Transcription

Industrial and Process Pressure Gauges– PGI Series1www.swagelok.comPre s sure G auge sIndustr ial a nd Proce s sPGI Se r ie s 40, 50, 63, 100, 115, and 160 mm (1 1/2, 2, 2 1/2, 4, 4 1/2 and 6 in.) dial sizes Accuracy in accordance with ASME, EN, and JIS Center-back, lower-back, and lower mount configurations Stainless steel and reinforced thermoplastic construction Available unfilled or liquid filledPRESSUREGAUGES Available with a variety of end connections, including Swagelok tube adapters

2Measurement DevicesContentsFeatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Testing and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Industrial Gauge ModelsStainless Steel Cases and Wetted ComponentsB Model: General-Purpose Gauge . . . . . . . . . . . . . . . . .4C Model: General-Purpose Gauge . . . . . . . . . . . . . . . . .6Process Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3S Model: Solid-Front Safety Gauge . . . . . . . . . . . . . . . .8Model Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3M Model: Miniature Gauge . . . . . . . . . . . . . . . . . . . . . . . 10Sw agelok Tube AdaptersSolve Alignment Problems . . . . . . . . . . . . . . . . . . . . . . . 2L Model: Low-Pressure Gauge . . . . . . . . . . . . . . . . . . . . 12Process Gauge ModelGlass-Reinforced Thermoplastic Case andStainless Steel, Brass, or Alloy 400 Wetted ComponentsP Model: Industrial Process Gauge . . . . . . . . . . . . . . . . 14A Model: Refrigeration Ammonia Gauge, . . . . . . . . . . . . 16Stainless SteelDial Range Designators . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 21FeaturesTesting and Calibration Monitor vacuum and positive system pressures up toEvery Swagelok industrial pressure gauge is factory calibratedand pressure tested.15 000 psi, 1000 bar, or 100 MPa Manufactured in accordance with industry standards Available with Swagelok tube adapter end connectionsSwagelok Tube Adapters Solve Alignment ProblemsSwagelok tube adapters can help eliminate difficult alignment problemsand can be used with any Swagelok tube fitting.Typical Alignment ProblemWhen installing a gauge with a pipe fitting end connection,it is often difficult to align the dial to the desired positionwithout damaging the gauge.Swagelok Tube AdaptersGauges with integral Swagelok tube adapters eliminatealignment problems.Installation Instructions1. Insert the gauge with integral Swagelok tube adapter intoa Swagelok tube fitting.2. Align the gauge dial to the desired position.PRESSUREGAUGES3. Install the fitting. wagelok tube adapters are to be used ONLY inSSwagelok tube fittings. Use in fittings made by othermanufacturers may result in leakage or slippage.100505001015014200

Industrial and Process Pressure Gauges– PGI Series3Process ConnectionsConnectionMaximum PressureSpecificationSwagelok Tube Adapter1/4 in. and 6 mm10 000 psi, 600 bar,60 MPa3/8 in. and 10 mm7500 psi, 500 bar,50 MPa1/2 in. and 12 mm6000 psi, 400 bar,40 MPa1/8 in.6000 psi, 400 bar,40 MPa1/4 and 1/2 in.15 000 psi, 1000 bar,100 MPa—Male NPTASME B1.20.1Male ISO Parallel Gauge Thread (EN)G1/8B (EN)6000 psi, 400 bar,40 MPaG1/4B (EN)G1/2B (EN)15 000 psi, 1000 bar,100 MPaEN 837-1EN 837-3Male ISO Parallel Gauge Thread (JIS)G1/4B (PF)G1/2B (PF)15 000 psi, 1000 bar,100 MPaJIS B7505Male ISO Tapered ThreadR1/8 (PT)6000 psi, 400 bar,40 MPaR1/4 (PT)R1/2 (PT)15 000 psi, 1000 bar,100 MPaISO 7/1JIS B0203G1/8B (EN), G1/4B (EN), and G1/2B (EN) are for use with Swagelok RGadapter fittings.G1/8B (PF), G1/4B (PF), and G1/2B (PF) are for use with Swagelok RJadapter fittings.Model Selection GuideDial RangePositive pressures:0 to 10 psi,400 mbar, or 50 kPaCompound pressures:Vacuum to 200 psi,9 bar, or 1.5 MPaPositive pressures:0 to 10 000 psi,600 bar, or 60 MPaCompound pressures:Vacuum to 200 psi,9 bar, or 1.5 MPaPositive pressures:0 to 15 000 psi,1000 bar, or 100 MPaDial Sizemm (in.)63(2 1/2)100(4)40(1 1/2)50(2)63(2 1/2)100(4)160 Yes———Yes—Yes————YesYes 1.5 % of spanASME B40.100 Grade B,EN 837-1 Class 1.6,JIS B7505 Class Yes—YesYesC 1 % of spanASME B40.100Grade 1A,EN 837-1 Class 1.0JIS B7505 Class PYesYesYesYes—YesPAccuracy 1.5 % of spanASME B40.100 Grade B,EN 837-3 Class 1.6,JIS B7505 Class 1.6 2.5 % of spanASME B40.100 Grade C,EN 837-1 Class 2.5,JIS B7505 Class 2.5115(4 1/2)160LM 0.5 % of spanASME B40.100 Grade 2A(6)➀ Configurations: L BM lower-back mountModelCBM center-back mountLM lower mount.➁ Liquid-fillable model available in lower mount configuration only. Glycerin- and silicone-filled gauges cannot be usedwhere strong oxidizing agents are present.PRESSUREGAUGESCompound pressures:Vacuum to 400 psi, 9 bar,1.5 MPa, or 2500 kPaPositive pressures:0 to 15 000 psi, 1000 bar,100 MPa, or 100 000 kPaConfigurations➀AdjustablePointer

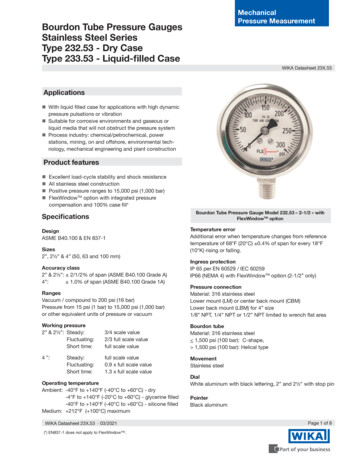

4Measurement DevicesB Model: General-PurposeStainless Steel GaugeFeatures 63, 100, and 160 mm (2 1/2, 4, and 6 in.) dial sizes areavailable. Bayonet ring allows easy access to pointer. Lens is constructed of polycarbonate for additionalprotection. Design is liquid fillable.Technical DataDial RangesEnd ConnectionsOperating TemperatureCompound Gauges63 mm (2 1/2 in.) Dial SizeAmbient Vacuum to 0 psi through vacuum to 1/4 and 3/8 in.; 6 and 10 mm Unfilled: –40 to 140 F (–40 to 60 C)200 psi Vacuum to 0 bar through vacuum to9 bar Vacuum to 0 MPa through vacuum to1.5 MPaPositive-Pressure Gauges 0 to 15 psi through 0 to 15 000 psi 0 to 1 bar through 0 to 1000 barSwagelok tube adapter 1/4 in. male NPT G1/4B (EN) G1/4B (PF) R1/4 (PT)100 mm (4 in.) Dial Size 1/2 in. and 12 mm Swagelok tubeadapter Glycerin-filled: –4 to 140 F (–20 to60 C) Low-temperature glycerin-filled:–29‑to 140 F (–34 to 60 C) Silicone-filled: –40 to 140 F (–40 to60 C)Media Unfilled: 392 F (200 C) maximum Liquid-filled: 212 F (100 C) maximum 0 to 0.1 MPa through 0 to 100 MPa 1/4 and 1/2 in. male NPTAccuracy G1/2B (EN)Temperature Error 63 mm (2 1/2 in.): 1.5 % of span G1/2B (PF) 0.4 % for every 18 F (10 C)temperature change from 68 F (20 C)(ASME B40.100 Grade B, EN 837-1Class 1.6, JIS B7505 Class 1.6) 100 and 160 mm (4 and 6 in.): 1.0 % of span (ASME B40.100Grade 1A, EN 837-1 Class 1.0,JIS B7505 Class 1.0) R1/2 (PT)160 mm (6 in.) Dial Size 1/2 in. male NPT G1/2B (EN) G1/2B (PF)Configurations R1/2 (PT) 63 mm (2 1/2 in.): center-back andWeather Protectionlower mount 100 and 160 mm (4 and 6 in.): lower-back and lower mount Weather-tight (NEMA 4X/IP65)Materials of ConstructionComponentEnd connectionBourdon tube316 SSCase304 SSFill fluid(if ordered)Glycerin, lowtemperature glycerin,or siliconeMovementStainless steelLensPolycarbonateLens gasketBuna NDialPRESSUREGAUGESMaterialPointerAluminumWetted components listed in italics.See page 21 for options andaccessories for field installation.

Industrial and Process Pressure Gauges– PGI SeriesDimensionsDial Sizemm (in.)Dimensions are for reference only andare subject to change.Lower MountC63(2 (6)End ConnectionSizeTypeSwagelok tubeadapterMale NPT1/4 in.G1/4B (EN)G1/4B (PF)R1/4 (PT)3/8 in.Swagelok tube6 mmadapter10 mm1/4 in.Male NPTSwagelok tubeadapterMale NPT1/2 in.G1/2B (EN)G1/2B (PF)R1/2 (PT)Swagelok tube12 mmadapter1/2 in.Male NPTG1/2B (EN)G1/2B (PF)R1/2 (PT)5Dimensions, in. (mm)AB2.26 (57.3)2.39 (60.8)2.09 (53.0)2.24 (62.3)(83.0)3.60 (91.4)3.44 (87.4)3.43 (87.0)3.27 (83.0)1.971.18(50.0)(30.0)0.63(16.0)3.60 (91.4)3.44 (87.4)4.65 (118)3.27 (83.0)➀1.97(50.0)➀1.97(50.0)➀ B is 3.90 in. (99.0 mm) and C is 2.60 in. (66.0 mm) for gauges with lower-back mount and pressureratings of 1500 psi, 10 MPa, 100 bar or higher.Ordering InformationBuild a B model gauge ordering number by combining the designators as shown below. List option designators alphabetically.PGI - 63B - PG100 - L AQ X - ABJProduct Function and TypePressure gauge, industrialDial Size and Model63B 63 mm (2 1/2 in.) dial100B 100 mm (4 in.) dial160B 160 mm (6 in.) dialDial RangeSee page 18 and 19.Process Connection LocationL Lower mount (all dial sizes)C Center-back mount (63 mm [2 1/2 in.]dial size only)B Lower-back mount (100 and 160 mm[4 and 6 in.] dial sizes only)63 mm (2 1/2 in.) Dial SizeAQ 1/4 in. Swagelok tube adapterBG 3/8 in. Swagelok tube adapterAS 6 mm Swagelok tube adapterBH 10 mm Swagelok tube adapterAO 1/4 in. male NPTAV G1/4B (EN)AX G1/4B (PF)BD R1/4 (PT)A ASME B40.100 level IV cleaning➀B Certificate of calibrationE Material certificationF Panel-mount clamp➁G Front flange➁H Rear flangeI Maximum indicating pointer➂J Adjustable pointer➃K Safety glassN Orifice (0.023 in. [0.58 mm])➀ Available for unfilled gauges only.➁ Not available in lower mount gauge configuration.Not available with maximum indicator pointer.➂ Not available with adjustable pointer; not availablewith dial range maximums lower than 54 psi(3.7 bar, 0.37 MPa). Not available with front flange.➃ Not available with maximum indicating pointer.Liquid Fill Fluid (see page 21)X Unfilled1 Glycerin2 Low-temperature glycerin3 Silicone100 mm (4 in.) Dial SizeAR 1/2 in. Swagelok tube adapterAT 12 mm Swagelok tube adapterAO 1/4 in. male NPTAP 1/2 in. male NPTAW G1/2B (EN)AZ G1/2B (PF)BE R1/2 (PT)160 mm (6 in.) Dial SizeAP 1/2 in. male NPTAW G1/2B (EN)AZ G1/2B (PF)BE R1/2 (PT)PRESSUREGAUGESFitting Size and TypeOptions (see page 21)

6Measurement DevicesC Model: General-PurposeStainless Steel GaugeFeatures 63 and 100 mm (2 1/2 and 4 in.) dial sizes are available. Crimped ring provides a permanent seal of gauge caseto lens. Lens is constructed of clear polycarbonate. Design is liquid fillable.Technical DataDial RangesConfigurationsOperating TemperatureCompound Gauges 63 mm (2 1/2 in.): center-back andAmbient Vacuum to 0 psi through vacuum to200 psi Vacuum to 0 bar through vacuum to9 bar Vacuum to 0 MPa through vacuum to1.5 MPaPositive-Pressure Gauges 0 to 15 psi through 0 to 15 000 psi 0 to 1 bar through 0 to 1000 bar 0 to 0.1 MPa through 0 to 100 MPaAccuracy 63 mm (2 1/2 in.): 1.5 % of span(ASME B40.100 Grade B, EN 837-1Class 1.6, JIS B7505 Class 1.6) 100 mm (4 in.): 1.0 % of span(ASME B40.100 Grade 1A, EN 837-1Class 1.0, JIS B7505 Class 1.0)lower mount 100 mm (4 in.): lower-back and lowermountEnd Connections63 mm (2 1/2 in.) Dial Size 1/4 and 3/8 in.; 6 and 10 mmSwagelok tube adapter 1/4 in. male NPT100 mm (4 in.) Dial Size 1/2 in. and 12 mm Swagelok tubeadapter 1/4 and 1/2 in. male NPT Unfilled: –40 to 140 F (–40 to 60 C) Glycerin-filled: –4 to 140 F (–20 to60 C) Low-temperature glycerin-filled:–29‑to 140 F (–34 to 60 C) Silicone-filled: –40 to 140 F (–40 to60 C)Media212 F (100 C) maximumTemperature Error 0.4 % for every 18 F (10 C)temperature change from 68 F (20 C)Weather Protection Weather-tight (NEMA 4X/IP65)Materials of ConstructionComponentEnd connectionPRESSUREGAUGESBourdon tubeMaterial316 SSCase304 SSFill fluid(if ordered)Glycerin, lowtemperature glycerin,or siliconeMovementStainless steelLensPolycarbonateLens gasketBuna NDialPointerAluminumWetted components listed in italics.See page 21 for options andaccessories for field installation.

Industrial and Process Pressure Gauges– PGI Series7DimensionsDimensions are for reference only and are subject to change.Lower MountCACenter-BackMountLower-BackMountBBEADDial Sizemm (in.)63(2 1/2)100(4)End ConnectionTypeSwagelok tubeadapter1/4 in.Male NPT3/8 in.Swagelok tube6 mmadapter10 mm1/4 in.Male NPTSwagelok tubeadapter1/2 in.Male NPTSwagelok tube12 mmadapterDimensions, in. (mm)SizeAB2.22 (56.3)2.37 (60.3)2.092.282.222.283.15(80.0)2.24 (57.0)2.43 (61.8)2.37 (60.3)2.43 (61.8)3.27 (83.0)3.64 (92.4)3.48 (88.4)3.43 (87.0)3.27 (83.0)3.64 (92.4)3.48 10.0)E—1.970.631.18(50.0)(16.0)(30.0)➀ 1.10 (28.0) for center-back mount.Ordering InformationBuild a C model gauge ordering number by combining the designators as shown below. List option designators alphabetically.PGI - 63C - PG100 - L AQ X - ABHOptions (see page 21)Product Function and TypeA ASME B40.100 level IV cleaning➀B Certificate of calibrationE Material certificationF Panel-mount clamp➁G Front flange➁H Rear flangeI Maximum indicating pointer➂N Orifice (0.023 in. [0.58 mm])9320 White9321 Orange9322 Green9323 GlowPressure gauge, industrialDial Size and Model63C 63 mm (2 1/2 in.) dial100C 100 mm (4 in.) dialDial RangeSee page 18 and 19.Process Connection LocationL Lower mount (all dial sizes)C Center-back mount (63 mm [2 1/2 in.]dial size only)B Lower-back mount (100 mm [4 in.]dial size only)➀ Available for unfilled gauges only.➁ Not available in lower mount gauge configuration.➂ Not available with dial range maximums lowerthan 54 psi (3.7 bar, 0.37 MPa).63 mm (2 1/2 in.) Dial SizeAQ 1/4 in. Swagelok tube adapterBG 3/8 in. Swagelok tube adapterAS 6 mm Swagelok tube adapterBH 10 mm Swagelok tube adapterAO 1/4 in. male NPT100 mm (4 in.) Dial SizeAR 1/2 in. Swagelok tube adapterAT 12 mm Swagelok tube adapterAO 1/4 in. male NPTAP 1/2 in. male NPTX Unfilled1 Glycerin2 Low-temperature glycerin3 SiliconePRESSUREGAUGESLiquid Fill Fluid (see page 21)Fitting Size and Type

8Measurement DevicesS Model: Solid-Front StainlessSteel Safety GaugeFeatures 63 and 100 mm (2 1/2 and 4 in.) dial sizes are available. Lower mount configuration is liquid fillable. Solid front and blowout back for severe service. Design meets safety requirements of ASME B40.100and EN 837-1.Technical DataDial RangesConfigur

ASME B40.100 Grade B, EN 837-3 Class 1.6, JIS B7505 Class 1.6 — — — — — Yes L 100 (4) — — — Yes — Yes Compound pressures: Vacuum to 200 psi, 9 bar, or 1.5 MPa Positive pressures: 0 to 10 000 psi, 600 bar, or 60 MPa 40 (1 1/2) 2.5 % of span ASME B40.100 Grade C, EN 837-1 Class 2.5, JIS B7505 Class 2.5 — — — — Yes Yes M 50 (2) Compound pressures: Vacuum to 200 psi, 9 .