Transcription

Thermal PackagingDesign Trade-Offs toConsiderAnthony Alleva, Associate Technical Director

Going through the thermal packaging design process, testing and qualification involvesmultiple decision points in order to best optimize the resulting package. Here are thesome important trade-offs to consider when specifying the package requirements.Montreal – Vancouver – New Jersey – Minnesota – California – Virginia – Arkansas – France

1. Custom Packaging Solutions VS« Off the Shelf » SolutionsMontreal – Vancouver – New Jersey – Minnesota – California – Virginia – Arkansas – France

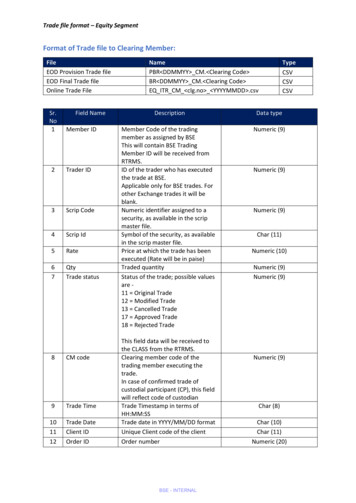

1. Custom Packaging Solutions VS « Off the Shelf » SolutionsThe first question that must be asked when specifying a thermal package system is whether todesign a new package or implement a previously designed system. Most major cold chain packagesuppliers are selling pre-qualified shippers to their customers. The manufacturer would have testedthe package against general industry specifications and should be able to provide a report on thepositive results of that testing. Depending on the size of your company, there may also be packagespreviously designed and/or in use already for other shipping situations.CUSTOM PACKAGINGProOFF THE SHELFConProConAbility to tailor designspecifically to applicationDesign process is timeconsumingReadily availableNo cost for designing thepackageOptimizing the design willlower the cost over thelifetime of the packageUpfront cost incurred todevelop the package canbe expensiveProven track record ofperformanceLikely overdesigned inorder to meet broadrequirementswww.cryopak.ca

2. Conventional Refrigerants Gels VSPhase Change MaterialsMontreal – Vancouver – New Jersey – Minnesota – California – Virginia – Arkansas – France

2. Conventional Refrigerant Gels VS Phase Change MaterialsPhase change materials (PCMs) are chemicals chosen for the temperatures at which they transitionbetween states of matter. The vast majority of PCMs are chosen for use of their solid/liquid phasechange temperature. The goal is to match the phase change temperature with the producttemperature requirements as the PCM will naturally maintain that temperature while melting orfreezing.REFRIGERANT GELSProPHASE CHANGE MATERIALSConProConInexpensive direct packagecostIndirect costs can be highfor shipping andwarehousingHigher temperaturestability within the desiredrangeExpensive direct packagecostComponents easy tosource and conditionThe phase changetemperature not beingideal means a morecomplex package resultsLess complex packages arepossible by simplysurrounding the productwith PCMConditioning can bedifficult if the properequipment is not availablewww.cryopak.ca

3. Lab Temperature Profile Testing VSReal World ShipmentMontreal – Vancouver – New Jersey – Minnesota – California – Virginia – Arkansas – France

3. Lab Temperature Profile Testing VS Real World ShipmentWhen testing to confirm that a package performs as needed it must be put together as though itwere being used for a live shipment then exposed to temperatures that are representative of theexpected shipping environment. This can be done either in a laboratory using an environmentalchamber to simulate the environment or via actually shipping the box between representative originsand destinations.LAB TEMPERATURE PROFILEProREAL WORLD SHIPMENTConProConVery repeatable from onetest to the nextA lot of equipment andmanpower needed toconduct the testingDefinitively mimics actualenvironmental conditionsLikely overdesigned inorder to meet broadrequirementsThe profiles can bedesigned to represent theworst case temperatureconditionsThe profile may be moreextreme than reallyneeded resulting in anoverdesigned packageIncorporates other fieldhazards such as shock andvibration effects on thepackageEvery box tested willexperience differentrequirements makingiterations difficult toanalyzewww.cryopak.ca

4. Reusable VS DisposableMontreal – Vancouver – New Jersey – Minnesota – California – Virginia – Arkansas – France

4. Reusable VS DisposableAll packaging can be designed with reuse as a possibility. Whether a package should be designedwith the intention to reuse depends on cost structures and the ability of the manufacturer toretrieve the package after the product is removed from it.REUSABLE PACKAGINGProDISPOSABLE PACKAGINGConProConEnvironmentally friendly,less waste per shipment,lower carbon footprintReverse logistics areneeded along with arefurbishment programOnce the shipment leavesthe distribution center itdoesn’t need to becontrolledUnless the packages arerecycled by the recipient,they will end up as garbagein land fillsCost of the entire systemcan be less if the numberof reuses possible is veryhighInitial direct cost of thepackage fleet is higherCost of the individualpackage is lessIf used for a long period oftime the cost will work outto be higher overallwww.cryopak.ca

5. Minimizing Direct Packaging Costs VSFreight CostsMontreal – Vancouver – New Jersey – Minnesota – California – Virginia – Arkansas – France

5. Minimizing Direct Packaging Costs VS Freight CostsWhen developing the cost model for a shipping package the cost of the freight to actually ship itcannot be ignored. The direct cost of the package itself plus the cost of the freight is the actuallycost of ownership for the system. The optimal system will balance these factors but they can be inconflict with one another so a decision needs to be made which one to focus more heavily upon.DIRECT PACKAGING COSTSProFREIGHT COSTSConProConMoney tied up byinventorying materials willbe lowerResults in a heavier, largerpackageA smaller and lighterweight package can resultfrom the processSpecialized materials maybe employed that are moredifficult to prepare ordispose ofLess expensive packagestend to use water gels andhave simpler conditioningrequirementsEnd user will have todispose of the heavypackage materialsCould also result in fewerlarge packages whichwould save on laborPrecludes a reuse programto save on any reverselogistics feeswww.cryopak.ca

To ensure the most success in designing a thermal package for cold chain distribution, allof the above trade-offs should be factored into the design process and multiple optionsshould be considered.Cryopak’s team of technical engineers can help to guide you through the package designprocess and qualify packaging that will maintain the integrity of your products within therequired temperature profile.REQUEST QUOTEMontreal – Vancouver – New Jersey – Minnesota – California – Virginia – Arkansas – France

Going through the thermal packaging design process, testing and qualification involves multiple decision points in order to best optimize the resulting package. Here are the some important trade-offs to consider when specifying the package requirements. Montreal -Vancouver -New Jersey -Minnesota -California -Virginia -Arkansas -France