Transcription

Independentcart technologyLinear Motors provide magneticpropulsion and control of multiple carts

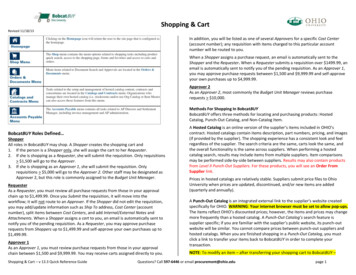

Moving conveyors forwardAdvances in linear motion are changing theway manufacturing and material handlingoriginal equipment manufacturers (OEMs),system integrators, and system operatorsapproach product flow. MagneMotion andiTRAK independent cart technology byRockwell Automation uses linear motorsto intelligently and accurately move a widevariety of products.Independent cart technology is the foundationfor new, intelligent conveyor systems whichare advanced and efficient alternatives toconventional conveyor and positioningsystems. These unique control systems havescalable, distributed architectures that cansafely and efficiently manage many carts acrossa network of linear motors enabling:§§ Independent position, speed, andacceleration control of each product on line§§ Intelligent management of traffic flowfor maximum throughput§§ Distributed communication betweencontrol modules for exceptional scalability§§ Built-in self-diagnostics and troubleshootingfor rapid identification of malfunctionsSmart Machines2

How the new Independentcart technology worksThe primary side of these motors is embeddedwithin the motor body; in the track itself withiTRAK, or on a custom track with MagneMotionproducts. The secondary side of the motorresides on individual carts in the form ofa permanent magnet array. Force or thrustis imparted by driving current through coilsin the motor body. Controlling the magnitudeand phasing of these currents creates magneticfields that propel the cart.Figure 1 outlines the technology used byiTRAK and MagneMotion products. Positiveor negative currents of varying magnitude aredriven into independent coils to create a localmagnetic field. Negative current in coils 2, 3, 5,and 6 result in a net forward force.As the cart moves along the track, magnitudesand polarity are adjusted to deliver the requiredthrust as efficiently as possible. Magnetic sensorsenable precise and continuous tracking of thecart, eliminating the need for external devicesand making the technology easy to apply.Benefits§§ Increased reliability with fewer components subject§§ Negotiate steep grades without depending on friction§§ No need for propulsion power or control on carts§§ Control of multiple carts on complex trajectories§§ No need to transfer communication or control signalsto wear§§ Acceleration and braking not dependent on friction§§ Improved performance and precise position control§§ Increased speed, acceleration and efficiency§§ Gentle, collision free, & zero pressure conveyanceto a moving cartPayloadMagnet array on cartsN1NN23Connect motors to controlmultiple carts simultaneouslyS4NN5678910Motor WindingsSmart Machines3

High level control optionsiTRAKMagneMotionWith iTRAK, each cart is an axis of motion,enabling high level control that allows everycart to be synchronized to an external axis suchas a robot or a cam. A benefit of this approachis that each cart can be individually controlledto be in a specific location on the trackat a specified time at all times. This not onlyenables camming to an external systemor device, but also enables adjacent cartsto change their relative spacing ina coordinated manner to support foldingor compacting type applications.MagneMotion’s high level control systemalso supports axis based cart motion usingour SYNC-enabled motors and Allen BradleyControlLogix contollers and motion profiles.MagneMotion also provides a ‘fire and forget’mode, ideal for complex tracks having multiplelanes and topologies where carts needto move from one station or locationto the next. The control system managesthe paths and flow of carts to avoid collisions.The ability to merge both operating modesprovides maximum flexibility to minimizethe customer’s PLC host interface.Smart Machines4

The definitive solutionfor diverse sectorsIndependent cart technology offers flexibility, scalability, and ease of use,and also minimize power draw compared to conventional conveyor systems sinceonly those coils required to support cart motion are powered.Factory automation applications using belt and chain conveyor systems, hydraulicactuators, and lead screw drives are a few examples where linear motors couldproduce the required action, serving as an alternative to these mechanicallydependent devices. These are five sectors where linear motor technology is provingto make a definable difference:Life sciences§§Track and Trace§§Collision avoidance§§Easy Serialization§§Fast Cycle Time§§Massive Flexibility§§Easy to CleanConsumerpackaged goods§§Reduced Maintenance§§Faster Cycle Time§§High Flexibility§§Quicker to Market§§Smaller footprintFood and beverage§§High Throughput§§Maximum Flexibility§§Repeatable Quality§§Easy to Clean§§Increased SpeedMaterial Handling§§Higher Throughput§§Sequenced delivery§§Smaller Footprint§§Programmable speedand accelerationHousehold &Personal Care§§Higher Throughput§§Broader Product Mix§§Innovative Packaging§§Faster ProductDevelopmentSmart Machines5

Independent carttechnology in summaryMagnets move over independentlyenergized coilsAbsolute positions are measuredwith closed loop servo control§§ Magnets and movers have no intelligence§§ Low moving mass maximizesTechnology enables high throughputand flexible machinesenergy efficiency Coils are stationary§§ No flexing cable wear or need for slip rings§§ Reduces wear items and maintenance§§ Technology can be applied to straight,curved, or merge/diverge motors.§§ Motors can be combined to createa multitude of system layouts§§ Systems support 100s to 1,000s ofindependently controlled moving carts§§ Layout and mover quantity flexibility leadto MagneMotion and iTRAK Contact 1 978-757-9100www.magnemotion.com1 Transforming Manufacturing With the Internet of Things, International Data CorporationSmart Machines6

Working together with Rockwell AutomationMake more of your Connected Enterprise by connectingwith Rockwell Automation and our partners.§§ Get answers to your questions on sales, products, servicesand technical support. Find out moreRockwell Automation, Inc. (NYSE:ROK), the world’s largest company dedicated to industrial automation, makes its customers more productive and the world more sustainable.Throughout the world, our flagship Allen-Bradley and Rockwell Software product brands are recognized for innovation and excellence.Follow ROKAutomation on Facebook, Twitter and Google Plus.Subscribe to us on Youtube. Connect with us on LinkedIn.PlantPAx, Integrated Architecture, Listen. Think. Solve., Motor Control Center, Total Cost to Design, Develop and Deliver, and PartnerNetwork are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automationare property of their respective companies.Publication MOTION-BR008A-EN-PCopyright October 2016 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Moving conveyors forward Advances in linear motion are changing the way manufacturing and material handling original equipment manufacturers (OEMs), system integrators, and system operators approach product flow. MagneMotion and iTRAK independent cart technology by Rockwell Automation uses linear motors to intelligently and accurately move a wide