Transcription

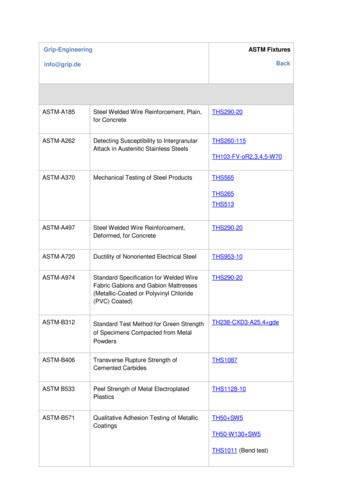

12/11/2013ProjectEngineeringUnderASTM E2500Andrew Faden, PMP,CPIPPresentation ObjectiveThe purpose of my presentation is to lookat industry expectations for GMP projectsin light of the ASTM E2500 guidance. I willalso look at the role of the Project Engineerin fulfilling these expectations.21

12/11/2013Presentation OutlineBackgroundCurrent state of practiceEngineering DisciplineReview of ASTM E2500 and other relevantguides Project Management Process Practical integration of ASTM E2500 withProject Management 3Prevailing Guidance in 2007 ICH Q8 2005 (R1) – Pharmaceutical Development– Approved design space– Proven acceptable range– Control strategy– CPP, CQA, QTPP ICH Q9 2005 – Quality Risk Management– Evaluation of risk to quality should be based on scientificknowledge and link to protection of patient– Level of effort of the QRM process should becommensurate with level of risk.42

12/11/2013Prevailing Guidance in 2007 Pharmaceutical cGMPs for the 21st Century – a Risk‐BasedApproach (FDA), Guiding principles include:– Risk‐based orientation– Science‐based policies and procedures– Strong public health protection The ISPE Baseline Guide Volume 5, Commissioning andValidation––––Design, construction, commissioning, and qualification of facilitiesSystem Level Impact AssessmentsApply GEP and commissioning to Indirect and No‐Impact SystemsAdditionally apply Qualification Practices (IQ, OQ, PQ) to Direct ImpactSystems5Prevailing Practice TodayPractitioner comments:“The traditional validation activities have become centeredaround documentation, instead of ensuring quality Traditionalvalidation activities stifle innovation, cause compliance riskand compromise a life science firm’s ability to bring products tothe market on time.” 2013, Valgenesis Webpage“The Quality Unit essentially behaved as a Quality Control unitchecking, reviewing and approving almost every validationdocument. This created a tense and bottleneck situation.” 2012,Jose Ochoa63

12/11/2013Prevailing Practice TodayLegacy guidance has not been followed as intended: ISPE Baseline Guide Volume 5 provides Direct ImpactCriteria but states that “These criteria should beused to inform a judgment based on thecomprehensive understanding of the product,process, and nature of the system. They should notbe used to replace the exercise of informedjudgment by appropriately qualified personnel.”According to FSE (2011), “The statement regardinginformed judgment often has not been applied”.7ASTM E2500 Intent Risk‐based and science‐based approach to thespecification, design, and verification of manufacturingsystems and equipment that have the potential to affectproduct quality and patient safety. Provide manufacturing capability to support defined andcontrolled processes that can consistently produceproduct meeting defined quality requirements. Subject Matter Experts (SMEs) with a technicalunderstanding of the critical aspects of manufacturingsystems to drive the specification, design, and verificationof facilities and equipment.84

12/11/2013Engineers are the SMEs for Facilities,Systems, and Equipment The industry has been slow to recognizethat the SMEs with a technicalunderstanding of facilities, systems, andequipment are engineers. In many cases, the industry does notrecognize the engineering discipline. The term Project Engineer is rarely foundin the industry vernacular – it is not evenmentioned in the ISPE GPG for ProjectManagement!9What is a Project Engineer?Breaking it down:A PROJECT is a temporary endeavor undertaken tocreate a unique product, service or result.‐ PMBOK GuideAn ENGINEER is concerned with applying scientificknowledge to develop solutions for technical problems.Engineers design systems while considering thelimitations imposed by practicality, regulation, safety,and cost.‐ Wikipedia105

12/11/2013Engineers are Wired Differently Press Play here11Project EngineeringProject Engineering bridges the boundariesbetween engineering and projectmanagement In some cases, the projectengineer is the same as a project manager butin most cases these two professionals havejoint responsibility for leading a project.‐ Wikipedia126

12/11/2013Current Guidance shapingthe GMP Project Engineer role ASTM E2500‐07 Standard Guide for Specification,Design, and Verification of Pharmaceutical andBiopharmaceutical Manufacturing Systems AndEquipment ISPE GPG: Science and Risk‐based Approach forthe Delivery of Facilities, Systems, and Equipment,(FSE Guide) 2011 ISPE GPG: Project Management for thePharmaceutical Industry, 2011 PMI PMBOK ‐ Project Management Body ofKnowledge13Significance of ASTM E2500 “Application of the approach is intended tosatisfy international regulatory expectationsin ensuring that manufacturing systems andequipment are fit for intended use, andsatisfy requirements for design, installation,operation, and performance” ASTM E2500§5.1147

12/11/2013Key concepts of ASTM E2500‐ Risk‐based approach“The evaluation of risk to quality should bebased on scientific knowledge and ultimatelylink to the protection of the patient” ASTME2500 §6.2.2.115Key concepts of ASTME E2500‐ Science‐based approachScience‐based approach ‐ “Product and processinformation, as it relates to product quality andpatient safety, should be used as the basis formaking science‐ and risk‐based decisions thatensure that the manufacturing systems aredesigned and verified to be fit for their intendeduse.” ASTM E2500 §6.3.1168

12/11/2013Key concepts of ASTME E2500‐ Science‐based approach“Examples of product and process informationto consider include: CQAs, CPPs, process controlstrategy information, and prior productionexperience.” ASTM E2500 §6.3.217Key concepts of ASTME E2500‐ Critical system aspects“Critical aspects of manufacturing systems aretypically functions, features, abilities, andperformance or characteristics necessary for themanufacturing process and systems to ensureconsistent product quality and patient safety.”ASTM E2500 §6.4.1189

12/11/2013Key concepts of ASTME E2500‐ Quality by Design“Quality by design concepts should be appliedto ensure that critical aspects are designed intosystems during the specification and designprocess.” ASTM E2500 §6.5.119Key concepts of ASTME E2500‐ Good Engineering Practice“Good Engineering Practice (GEP) shouldunderpin and support the specification, design,and verification activities.” ASTM E2500 §6.6.12010

12/11/2013Key concepts of ASTME E2500Specification, Design, Verification21Key concepts of ASTME E2500– Subject Matter Experts “Subject Matter Experts are defined as those individualswith specific expertise and responsibility in a particulararea or field (for example, quality unit, engineering,automation, development, operations ).” ASTM E2500§6.7.1. “Subject Matter Experts should take the lead role in theverification of manufacturing systems as appropriate withintheir area of expertise and responsibility.” ASTM E2500§6.7.2.2211

12/11/2013Key concepts of ASTME E2500‐ Vendor Documentation“The decision and justification to use vendordocumentation, to support the verification ofcritical aspects of the manufacturingelement should be documented and approvedby SMEs.”ASTM E2500 §6.8.3.23ASTM E2500 is only five pageslong, yet it refers to SMEs 21times!2412

12/11/2013ISPE FSE GuideThe GPG Science and Risk‐based Approach forthe Delivery of Facilities, Systems, andEquipment (FSE Guide, 2011) Provides direction to industry on theimplementation of a science and risk‐basedapproach Compatible with Q8, Q9, Q10 and E250025Objective of FSE “ to facilitate the translation of the scientificknowledge about the product and processinto documented specification, design, andverification of equipment, systems andfacilities which are fit for intended use, andminimize risk to product quality and patientsafety.” FSE §1.22613

12/11/2013FSE on SME Role “SMEs should take the lead role in theverification of manufacturing elements.” FSE§2.8.1 “Before acceptance and release, changemanagement should be applied. This processshould be managed by and changes approvedby SMEs.” §10.427FSE – Typical Areas of SME Highlights from Table 2‐1– Process Scientists – determine CQAs and CPPs– Engineering/Technical – specification, verification– Automation SME – develop, verify, and optimizeautomation and process control elements– Quality – develop and approve verification planswith other SMEs; compliance with site QMS– Manufacturing personnel – operability, SOPs2814

12/11/2013FSE – Tools FSE Appendices demonstrate tools for:– Risk Assessments FMEA & FMECAFTAHACCPHAZOPFishbone, etc.– Impact Assessments– Commissioning29FSE – Qualification ApproachFSE Appendix 14: Qualification Approaches– Guidance on how PMs can apply [theguide’s]principles to eliminate non‐value‐addedQualification practices. FSE §14– Technical SMEs can determine separately how toinspect or test a given engineering aspect, and thefield work can be carried out and documentedunder GEP FSE §14.23015

12/11/2013ISPE Applied Risk Management GuideThe guide describes how organizations canmove from established baseline practice(Volume 5) to a more efficient science‐ and risk‐based framework (FSE).31PMBOK Describes the project management life cycle Recognizes 47 processes in five basic processgroups and ten knowledge areas3216

12/11/2013PMBOK Insert process group matrix here33ISPE GPG: Project Management for thePharmaceutical Industry“It is considered good project managementpractice to integrate GxP with relevant projectmanagement activities to ensure thatcompliance risk is managed effectively andproactively.” PMPI §1.13417

12/11/2013Purpose of the ISPE PMPI Guide“ to provide a reference source of goodpractices for project management for a widevariety of project types within thepharmaceutical industry.” PMPI §1.235PMPI Alignment with ASTM E2500‐SMEs“Project Managers may need to coordinate awide range of knowledge in pharmaceuticalindustry projects and may not be a SME for theproject type.” PMPI §2.2.13618

12/11/2013PMPI Alignment with ASTM E2500‐Product QualityProject requirements that relate to productquality are defined in ASTM E2500‐07 as: Product knowledge Process knowledge Regulatory requirements Company quality requirements37PMPI Alignment with ASTM E2500A Question of Balance“Team members need to understand their SMErole and also the need to balance deliverablesand expectations with cost and schedule, as thePM does.” FSE §2.43819

12/11/2013Project Management Flowchart (PMPI)Suggested PE involvement in blue (mine)39Proposed Tool – CSA RegistryThe CSA Registry is a trace matrix thatlinks CQAs, CPPs, and critical systemaspects with patient safety to help meetthe intent of ASTM E25004020

12/11/2013CQA,CPP, Prior Production Experience, andCritical Aspects of a Manufacturing SystemSyringeComponentWasherRubberPlungerCartridge and Needle41CSA Registry ‐ Process Perform an impact assessment on proposed changes,per FSE Appendix 2, to identify critical aspects– Collect product and process knowledge (CQAs, CPPs, etc.)– Determine the impact to all CQAs and CPPs for each criticalsystem aspect Determine the impact to patient safety for eachimpacted CQA Develop test protocols to verify each critical systemaspect and include the corresponding test references inthe CSA registry Create a trace matrix or registry linking CQAs, CPPs,critical system aspects, and verification results topatient safety4221

12/11/2013Proposed Tool ‐ Critical System lsystemaspectSiliconedosing ofplungersImpacted CQAsImpacted angeRisk to patient safetyCQAsReferenceFilm thickness of4.5 to 6.01‐2High plunger force can causesilicone on plunger micronsPlunger force newtonsVT 1.1.1cartridge to break during useLow epi concentration canEpinephrinecause anesthetic to wear offAmount of siliconeconcentration 5 ‐ 7 %in solution 1 PPMVT 1.1.2before procedure is complete43SummaryThe intent of ASTM E2500 is to provide a “Risk‐based and science‐basedapproach to the specification, design, and verification of manufacturingsystems and equipment that have the potential to affect product qualityand patient safety.” The guide requires that SMEs lead this effort.The SMEs for manufacturing systems and equipment are engineers.Partnering a Project Engineer with a Project Manager can lead to moreefficient and effective project delivery. It delivers on the ASTM E2500requirement to incorporate science‐based and risk‐based understandingof manufacturing systems that can impact patient safety. The PM canfocus on the business and administrative tasks while the PE can focus onthe technical aspects.A Critical System Aspect Registry is proposed as a new tool and processfor helping to manage the life‐cycle of critical systems under E2500.4422

12/11/2013WorkBreakdownStructureAndrew Faden, PMP,CPIPPMBOK Process Map4623

12/11/2013Why is WBS Important?47Why is WBS Important?4824

12/11/2013WBS Process ‐ InputsThe inputs to the WBS process are: Project scope statement – narrative description ofscope with major deliverables Requirements documentation – conditions andcapabilities that must be met to satisfy formallyimposed documents– The wants, needs, and expectations of sponsors,customers, and other stakeholders Organizational Process Assets – formal and informalpolicies and procedures‐ PMI PMBOK Guide Fourth Edition49DefinitionsWork Breakdown Structure ‐ A deliverable‐orientedhierarchical decomposition of the work to be executedWork Breakdown Structure Component – An entry in theWBS that can be at any levelWork Breakdown Structure Dictionary – A document thatdescribes each component in the WBSWork Package ‐ A deliverable or project work component atthe lowest level of each branch of the WBS‐ PMI PMBOK Guide Fourth Edition5025

12/11/2013WBS ProcessBreak the total project work into work pa

13.12.2013 · Key concepts of ASTM E2500 ‐Risk‐based approach “The evaluation of risk to quality should be based on scientific knowledge and ultimately link to the protection of the patient” ASTM E2500 §6.2.2.1 15 Key concepts of ASTME E2500 ‐Science‐based approach Science‐based approach ‐“Product and File Size: 1MBPage Count: 28