Transcription

Guidelines for Energy-EfficientCommercial Unitary HVAC SystemsFinal Report(Revised January 19, 2001)Prepared for:Consortium for Energy EfficiencyOne State Street, Suite 1400Boston MA 02109-3507Contact: Denise Rouleau

Guidelines for Energy-Efficient Commercial Unitary HVAC SystemsTABLE OF CONTENTS1. INTRODUCTION . 11.1 Executive Summary1.2 Applications1.3 Benefits Due to Energy Efficient Installation Practices1.4 How to Use This Document1.5 References and Acknowledgements2. UNITARY AIR CONDITIONERS AND HEAT PUMPS 42.1 Load Calculation – New or Retrofit Construction2.1.1 Benefits2.1.2 Methodology2.1.3 Design Conditions2.1.4 Peak Load Reduction2.1.5 Selecting Unit Capacity to Meet Calculated Loads2.2 Equipment Selection2.2.1 Benefits2.2.2 Efficiency Standards for New Equipment2.2.3 Evaluation/Replacement of Existing Units2.2.4 Selection of Heating Equipment2.3 Unit Configuration and Location2.3.1 Benefits2.3.2 Best Practices2.4 Unit Installation2.4.1 Benefits2.4.2 Sealing Around Rooftop Units2.4.3 Split-System Refrigeration Piping2.5 Economizers2.5.1 Benefits2.5.2 Best Practices2.5.3 Economizer Retrofits2.5.4 Economizer Components – New or Retrofit2.6 Energy Efficient Ventilation2.6.1 Benefits2.6.2 Methodology2.7 Additional Options & Accessories2.7.1 Benefits2.7.2 Options for Increasing Energy Efficiency3. AIR DISTRIBUTION . . 13Final Reporti1/19/01

Guidelines for Energy-Efficient Commercial Unitary HVAC Systems3.1 Zoning3.1.1 Benefits3.1.2 Best Practices3.2 Distribution System Types3.2.1 Best Practices for Constant Volume (CV) Systems3.2.2 Best Practices for Variable Air Volume (VAV) Systems3.2.3 Best Practices for Constant to Variable Volume Retrofits3.2.4 Best Practices for Variable Volume & Temperature (VVT) Systems3.3 Duct System Types3.4 Duct System Parameters3.4.1 Benefits3.4.2 Duct Locations3.4.3 Duct & Accessory Selection3.4.4 Duct System Design3.4.5 Duct Layout3.4.6 Duct Velocity3.4.7 Design Pressure3.5 Ductwork Installation3.5.1 Benefits3.5.2 Duct Construction3.5.3 Air Plenum Construction3.5.4 Duct Sealing3.5.5 Duct Insulation & Liners3.6 Evaluation of Existing Ductwork Systems for Retrofit3.7 Reconditioning Existing Ductwork Systems3.7.1 Benefits3.7.2 Best Practices4. CONTROLS . . 224.1 Benefits4.2 Best Practices4.3 Controls Retrofits4.3.1 Benefits4.3.2 Evaluating Existing Controls4.4 Systemwide Controls4.5 Fan Controls4.5.1 Benefits4.5.2 Methodology4.6 Night Ventilation4.6.1 Benefits4.6.2 Best Practices5. HVAC COMMISSIONING – NEW & EXISTING SYSTEMS . 25Final Reportii1/19/01

Guidelines for Energy-Efficient Commercial Unitary HVAC Systems5.1 Benefits5.2 General5.2.1 Existing/Retrofit Systems5.3 Commissioning Personnel5.4 Documentation5.4.1 HVAC Commissioning Plan5.4.2 HVAC Commissioning Report5.4.3 Operation & Maintenance Manual5.5 Commissioning Best Practices5.6 Commissioning Unitary Equipment5.6.1 General5.6.2 Functional Testing of Roof Top Units5.6.3 Air Handling Equipment5.6.4 Cooling Equipment5.6.5 Refrigerant Charge5.6.6 Heating Equipment5.6.7 Economizers5.7 Commissioning Ductwork Systems5.7.1 General5.7.2 Duct & Plenum Construction5.7.3 Duct & Air Leakage5.7.4 Duct Insulation & Liners5.7.5 Air Terminals5.8 Testing & Balancing5.9 Commissioning Controls5.9.1 General5.9.2 Energy Management Systems5.10 Training5.11 Operation & Maintenance (O&M)5.11.1 Benefits5.11.2 Best Practices5.11.3 O&M Checklist6. DEFINITIONS . 367. REFERENCES . 40Final Reportiii1/19/01

Guidelines for Energy-Efficient Commercial Unitary HVAC Systems1 INTRODUCTION1.1 EXECUTIVE SUMMARYThis specification is a compilation of energy-efficient best practices for the sizing, selection,installation and commissioning of unitary air-source air conditioner and heat pump systemsup to 30 tons. Commercial new and retrofit construction projects are included. This documentis intended as a tool for improving the energy efficiency of commercial unitary HVACinstallations, which make up approximately 55 percent of the total annual tonnage ofcommercial HVAC equipment sold in the United States.15The purpose of this document is to facilitate implementation of energy-efficient installationpractices by providing a specification guide that can easily be used by key people in theindustry, namely installing contractors, service providers, and designers. In addition, thisdocument may be used as a specification for equipment manufacturers and incentiveprograms, and as a training tool for program managers. The program goal is a substantialincrease in commercial HVAC energy efficiency with reduced construction and energy costsas the incentive.The following table highlights key energy-saving practices:Key Elements for Energy-Efficient InstallationsElementLoad CalculationsUnit SelectionDuctwork DesignSystem InstallationControlsCommissioningOperation &MaintenanceSpecification for Best PracticesSection 2.1, calculate loads using ASHRAEFundamentals2a, ACCA Manual N17 or softwarebased upon these methods34Section 2.2, CEE HECAC Initiative1 for newequipment - Minimum Efficiency: Tier 1,Premium Efficiency: Tier 2Section 3, installation should comply withASHRAE Fundamentals2a, ACCA Manual N1,or SMACNA HVAC Systems – Duct Design12dSections 2-4, manufacturer’s instructions,SMACNA HVAC Duct Construction Stds12a,and ASHRAE 90.1-19992aPotential Energy Savings*Up to 50 percent efficiency increasewhen compared with substantiallyoversized equipment410-20 percent compared with U.S. Fed.minimum efficiency units4, or up to40 percent compared with older units.15bSection 4, design & installation perASHRAE 90.1-19992aSection 5 & mgr’s instructionsSection 5 & manufacturer’s instructionsEconomizers may save 15 - 80 percent ofcooling energy4Up to 20 percent energy savings1811-42 percent energy savings16VariesUp to 20 percent supply air leakage canresult in a 60-70 percent increase in fanpower19*savings are not additiveFinal Report11/19/01

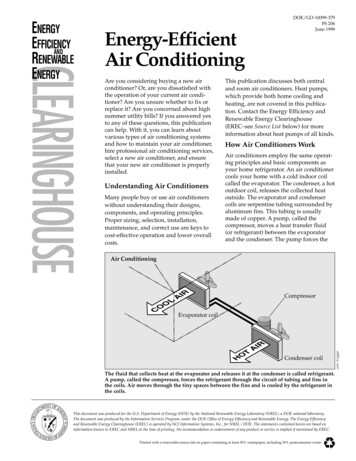

Guidelines for Energy-Efficient Commercial Unitary HVAC Systems1.2 APPLICATIONSThis document provides specifications for energy-efficient installation practices relating tothe following commercial systems: Unitary Air Conditioners and Air-to-Air Heat Pumps up to 30 tons capacity,including packaged rooftop units and matched split systems. Built-up systems,packaged terminal air conditioners (through-the-wall), chilled water systems andwater-cooled equipment are not included. Heating systems integral with the above unitary air conditioners and heat pumps,including gas furnaces, electric resistance, electric heat pumps and water/steam coils. Air Distribution Systems applicable to the above unitary equipment, includingductwork, accessories, controls, commissioning and maintenance. New Construction and Retrofits of existing unitary HVAC systems of the abovetypes.This document covers installation practices relating to energy efficiency and is not meant as acomplete guide for installation, nor does it directly address elements of installation that canimpact occupant and installer health and safety. This document is a supplement to applicablecodes and manufacturers’ instructions. Whenever uniform or local codes or standards requirestricter measures or differing practices, the codes and standards shall govern.1.3 BENEFITS DUE TO ENERGY-EFFICIENT INSTALLATION PRACTICESEnergy Cost Savings: When compared to conventional installations, up to 40percent of energy costs can be saved by sizing equipment properly and selectingequipment with high efficiency ratings and energy-efficient options.15b Energyefficient installation practices such as proper duct installation and sealing can result inenergy savings up to 11 percent.6b A properly commissioned HVAC system can useup to 20 percent less energy by correcting installation and operation problems, andoptimizing system controls.18Construction Cost Savings by avoiding common practices such as equipmentoversizing, installation errors, and excessive ductwork.Improved Comfort by reducing equipment cycling, duct losses, faulty controls anduneven air distribution.Reduced Maintenance & Business Interruption due to proper equipment selection,installation and commissioning.Decreased Environmental Impact from consumption and waste products of energy,materials and refrigerants.1.4 HOW TO USE THIS DOCUMENTThese energy-efficient specifications are recommended for use in full or partial installationsof the types listed in Section 1.2. The document is also useful for repairs, upgrades,reconditioning, (re)commissioning and evaluating existing systems. For optimal energyefficiency of new installations, careful compliance with the entire specification isrecommended, where applicable. However, most of the specifications can be used andcommissioned independently as best practices for energy efficiency.Final Report21/19/01

Guidelines for Energy-Efficient Commercial Unitary HVAC SystemsProper commissioning is crucial for components that require setting, adjustment orprogramming, such as economizers, refrigerant charging, fans, controls and damperpositions. Failure to properly commission these items can negate energy savings and oftenincreases energy use dramatically.In the case of unit and ductwork installation, however, most efforts should be spent on carefulinstallation, as opposed to testing for leaks afterward when much of the ductwork is difficultand expensive to access. It is highly recommended that these specifications be appliedconscientiously and inspected often during installation of ductwork systems.1.5 REFERENCES AND ACKNOWLEDGEMENTSDavis Energy Group and the Consortium for Energy Efficiency compiled the information inthis document from a number of sources, including published papers, studies and industrystandards. Christina Manansala of Davis Energy Group was the principal author. Section 7lists the referenced source publications, standards and agencies.The project was sponsored by the following organizations:National Grid USANew York State Energy Research & Development AuthorityNSTAR ElectricPacific Gas & Electric CompanySacramento Municipal Utilities DistrictValuable information and reviews were contributed by the Project Subcommittee andIndustry Advisors from equipment manufacturers, utilities, research institutes, consultantfirms and publishers of standards. This assistance has been greatly appreciated.Project SubcommitteeJohn daSilva, NSTAR ElectricDenise Rouleau, Consortium for Energy EfficiencyMahri L. Lowinger, Consortium for Energy EfficiencyKathleen Yetman, National Grid USAColin Odell, Northeast UtilitiesJon Linn, Northeast Energy Efficiency PartnershipsChris Reohr, NYSERDADon Felts, Pacific Gas & Electric CompanyCraig Sherman, Sacramento Municipal Utilities DistrictIndustry AdvisorsWm. Woody Delp, PhD., Lawrence Berkeley National LaboratoryJohn Shugars, Lawrence Berkeley National LaboratoryFinal Report31/19/01

Guidelines for Energy-Efficient Commercial Unitary HVAC SystemsPhil Coleman, Lawrence Berkeley National LaboratoryMark Modera, Lawrence Berkeley National LaboratoryTerry Chapp, Modine Manufacturing CompanyTed Gilles, LennoxJeffrey Warther, Carrier CorporationJeff McCullough, Pacific Northwest National LaboratoryJeff Johnson, The New Buildings InstituteJoel Kinsch, North American Technician ExcellenceMichael Scofield, Conservation Mechanical SystemsMichael Woodford, Air Conditioning and Refrigeration InstituteRichard Bourne, Davis Energy GroupAdrian Tuluca, Steven Winters Associates2 UNITARY AIR CONDITIONERS AND HEAT PUMPS2.1LOAD CALCULATION – NEW OR RETROFIT CONSTRUCTION2.1.1 BenefitsLoad calculations are crucial for both new and retrofit construction to ensure comfort andefficient operation, as well as to prevent expensive oversizing of equipment or problems dueto insufficient capacity. At least 25 percent of rooftop units are oversized by 25 percent ormore7, resulting in inflated construction costs and increased energy usage. Oversizedequipment efficiency can drop by up to 50 percent due to part-load operation and excessiveshort cycling.4 Oversizing also increases equipment wear and decreases dehumidificationcapacity. One study of 15 light commercial systems found that 66 percent of the systemstested operated a significant portion of the time with on-time cycles less than ten minutes and33 percent never had cycles exceeding 10 minutes.20Load calculations are necessary for retrofits in order to evaluate the adequacy of existingequipment and/or specify replacement equipment. Direct tonnage replacement and rule-ofthumb sizing, which are typical for small commercial installations, do not account for currentequipment, controls or code requirements and can result in incorrect equipment selection andinefficient energy use.2.1.2 MethodologyCalculate cooling and heating loads using ASHRAE-based load calculation methodology ormodeling software. Calculate the peak block load and airflow rate for each system, as well asfor each room/zone. Factor in extreme conditions such as arid or humid climates. Approvedmethods include:A.B.C.Final ReportASHRAE Fundamentals – Load and Energy Calculations2cACCA Manual N – Commercial Load Calculation5aComputer software such as DOE-2, ASEAM or other non-proprietary softwarebased upon ASHRAE or ACCA methods3441/19/01

Guidelines for Energy-Efficient Commercial Unitary HVAC SystemsA number of proprietary commercial ASHRAE-based software packages are available aswell3 .2.1.3 Design ConditionsIndoor cooling and heating design temperatures should be based upon local energy codes.Temperatures of 78 F for cooling and 70 F for heating are commonly used for typicalcommercial occupancies. Design conditions for specific occupancies are specified inANSI/ASHRAE 55-19922f. For specialized occupancies the facility engineer should beconsulted.2.1.4 Peak Load ReductionReducing peak loads results in substantial year-round cost savings due to reduced coolingenergy, smalle

3.2.4 Best Practices for Variable Volume & Temperature (VVT) Systems 3.3 Duct System Types 3.4 Duct System Parameters 3.4.1 Benefits 3.4.2 Duct Locations 3.4.3 Duct & Accessory Selection 3.4.4 Duct System Design 3.4.5 Duct Layout 3.4.6 Duct Velocity 3.4.7 Design Pressure 3.5 Ductwork Installation 3.5.1 Benefits 3.5.2 Duct Construction 3.5.3 Air Plenum Construction 3.5.4 Duct Sealing 3.5.5 Duct .