Transcription

EnergyChemical/petrochemical industryOil & gasWater/wastewaterTemperature gaugesin the process industry

Our knowledge for yoursuccessAlexander Wiegand,Chairman and CEO, WIKAAbout usExcellence intechnology andserviceAs a family-run business acting globally, with 10,000 highly qualified employees, theWIKA group of companies is a worldwide leader in pressure and temperature measurement. The company also sets the standard in the measurement of level, force andflow, and in calibration technology.Founded in 1946, WIKA is today a strong and reliable partner for all the requirementsof industrial measurement technology, thanks to a broad portfolio of high-precisioninstruments and comprehensive services.With manufacturing locations around the globe, WIKA ensures flexibility and the highestdelivery performance. Every year, over 50 million quality products, both standard andcustomer-specific solutions, are delivered in batches of 1 to over 10,000 units.With numerous wholly owned subsidiaries and partners, WIKA competently and reliablysupports its customers worldwide. Our experienced engineers and sales experts are yourcompetent and dependable contacts locally.2

Global player for mechanicaltemperature measuringinstrumentsPresence in over 80countriesThis makes usuniqueThink global, act local: WIKA is represented around the world by numerous wholly-owned subsidiaries and other sales agencies. And because we are local, weunderstand the relevant country-specific requirements, standards and applications.This is how we ensure individual support to our customers. Global production sites Qualified technological know-how Unrivalled breadth and depth of products Practical expertise in manufacturing processes Perfected lean management Customer-focused consulting and service3

Quality made by WIKAGlobal production sitesThe high-tech production in our owned modern productionfacilities (Germany, Brazil, China, India, South Africa andUSA) is the best guarantee for short delivery times throughoutthe world. It also enables a high flexibility for country orcustomer-specific special features. WIKA also stands forexcellent quality:Since 1994 the quality management system has beencertified to ISO 9001. The effectiveness of the qualitymanagement system is regularly evaluated and improvedupon through internal and external audits. Through WIKA'scorporate quality standards, uniform and effective worldwide,we set the benchmark here.Qualified technological know-howThe 3 technologies, with bimetal coil, expansion andgas-actuated systems are developed, qualified andmanufactured in-house by WIKA. With the manufacture of ourbimetal thermometers, we apply the highest quality in ourchoice of raw materials and ensure that the measured valuedisplays are matched individually to the instrument.Our “Swiss Movement” movements are not only as precise asa Swiss clockwork, but they are also especially robust anddurable. These elementary assemblies are the perfect basisfor the development of new products. When the productdesign is defined, the production line is also planned andimplemented within WIKA s equipment construction. Finally,the product and process development is extensively qualifiedwithin our own test laboratory.Unrivalled breadth and depth of productsOur dial indicating thermometers work on the bimetal,expansion or gas actuation principle. This enables scaleranges of -200 . 700 C in different accuracy classes,response times and resilience to environmental influences.Diverse connection designs, stem diameters and individualstem lengths enable a flexible measuring point design.4Dial indicating thermometers with capillaries are particularlyversatile. All thermometers are suited for operation in athermowell if necessary. Accepted around the world, a varietyof measuring ranges, process connections, approvals,nominal sizes or liquid fillings are a guarantee for the optimalmeasuring point design.WIKA offers a comprehensive range of measuring instruments for process technology

Benefit from our many yearsof experiencePractical expertise in manufacturing processesManufacturing processes and procedures at WIKA are basedon many years of experience. This technical expertise inprocesses is typically documented within process controlplans as well as operating procedures and work instructions.New or modified processes are evaluated with regard toperformance and quality and released for manufacturing byprocess sign-offs.The core processes in the thermometer production are, forexample, 100 % calibration and the adjustment of theinstruments. Here, we use various temperature baths in orderto cover the full selection of temperature ranges. It is not onlythe processes that are clearly defined, but also the employees who are appropriately trained.Perfected lean managementProduction processes are designed and continuouslyimproved in accordance with the WIKA Production System(WPS), based on the KAIZEN philosophy. The environmentand energy programme is also refined continuously withinthe meaning of “continuous improvement”. Complex problems are dealt with in a structured way by in-house BlackBelts using the Six Sigma Method, thus ensuring lastingsolutions.Through the WPS, we pursue the objective of improving thequality of the products and processes, and thus to achievethe highest possible customer satisfaction through the bestquality, the highest delivery reliability as well as attractivedelivery times and prices. Customer orientation is at thecentre of all our efforts at WIKA.Customer-focused consulting and serviceOur sales organisation not only offers you standard products,but also our consulting competence for complete measuringassemblies. As a reliable partner in the contractor business,we can support you through all phases of the project, fromplanning, through the realisation and implementation of theproject to technical inspections, logistics solutions, on-sitesupport and after-sales service.We also offer you a comprehensive range of services incalibration technology through our worldwide subsidiarieswhich are accredited to country-specific regulations, on-siteservice of your instruments, calibration equipment and alsoconsulting and training in the field of calibration.5

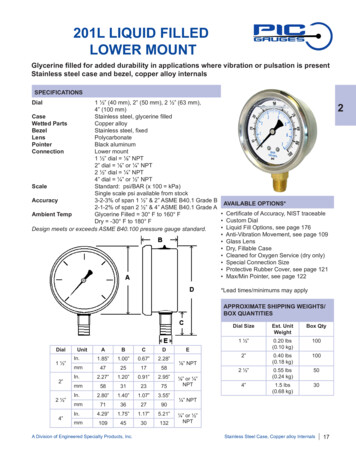

7 selection criteria lead you to theright standard product .2 55 701)73 Accuracy: Cl. 2 to EN 13190 possiblenot possibleModel TG53Bimetal thermometer for therequirements of ASME B40.2006Model TG543", 4", 5", 6"TG54160 mm 80 mm 63 mm 600 C 700 C 400 C -200 C -70 CNominal sizeTG53Model1)Maximum scale range -60 CMinimum scale range3100 mm1Bimetal thermometer for therequirements of EN 13190Model 55Bimetal thermometer withmaintenance-friendly bayonet case

Specifications6Liquid dampingVersion with adjustable stemand dial Model 70Expansion thermometer, remotetransmission Cl. 1 to EN 13190 3 min. Special features Accuracy 7 1 % of full scale value,ASME B40.200 (grade A)Response time 3 min.Remote displayRemote display(with capillary)5Direct on-site display4Model 73Gas-actuated thermometer, fastresponse characteristics, remotetransmission7

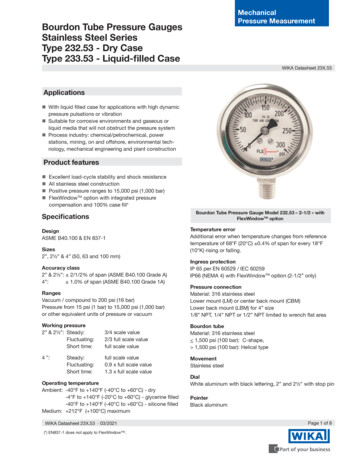

The products in detailThese measuring instruments for the process industry aremanufactured completely from stainless steel for increasedcorrosion resistance. They are developed, qualified andprocess-monitored in production in line with DIN EN 13190.The core components are WIKA's internally developedmeasuring systems and the Swiss precision movement.For harsh operating conditions, all instruments are alsoavailable with liquid filling.Mechanical versionA specific selection of instruments are also available withintegrated switch contacts or transmitters. Thus, not onlydoes a measuring point provide an on-site display withoutthe need for a power supply, but also it provides anelectrical output signal for monitoring or control.Model TG53Model TG54Model 55Scale range-70 250 C to 0 600 C-70 250 C to 0 600 C-70 250 C to 0 600 CNominal size3", 4", 5", 6"63, 80, 100, 160 mm63, 100, 160 mm--------- 3 minutes 3 minutes 3 minutesCl. 1Cl. 1Remote display(with capillary)Response timeAccuracy class 1 % of full scale value,ASME B40.200 (grade A) Liquidfilling up to max. 250 C Versionand dialSpecial features ATEXwith adjustable stemversion Externalzero adjustment ApprovalMechatronic version8DNV-GL--- Liquidfilling up to max. 250 C Versionand dial ATEXwith adjustable stemversion Approval ExternalDNV-GLzero adjustment--- Liquidfilling up to max. 250 C Versionand dial ATEXwith adjustable stemversion Casingwith epoxy resin coatingModel 55-8xx

SpecificationsModel 70Model 73-60 40 C to 0 400 C-200 50 C to 0 700 C63, 100, 160 mm100, 160 mm Up Upto a max. of 10 m possible Protectivesleeve for capillary:spiral protective sleeveto a max. of 60 m possible Protective 7 mm or PVC coating 3 minutes 3 minutesCl. 2, optional Cl. 1Cl. 1 Liquid Liquidfilling up to max. scale range Temperaturemeasurement withoutrangefilling up to max. scaleany contact to the medium Versiondial ATEX Versionwith adjustable stem andsleeve for capillary:spiral protective sleevedialwith adjustable stem andversion Temperaturemeasurementwithout any contact to the mediumModel 70-8xxModel 73-8xxYou can find many more products in the “Mechanical temperature measuring instruments” and“Mechatronic temperature measuring instruments” product reviews at www.wika.com.9

Temperature measuring instrumentswith electrical output signalA temperature measuring instrument with an electrical output signal from the intelliTHERM series combines all the advantages of an on-site display (without the need for a power supply)with the requirements of an electrical signal transmission for a measured value registration tothe latest technology requirements.A magnet on the pointer shaft rotates proportionally to the instrument pointer as a direct linearfunction of the process temperature. The electronics positioned opposite the magnet registerthe rotary motion of the magnet. A magnetic-field-dependent sensor picks up this change onthe electronic side, contact-free, wear-free and without influence on the pressure element.The sensor signal, proportional to the deflection, is converted to an electrical output signal viaan amplifier (US patent no. 8.030.990).Temperature measuringinstruments with switch contactsSwitch contacts built into mechanical temperature measuring instruments close or opencircuits depending on the process temperature. They can be used for various monitoringfunctions when a measured value either falls below or exceeds a preset value. Switchcontacts are fitted behind the dial and can be set over the entire scale range using the setpointer. The instrument pointer actual value pointer) moves freely across the entire scalerange, independent of the setting. The contacts can be adjusted individually, using a removable adjustment key in the window.For generalapplicationsFor hazardous areasFor PLCFor generalapplications and roniccontactReed contactModel 821Model 831Model 830 EModel 85110

ExtrasAdditional servicesAssemblyFor all temperature measuring instruments we offer you a widevariety of options, approvals, certificates and also thermowells, .Temperature measuringinstrument model55 with thermowellmodel TW31 Liquid filling for applications with shocks and vibration Complete measuring point design taking all environmental factors intoaccount Various mounting and fitting solutions (e.g. clamping ring) 2.2 test report to EN 10204 (e.g. state-of-the-art manufacturing,material proof, indication accuracy) 3.1 inspection certificate to EN 10204 (e.g. indication accuracy) Extensive product certifications such as EAC, GOST, GL CE conformity (ATEX, EMC, NSR) Thermowell mountingThermowellsNon-destructive tests Hydrostatic pressure testThis test is carried out using external pressure onflanged thermowells, and using an internal pressuretest for welded or threaded thermowells. Usually, thepressure tests are with 1.5 times the flange pressurerating for 3 to 15 minutes. Liquid penetrant testThis testing is used, in particular, to examine theweld seams for surface defects. In this process, thethermowell is wetted with a low-viscosity indicator, whichinfiltrates any possible cracks which exist. After beingthoroughly cleaned, defects are made visible using adeveloper. Positive Material Identification test (PMI)The PMI (positive material identification) test proveswhich alloy constituents exist in the material. WithX-ray analysis, the atoms of the thermowell material areenergised by the X-rays until they radiate themselves.The wavelength and intensity of the emitted radiation isin turn a measure of the alloy’s constituent elements andtheir concentration.11

WIKA worldwideEuropeNorth AmericaAustriaWIKA MessgerätevertriebUrsula Wiegand GmbH & Co. KGPerfektastr. 731230 ViennaTel. 43 1 8691631Fax: 43 1 8691634info@wika.atwww.wika.atPolandWIKA Polska spółka z ograniczonąodpowiedzialnością sp. k.Ul. Legska 29/3587-800 WloclawekTel. 48 54 230110-0Fax: 48 54 IKA Instruments Ltd.Head Office3103 Parsons RoadEdmonton, Alberta, T6N 1C8Tel. 1 780 4637035Fax: 1 780 4620017info@wika.cawww.wika.caBelarusWIKA BelrusUl. Zaharova 50B, Office 3H220088 MinskTel. 375 17 2244164Fax: 375 17 2635711info@wika.bywww.wika.byRomaniaWIKA Instruments Romania S.R.L.050897 BucurestiCalea Rahovei Nr. 266-268Corp 61, Etaj 1Tel. 40 21 4048327Fax: 40 21 4563137info@wika.rowww.wika.roUSAWIKA Instrument, LP1000 Wiegand BoulevardLawrenceville, GA 30043Tel. 1 770 5138200Fax: 1 770 3385118info@wika.comwww.wika.comBeneluxWIKA BeneluxIndustrial estate De BerkNewtonweg 126101 WX EchtTel. 31 475 535500info@wika.nlwww.wika.nlBulgariaWIKA Bulgaria EOODAkad.Ivan Geshov Blvd. 2EBu

ASME B40.200 (grade A) Cl. 1 Cl. 1 Cl. 2, optional Cl. 1 Cl. 1 Special features Liquid filling up to max. 250 C Version with adjustable stem and dial ATEX version External zero adjustment Approval DNV-GL Liquid filling up to max. 250 C Version with adjustable stem and dial ATEX version Approval DNV-GL External zero adjustment