Transcription

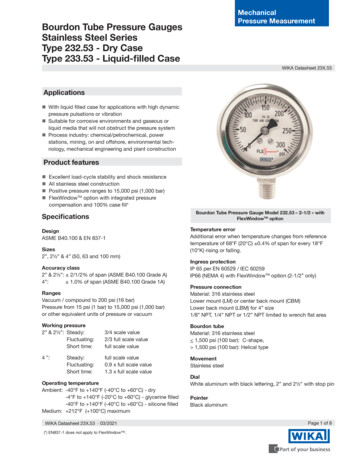

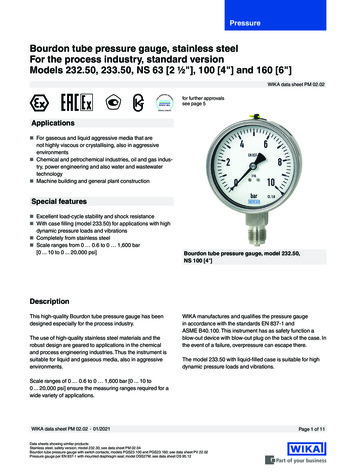

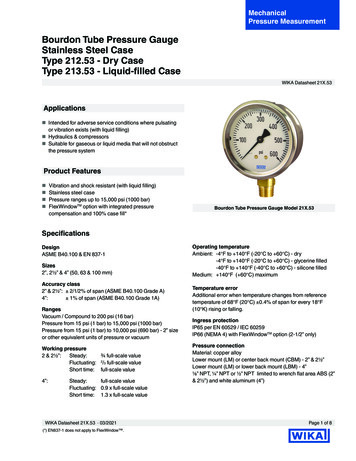

MechanicalPressure MeasurementBourdon Tube Pressure GaugesHigh Purity SeriesType 130.15WIKA Datasheet 130.15Applications Semiconductor and electronic industry, medical industry,gene technology, biotechnology and pharmaceuticalindustries. Suitable for corrosive environments and gaseous or liquidmedia that will not obstruct the pressure system Where measurement of high purity gases is needed without contamination of the process media.Special Features 316L wetted parts Electro-polished stainless steel case Positive and compound pressure ranges to 6000 psiBourdon Tube Pressure Gauge Model 130.15Standard FeaturesDesignASME B40.100Sizes2” (50 mm)1 ½” (40 mm)Accuracy Class2”: 2/1/2% of span (ASME B40.100 Grade A)1 ½”: 3/2/3% of span (ASME B40.100 Grade B)RangesVacuum / compound to 30”Hg/0/300 psiPressure from 15 psi up to 6000 psior other equivalent units of pressure or vacuumWorking PressureSteady:¾ full-scale value2 full-scale valueFluctuating:/3Short time:full-scale valueOperating TemperatureAmbient: -40 F to 140 F (-40 C to 60 C)Medium: 212 F ( 100 C) maximumWIKA Datasheet 130.15 · 4/2019Temperature ErrorAdditional error when temperature changes from referencetemperature of 68 F (20 C) 0.4% for every 18 F (10 C)rising or falling. Percentage of span.Weather ProtectionWeather resistant (NEMA 3 / IP 54)Pressure ConnectionMaterial: 316L SSPosition: Lower mount (LM) & center back mount (CBM)Type of connection: ¼” NPT - maleWetted surface finish: Ra 1.0µm (Ra 40µinch)-internalBourdon TubeMaterial: 316L SS30”Hg (vac) to 1,000 psi, C-type1,500 to 6000 psi, helical typeHelium leak tested 1 x 10-9 scc/sec (inboard)SocketMaterial: 316L SSRa 1.0µm (Ra 40µinch) - internal(Standard Features continued on Page 2 of 5)Page 1 of 5R

MovementStainless steelDialWhite aluminum with stop pin and black letteringPointerBlack aluminumCase304 SS, electropolishedWindowPolycarbonate: twist-lock (2”); snap cap (1½”)CleanlinessASME B40.1 Level IVPackaged in single nylon bagPurged with NitrogenProtective cap over threaded connectionOrder Options (minimum order may apply)Alarm contact (830.1E), inductivePackaged in two bagsOther special connections limited to wrench flat areaCustom dial layoutStainless steel restrictorParticle test with certificateDual pressure scalesAdditional process wetted materials available per request130.15 2” LM¼” NPT-MALE (NPTM)130.15 1½” CBM¼” NPT-MALE (NPTM)Page 2 of 5WIKA Datasheet 130.15 · 4/2019

Dimensions130.15 2” CBM¼” NPT-MALE (NPTM)130.15 2” CBM w/U-CLAMP¼” NPT-MALE (NPTM)130.15 2” CBM w/ FRONT FLANGE¼” NPT-MALE (NPTM)WIKA Datasheet 130.15 · 4/2019Page 3 of 5

CaseWetted ing304 SS, electropolished316L SSPolycarbonateAluminum, white with stop pinAluminum black2” /- 2/1/2% of span (ASME B40.1 Grade A)1½” /-2/3/2% of span (ASME B40.1 Grade B)ASME B40.1 Level IVSingle nylon bag, nitrogen purgedField No. Code FeatureNominal Case Size61.5" (40 mm)172.0" (50 mm)UnitPpsiBbarLkPaEMPaKKg/cm22?otherPressure RangeV310 -30 inHg . 0 psiV321 -30 inHg . 15 psiV331 -30 inHg . 30 psiV352 -30 inHg . 60 psiV379 -30 inHg . 100 psiV412 -30 inHg . 160 psiV415 -30 inHg . 200 psiV422 -30 inHg . 300 psiG310 0 . 15 psiG321 0 . 30 psiG341 0 . 60 psiG369 0 . 100 psiG411 0 . 160 psiG414 0 . 200 psiG421 0 . 300 psiG428 0 . 400 psiG441 0 . 600 psiG455 0 . 800 psiG469 0 . 1000 psiG510 0 . 1500 psiG514 0 . 2000 psiG521 0 . 3000 psiG528 0 . 4000 psiG534 0 . 5000 psiG541 0 . 6000 psi3? other - please specifyPage 4 of 5WIKA Datasheet 130.15 · 4/2019

Field ?otherProcess ConnectionNB 1/4" NPT - male5?other - please specifyConnector PositionBCenter back mount6ULower mountMounting Flange/BracketZWithoutKPanel mount with SS mounting bracket (2" CBM only)7FFront flange, polished SS (2” CBM only)Switch TypeZwithoutNInductive NPN (2" case only) 830.1E8PInductive PNP (2" case only) 830.1EElectrical Connection9ZZwithoutQuality CertificatesZwithout10?other - please specifyAdditional Order DetailsZwithout11TAdditional textOrder Code:130.15 -1-234-5-67-8-910 11**Additional order detailsSpecifications provided in this datasheet represent the state of engineering at the time of printing.Modifications may take place and the specified materials may change without prior noticeWIKA Datasheet 130.15 · 4/2019Page 5 of 5RWIKA Instrument, LP1000 Wiegand BoulevardLawrenceville, GA 30043-5868Tel: 888-WIKA-USA 770-513-8200Fax: 678-739-2569E-Mail: UHP@wika.comwww.wika.com/UHP

ASME B40.1 Level IV Packaged in single nylon bag Purged with Nitrogen Protective cap over threaded connection Order Options (minimum order may apply) Alarm contact (830.1E), inductive Packaged in two bags Other special connections limited to wrench flat area Custom dial layout Stainless steel restrictor Particle test with certificate Dual pressure scales Additional process wetted materials .File Size: 865KBPage Count: 5