Transcription

Laboratory Ventilation ACH RatesStandards and GuidelinesWhite Paper SeriesJanuary 3, 2012

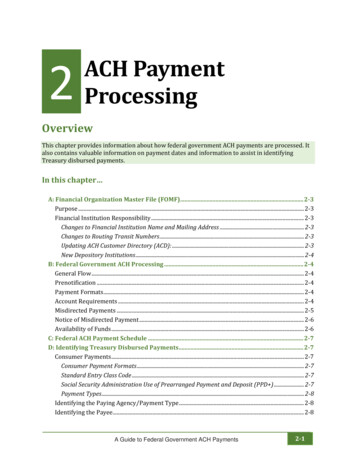

Lab Ventilation ACH Rates Standards and GuidelinesJanuary 3, 2012Table of Contents1.0Introduction .22.0Executive Summary .23.0Survey of Applicable Existing Standards and Guidelines .21.US NFPA (National Fire Protection Association) Standard 45 .22.US OSHA (Occupational Safety and Health Administration) Regulations .33.ANSI/AIHA Z9.5 Laboratory Ventilation Standard .34.ACGIH Industrial Ventilation Manual .55.ASHRAE 62.1 Standard on Ventilation for Acceptable Indoor Air Quality .56.International Mechanical Code (IMC 2009) .77.ASHRAE HVAC Applications Handbook, Chapter 14/16: Laboratories .88.European Ventilation Code Information .124.0Laboratory Spill Test Performance and Conclusions .131.Yale Article Published in the Journal of Chemical Health and Safety .132.Demand Based Control Study Article Published in the ASHRAE Journal.14White Paper SeriesPage 1

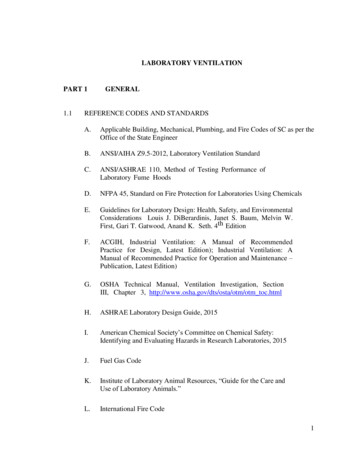

Lab Ventilation ACH Rates Standards and GuidelinesJanuary 3, 20121.0 IntroductionThis document provides an overview of current US and European design practices, standards, andregulations regarding laboratory air change rate minimums for dilution ventilation.2.0 Executive SummaryIn the US and Europe there are no prescriptive requirements for air change rates in labs other thanthe ASHRAE 62.1-2010 fresh air requirements for university/college laboratories that correspondsto about 1.2 ACH (.18 cfm/sq. ft or 0.9l/s/m2). In terms of recommended levels, standards are alsosignificantly moving away from the prescribed values of the past to a more performance basedapproach based on the specific requirements of a given lab space.3.0 Survey of Applicable Existing Standards and GuidelinesThe following codes and standards have existing or past sections relating to laboratory air changerates.1. US NFPA (National Fire Protection Association) Standard 45The NFPA 45 standard is the US Standard on Fire Protection for Laboratories Using Chemicals.The previous version of this standard, NFPA 45-2004, had no actual requirements on Lab ACHs,although in the non-binding appendix of the standard there were some recommendations relatingto lab ACHs that in the past had been sometimes used as a design practice. The text of theserecommendations was as follows:A.8.2.2: A minimum ventilation rate for unoccupied laboratories (e.g., nights and weekends) isfour room air changes per hour. Occupied laboratories typically operate at rates of greaterthan eight room air changes per hour, consistent with the conditions of use for the laboratory.It is not the intent of the standard to require emergency or standby power for laboratoryventilation systems.However, this text and any mention of specifying lab ACHs was eliminated in the current NFPA 45– 2011 standard that just recently issued:A.8.2.2: It is not the intent of this standard to require emergency or standby power forlaboratory ventilation systems.The only remaining reference to lab ventilation is as follows which did not change between the2004 and 2011 versions and does not provide any prescriptive rates:8.2.2* Laboratory units and laboratory hoods in which chemicals are present shall becontinuously ventilated under normal operating conditions.As such with the 2011 version, NFPA is now silent on prescribing any lab air change rates otherthan to require continuous ventilation.White Paper SeriesPage 2

Lab Ventilation ACH Rates Standards and GuidelinesJanuary 3, 20122. US OSHA (Occupational Safety and Health Administration) RegulationsOSHA in the US provides little guidance on air change rates for labs. The only reference OSHAhas to laboratory air change rates is quite old and is from a document published on January 31,1990 titled “Occupational Exposures to Hazardous Chemicals in Laboratories; Final Rule” and waspublished in the Federal Register as 29 CFR Part 1910.This document does not provide any prescriptive rates for minimum air change rates and mainlyrequired the creation of a Chemical Hygiene Plan by employers to document procedures, policies,and work practices to ensure workers would be protected from hazardous substances. Thedefinition of what specifically should be in the plan was left to the employers. A representativeexample of a Chemical Hygiene Plan that could be used as guidance for an employer to createtheir own Plan was provided in this document but was specifically marked as being nonmandatory. This non-mandatory plan was extracted from a 1981 book entitled “Prudent Practicesfor Handling Hazardous Chemicals in Laboratories”.Under “Section C. The Laboratory Facility” the following sections 4(a) and 4(f) are the only sectionspotentially relevant to lab air change rates:4. Ventilation(a) General laboratory ventilation. This system should: Provide a source of air for breathingand for input to local ventilation devices (199); it should not be relied on for protection fromtoxic substances released into the laboratory (198); ensure that laboratory air is continuallyreplaced, preventing increase of air concentrations of toxic substances during the working day(194); direct air flow into the laboratory from non-laboratory areas and out to the exterior of thebuilding (194).(f) Performance. Rate: 4-12 room air changes/hour is normally adequate general ventilation iflocal exhaust systems such as hoods are used as the primary method of control [194].”The only reference to air change rates as noted above are not mandatory nor are they evenrecommendations but rather indications of what is normally adequate general ventilation ifhoods are used. Additionally, the range is quite broad being 4 to 12 ACH and as written does notreally preclude the use of lower rates.3. ANSI/AIHA Z9.5 Laboratory Ventilation StandardThe 2003 version of this standard is the latest published version of this standard. With respect tolaboratory air change rates and ventilation the standard does not take a prescriptive approach. Theformat of this standard is that it has both a requirements section as expressed by the use of “shall”,and a recommended section that provides description and explanation of the requirements plussuggested good practices as expressed by the use of “should.” The text of the relevant sections isas follows:Section 2.1.2 - Volume Flow Rates/Room Ventilation Rate (2003):Requirements:The specific room ventilation rate shall be established or agreed upon by the owner orhis/her designee.White Paper SeriesPage 3

Lab Ventilation ACH Rates Standards and GuidelinesJanuary 3, 2012Recommendations:Since a ventilation system designer cannot know all possible laboratory operations,chemicals to be utilized, and their potential for release of fumes and other toxic agents, oneair exchange rate (air changes per hour) cannot be specified that will meet all conditions.Furthermore, air changes per hour is not the appropriate concept for designing contaminantcontrol systems. Contaminants should be controlled at the source.Section 2.1.4 - Dilution Ventilation (2003)Requirements:Dilution ventilation shall be provided to control the buildup of fugitive emissions and odors inthe laboratory.Recommendations:Control of hazardous chemicals by dilution alone, in the absence of adequate laboratorychemical hoods, seldom is effective in protecting laboratory users. Because the exhaustfrom that type of system must be discharged to the outside or treated intensively beforebeing used as return air, these systems usually are not economical for controlling exposureto hazardous materials compared with use of local exhaust hoods.The latest version and content of the ANSI/AIHA Z9.5 standard has been completed, voted on andwas approved. It is now in the process of being properly formatted to ANSI requirements andshould be published in the first quarter of 2012.The new language of what should be named theZ9.5-2012 standard is similar to the 2003 standard but provides some additional clarificationlanguage beyond what the 2003 standard stated as noted below:Section 2.1.2 - Laboratory (Room) Ventilation Rate (2012)Requirements:The specific room ventilation rate shall be established or agreed upon by the owner or hisor her designee.Recommendations:Ventilation is a tool for controlling exposure. Contaminants should be controlled at thesource. Potential sources should be identified and exposure control devices should bespecified as appropriate to control emissions at the source. (See sections 3 and 4) Allsources and assumptions should be clearly defined and documented.An air exchange rate (air changes per hour) cannot be specified that will meet allconditions. Furthermore, air changes per hour is not the appropriate concept for designingcontaminant control systems.Excessive airflow with no demonstrable safety benefit other than meeting an arbitrary airchange rate can waste considerable energy.White Paper SeriesPage 4

Lab Ventilation ACH Rates Standards and GuidelinesJanuary 3, 2012Section 2.1.3 - Dilution VentilationRequirements:Dilution ventilation shall be provided to control the buildup of fugitive emissions and odors inthe laboratory. The dilution rate shall be expressed in terms of exhaust flow in negativelypressurized laboratories and supply flow in positively pressurized laboratories.Recommendations:Control of hazardous chemicals by dilution alone, in the absence of adequate laboratoryfume hoods, is seldom effective in protecting laboratory users. It is almost alwayspreferable to capture contaminants at the source, than attempt to displace or dilute them byroom ventilation. Nevertheless, dilution or displacement may remove contaminants notcaptured by a specifically applied device.The quantity of dilution (or displacement) ventilation required is a subject of controversy.Typical dilution ventilation rates can range from 4 to 10 air changes per hour depending onheating, cooling, and comfort needs and the number and size of exposure control devices.As noted above in this recommendations section, like with the old OSHA regulations, the new 2012ANSI standard is giving a range of what is typically used in the industry vs. providing any strictguidance as to what should be used as a minimum or recommended lab ACH level. In fact, in bothversions of the standard the recommendations clearly state that setting a fixed ACH rate for alaboratory for all conditions is not the appropriate design approach.4. ACGIH Industrial Ventilation ManualA well known and frequently published handbook of the American Conference of GovernmentalIndustrial Hygienists (ACGIH) is entitled, “Industrial Ventilation, A Manual of RecommendedPractice.” The current revision is the 27th edition. A representative quote from the manual’s 22ndedition published in 1995 states on page 7-5 that:“‘Air changes per hour’ or ‘air changes per minute’ is a poor basis for ventilation criteria whereenvironmental control of hazards, heat, and/or odors is required. The required ventilationdepends on the problem, not on the size of the room in which it occurs.”5. ASHRAE 62.1 Standard on Ventilation for Acceptable Indoor Air QualityThis is the definitive standard in the US as well as many parts of the world on ventilation rates forbuildings. Many codes and other standards reference the information and tables in this standard.The standard itself has gone through considerable revisions over the last 10 years with versionspublished in 2001, 2004, 2007 and most recently in 2010. There was a major change moving from2001 to 2004 which changed the basis of the recommendations from strictly a flow per personrequirement to a combination of a flow per person requirement plus a flow per unit arearequirement.Regarding laboratory ventilation, there was confusion introduced in 2004 when the occupancycategory “Science Laboratory” which was under the “Educational” spaces section was introduced.This category had a fresh air minimum requirement of 0.18 cfm/sq. ft (0.9 l/s/m²) or about 1.2 ACHfor a room with a 9 foot ceiling. There was also a higher exhaust requirement stated of 1 cfm/sq. ftor about 6 ACH that was listed for a different category labeled as “Science Lab Classrooms” in theMinimum Exhaust Rates table (6-4). The latter was intended to refer to non-college/universityWhite Paper SeriesPage 5

Lab Ventilation ACH Rates Standards and GuidelinesJanuary 3, 2012science classrooms with only moderate contaminant concentrations that might be mildly irritating ormildly offensive, most typically for high school (grades 9-12) or technical training schools. However,the terminology and lack of other lab categories was confusing and ambiguous. In 2006 this wascorrected by an addendum to 62.1-2004 that was included in the 62.1-2007 version and isunchanged in the 62.1-2010 version.This 2006 revision clarified the distinction between university/college laboratories and lower leveleducational facilities such as high school or technical training schools by creating a new occupancycategory in the educational spaces section entitled “University/college laboratories”. This categoryhad the same 0.18 cfm/sq. ft minimum space ventilation level as the educational science

The latest version and content of the ANSI/AIHA Z9.5 standard has been completed, voted on and was approved. It is now in the process of being properly formatted to ANSI requirements and should be published in the first quarter of 2012.The new language of what should be named theFile Size: 874KBPage Count: 15