 4・ 1 Arc ResistanceT h e a r c r e s i s t a n c e o f Iupilon / NOVAREX based on ASTM-D495 isTungsten electrode100 120sec.Stainless steel electrode10 11secT h e a r c r e s i s t a n c e o f Iupilon / NOVAREX after immersing in water at room temperature for 100 hours isTungsten electrode93sec.The influence of carbon black addition on the arc resistance of Iupilon / NOVAREX, and the influence ofcolorant addition are shown in Table 5・4・1‐1 and Table 5・4・1‐2, respectively.Table 5・4・1‐1Influence of carbon black addition on the arc resistance of Iupilon / NOVAREX(use of tungsten electrode)Mv 2.4Additive rate of carbon black 〔wt%〕 0Arc resistance〔sec〕1100.01 3985838104

Table 5・4・1‐2 Influence of colorant addition on the arc resistance of Iupilon / NOVAREX(addition of 0.1wt% colorant, use of tungsten electrode)M v 2. 4 1 0 4ColorantsArc resistance〔sec〕ColorantsArc resistance〔sec〕BlackGreen seriesOrange series117121110Green seriesCyanine blueOrange series96104121Blue series119Yellow series116Yellow series“Red series119123107“118Orange seriesPink seriesFluorescent pigmentTitanium white118118122119Green series109The arc resistance of various thermoplastic resins is shown in Table 5・4・1‐3.Table ison of arc resistance, use of tungsten electrodeArc resistanceBreakdown〔sec〕status *110A 240D66 Nylon 140CPolypropylene 140E6 NylonPolyethylenePolystyrene140B 130E 130E125A12 NylonPolymethylmethacrylate 120C 120EASPolyethyleneterephthalatePC・ABS blended product 120IonomerHighimpactpolystyreneABSPolysulphone 111PBT(composite reinforced)Modified PPEstrengthB.E.120A112AB.E. 95E93A78A67A* Breakdown statusA:B:C:D:arc extinction by carbonizationarc extinction by inflammationburn, but arc does not extinctleave a hole due to melting but arcdoes not ectinctE: burn and leave a hole but arc does notextinct

5・ 4・ 2Tracking ResistanceThe tracking resistance of polycarbonate isIE C 1 12( platinu m electro de) 2 40 2 60IE C 1 12( brass electrod e)1 35 1 505・4・3 Corona ResistanceThe corona resistance of polycarbonate is shown in Fig. 5・4・3‐1. It indicates infinite endurance at about 30MV/m.The corona inception voltage of Iupilon / NOVAREX is shown in Table 5・4・3‐1.fieldstrength(Mv/m)duration time (S)Fig. 5・4・3‐1Relation between dielectric breakdown voltage (frequency 50Hz) andexposure time of polycarbonateTable 5・ 4・ 3‐ 1Iupilon / NOVAREX rodEpoxy laminated rodPhenol laminated rodMelamine laminated rodCorona inception voltage(kV)Flashover voltage(kV)45‐505030‐5030‐50Above 50Above 50Above 40‐50Above 50

The dielectric breakdown strength of Iupilon / NOVAREX is 18 22MV/m by ASTM-D149, thickness 1.6mm. The characteristics of test piece thickness and temperature are shown in Fig. 5・1‐1 and Fig. 5・1‐2, respectively. Fig. 5・1‐1 Dielectric breakdown strength – thickness characteristic of Iupilon / NOVAREX (room temperature, in oil, short time voltage increase) Table 5 ・1-Impulse bre