Transcription

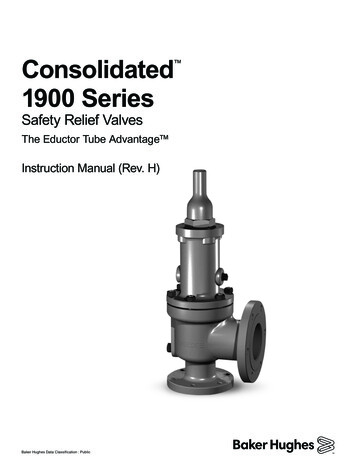

Consolidated1900 Series Safety Relief ValvesThe Eductor Tube Advantage Instruction Manual (Rev. H)Baker Hughes Data Classification : Public

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFICREFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATIONAND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE PHILOSOPHIES VARY,BAKER HUGHES (AND ITS SUBSIDIARIES AND AFFILIATES) DOES NOT ATTEMPT TO DICTATESPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND REQUIREMENTS CREATED BYTHE TYPE OF EQUIPMENT PROVIDED.THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDINGOF THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENTIN POTENTIALLY HAZARDOUS ENVIRONMENTS. THEREFORE, THESE INSTRUCTIONS SHOULDBE INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY RULES AND REGULATIONSAPPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHEREQUIPMENT AT THE SITE.THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENTNOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITHINSTALLATION, OPERATION OR MAINTENANCE. SHOULD FURTHER INFORMATION BE DESIREDOR SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED SUFFICIENTLY FOR THECUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO BAKER HUGHES.THE RIGHTS, OBLIGATIONS AND LIABILITIES OF BAKER HUGHES AND THE CUSTOMER/OPERATORARE STRICTLY LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THESUPPLY OF THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY BAKERHUGHES REGARDING THE EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OFTHESE INSTRUCTIONS.THESE INSTRUCTIONS ARE FURNISHED TO THE CUSTOMER/OPERATOR SOLELY TO ASSIST IN THEINSTALLATION, TESTING, OPERATION, AND/OR MAINTENANCE OF THE EQUIPMENT DESCRIBED.THIS DOCUMENT SHALL NOT BE REPRODUCED IN WHOLE OR IN PART WITHOUT THE WRITTENAPPROVAL OF BAKER HUGHES.2 Baker Hughes 2022 Baker Hughes Company. All rights reserved.

Conversion TableAll the United States Customary System (USCS) values are convertedto metric values using the following conversion factors:USCS UnitConversion FactorMetric rpsig0.06894757bargft lb1.3558181Nm F5/9 ( F-32) CNote: Multiply USCS value with conversion factor to get metric value.NOTICE!For valve configurations not listed in this manual,please contact your local Green Tag Center(GTC ) for assistance. 2022 Baker Hughes Company. All rights reserved.Consolidated 1900 Series SRV Instruction Manual 3

Table of ContentsI.Product Safety Sign and Label System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6II.Safety Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7III.Safety Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8IV.Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8V.Terminology for Safety Relief Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9VI.Handling and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10VII.Pre-Installation and Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10VIII.Design Features and Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11IX.Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11X.Consolidated 1900 Series Safety Relief Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12XI.Read - Understand - Practice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Cap and Lever Interchangeability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Design Simplicity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Nomenclature Related to Design Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Simple Blowdown Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Valve Interchangeability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11A.B.C.D.E.F.G.Metal Seat Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Standard Cap Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Bellows Metal Seat Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14V-W Bellows Metal Seat Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Soft Seat Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16Themodisc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17UM Cryogenic Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Recommended Installation Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19A. Mounting Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19B. Inlet Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19C. Outlet Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20XII.Disassembly of 1900 Series Safety Relief Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21XIII.Maintenance Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25XIV.A. General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21B. SRV Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21C. Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24A.B.C.D.E.F.General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lapping Nozzle Seats (Non-O-Ring Styles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lapped Nozzle Seat Widths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lapping Disc Seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Precautions and Hints for Lapping Seats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lapping O-Ring Seating Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252526282829Inspection and Part Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35A. Nozzle Inspection Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35B. Nozzle Seat Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35C. Nozzle Bore Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354 Baker Hughes 2022 Baker Hughes Company. All rights reserved.

D. 1900 Series SRV Standard Disc Inspection Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35TME. 1900 Series Thermodisc Replacement Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35F. 1900 UM Series Cryogenic Disc Replacement Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35G. Disc Holder Inspection Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41H. Guide Inspection Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44I. Spindle Inspection Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44J. Spring Inspection Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45XV.Reassembly of 1900 Series SRV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46XVI.Setting and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53A.B.C.D.A.B.C.D.E.F.G.H.I.J.K.General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Reassembly Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Test Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Setting the Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Set Pressure Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Setting the Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Seat Tightness Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Recommended Backpressure Testing for Joint Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Blowdown Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hydrostatic Testing and Gagging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Manual Popping of the Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .464646465353535353555557575858XVII. Troubleshooting 1900 Series SRVs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59XVIII. 1900 Series Safety Relief Valve Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60A.B.C.D.General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Conversion from Conventional to Bellows Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Conversion from Bellows to Conventional Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Optional Glide-Aloy Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60606263XIX.Maintenance Tools and Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64XX.Replacement Parts Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66XXI.Genuine Consolidated Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67A. Lapping Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65A. Basic Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66B. Replacement Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66C. Identification and Ordering Essentials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66XXII. Recommended Spare Parts for 1900 Series SRVs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68XXIII. Manufacturer’s Field Service, Repair and Training Program. . . . . . . . . . . . . . . . . . . . . . 70 2022 Baker Hughes Company. All rights reserved.Consolidated 1900 Series SRV Instruction Manual 5

I.Product Safety Sign and Label SystemIf and when required, appropriate safety labels have been included inthe rectangular margin blocks throughout this manual. Safety labels arevertically oriented rectangles as shown in the representative examples(below), consisting of three panels encircled by a narrow border. Thepanels can contain four messages which communicate: The level of hazard seriousness The nature of the hazard The consequence of human, or product, interaction with the hazard. The instructions, if necessary, on how to avoid the hazard.The top panel of the format contains a signal word (DANGER, WARNING,CAUTION or ATTENTION) which communicates the level of hazardseriousness.The center panel contains a pictorial which communicates the natureof the hazard, and the possible consequence of human or productinteraction with the hazard. In some instances of human hazards thepictorial may, instead, depict what preventive measures to take, such aswearing protective equipment.The bottom panel may contain an instruction message on how to avoidthe hazard. In the case of human hazard, this message may also containa more precise definition of the hazard, and the consequences of humaninteraction with the hazard, than can be communicated solely by thepictorial.1Do not remove boltsif pressure in line, asthis will result in severepersonal injury ordeath.6 Baker Hughes1DANGER — Immediatehazards which WILL result insevere personal injury or death.2WARNING — Hazards orunsafe practices which COULDresult in severe personal injuryor death.3CAUTION — Hazards orunsafe practices which COULDresult in minor personal injury.4ATTENTION — Hazards orunsafe practices which COULDresult in product or propertydamage.234Know all valve exhaust/leakage points toavoid possible severepersonal injury ordeath.Wear necessaryprotective equipment toprevent possible injuryHandle valvecarefully. Do notdrop or strike. 2022 Baker Hughes Company. All rights reserved.

II.Safety AlertsRead - Understand - PracticeDanger AlertsA DANGER alert describes actions that may causesevere personal injury or death. In addition, itmay provide preventive measures to avoid severepersonal injury or death.DANGER alerts are not all-inclusive. Baker Hughescannot know all conceivable service methods norevaluate all potential hazards. Dangers include: High temperature/pressure can cause injury.Ensure all system pressure is absent beforerepairing or removing valves. Do not stand in front of a valve outlet whendischarging. STAND CLEAR OF VALVE to avoidexposure to trapped, corrosive media. Exercise extreme caution when inspecting apressure relief valve for leakage. Do not work or allow anyone under the influenceof intoxicants or narcotics to work on or aroundpressurized systems. Workers under the influenceof intoxicants or narcotics are a hazard tothemselves and other employees. Actions takenby an intoxicated employee can result in severepersonal injury or death to themselves or others. Always perform correct service and repair. Incorrect service and repair can result in productor property damage or severe personal injury ordeath. Always use the correct tool for a job. The misuseof a tool or the use of an improper tool can resultin personal injury, damage to product or property. Ensure the proper “health physics” procedures arefollowed, if applicable, before starting operation ina radioactive environment.Caution Alerts Allow the system to cool to room temperaturebefore cleaning, servicing, or repairing. Hotcomponents or fluids can cause severe personalinjury or death.A CAUTION alert describes actions that may resultin a personal injury. In addition, they may describepreventive measures that must be taken to avoidpersonal injury. Cautions include: Always read and comply with safety labels on allcontainers. Do not remove or deface containerlabels. Improper handling or misuse could result insevere personal injury or death. Heed all service manual warnings. Readinstallation instructions before installing valve(s). Never use pressurized fluids/gas/air to cleanclothing or body parts. Never use body parts tocheck for leaks, flow rates, or areas. Pressurizedfluids/gas/air injected into or near the body cancause severe personal injury or death. Wear hearing protection when testing or operatingvalves. Wear appropriate eye and clothing protection. Wear protective breathing apparatus to protectagainst toxic media. It is the owner’s responsibility to specify andprovide protective wear to protect personsfrom pressurized or heated parts. Contact withpressurized or heated parts can result in severepersonal injury or death. 2022 Baker Hughes Company. All rights reserved.Consolidated 1900 Series SRV Instruction Manual 7

III.Safety NoticeProper installation and start-up is essential to the safe and reliable operation of all valveproducts. The relevant procedures recommended by Baker Hughes, and described inthese instructions, are effective methods of performing the required tasks.It is important to note that these instructions contain various “safety messages” whichshould be carefully read in order to minimize the risk of personal injury, or the possibilitythat improper procedures will be followed which may damage the involved Baker Hughesproduct, or render it unsafe. It is also important to understand that these “safety messages”are not exhaustive. Baker Hughes can not possibly know, evaluate, and advise anycustomer of all of the conceivable ways in which tasks might be performed, or of thepossible hazardous consequences of each way. Consequently, Baker Hughes has notundertaken any such broad evaluation and, thus, anyone who uses a procedure and/or tool, which is not recommended by Baker Hughes, or deviates from Baker Hughesrecommendations, must be thoroughly satisfied that neither personal safety, nor valvesafety, will be jeopardized by the method and/or tools selected. If not so satisfied, pleasecontact your local Green Tag Center if there are any questions relative to procedures and/or tools.Wear necessaryprotective equipment toprevent possible injuryThe installation and start-up of valves and/or valve products may involve proximity tofluids at extremely high pressure and/or temperature. Consequently, every precautionshould be taken to prevent injury to personnel during the performance of any procedure.These precautions should consist of, but are not limited to, ear drum protection, eye protection, and the use of protectiveclothing, (i.e., gloves, etc.) when personnel are in, or around, a valve work area. Due to the various circumstancesand conditions in which these operations may be performed on Baker Hughes products, and the possible hazardousconsequences of each way, Baker Hughes can not possibly evaluate all conditions that might injure personnel orequipment. Nevertheless, Baker Hughes does offer certain Safety Alerts, listed in Section II, for customer informationonly.It is the responsibility of the purchaser or user of Baker Hughes valves/equipment to adequately train all personnelwho will be working with the involved valves/equipment. Further, prior to working with the involved valves/equipment,personnel who are to perform such work should become thoroughly familiar with the contents of these instructions.IV.Warranty InformationWarranty Statement:(1) Baker Hughes warrants that its products and work will meet all applicable specifications and otherspecific product and work requirements (including those of performance), if any, and will be free from defects in materialand workmanship.CAUTIONDefective and nonconforming items must be heldfor Baker Hughes’ inspection and returned to theoriginal F.O.B point upon request.Incorrect Selection or Misapplication of Products: Baker Hughes cannot be responsible for customer’s incorrect selectionor misapplication of our products.Unauthorized Repair work: Baker Hughes has not authorized any non-Baker Hughes affiliated repair companies,contractors or individuals to perform warranty repair service on new products or field repaired products of itsmanufacture. Therefore customers contracting such repair services from unauthorized sources must do at their own risk.Unauthorized Removal of Seals: All new valves and valves repaired in the field by Baker Hughes Field Service are sealedto assure the customer of our guarantee against defective workmanship. Unauthorized removal and/or breakage of this sealwill negate our warranty.(1) Refer to Baker Hughes’s Standard Terms of Sale for complete details on warranty and limitation of remedy and liability.8 Baker Hughes 2022 Baker Hughes Company. All rights reserved.

IV.Warranty Information (Cont.)SEALEDDefective andnonconforming itemsmust be inspectedby Baker HughesV.Removal and/orbreakage of seal willnegate our warranty.Terminology for Safety Relief Valves Accumulation - the pressure increase over themaximum allowable working pressure of the vesselduring discharge through the SRV, expressed as apercentage of that pressure or in actual pressureunits. Backpressure - the pressure on the discharge sideof the SRV:– Built-up backpressure - the pressure thatdevelops at the valve outlet, after the SRV hasbeen opened, as a result of flow.– Superimposed backpressure - the pressure inthe discharge header before the SRV is opened. – Constant backpressure - the superimposedbackpressure that is constant with time.– Variable backpressure - the superimposedbackpressure that varies with time. Blowdown - the difference between set pressureand re-seating pressure of the SRV, expressedas a percentage of the set pressure or in actualpressure units. Cold Differential Set Pressure - the pressure atwhich the valve is adjusted to open on the teststand. This pressure includes the correctionsfor backpressure and/or temperature serviceconditions. Differential Between Operating and Set Pressures Valves in installed process services will generallygive best results if the operating pressure doesnot exceed 90% of the set pressure. However,on pump and compressor discharge lines, thedifferential required between the operating and 2022 Baker Hughes Company. All rights reserved.set pressures may be greater because of pressurepulsations coming from a reciprocating piston.The valve should be set as far above the operatingpressure as possible. Lift - the actual travel of the disc away from theclosed position when a valve is relieving. Maximum Allowable Working Pressure - theaximum gauge pressure permissible in a vesselat a designated temperature. A vessel may not beoperated above this pressure, or its equivalent, atany metal temperature other than that used in itsdesign. Consequently, for that metal temperature,it is the highest pressure at which the primarypressure SRV is set to open. Operating Pressure - the gauge pressureto which the vessel is normally subjected inservice. A suitable margin is provided betweenoperating pressure and maximum allowableworking pressure. For assured safe operation, theoperating pressure should be at least 10% underthe maximum allowable working pressure or 5 psi(.34 bar), whichever is greater. Overpressure - a pressure increase over the setpressure of the primary relieving device.Overpressure is similar to accumulation when therelieving device is set at the maximum allowableworking pressure of the vessel. Normally,overpressure is expressed as a percentage of setpressure.Consolidated 1900 Series SRV Instruction Manual 9

V. Terminology for Safety Relief Valves (Cont.)VI. Handling and Storage (Cont.) Rated Capacity - the percentage of measured flowat an authorized percent overpressure permittedby the applicable code. Rated capacity is generallyexpressed in pounds per hour (lb/hr) for vapors,standard cubic feet per minute (SCFM) or m3/min forgases, and in gallons per minute (GPM) for liquids.Wrap a chain or sling around the discharge neck andaround the upper bonnet structure to move or hoistan uncrated valve. Ensure the valve is in a verticalposition during the lift. Relief Valve - an automatic pressure-relieving device,actuated by static pressure upstream from the valve.A relief valve is used primarily for liquid service. Safety Relief Valve (SRV) - an automatic pressurerelieving device used as either a safety or reliefvalve, depending upon application. The SRV is usedto protect personnel and equipment by preventingexcessive overpressure. Safety Valve - an automatic pressure-relieving deviceactuated by the static pressure upstream of the valve,and characterized by a rapid opening or “pop” action.It is used for steam, gas, or vapor service. Set Pressure - the gauge pressure at the valveinlet for which the relief valve has been adjusted toopen under service conditions. In liquid service, theinlet pressure at which the valve starts to dischargedetermines set pressure. In gas or vapor service, theinlet pressure at which the valve pops determinesthe set pressure. Simmer - the audible passage of a gas or vaporacross the seating surfaces just before “pop.” Thedifference between this start-to-open pressureand the set pressure is called “simmer.” Simmer isgenerally expressed as a percentage of set pressure.VI.Handling and StorageHandlingAlways keep the inlet flange down on a crated oruncrated flange valve to prevent misalignment anddamage to valve internals.ATTENTION!Never lift the full weight of the valve by thelifting lever.ATTENTION!Handle carefully. Do not drop or strike the valve.Do not subject SRVs, either crated or uncrated, tosharp impact. Ensure that the valve is not bumpedor dropped during loading or unloading from atruck. While hoisting the valve, take care to preventbumping the valve against steel structures and otherobjects.ATTENTION!Prevent dust and debris from enteringinlet or outlet of the valveStorageStore SRVs in a dry environment and protect themfrom the weather. Do not remove the valve from theskids or crates until immediately before installation.Do not remove flange protectors and seating plugsuntil the valve is ready to be bolted into place duringthe installation.VII. Pre-Installation andInstallation InstructionsWhen SRVs are uncrated and the flange protectorsor sealing plugs are removed, exercise meticulouscare to prevent dirt and other foreign materials fromentering the inlet and outlet ports while bolting thevalve in place.ATTENTION!Do not rotate the valve horizontally orlift/carry using the lifting lever.10 Baker Hughes 2022 Baker Hughes Company. All rights reserved.

VIII. Design Features andNomenclatureIX.Cap and Lever InterchangeabilityThe safety relief valve (SRV) is an automatic,pressure-actuated relieving device suitable for useeither as a safety valve or relief valve, depending onapplication.In the field, it is often necessary to change the typeof cap or lever after a valve has been installed. Allflanged Consolidated SRVs are designed to beconverted to any type of lever or cap desired. It is notnecessary to remove the SRV from the installation,nor will the set pressure be affected when makingsuch a change.Design SimplicityConsolidated SRVs have few component parts,resulting in savings by minimizing spare partsinventory and simplifying valve maintenance.IntroductionSRVs are used on hundreds of different applications,including liquids and hydrocarbons; therefore, thevalve is designed to meet many requirements.The 1900 Series valves included in this manual maybe used to meet the requirements for ASME SectionIII and Section XIII (UV Designator). They cannotbe used on ASME Code Section I steam boilers orsuperheaters, but may be used on process steam.Nomenclature Related to DesignFeaturesThe nomenclature of the components of 1900 Seriesvalves, including those with design options foruniversal media, universal media soft-seat bellows,O-ring seat, liquid trim, and Thermodisc, is identifiedin Figu

Consolidated 1900 Series SRV Instruction Manual 7. Proper installation and start-up is essential to the safe and reliable operation of all valve products. The relevant procedures recommended by Baker Hughes, and described in these instructions, are effective methods of performing the required tasks.