Transcription

NOVA Energy & AutomationProduct SpecificationsMRI Trench DuctModel AT Aluminum Non Ferrous03 January 2012

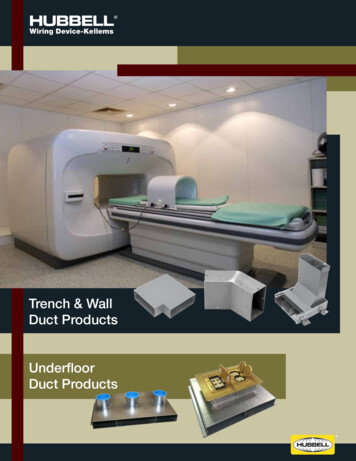

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATDProduct Description1. Non Ferrous Large Capacity Trench (Floor) DuctNon Ferrous (Aluminum) Large capacity metal trench duct is commonly used to route signalling,power, data, and mechanical connections in the floor to MRI imaging equipment during newconstruction and renovations. Trench Duct allows cable routing to be accomplished in applicationswhere conduit is not feasible while maintaining the integrity and aesthetics of the medical imagingsuite. Upgrades and maintenance to the MRI equipment are easy to accomplish with the removablecovers and modular design of the Nova trench duct.Aluminium wire ways (Non Ferrous Metal) are commonly used inside of the MRI Magnet room.Trench Duct can be installed in load-bearing applications flush mounted in the floor. Trench Duct ismanufactured in a variety of sizes from 4 inch up to 48 inches.Nova duct is engineered for the simplest installation. Trench duct is manufactured to the exactdimensions of the individual project which requires no field cutting or modifications.Figure 1: Aluminum Trench Duct Example 1 Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft2

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATD2. Features/BenefitsFeatures ETL listed to UL 870 and cUL standards to conform to NEC.Constructed of 12GA 3003 formed Aluminium¼” plated aluminum load bearing cover, with center supports on sizes which exceed 18”Polished Aluminum FinishGuaranteed Bill of MaterialsAuto Cad Drawings available for every projectSuperior packaging and labellingContinuous water tight gasket runs the entire length of the ductBenefits Allows access to wiring and mechanical connections for maintenanceProvides a standardized platform for future modifications or upgrades¼” Rabbetted cover provides superior protection of cabling, and clean lookAllows cable routing to be accomplished in applications where conduit is not feasibleEngineering and customer service support throughout the projectNo Small order chargePackaged and labeled with project identification such as room number, wall number andconfiguration to assist in faster installationsDesigned for Tile flooring, laminate flooring and non covered flush mountedapplicationsNon Ferrous for MRI ApplicationsOptions Custom Paint (please specify DuPont code)Custom sizes up to 48 inches wideCustom fittings and angles designed around the project specificationsLockable security CoverLoad ratings available up to 36 ton Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft3

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATD3. Commonly Used SizesSize6”x3.5”Example Part NumberAT0635-FTExample Description6” Wide x 3.5” Deep Aluminium Flat T10”x3.5”18”x3.5”18” x 6”24” x 3.5”AT1235-FTAT1835-FTAT1860-FTAT2435-FT12” Wide x 3.5” Deep Aluminium Flat T18” Wide x 3.5” Deep Aluminium Flat T18” Wide x 6” Deep Aluminium Flat T24” Wide x 3.5” Deep Aluminium Flat T24” x 6”AT2460-FT24” Wide x 6” Deep Aluminium Flat T24” x 8”AT2480-FT24” Wide x 8” Deep Aluminium Flat T30” x 3.5”AT3035-FT30” Wide x 3.5” Deep Aluminium Flat T36”x 6”AT3660-FT36” Wide x 6” Deep Aluminium Flat TOther sizes readily available uponrequestFigure 2: Aluminum Trench Duct Example 2 Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft4

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATD4. Auto Cad DrawingsFigure 3: Example of Auto Cad Drawing for Trench DuctAuto cad drawings are created for every project and the measurements are verified in the field priorto manufacturing. The trench duct is assembled prior to shipping and all measurements are verified.The end result is a trench duct that is tested and does not require any field modifications.Installation simply requires fastening the components together and grouting the duct into thetrench. A large, custom, trench duct installation can be installed in under 2 hours. Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft5

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATD5. SpecificationsNon Ferrous Trench Duct Component Quick Reference GuideDescriptionDuct Body with coverCouplingTransition CouplingDividerEnd ClosureFloor to Wall Duct RiserReferenceFigure 4Figure 5Figure 6Figure 7Figure 8Figure 9Flat 900Figure 10Flat 450Figure 11Flat TFlat T TunnelFlat XFlat X TunnelFigure 12Figure 13-Grommet MaterialFigure 14Custom Fittings also availableAluminum Trench Duct BodyDescriptionConstructionCover um trench duct body12 Gauge AluminiumRabbetted cover ¼” aluminium ratedfor 200lbs/sq ftPolished AluminumGrounding Lug includedETL Listed to UL/cUL 870, NEC Article376, NEC 517Stainless Steel spring nuts, clips, predrilled holes, mounting screws, andlevelling bolts includedFigure 4: Aluminum TrenchDuct Body Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft6

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATDAluminum Trench Duct num trench duct coupling used to connect 2 sections of trench duct. 1piece needed for every splice. The coupling is welded to the outside of the firstsection of trench duct and is fastened to the next piece of trench duct withsupplied hardware. The coupling sits .25” below finished floor level.12 Gauge AluminiumPolished AluminumPre drilled holes and stainless steel mounting hardware includedApprovalsETL Listed to UL/cUL 870, NEC Article 376, NEC 517Figure 5: Aluminum Trench Duct Coupling.Trench Duct Body shaded green to emphasize couplingAluminum Trench Duct Reducing CouplingDescriptionAluminum trench duct coupling used to connect two varying sizes of duct. 1piece needed for every splice.ConstructionFinishHardware12 Gauge AluminiumPolished AluminumPre drilled holes and stainless steel mounting hardware includedApprovalsETL Listed to UL/cUL 870, NEC Article 376, NEC 517Figure 6: Aluminum Reducing Transition Trench Duct Coupling Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft7

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATDAluminum um divider (partition) used to separate power and signalling cables insideof the duct. Used to create multiple compartments inside of 1 piece of wireway.12 Gauge AluminiumPolished AluminumPre drilled holes and stainless steel mounting hardware includedApprovalsETL Listed to UL/cUL 870, NEC Article 376, NEC 517Figure 7: Aluminum Wire Duct DividerAluminum Trench Duct End ClosureDescriptionAluminum Trench duct end closure used to terminate wire ductConstructionFinishHardware12 Gauge AluminiumPolished AluminumPre drilled holes and stainless steel mounting hardware includedApprovalsETL Listed to UL/cUL 870, NEC Article 376, NEC 517Figure 8: Aluminum Trench Duct End Closure Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft8

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATDAluminum Trench Duct RiserDescriptionConstructionFinishHardwareInside 90 degree elbow used to transition from trench duct to vertical wall duct.12 Gauge AluminiumPolished AluminumPre drilled holes and stainless steel mounting hardware includedApprovalsETL Listed to UL/cUL 870, NEC Article 376, NEC 517Figure 9: Aluminum Trench Duct RiserAluminum Trench Duct Flat 900DescriptionConstructionCover ConstructionFinishHardwareFlat (Horizontal) 90 degree turn.12 Gauge AluminiumRabbetted cover ¼” aluminium rated for 200lbs/sq ftPolished AluminumStainless Steel spring nuts, clips, pre-drilled holes, mounting screws, andlevelling bolts includedApprovalsETL Listed to UL/cUL 870, NEC Article 376, NEC 517Figure 10: Aluminum Trench Duct Flat 900 Nova Energy & Automation, 2012Issue Date:03 Jan 2012Author: JFDocument Status: Draft9

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATDAluminum Trench Duct Flat 450DescriptionConstructionCover ConstructionFinishHardwareFlat (Horizontal) 45 degree turn.12 Gauge AluminiumRabbetted cover ¼” aluminium rated for 200lbs/sq ftPolished AluminumStainless Steel spring nuts, clips, pre-drilled holes, mounting screws, andlevelling bolts includedApprovalsETL Listed to UL/cUL 870, NEC Article 376, NEC 517Figure 11: Aluminum Trench Duct Flat 450Aluminum Trench Duct Flat TDescriptionConstructionCover ConstructionFinishHardwareApprovalsTrench Duct Flat T intersection.12 Gauge AluminiumRabbetted cover ¼” aluminium rated for 200lbs/sq ftPolished AluminumStainless Steel spring nuts, clips, pre-drilled holes, mounting screws, andlevelling bolts includedETL Listed to UL/cUL 870, NEC Article 376, NEC 517Optional FittingsDivider TunnelFigure 12: Aluminum Trench Duct Flat T Nova Energy & Automation, 2012Issue Date:10 Dec 2012Author: JAFDocument Status: Rev 110

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATDAluminum Trench Duct Flat XDescriptionConstructionCover ConstructionFinishHardwareApprovalsTrench Duct Flat X intersection.12 Gauge AluminiumRabbetted cover ¼” aluminium rated for 200lbs/sq ftPolished AluminumStainless Steel spring nuts, clips, pre-drilled holes, mounting screws, andlevelling bolts includedETL Listed to UL/cUL 870, NEC Article 376, NEC 517Optional FittingsDivider TunnelFigure 13: Aluminum Trench Duct Flat XGrommet MaterialModelDescriptionDimensionsGrommetRubber reinforced with an aluminium insert used to protect the cabling whenfield modifications have been made to the wire duct.20’ L x .5” HFigure 14: Grommet Material Nova Energy & Automation, 2012Issue Date:10 Dec 2012Author: JAFDocument Status: Rev 111

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATD6. PackagingMaterials are packaged with the information necessary to expedite the delivery to thecorrect person, in the correct room, and in the correct location. All items are individuallylabelled with Drawing reference notes.Figure 16: Sample Labels (Pallet and Component)7. Product Service and Technical AssistanceNova Automation, LLC2722 N. Avondale BlvdMilwaukee WI 53210PH# 262-309-2950Website: www.NovaAutomation.net8. WarrantyThis limited warranty set forth below is given by Nova Automation (“Seller”) with respect to theelectrical equipment (“Product”) packaged with this limited warranty. The Product, when deliveredto you in new condition in its original packaging, is warranted against defects in materials orworkmanship as follows: For a period of three (3) years from the date of original purchase, defectiveparts or a defective Product returned to a Seller, or its authorized service providers, as applicable,and proven to be defective upon inspection, will be repaired, or exchanged for a new Product, asdetermined by the Seller, or the authorized service provider.This limited warranty covers all defects encountered in normal use of the Product, and does notapply in the following cases: Loss of or damage to the Product due to abuse, mishandling, alteration,accident, electrical current fluctuations, failure to follow operating, maintenance or environmentalinstructions prescribed by Seller, failure to follow Sellers installation instructions, or serviceperformed by someone other than Seller or its authorized service provider. Nova Energy & Automation, 2012Issue Date:10 Dec 2012Author: JAFDocument Status: Rev 112

Project Name: Aluminum Trench Duct- Wire DuctDocument Number: NV-WD0112Model: ATDNova assumes no responsibility for labor or freight costs incurred in connection with the installation,removal, or replacement of products determined to be defective or any consequential or incidentaldamages arising from the use of the product. Nova Automations entire liability on any claim of lossor damage resulting from a defective product is limited to the replacement of the product.WARRANTY IS VOID IF PRODUCT IS NOT USED FOR THE PURPOSE FOR WHICH IT WASMANUFACTURED.9. ApprovalsPrepared By([Job Title])This document requires the following approvalsApproved By([Job Title])([Job Title])Approval Date Nova Energy & Automation, 2012Issue Date:10 Dec 2012Author: JAFDocument Status: Rev 113

Description Aluminum trench duct coupling used to connect 2 sections of trench duct. 1 piece needed for every splice. The coupling is welded to the outside of the first section of trench duct and is fastened to the next piece of trench duct with supplied hardware. The coupling sits .25" below finished floor level. Construction 12 Gauge Aluminium